Value Chain for Product and Service

Differences

There are numerous differences between service and product. First, a product is tangible while service is not. Nonetheless, products cannot be created and shipped/ delivered all at once. Another key difference consists in the fact that products can be inventoried. At the same time, services are better approved by the customers and have lower entry/ exit barriers. Moreover, when it comes to service design, location becomes one of the most important things (in the case of product design, location is not so pivotal). The last thing is the range of service systems which is inextricably linked to the inconsistency in demand. The elementary examples of product and service can be given based on Starbucks:

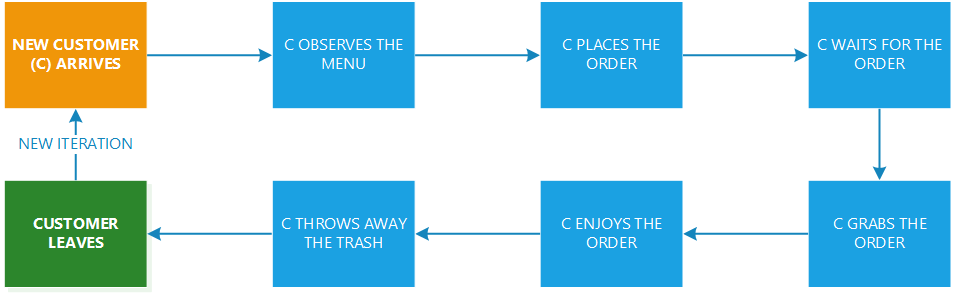

- Service (see Figure 1)

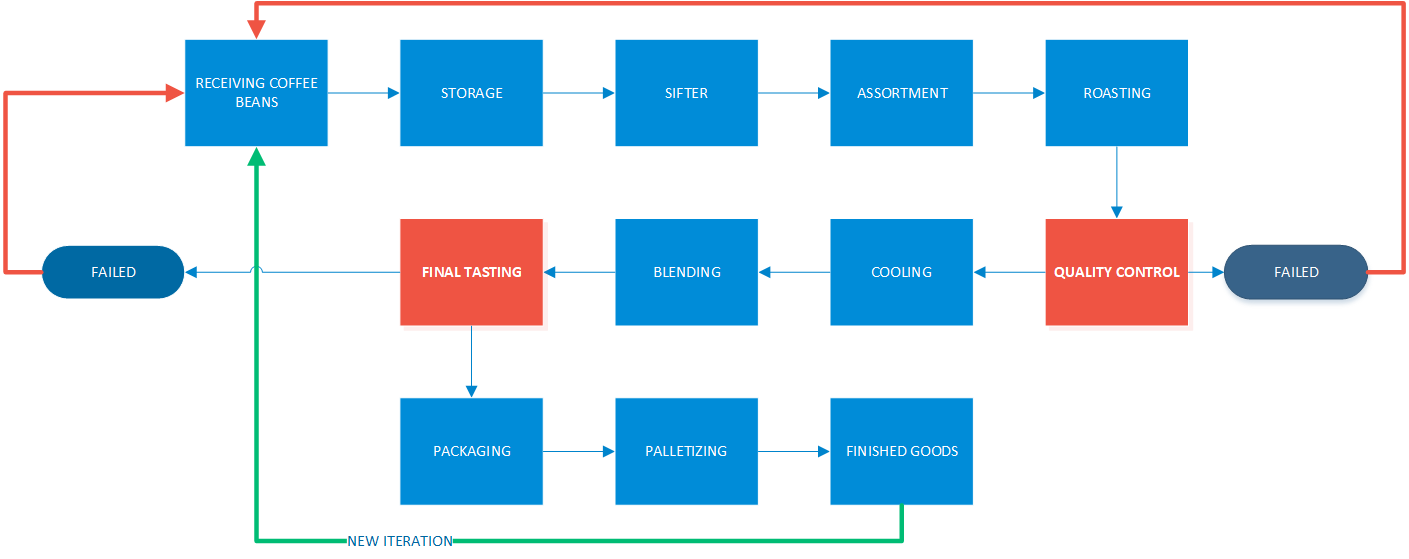

- Product – baked goods, boxed tea, smoothies, and different types of coffee (see Figure 2)

Explanation of a Value Chain

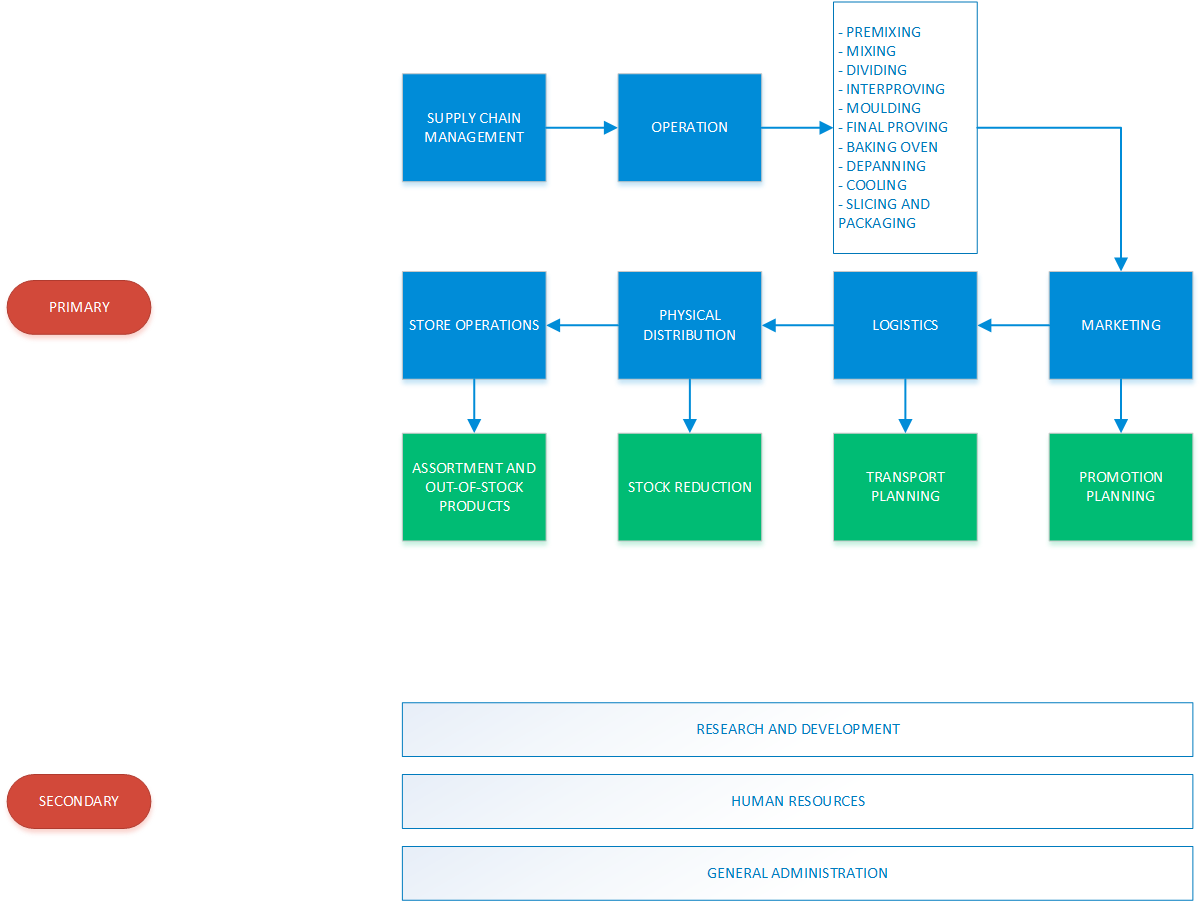

The very first draft of a value chain was developed by Michael Porter. It is a high-level model that is utilized to outline the progressions that delineate the processes of acquiring raw materials and adding value to them. The latter is done by developing the finished product and selling it to customers. The majority of companies also have to conduct a value chain analysis to evaluate every production stage and come up with certain innovations that will improve performance and efficiency. The ultimate objective is to obtain maximum value for the minimum cost and deliver this end product to the customers. In perspective, this allows the company to generate a competitive advantage. One of the basic examples may be a bakery. They may purchase the ingredients that are necessary to bake bread. In the end, they will add value by packaging the results of their products and delivering the product to local stores (see Figure 3). The value chain also includes the options regarding product marketing (how the product is going to be promoted to the local purchasers), logistics (how the product is going to be transported from point A to point B), and store operations (how the organization is going to manage its product stock and assortment).

Outsourcing

Outsourcing is recurrently utilized by numerous businesses to minimize the overall costs. It is done by shifting some of the production responsibilities from the internal environment to outside contractors. The proper application of this strategy allows to cut costs significantly and make the best use of this competitive advantage. It can be explained by the fact that sometimes it is better to buy something from another supplier than producing it internally. The connection between value chain activities and outsourcing can be explained by the reduction of the load on a value chain using subcontracting. By doing this, an organization may specialize only in several value chain activities instead of concentrating on the whole production process. Therefore, outsourcing can be explained using a value chain if we assess the down- and upstream activities that are performed by the business and evaluate the appropriateness of vertical integration of the latter.

To expand on the topic, value chains can be used to simplify the existing business decisions concerning outsourcing by analyzing the existing state of affairs. On a bigger scale, the relationship between value chains and outsourcing can be described as a direct representation of the organization’s upsides and downsides. The combined use of value chain activities and outsourcing may allow the company to differentiate itself from the competitors and reduce the costs of its projects. Some things have to be considered when reviewing the association of outsourcing and value chains. First of all, we can use value chains to display cheaper ways of manufacturing goods using outsourcing (low-priced or high-class contractors). Second, we may utilize value chains to identify the fundamental competencies that will have to be used by the company to conquer the market or elicit cost-effectiveness and product differentiation.

Third, value chains can certify outsourcing using mitigating the risks of performing internal activities that may have a negative influence on the business. This can relate to constantly altering technological innovations or rapidly fluctuating markets. In this case, value chains will be used to outsource only the activities that are advantageous for the organizations and helpful in terms of maintaining manufacturing flexibility. Consequently, the fourth way to explain outsourcing by dint of value chain activities is the ultimate effect of business improvements such as reduced inventory and lead time. Dell is one of the best examples of outsourcing companies because they prefer to buy computer parts from other manufacturers to reduce the ultimate costs of production. Outsourcing may also be used when it comes to accounting (for instance, external accounting businesses may help with fulfilling bookkeeping duties) because hiring an internal certified public accountant may be too expensive.

What is Green Value Chain? How is green different from the conventional value chain?

One of the key differences between the green value chain and conventional value chain consists of the fact that the former implies several eco-friendly innovations to comply with energy-saving and nature-preserving directives. The green value chain is aimed at minimizing both costs and environmental impact using recyclable items and “green” technologies. The local supermarket chain that will be used as an example is called Greenpark. This supermarket functions based on a supply chain management value chain. Several factors differentiate this market from other local stores. The second difference consists in the fact that the market reduces imports and uses local resources instead to reduce the carbon footprint on the environment.

When it comes to transportation, Greenpark prefers hybrid vehicles because they do not produce carbon dioxide emissions. The third difference is that one of the key points of the market’s strategy is the ability to recycle and reuse. It is why the administration does its best to reduce the use of paper (for instance, using online transactions and phone orders) and promote an environment-friendly approach to the business. You can also bring your bags to promote the recycling of resources. The cashiers will ask you if you need a printed receipt to preserve paper and support the “green” movement that is promoted by the Greenpark supermarket. The fourth difference between the green value chain and conventional value chain consists of the fact that the former fully supports the global economic and social shifts while the latter does not due to its inflexibility and business-centeredness. The green value chain takes into consideration the needs and wishes of the Millennials and advocates for massive infrastructure investments.

Supply chain management

Supplier Management

This particular type of management is used to ensure the availability of all the essential external services and configuration objects. The agreements are reached at the service level, and all the items are only available per request. One of the significant benefits of supplier management is that it helps merge the requirements for supplies and services (external) and skim through the market in search of providers. Supplier management is effective when it comes to negotiating with the suppliers and tracking changes in the external service and service provider environment. Additionally, supplier performance and relationships can be directed using supplier management practices. Supplier management is also inextricably linked to the establishment of supplier policies and their recurrent appraisal.

Supply Management

The term “supply management” relates to several events that are connected to the processes of categorizing, attaining, and managing the products. The latter is necessary to direct the organization and run the business efficiently. These products include both tangible and intangible assets (for instance, physical goods and information respectively) and any other resources that are required by the business. The divisions that are responsible for supply management in great corporations are usually large as well because the budget cap in these organizations may reach billions and the number of employees may easily exceed tens of hundreds. The key objectives of supply management are to allocate resources efficiently, to control the overall production costs, and to acquire the information that will be useful when making important strategic decisions.

Lean Management and Supplier Management

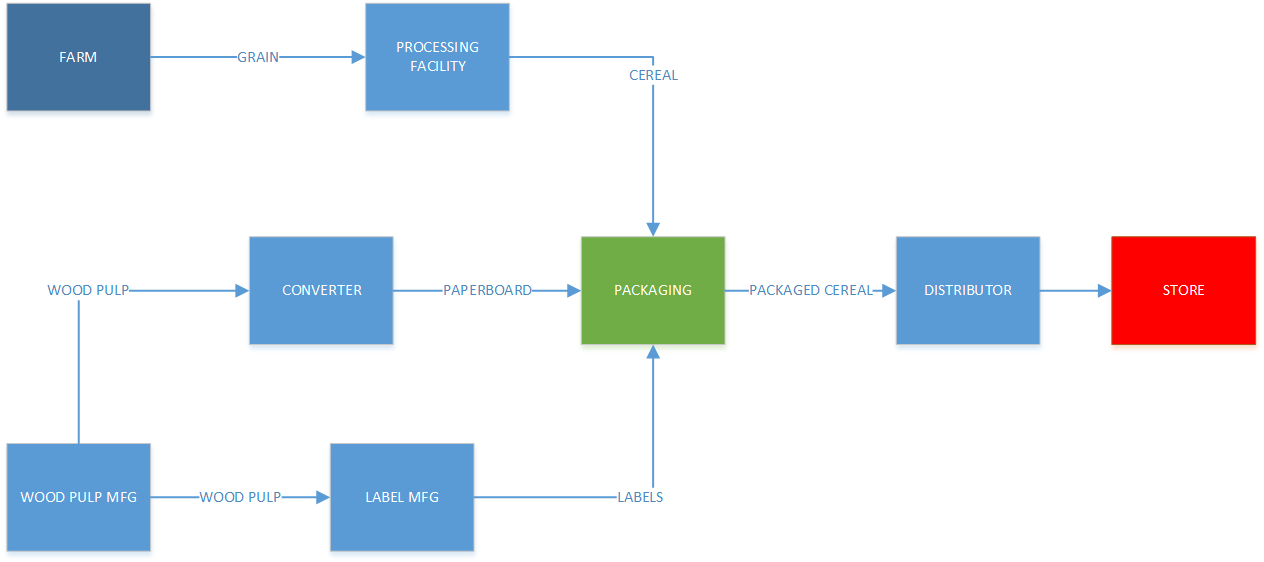

Lean management and supplier management can be utilized together to do some crucial things. First, this duo is effective in terms of providing possibilities for the evaluation of suppliers. Lean management supports practical evaluation of the resources and allows the business to appraise the available suppliers in line with their budget and possibilities. Moreover, the combination of supplier and lean management positively affects the structure of the company. One of the key reasons why supplier management adds value to the implementation of lean management is that supports the verification of the supplied products. There are several predetermined standards against which these services are normally checked. A basic supply chain representation (cereal production example) can be found in the flowchart below (see Figure 4).

Supplier Management and Bullwhip Effect

The bullwhip effect transpires within the supply chain when the demand raises, and businesses have to both order and produce more goods that are in demand to meet customer expectations. Commonly, the bullwhip effect has the most influence on the first stages of the supply chain (including the retailer, distributor, and raw materials supplier). Numerous industries are no strangers to such changes in their supply chains. On a bigger scale, this happens because the overall demand is grounded on the estimations and not the real-life customer demand and expectations. The underlying cause of the bullwhip effect lies within the problems with individual demand predictions that are usually different from all the companies in the supply chain. This results in an increased demand among the businesses that partake in the supply chain and not the end purchasers.

Inventory Management

The term “inventory management” stands for the procedures regarding storage, purchasing, and management of the items that are used by the company during the manufacturing process. Also, it can be described as both the quality and quantity control process of the finished product. Any company’s inventory is one of its biggest assets, and almost every step of production depends on it. An efficient inventory management practice comprises a procurement plan that includes all the necessary items and a list of the purchased goods to track the available inventory. Two of the most prevalent strategies of inventory management are JIT (just-in-time) and MRP (materials requirement planning). The first method presupposes that all items should be received on the spot (exactly when they are necessary) instead of keeping a high inventory level while the second method is based on specific item delivery schedules that are grounded on sales predictions.

Economic Order Quantity (EOQ)

This concept can be defined as an equation that helps the company to determine the correct amount of inventory based on several contextual variables that include demand rate, production costs, and any other significant values. The key objective of EOQ is to reduce the inventory expenditures, so it is crucial to take into account the ordering costs, holding (storage) costs, and deficiency costs. Therefore, this concept is inextricably linked to the amount of cash that is spent on inventory. The EOQ is essential for the companies as it is one of the biggest assets available to business owners. If the company can save money on inventory, it will be able to invest in some other activities or items.

Technological Impact on Inventory Management

The impact of technology on inventory management is significant and rather evident. There are now technologies that allow to capture certain data automatically and scan barcodes on the fly. It positively affects the employees and their options when it comes to cataloging, managing, and inspecting the available information. In other words, technology-enabled a real-time means of processing the data. One of the problems with inventory consists of the fact that the longer you keep it, the more it loses its original value. Nonetheless, the issue can be easily mitigated using modern technologies because one can effortlessly analyze the available data and make decisions regarding the item available based on customer demand or any other relevant forecasts.

Moreover, technology may be useful in terms of restocking the warehouse with necessary items and creating an efficient layout and product placement schemes. In other words, the products that are in demand will be located in a way that will promote workflow agility and limit job redundancies by reducing worker obligations. RFID technology is an example of technology that significantly impacts inventory management. It is used in supermarkets (prevalently) to read barcodes and have access to track identification numbers of the products and store them in the database. Also, this information can be rewritten (for example, if the product has been moved to another department), edited, and deleted. The RFID technology allows its users to improve quality control at any given supermarket because it is useful when dealing with products that have a limited shelf life.