Abstract

The construction industry is changing rapidly, modernising and improving existing house-building tools. These changes are coupled with an increasing trend towards green construction, in which the environmental and economic aspects of construction are effectively balanced, and harm to the environment and people minimised. This is especially noticeable in the cladding industry, which protects buildings from external hazards and adds aesthetic features. Different materials are used for cladding, but it is not clear which is more sustainable and user-friendly. In 2020, propelled by UK environmental organizations, the UK expert panel recommended large scale testing of cladding systems to better understand what types of cladding are more eco-friendly. In this context a review of popular cladding material aimed at finding the most eco-friendly cladding is especially relevant. An extensive literature review of digitally available academic sources, interviews and questionnaires with professionals in the industry was undertaken to find the best façade material to meet the requirements of eco-sustainability and cost-effectiveness.

In this work the comparison of different cladding materials was undertaken. They were compared in terms of durability, cost-effectiveness, water and heat retention, combustibility, and harmful emissions into the atmosphere. The data was gathered through looking at raw official statistics posted by official government bodies such as the office for national statistics and by looking at cladding ecological properties analyzed in scholarly sources. Moreover, interviews were taken from leading experts in the industry to find out modern tendencies in building.

The key trends in cladding industry nowadays include the use of vinyl siding, sandwich panels, thermopanels and clinker. Siding is made of vinyl, and though it is a low-cost material, plastic is prone to cracking, so it is not suitable for buildings situated in hot regions. Sandwich panels are cost-effective but not environmentally friendly; production of panels presupposes chemical processing, as a result of which formaldehyde is released into the environment. Moreover, strength indicators of buildings made of sandwich panels are lower that the indicators of houses made of wood or brick. Clinker is not cheap; although it has excellent performance properties, including great strength, it can hardly be used for large-scale building due to its high price. Thermopanels blend the ease of use of vinyl siding and the strength of clinkers. They are durable and resistant to decay and heat, and have excellent building properties. Moreover, thermopanels are ecologically friendly. However, panels with polyurethane foam are more expensive than siding.

The key finding of the whole study is that wood is a material with a unique combination of natural, environmentally friendly properties and a comparable low cost of use. For the UK market, wood is an excellent resource that is technically easy to transport and renewable. Based on the findings, it can be concluded that wood building materials, including recycled materials, should be used for façade cladding. This has made it possible to follow the principles of green building and invest in improving Britain’s environmental and economic agenda.

Introduction

The ongoing civilisational progress of society is naturally reflected in all professional spheres. The emergence of new ethical standards and a philosophy of concern for the environment as a manifestation of the evolution of human consciousness impose restrictions on the activities undertaken. While in the context of professions related to environmental activism and human interaction, such transformations are evident, these trends are not so tangible in the construction industry. Nevertheless, the gradual incorporation of new social and environmental standards into the construction industry is difficult to ignore: more and more companies are starting to produce environmentally friendly materials or products with a reduced carbon footprint (REF). At the same time, the production of such materials aims to reduce non-recyclable industrial waste and reduce the company’s polluting footprint (REF).

From a developer’s point of view, trends towards a new construction approach are also being seen: houses and neighbourhoods under construction are being made green and environmentally friendly (REF). This mainly includes the use of durable but high-quality materials, whose long-term sustainability will not affect their ecological performance (REF). However, the impact on the local landscape, the number of natural resources expended, and the cumulative construction waste are also considered.

At the same time, the central aim of any business, namely the preservation and multiplication of capital, dictates its requirements for companies in the construction industry (|REF). This is not a negative manifestation of capitalism, but the thesis of companies’ emphasis on profitability should be recognised as a fact. Manufacturers cannot focus only on finding and producing entirely environmentally friendly materials, as this would have a tangible effect on the financing of projects. In pursuing the perfect resource, a company risks losing all profits and delaying production, which becomes a serious threat to local competitiveness.

Consequently, companies struggling to meet current agendas and social demands need to find a sustainable balance between environmental and economic benefit strategies. For this reason, business leaders are not faced with the idea of pouring all their resources into the environmental direction, so the term most eco-friendly product may seem redundant. On the contrary, among the many evolving options, manufacturers are looking for those that best fit the company’s and the market’s economic and environmental needs.

In the context of the discussion of this balance, the phenomenon of green building should be highlighted. This is a new socio-economic trend, which refers to the construction and development areas that seek to minimise their negative impact on the environment. The concept reflects an unconditional desire on the part of the community to care for and protect nature, including in such an avant-garde area as construction. The traditional view of construction as profit maximisation with no regard for environmental damage is rapidly replaced by a green building philosophy. This is particularly noticeable in developed countries, among which the UK is a prime example. The choice of a particular European region is driven by the UK’s strong economic and investment appeal on the world stage.

As a centre of international trade, the UK is highly socio-economically and culturally developed. This, in turn, is reflected in the public consciousness of both ordinary consumers and local companies: by keeping to market relevance, parties ensure that construction is environmentally friendly. This applies to choosing green neighbourhoods, reducing construction’s carbon footprint, and investing in the most environmentally and economically balanced consumables. The UK context will therefore prove most informative in the European market to explore critical green building trends in the production and use of cladding materials.

The purpose of the research work

This research project’s central and sole purpose is to examine available academic sources and case studies to identify the most environmentally friendly and cost-effective cladding material for the UK context.

Objectives of the research work

As the research objective described above is complex and multi-factorial, it is appropriate to fragment it into separate goals, the sequential resolution of which is a crucial methodological strategy of the paper. Thus, the overall academic objectives of this study include, but are not limited to:

- To conduct a comprehensive literature review based on primary and secondary filtering criteria collected through digital academic platforms.

- To critically evaluate and qualitatively compare the literature prepared, justify its selection and assess the reliability of the sources used.

- To theorise and outline the academic framework of the green building phenomenon.

- To identify the parameters governing the metrics of environmental friendliness and profitability of material production.

- To identify the cladding material used in the UK construction market, which satisfies environmentally friendly and profitable production criteria.

- To summarise the findings and form a unified and holistic conclusion of the entire research project.

Literary overview

A brief history of construction

Construction is one of the fundamental trades of human activity, dating back literally to the emergence of primitive communities. The first manifestations of this craft were attempts to create safe shelter from whatever materials were available: the first rock caves and mounds that protected humans from survival threats were built (Swenson, 2020). Along with the development of human thinking, there was a parallel enhancement of creative and economic skills, often attributed to the biological evolution of the brain through the development of tools (Swenson, 2020; Fiodorov, 2021). Although there may be alternative views of this evolution, such as the religious context described by Verkaaik (2013), the phenomenon of general cognitive-labour evolution is challenging to deny. To put it another way, better houses and buildings appeared over time, corresponding to the increasing human need for comfort. Stony caves could no longer provide comfort and status to individuals, and as a result, the first decorated houses, called dugouts, began to appear (Trofimova et al., 2019).

Such structures did not have the windows and doors familiar to the modern reader, and in fact, they were earth hollows that maintained a favourable temperature regime inside (Frost, 2018). Such constructions were made more complex and improved to obtain more comfortable microclimatic conditions, applied and aesthetic appeal, as shown in Figure 1.

Eventually, construction reached the level of progress described by current trends. The requirements of modern humans for housing have increased to a large extent, and this is only natural given the evolutionary increase in the needs of individuals associated with general civilisational socio-economic development (Fiodorov, 2021). One such criterion for quality housing in the new market is fulfilling the new basic requirements of safety and security and the observance of an environmental safety framework. Socially responsible individuals understand how damaging the construction business can be, encouraging environmentally conscious producers (Ghisellini et al., 2018).

However, it is fair to acknowledge that this thesis is not exhaustive for contemporary society, as overpopulation and intensifying competition for resources reflect an alternative plan. More precisely, even environmentally damaging, environmentally hazardous, but relatively safe for humans, construction will find a consumer who does not consider the environmental aspects of production. This is a natural phenomenon, reflecting the ambiguity of the current phase of construction. At the same time, it can be expected that the emerging trend towards sustainable production will become a common agenda for the years to come; for this reason, discussions about these principles are relevant now.

Green building

As a natural stage in the development of building philosophy, the concept of green building has emerged. In general, the term refers to the construction of buildings, which aims to reduce energy and material resources consumption from the production phase to the long-term operation phases. It is a form of subsistence construction, prioritising building houses’ economic and economic needs and environmental concerns.

Academic literature has identified five key challenges for green building. Firstly, the trend aims to reduce the cumulative negative impact of construction and building materials on human health and the environment. GABS (2016) writes about reducing CO2 emissions by 84 gigatons per year by 2050. Second, the green building aims to use municipal resources more sustainably, which means more meaningful energy use. Green building is expected to reduce energy consumption by 50% by 2050 (Rakicevic, 2021). Thirdly, this philosophy invests in finding the most eco-friendly materials, which means that the research function is an integral part of green building. One of the non-obvious areas of such construction is to support the national economy by creating new jobs (Canada GBC, 2016). Finally, the green philosophy seeks to maximise the optimised use of home resources and maximise benefits with little risk to the environment.

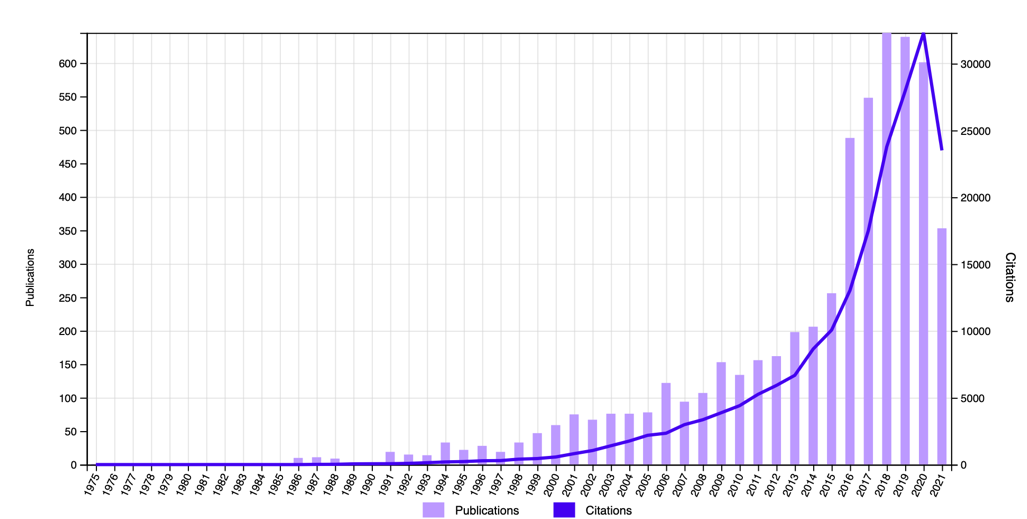

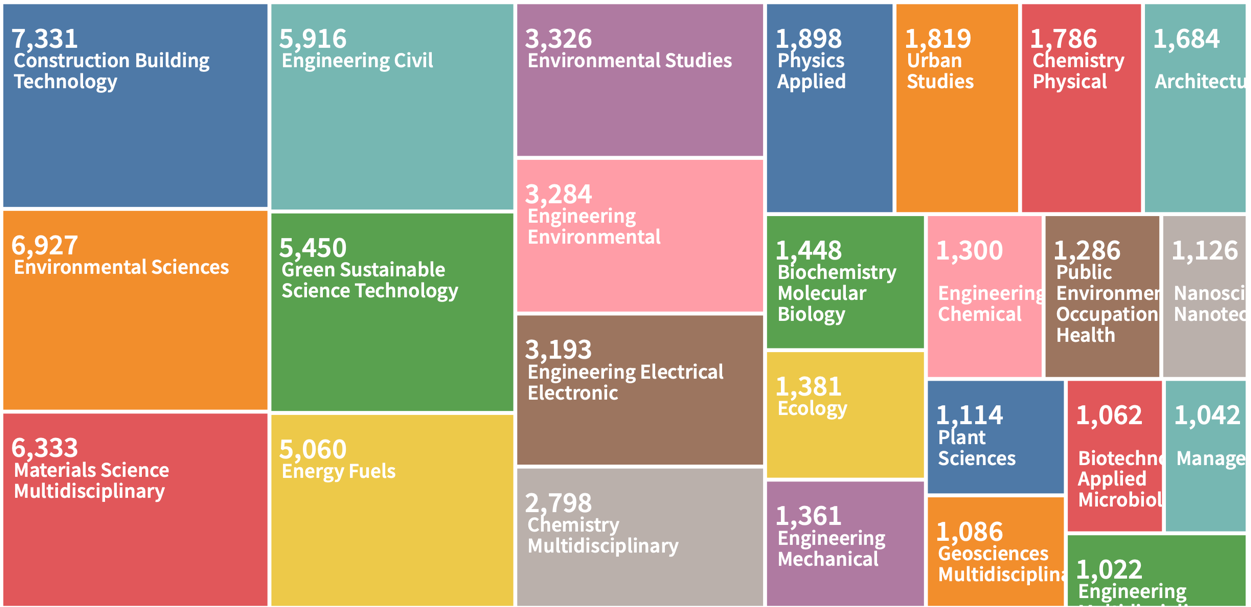

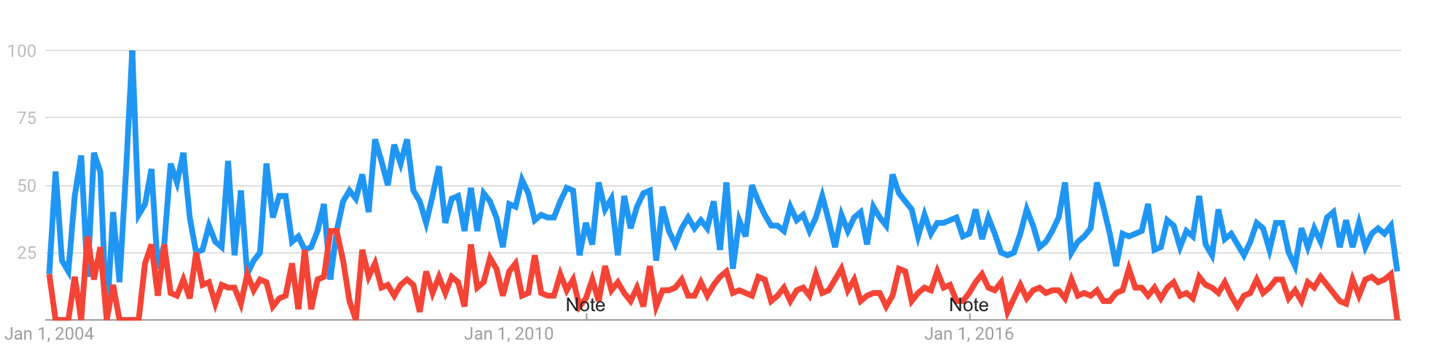

Notably, this trend for the UK is relatively recent. Figure 8 shows that academic interest in Green Building emerged around 35 years ago and increased exponentially almost every year. This confirms the hypothesis of increased environmental awareness among the population. Remarkably, contrary to expectations, the scientific study of Green Building goes beyond a thematic focus. More specifically, Figure 9 describes the general academic categories in which scientific papers are published. Energy sciences, applied physics, plant sciences, and green sustainability research are also interested in green building. Public interest in this issue is generally stable for Britons: Figure 10 shows a histogram of google query frequencies for critical terms. From this data: people search for information on green building with equal frequency, but that activity peaks during the autumn/winter season. It can be assumed that at this time, users are actively planning home renovations, which will begin with the arrival of spring.

The evolution of cladding materials

One of the developments in the construction industry has been the production of cladding materials. At this point in the scientific literature, a plurality of views has emerged about what such materials are and what functional role they fulfil. For example, Miller (2020) points out that cladding is one of the most common construction materials, including paving stones, siding, tiles, that has a breathable function. Liška and Nečasová (2020) point to the protective role of cladding, saying that “the basic function of building cladding is to protect the interior against the effects of the external environment” (p. 127).

A similar view is taken by Ginwala and John (2017), who prioritise the protective function of cladding against external stimuli. Such threats include fire, wind, and physical damage, including corrosion of building materials (Dahlstrom Roll Form, 2018). Finally, Dmitrieva et al. (2021) highlighted a unique, decorative role. In this context, it is particularly noteworthy to note that cladding materials often have aesthetic characteristics that make consumers choose them over their competitors. Figure 2 displays the differences in the cladding materials used. It shows wood, stoneware, and putty cladding materials, which give the overall exterior a unique visual characteristic. In general, there are no rules regarding the use of cladding in terms of aesthetic objectives, with identical or similar technical aspects of materials: every builder and homeowner has the right to choose any covering that seems most attractive.

Generally, it is appropriate to summarise that cladding materials are used in construction to decorate buildings and protect them from external and internal hazards, including harmful environmental influences and corrosion. This set of goals drove the creation of cladding materials from antiquity when primitive communities fortified their homes with clay, leather, wood, or stone cladding (Fiodorov, 2018; Swenson, 2020). This preserved houses from winds and other natural shocks but did not always fulfil a strictly aesthetic function. Cladding materials first gained particular significance in ancient civilisational communities, such as Ancient Egypt and Ancient Rome (McGreevy, 2020). At that time, clay materials were used to create a fireproof protective layer and solve problems of visual significance. Figure 3 perfectly shows the first ancient Roman ceramic tile linings made of clay.

By now, the need to clad buildings has undergone significant modernisation compared to how it used to be. The need to optimise the choice of cladding at the expense of the economy, adequate resource utilisation and optimal thermal-mechanical and anti-corrosive properties has led to the emergence of new materials, which have taken over the building material market in a few decades. These include siding, sandwich panels, clinker panels, and thermopanels as forms of relatively new exterior coatings for structures.

Siding

Vinyl siding was first mentioned more than seventy years ago. Siding made from polyvinyl chloride polymer was invented in the US market in the 1950s (CCH, 2020). It is a lightweight and flexible plastic material that found practical use in quickly erected timber frame houses, as shown in Figure 4. Vinyl siding was inexpensive and relatively easy to attach to the exterior wall surfaces of homes: such advantages have caused the siding material to become a traditional cladding material not only in American homes but also in Europe. The use of siding was prevalent in the former Soviet Union and Eastern Europe due to the material’s low cost (Reportbuyer, 2017). The use of plastic technology, which flourished in the second half of the last century, has influenced the variety of commercial siding materials: has the supply of different designs of siding sheets increased and the technology used. Sheet profiles, as depicted in Figure 4, were given secure fasteners that eliminated the need for the builder to use large quantities of screws and or adhesive, as the siding plates were bonded together. This solution improved the visual characteristics of the siding and saved on construction consumables.

Excessive amounts of plasticisers were added to the plastics to strengthen their properties. This has solved the photodegradation of the cladding material by solar ultraviolet light (Alahapperuma and Samarasekara, 2019). Studies show improvements in mechanical properties, be it bending strength and density of the material, when shungite is added (Kopylov et al., 2021). Similar techniques include modifying iron additives instead of classic antimony oxide (Howell et al., 2020). No matter how much siding technology is upgraded, plastic remains a short-lived and ineffective cladding material. Over time, siding tends to fray and crack when exposed to warm climates (Tsongas, 2017). In addition, PVC is not flame retardant, so the choice of this material cannot be justified by economic considerations for long-lasting, sustainable construction.

Sandwich panels

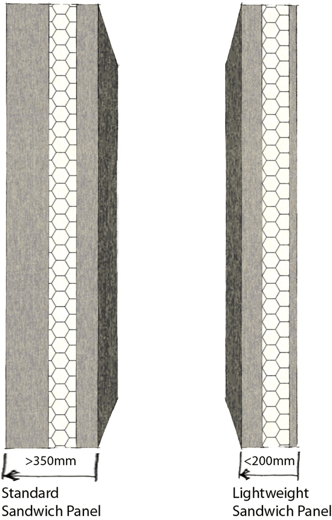

Complex sandwich panels based on a combination of layer technology have emerged. It is reasonable to view the panels as a natural evolution of PVC cladding. Composite panels made a revolutionary leap for all exterior construction: the material was lightweight, comfortable, and durable and perfectly suited to decorative and functional cladding (de Sousa et al., 2021). Modern sandwiches consist of three layers, including boundary stiffening materials and a layer of sealant between them, as shown in Figure 5. Like PVC, sandwich panels are used in fast construction, which means that the mechanical characteristics of such material are not designed for durability. Thus, the additional structure of new storeys can overload the sandwich panels, causing them to warp and crack (Skrifvars et al., 2019). In addition, such panels are vulnerable to temperature fluctuations: due to the condensation of fog and dew on the inner layers of the panels, premature rotting occurs (Vidmar, 2020). In addition, such panels are often finished with formaldehyde resins to cover gaps and strengthen the material. Still, this fact significantly degrades the environmental properties of sandwich panels (Barbu et al., 2020). As a general conclusion, such materials are not a good choice for sustainable construction.

Clinker

It comes as no surprise that cladding materials with a more extended history tend to be more eco-friendly. In general terms, clinker should be understood as the product of high-temperature firing of natural clay mixed with slags, small stones, and limestone (Khomenko and Purdik, 2017). The resulting mixture is finely ground to form refractory layers used in exterior finishing works (Figure 6). However, recent studies show ample evidence to support the severe respiratory hazards of ground clinker, including the threat of cancer (Di Ciaula, 2021; Spasiano and Pirozzi, 2017). Sintered clinker used as facade scenery has no such harm. At the same time, the operating guidelines for clinker mixtures prohibit the flushing of powder into sewage systems and water bodies, as this leads to clogging of tanks and the formation of cement plugs (Portland Cement Clinker, 2015). This leads to the conclusion that clinker itself is a more environmentally friendly and cost-effective material than vinyl plastics but that its use is not entirely safe either.

Thermopanels

One of Europe’s most popular cladding materials are thermopanels, which are typically thermally insulated polyurethane foams. Thermopanels are often called hygienic insulation of facades due to their functional purpose: such materials are very light in use and can be used not only for external but also for internal walls of a building (Burlachenko et al., 2021). Compared to the previously discussed forms, thermopanel is an excellent combined material, combining the flexibility and ease of use of vinyl siding sheets, the thermal insulation properties of sandwich panels and the strength of clinkers. Often these panels are made to resemble brick tiles, allowing the imitation of an expensive façade at a comparatively lower cost, as shown in Figure 7. The use of insulating panels for both new and refurbished buildings ensures a significant reduction in heat loss (Greenspec, 2020). Ultimately, it is the most cost-effective material, although its sustainability is still unexplored.

Wood cladding

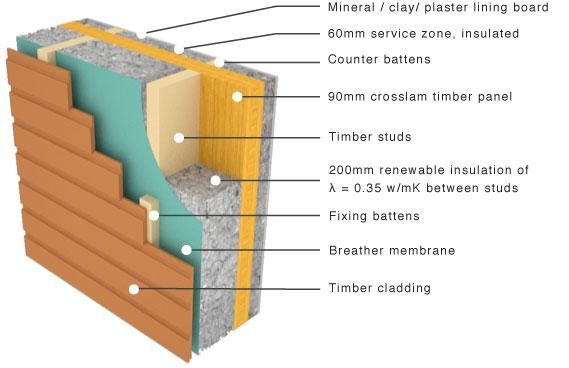

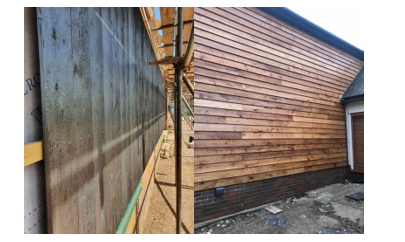

From the name, green building strives to use as many plant forms as possible in exteriors. For this reason, one of the most popular materials supporting eco-sustainability is wood. Wood cladding materials are renewable resources, mostly not requiring artificial synthetic additives in production (Almusaed, 2021). In addition, there is evidence of the low carbon footprint of such material: wood can absorb as much carbon dioxide as it releases oxygen, making it relatively neutral in terms of carbon dioxide pollution (Godinho, 2018; Almusaed, 2021). In addition, even felled wood is durable and does not rot if adequately maintained without plastic additives. At the same time, wood is relatively easy to stain and sand (Figure 11), so a façade made of this material can meet individual home design requirements.

Other forms of eco-friendly cladding

Wood cladding is not the only form of environmentally friendly cladding, however. Building activists worldwide are trying to solve the problem of a completely neutral product that can be used as a façade material. Often such answers take construction back to the stages of primitive settlements when the house was protected by natural waste. For example, one such option is cob, made from clay, sand, straw and soil mixed with water: Figure 12. Cob is a legacy from prehistoric times, as the active use of readily available natural materials is a feature of pre-industrial civilisations. At the same time, cob meets the critical needs of a modern façade material. For example, this mixture is easy to handle and take the desired shape, is fire-resistant and retains heat indoors (Spinell et al., 2020). In addition, the hardening structure of the material makes it possible to give it any design. Although the environmental safety of this cladding material is not in doubt, the cob is quite easily damaged in the event of earthquakes.

Critical material is recycled steel, which is used to make metal siding: Figure 13. It is worth saying that steel is one of the most recycled materials in the world (Nechifor et al., 2020). Although this material is safe and generally resistant to fire, steel is prone to corrosion and is difficult to manipulate in the manufacturing process. In general, there are also entirely radical methods that cannot find a mass producer at this stage. These include sheep’s wool, cork, straw, and bamboo (Barbulianno, 2020). Ultimately, the trend towards the maximum use of recycled materials and plants is evident.

General outcomes

In general, the apparent trend towards greater environmental awareness, not only among the public but also among the academic community, should be highlighted. More and more people are willing to invest in eco-friendly materials, with their use shown to be accompanied by good visual and performance characteristics. However, the green building philosophy opposes traditional plastic and other synthetic building materials, polluting the environment and posing a risk to humans. However, an important conclusion to be drawn from this literature review is the lack of a formalised view of the most environmentally friendly and beneficial material to use. Consideration of this issue is central to the following sections.

Methodology

The methodological basis for this project is based on the concept of qualitative secondary research, using available data for comparative analysis. To determine the optimal type of cladding material, thematic sources presenting full or partial information on environmental and economic benefits have been studied. Academic searches were carried out using digital databases, including Google Scholar, Microsoft Academic, Research Gate and Pubmed. In addition, a standard Google search algorithm was used to identify alternative views and public opinion. The choice of a secondary research mechanism was fully justified by the low relevance of the other options to the present research work. Interviews and quantitative physical experiments were not feasible due to insufficient and limited resources available, whereas academic search fully met all requirements.

Articles, government data and websites were searched using primary filtering mechanisms that included criteria of English spelling, temporal relevance, and author and publication authority. Searches were carried out through textual and content analysis, including the use of thematic keywords. Thus, the total number of sources used was 53, of which 63% should be classified as academic literature. This fact confirms the chosen methodological framework’s reliability and supports the present study’s scientific relevance.

Adherence to high ethical standards is also a necessary part of the selection methodology. Only those sources that have been placed in the public domain. In other words, there was no fraud or illegal use of educational spectrum material. At the same time, the current work does not conflict with other studies but actively complements them through comparative analysis.

Results

Results and analysis

Since the main interest of this project was to determine the optimal cladding for façade construction in the UK context, this section highlights the finding from a technical and ecological as well as economic point of view. The following table displays the key characteristics of building materials in terms of cost, durability, water and heat resistance, heat retention within the house, combustibility and harmful emission into the atmosphere.

Figure 12: Key properties overview (own illustration).

As can be seen from the table, in terms of price clinker and cladding thermal systems are most expensive, while vinyl is the cheapest alternative. The most durable material is clinker, but it has poor heat retentive qualities and is costly. Wood and cladding thermal systems enjoy greater air combustibility, important for creating a comfortable microclimate in the house, as well as good heat retention properties. Considering harmful emission into the atmosphere, only sandwich panels emit formaldehyde, while other materials are eco-friendly. Summing up all the data, the following may be said about cladding materials considered in this work.

- Vinyl siding, that has remained a popular cladding material over decades, in terms of cost-effectiveness, is a cheap building material. Moreover, it is ecologically friendly, since when vinyl is recycled, chlorine gas is not released into the atmosphere; vinyl can be safely incinerated and its energy reused. Its is ecologically inert and its molecules do not interact with chemicals or other substances; vinyl panels are light and easy to install. However, they are not waterproof and can bend or deform under pressure or in fire. Vinyl has an average durability, doesn’t let air in the house due to which inhabitants have to open windows to let air in. It is not suitable for creating comfortable microclimate in the house, that is why this cladding material is not used in large-scale building.

- Sandwich panels are inexpensive alternative to vinyl siding. Technical properties of sandwich panels outdo technical characteristics of vinyl siding in terms of strength, durability, thermal insulation properties and water resistance. Like vinyl siding, sandwich panels are light and easy to install; however, they are not eco-friendly. The process of production of sandwich panels includes pressing wood-based materials at temperatures from 160°C to 175°C. When wood-based materials are heated, they emit free formaldehyde. The emissions of formaldehyde take place not only when sandwich panels are processed but also after their installation in the houses, since it is the continuous chemical process. Formaldehyde vapors are toxic; they strongly affect the central nervous system, especially the visual organs and the retina of the eyes.

- Clinker is an environmentally friendly ceramic cladding material; its reliability and durability are very high and its strength equals that of a stone. However, click is rather costly; the use of clink significantly raises building costs, that is why clink is rarely used for large-scale building. Clinker is sometimes used for decoration of buildings, but as a cladding material loses to all other alternatives in price. Moreover, clicker enjoys poor heat retentive properties, and clinker-cladded houses are cold in autumn and winter without proper heating.

- Thermopanels are modern materials that have high durability, strength, and are water resistant and flame retardant. In terms of ecological safety, thermopanels are eco-friendly, since they are inert and can not cause any allergic reactions. While prosessing thermopanels no harmful emissions are made into the air. However, thermopanels are not cheap that is why they would not be considered for economical building.

In general, it has been found that wood is the best material for environmentally friendly and most profitable cladding. The following facts provide sufficient evidence for this choice.

Firstly, it has been shown that the choice of wood fully responds to the trend of environmentally conscious communities towards natural materials. Unlike plastic and synthetic raw materials, wood is a product of natural origin and, what is essential, is renewable. From this comes a second reason: there are at least 60,000 different biological species of trees, most of which are highly durable and relatively easy to manipulate (Cottam, 2018). This makes it possible to use wood in a variety of design configurations and to give it the desired shape, as illustrated in Figure 14. This includes the overall styling of the wood facade and the choice of material colour, density, and thickness. These variations lead to a third significant result: wood cladding has uniqueness because it is impossible to recreate the unique structure of a sawn wood fibre.

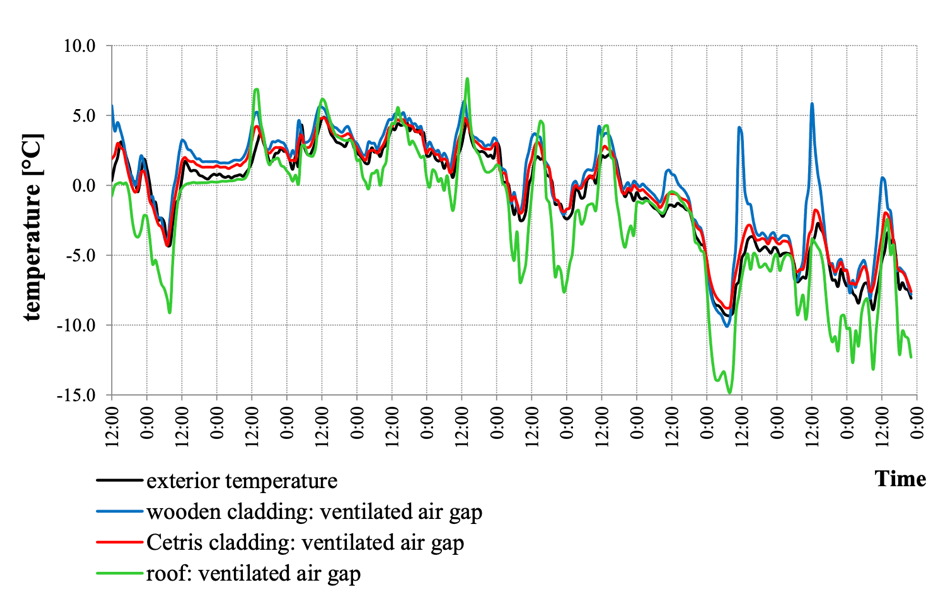

Remarkably, the technical properties of wood cladding also make it profitable to use. Dense timber has high sound insulation properties, allowing to keep sounds inside the home. High insulation is also characteristic of heat, as wood has excellent insulating properties. This is especially true in winter in the UK, where temperatures are known to approach zero Celsius (Jaganmohan, 2021). Figure 15 shows perfectly that the inner layers of the double-layered timber façade consistently retain higher temperatures despite the lowering of the ambient air temperature. In addition, the additional modification of the wood façade with Cross-laminated timber reduces the heat loss of -1.14% compared to traditional wood cladding and -5.07% (Pelaz et al., 2017). This confirms the tendency of wood to breathe actively and meets the required thermal performance.

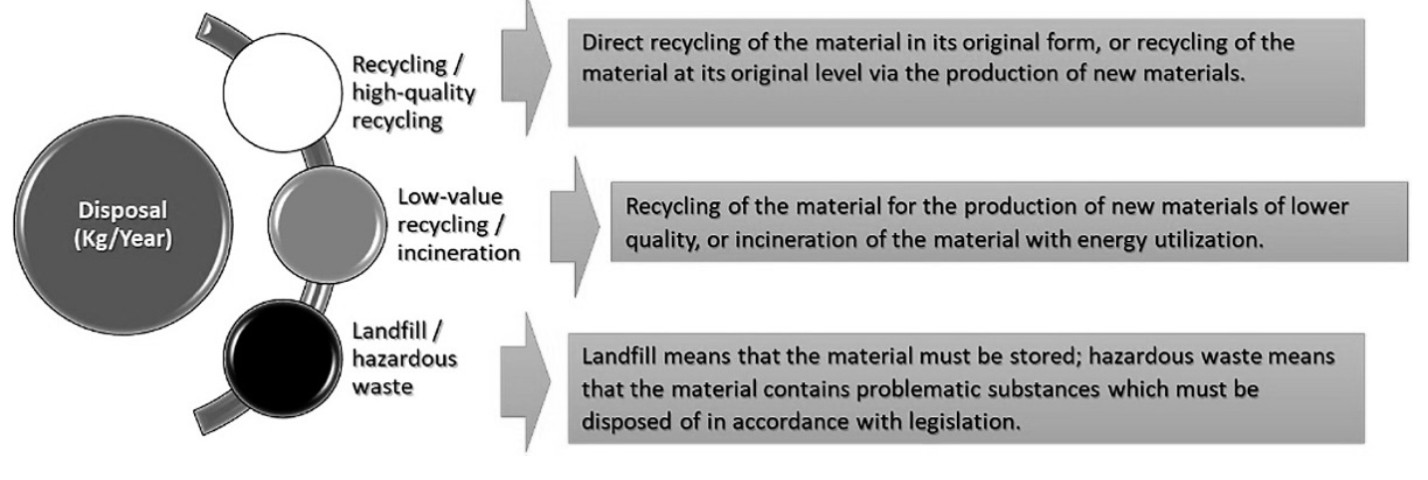

The ecological characteristics of the wood cladding found in the study also confirm the expectation of high eco-security. In addition to being a renewable source, the use of wood in façade construction allows the accumulation of excess carbon dioxide already at the plant’s growth stage and preserves it in a bound state when used as building materials (Godinho, 2018; Almusaed, 2021). The use of wood also requires minimal transport costs, as the resource grows almost everywhere. In addition, wood is relatively easy to recycle and leaves virtually no negative impact on the environment: Figure 16. Consequently, this material can be used as a valuable biofuel at the end of its useful life.

The economic performance of timber cladding has also been of interest. The use of hardwood as a building material has been shown to increase the cost of construction by an average of up to £40 per square metre (Tradesmen, 2020). If the housebuilder decides to use untreated softwood, the cost is reduced to £8, although additional spending in treatment, be it painting and polishing, is required (Build It, 2018). This is generally well within the average cost of cladding a building from £20 per square metre across the UK (MyJobQuote, 2020). Consequently, there are significant economic benefits to using wood cladding.

Discussion

The results obtained allow classifying wood as an eco-friendly and profitable building material for cladding work. Wood has been shown to have excellent environmental properties and is comparably easy to use, and its purchase will not put much financial pressure on the homeowner, especially with other materials. Wood is much healthier and more efficient than plastic options and is not corroded like expensive metal cladding (Dahlstrom Roll Form, 2018). At the same time, wood materials create a favourable climate inside the house and a favourable neighbourhood due to their natural feel. Sound insulation is of distinctive importance for the choice of this material, as in densely built-up areas, the internal noise of one house can disturb neighbours.

As it is a natural material, it is easily affected by climatic fluctuations. On the one hand, the high humidity characteristic of the UK leads to changes in the mechanical properties of the wood (Humar et al., 2020). On the other hand, increasing average annual temperatures hurt the material’s durability (Godinho, 2018). In addition, wood burns very well, which makes it poorly efficient in terms of fire resistance. At the same time, the naturalness of the building product leads to threats of biological hazards, namely infestation of wood cladding with fungi and insects (Vacenovská, 2020). However, the solution to these problems is obvious: it is sufficient to use hydrophobisers and flame retardants, including caffeine, which prevents the material from being affected by the threats (Šimůnková et al., 2021). Nowadays, the market offers sufficient environmentally friendly variants of liquid treatments which allow preserving the beneficial properties of wood for a long time.

Conclusion

To conclude, it must be stressed that wood remains one of the most environmentally and economically optimal alternatives out of a wide variety of cladding materials. A comprehensive literature review has shown that cladding materials are undergoing significant changes due to the development of green building philosophy. Although the modern market offers dozens of commercial cladding options, most of them are not environmentally friendly, although they are well priced. That said, green building requires a harmonious balance in these two categories. Wood is such an element, as it combines naturalness and the resulting eco-sustainability. However, it was shown that wood is not a final product, as it has some disadvantages: this confirms the hypothesis of the literature review that an utterly eco-friendly material cannot exist.

Limitations

Some limitations are inherent to this project. On the one hand, the results were relevant for the UK market, although not every country has the availability of wood. In the Gulf countries, for example, this cladding material can be costly. On the other hand, the study did not empirically observe the properties of specific claddings and used ready-made primary data. This may have affected the overall unbiased nature of the study and reduced its novelty. In addition, no general methodological system of scales for comparing different cladding was developed, and their comparative analysis was weakly qualitative.

Future work

In developing this topic, it is recommended that some new goals be achieved, allowing for impressive results in the future. A cohort study of different woods is proposed to identify the type of material that would have the best characteristics. It is also recommended to extend the study area to the European zone to assess the scalability of current results in new markets. In addition, a more in-depth study of wood’s environmental and technical properties would be helpful, using statistical processing methods.

Reference List

Adam (2020) External timber cladding for sale UK. Web.

Alahapperuma, K.G. and Samarasekara, A.M.P.B. (2019) ‘Degradation of unplasticised poly vinyl chloride based engineering products upon exposure to ultra violet radiation,’ Tropical Agricultural Research, 30(4), pp. 117-123.

Almusaed, A., Yitmen, I., Almsaad, A., Akiner, İ. and Akiner, M.E. (2021) ‘Coherent investigation on a smart kinetic wooden façade based on material passport concepts and environmental profile inquiry,’ Materials, 14(14), pp. 1-17.

Barbu, M.C., Lohninger, Y., Hofmann, S., Kain, G., Petutschnigg, A. and Tudor, E.M. (2020) ‘Larch bark as a formaldehyde scavenger in thermal insulation panels,’ Polymers, 12(11), p. 2632-2648.

Barbulianno (2020) 18 eco-friendly building materials that help you save energy and the Earth. Web.

Bates, C. (2019) Metal cladding options explained. Web.

Build It (2018) Timber cladding: what will it cost?. Web.

Burlachenko, O.V., Chesnokova, O.G. and Cherednichenko, T.F. (2021) ‘The possibility of using the ultra-thin liquid thermal insulation to insulate the ceiling above the basement in residential buildings,’ Solid State Phenomena, 316, pp. 1013-1018.

Canada GBC (2016) New CaGBC market impact report demonstrates green buildings are an engine of economic growth in Canada. Web.

CCH (2020) Who invented siding?. Web.

Cottam, L. (2018) What are the most common trees in the UK?. Web.

Dahlstrom Roll Form (2018) Salty about coastal construction? Use the right architectural metal. Web.

de Sousa, C., Barros, J.A., Correia, J.R. and Valente, T.D. (2021) ‘Development of sandwich panels for multi-functional strengthening of RC buildings: characterization of constituent materials and shear interaction of panel assemblies,’ Construction and Building Materials, 267, pp. 1-12.

Di Ciaula, A. (2021) ‘Bioaccumulation of Toxic metals in children exposed to urban pollution and to cement plant emissions,’ Exposure and Health, 2, pp. 1-15.

Dizhur, D., Giaretton, M. and Ingham, J. (2017) ‘Performance of early masonry, cob and concrete buildings in the 14 November 2016 Kaikoura earthquake,’ Bulletin of the New Zealand Society for Earthquake Engineering, 50(2), pp. 194-205.

Dmitrieva, T.L., Podshivalova, K.A., Molchanov, D.O. and Beloborodov, K.M. (2021) ‘Current approaches to the modeling and calculation wood frame building, taking into account the joint work of the load-bearing elements of the frame and cladding,’ IOP Conference Series: Earth and Environmental Science, 75(1), pp. 1-8.

Duffield Timber (2021) Timber cladding guide: best wood cladding profiles, types, species & other tips. Web.

Fiodorov, N. (2021) ‘Contemporary architecture in the historical urban context. Abandoned buildings,’ Probleme actuale ale urbanismului şi amenajării teritoriului, 1, pp. 47-51.

Frost, N. (2018) 9 ways stone age human ancestors were like us. Web.

GABS (2016) Towards zero-emission efficient and resilient building. Web.

Ghisellini, P., Ripa, M. and Ulgiati, S. (2018) ‘Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector: a literature review,’ Journal of Cleaner Production, 178, pp. 618-643.

Ginwala, H.A. and John, R. (2017) ‘Dynamic analysis of stone cladding system in multi storey building,’ International Journal of Science Technology & Engineering, 4(5), pp. 151-165.

Godinho, D., Ferreira, C., Paiva, T.I., Alves, J.A., Loureiro, D. and Diamantino, T.C. (2018) ‘The influence of climatic parameters on wood durability: a review,’ CNMAT 2018: XV Congreso Nacional de Materiales, I Iberian Meeting on Materials Science, 1, pp. 1-2.

Greenspec (2020) The principles of functional layer crosslam walling assembly. Web.

Howell, B.A., Daniel, Y.G., Weil, E.D. and Butwin, F.J. (2020) ‘Thermal stability of poly (vinyl chloride) formulations containing iron additives as a replacement for antimony oxide,’ International Journal of Material Science Research & Technology, 1(1), pp. 15-20.

Humar, M., Lesar, B. and Kržišnik, D. (2020) ‘Moisture performance of façade elements made of thermally modified Norway spruce wood,’ Forests, 11(3), pp. 348-361.

Jaganmohan, M. (2021) Monthly average daily temperatures in the UK 2015-2021. Web.

Khomenko, E.S. and Purdik, A.V. (2017) ‘Particulars of microstructure formation in clinker ceramic,’ Glass and Ceramics, 74(1), pp. 48-51.

Kopylov, M.V., Kleymenova, N.L., Bolgova, I.N. and Zheltoukhova, E.Y. (2021) ‘Nanocarbon additives application in the polyvinyl chloride siding panels manufacture,’ IOP Conference Series: Materials Science and Engineering, 1079(2) pp. 1-19.

Liška, P. and Nečasová, B. (2020) ‘Revitalisation of lightweight cladding of buildings,’ Key Engineering Materials, 868, pp. 127-134.

McGreevy, N. (2020) Ancient roman mosaic floor unearthed beneath italian vineyard. Web.

Miller, C.S. (2020) ‘Design wind loads for air-permeable multilayer cladding systems,’ Electronic Thesis and Dissertation Repository, 6927, pp. 1-152.

MyJobQuote (2020) House cladding costs. Web.

Nechifor, V., Calzadilla, A., Bleischwitz, R., Winning, M., Tian, X. and Usubiaga, A. (2020) ‘Steel in a circular economy: global implications of a green shift in China,’ World Development, 127, pp. 1-15.

O’Hegarty, R., Kinnane, O., Grimes, M., Newell, J., Clifford, M. and West, R. (2021) ‘Development of thin precast concrete sandwich panels: challenges and outcomes,’ Construction and Building Materials, 267, pp. 1-12.

Pelaz, B., Blanco, J.M., Cuadrado, J., Egiluz, Z. and Buruaga, A. (2017) ‘Analysis of the influence of wood cladding on the thermal behavior of building façades; characterization through simulation by using different tools and comparative testing validation,’ Energy and Buildings, 141, pp. 349-360.

Portland Cement Clinker (2015) Safety data sheet. Web.

PPW (2021) Durasid natural cedar 167mm x 5M (Pk 4). Web.

Rakicevic, M. (2021) 26 amazing green building statistics for a cleaner 2021. Web.

Reportbuyer (2017) World siding (cladding) market. Web.

Šimůnková, K., Reinprecht, L., Nábělková, J., Hýsek, Š., Kindl, J., Borůvka, V., Lišková, T., Šobotník, J. and Pánek, M. (2021) ‘Caffeine–perspective natural biocide for wood protection against decaying fungi and termites,’ Journal of Cleaner Production, 304, pp. 1-10.

Skrifvars, M., Dhakal, H., Zhang, Z., Gentilcore, J. and Åkesson, D. (2019) ‘Study on the mechanical properties of unsaturated polyester sandwich biocomposites composed of uniaxial warp-knitted and non-woven viscose fabrics,’ Composites Part A: Applied Science and Manufacturing, 121, pp.196-206.

Spasiano, D. and Pirozzi, F.J.J.O.E.M. (2017) ‘Treatments of asbestos containing wastes,’ Journal of Environmental Management, 204, pp. 82-91.

Spinell, R., Lerin, D., Spoh, G.L., Francischett Pito, A., Dall Agnol Pasqual, P.H., Haetinge, C., Cambeiro, F.P. and Konrad, O. (2020) ‘Development of natural and innovative material for application as thermal insulation in buildings,’ Sustainability in Debate/Sustentabilidade em Debate, 11(1), 1-17.

Ströher (2021) Keravette. Web.

Swenson, A. (2020) Construction. Web.

Tradesmen (2020) House cladding cost: 2021 installation price comparison. Web.

Trofimova, S.S., Zaretskaya, N.E., Lapteva, E.G., Lychagina, E.L. and Chernov, A.V. (2019) ‘Methods of paleoecological investigations: a case study of the holocene environmental reconstruction,’ Russian Journal of Ecology, 50(6), pp. 543-550.

Tsongas, G.A. (2017) ‘Cautionary Case studies: damage in multifamily housing walls with vinyl siding,’ ASHRAE Journal, 59(7), p. 44.

Vacenovská, V. (2020) ‘The treehouses,’ IOP Conference Series: Materials Science and Engineering, 867(1), pp. 1-15.

Valachova, D., Badurova, A. and Skotnicova, I. (2021) ‘Thermal technical analysis of lightweight timber-based external wall structures with ventilated air gap,’ Sustainability, 13(1), pp. 378-393.

Verkaaik, O. (2013) Religious architecture: anthropological perspectives. Amsterdam: Amsterdam University Press.

Vidmar, G. (2020) ‘Treatment of condensation in sandwich panels without known vapour resistance of sealant,’ E3S Web of Conferences, 172, pp. 1-7.