Introduction

When we talk of supply chain management, we look at different factors and scenarios which are important in the management of the supply chain. In supply chain management mainly focuses on forecasting in particular collaborative forecasting, which is important in that it helps an organization reduces costs associated with inventory.

In an organization, we look at inventory control closely and as a result we have to make plans for the control and management of internal and external factors (Chopra, 2009). To ensure that the organization remains at a competitive advantage supply chain management through collaborative forecasting is very important.

Effect of data points on confidence intervals

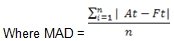

In our case, various data points are available that affect the way the inventory ordering is done; the data points enable us to gauge the accuracy of our forecasting. While forecasting it’s important to note errors due to forecasting based on historical data, the less the number of data points the higher the confidence levels and vice-versa (Lambert, 2008). MAD (mean absolute deviation) is a technique used to trace errors in the process of forecasting.

In the process of collaborative forecasting, inventory forecasting is done through various means and in our case multi-period inventory system was used. This system depends on fixed order periods, in that order of inventory is done when time for the current inventory expires.

In our scenario provided we look at collaborative forecasting using the technique of fixed time period model, this model explains on how inventory should be ordered according to the calculations done using fixed values and assumptions (Chopra, 2009).

This model assumes that the demand and cost of a product is uniform and goods ordered will not be returned. The model looks at the costs involved and as a result the accuracy levels of using this model are very high with minimal errors.

Role of global factors and competition

When an organization is forecasting we have to look at factors which influence the forecasting. In our case global factors such as change in currency exchange rates and price of oil, affect the forecasting task. These and other global factors have made the forecasting process difficult, these factors might make the forecast have errors which will lead to costly overheads in organizations.

According to Helms (2000), some global factors that are to be considered when forecasting include competitor’s advantage, market demand and economic conditions which have had an influence in the forecasting of how many vehicles will be sold in our case.

On the issue of forecasting bearing in mind the competitive nature of the world markets, we have to analyze demand based on the customer’s expectation and the use of technology in the forecasting process (Lambert, 2008).

When make use of technology such as ERP systems we are able to come up with a system which relies on dependant demand, in this case we are able to predict inventory through partnerships with suppliers and customers leading to better forecasting techniques.

Another technique used to gain competitive advantage over our competitors is by use of seasonal forecasting and partnerships with all people involved in the supply chain, this external information when fused with internal data enables the company to focus on the customer needs.

Challenges faced in previous evaluation

Many challenges were faced in the forecasting of inventory and how to handle information for proper forecasting. Challenges faced included assumptions that the demand of goods will remain constant and returned goods may increase inventory leading to additional costs.

According to Lapide (2001), the effect of inventory on increasing cost makes forecasting difficult; another task which makes forecasting difficult is the use of historical information in the process. The use of this information is inaccurate since it does not take into consideration future change or trends.

In the process of forecasting, challenges are usually based on the methods used for forecasting. In our case challenges such as constant monitoring of inventory, returned goods and changes in current trends have an effect on inventory are considered as common challenges faced in the evaluation process (Seifert, 2003). Some of the challenges like weather, entry errors, and obsolete demand forecasting are that face us in the forecasting process.

Lack of enough expertise to enable us to do better forecasting of seasonal, time horizons and financial planning are some of the challenges we have to undergo. This is due to the fact that the dealership we are about to open is a new office and total coordination of all chains of supply chain will take time.

Conclusion

The process of supply chain management is very important in today’s organizations. With this in mind, we must take prudent and efficient steps to come up with right measures to control this information. Forecasting taking a center stage in the management of companies’ information; current trends have shown that data mining for effective management of organization help them to plan on the time, quantity and supply of products, leading to saving which contribute to bottom lines (Seifert, 2003).

With current changes in the market, organization should harness the benefits of collaborative demand forecasting through partnerships, technology and other techniques. This process will take organizations closer to demand forecasting techniques leading to better customer service and better management of the supply chain.

References

Chopra, S., & Meindl, P. (2009). Supply chain management: Strategy, planning, and operation. Boston, MA: Prentice Hall.

Helms, M., Ettkin, L., & Chapman, S. (2000). Supply chain forecasting – Collaborative forecasting supports supply chain management. Business Process Management Journal, 6(5), 392.

Lambert, D. (2008). Supply chain management: Processes, partnerships, performance. San Francisco, CA: Supply Chain Management Ins.

Lapide, L. (2001). Developments in Demand Forecasting from Ancients Greeks to Present. The Journal of Business Forecasting Methods & Systems, 16(1), PP. 33-41.

Seifert, D. (2003). Collaborative planning, forecasting, and replenishment: How to create a supply chain advantage. New York, NY: AMACOM Div American Mgmt Assn.