Zara is one of the internationally operating manufacturers and retailers of clothing and accessories. It has several lines of apparel. Nevertheless, because the primary group of products is clothing, special attention will be paid to developing the process flow map of these commodities.

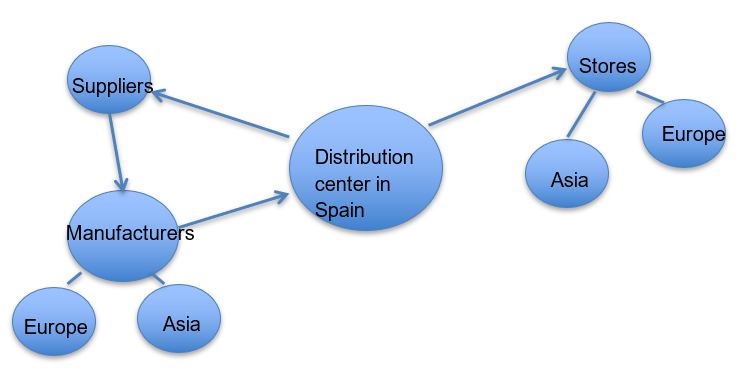

To begin with, it is essential to understand the steps of the manufacturing and distribution process, developed by Zara. The initial stage of the manufacturing process is the design of clothing and the choice of needed garments. The next step is contacting raw materials suppliers with the aim of ordering needed textiles. Another phase is delivering fabrics to manufacturing facilities and the manufacturing process itself. Manufacturing facilities are located in Morocco, Turkey, Spain, Portugal, Brazil, China, Bangladesh, and Vietnam (Hansen 2012). They are automated, which makes the process more cost-effective and faster (Petro 2012). Here, it is critical to mention that all clothing is delivered to the central distribution department in Spain and processed there. After the goods are processed and inspected, the next step of the whole process is the distribution of ready-to-wear apparel to stores around the globe. In most cases, delivery of manufactured goods to the stores takes around ten to fifteen days. In this case, it is essential to note that finished goods are delivered to stores two times a week (Sowray 2015). More than that, each store has an option of contacting manufacturers directly and ordering necessary design series. Finally, goods are sold either online or in stores. It is as well imperative to note that shipping services are available. For the better understanding of the process flow, see Figures 1 and 2 below.

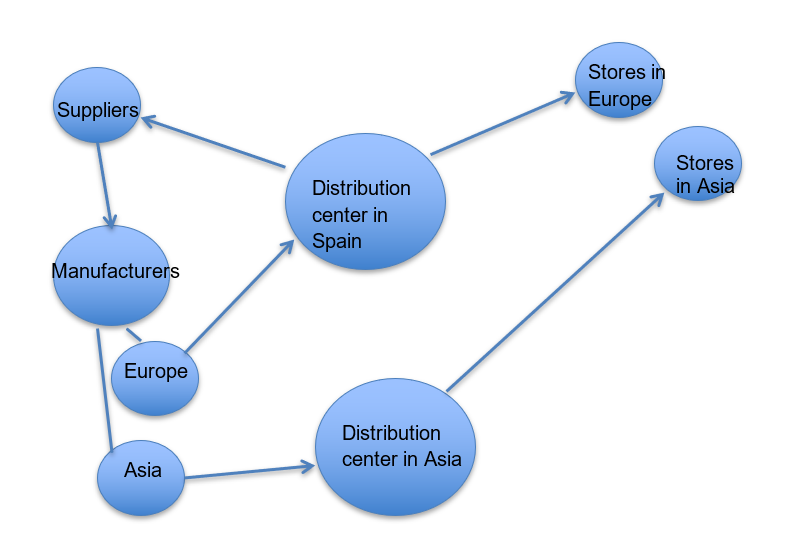

Based on the process flow chart and the description of the manufacturing and distribution processes provided above, it is evident that regardless of the relatively high effectiveness of the process, there are still ways to improve it. For instance, opening distribution centers around the globe would decrease transportation costs and reduce time necessary for the delivery of finished goods to the stores. It might be especially critical in the case of manufacturing goods in Asian countries, which are distant from Spain. Opening distribution centers in nearby countries (Turkey, Morocco, and Portugal) might not be cost-effective. However, doing it in Asian countries is advisable. In this way, distribution center in Spain should remain the major decision-making body, specializing in designing new collections and making orders for garments. However, the further process should be changed: Asian manufacturers are recommended to cooperate with Asian distribution centers, while European manufacturers should continue working with the distribution center located in Spain. Moreover, Asian distribution centers should dispatch clothing to Asian stores, while Spanish distributor should focus on the nearby stores. Modified process flow map is provided below (see Figure 3).

Reference List

Hansen, S 2012, How Zara grew into the world’s largest fashion retailer.Web.

Petro, G 2012, The future of fashion retailing: Zara approach.Web.

Sowray, B 2015, The ingredients of Zara’s success. Web.