Introduction

Quality management is a coordinated activity aimed at directing and controlling the work from the point of view of the quality. There are a lot of different tools which are designed with the purpose to support quality management. Quality management tools are useful for progress controlling, product monitoring and system improvement. There are seven traditional quality control tools and seven new once.

The main focus of this discussion is to consider one of the new management tools aimed at controlling the quality of the performance and to apply this in practical sphere.

The performance of the ADWEA is going to be considered within the affinity diagram; we are going to check the major problems and key issues in ADWEA with the help of nominal group technique, implement flowcharting into quality management control and crate an affinity diagram which is going to point to the gaps in the workflow which could have caused a number of problems and errors in ADWEA performance.

Affinity diagram as a quality planning tool

Affinity, matrix, relationship, tree, activity network diagrams, prioritization matrix and process decision program chart are the new quality management tools. Focusing on the affinity diagram, it should be mentioned that its main purpose is to provide effective and efficient working process. Brainstorming is the main technique used for creating affinity diagram. To understand the implementation of this tool in the quality planning, it is important to consider the methodology and steps for designing an affinity diagram.

There are 5 main steps for affinity diagram methodology implementation. The first step is problem definition as clearly as possible. The second step is the use of brainstorming technique when everyone writes down the ideas.

The third and the fourth step is the mixture of the cards and asking the team to arrange the ideas in accordance with the groups they may be related to. The final fifth step of the affinity diagram methodology is devoted to the naming the groups and understanding the scope of work which should be implemented in each issue.

To use the affinity diagram as a quality planning tool, it is important not only understand the methodology of the process, but also keep in mind the structure of the work. Here are the issues the group should solve in case a quality planning is going to be based on the affinity diagram.

- Group creation. About 5-8 members should comprise a group who are going to consider the quality of the completed work.

- The specific time and venue of the meeting should be fixed by the moderator.

- Each member of the group should write what h/she thinks is a great solution for the problem.

- Then, it is necessary to review the ideas and get rid of the similar ones and those which are not related to the problem in a direct way or seem dissatisfactory for the vast majority of the team members.

- The related ideas should be gathered in groups and logically named.

- The ideas are put under the group name and the picture is transferred into a computer. The affinity diagram is ready and can be used for planning quality work and analyzing the results of the already completed tasks (Subburaj 14.2).

Paying attention to affinity diagram as to the quality planning tool, one should refer to the stated objectives before getting down to designing an affinity diagram. ADWEA is a company which deals with water and electricity sectors.

Using affinity diagram, it is possible to understand how effective different departments in the company work, how efficient the resources are used, etc. Creating an affinity diagram for ADWEA, a team should identify the desired goals of the company and analyze the actions which have been provided. Whether the whole potential is used? Are there any specific issues which may be addressed?

Major Problems and Key Issues in ADWEA (Nominal Group Technique)

The Nominal Group Technique is a “structured approach to a brainstorming session” (Jacobson 127). This technique has been created with the purpose to show that working in a group but without interacting, people perform better and more creative.

The Nominal Group Technique in a narrower sense is a “consensus-building strategy useful in goal-setting or problem solving applications and is a tool that public land planners can use to effectively incorporate local stakeholders into the planning process and to help guide the design of new programs” (Jacobson 127).

Using this Nominal Group Technique, we are going identify the major issues and problems ADWEA faces and rank them. Six stages should be completed to do it,

- issue/problem presentation,

- reflection and brainstorming,

- presentation of ideas in round-robin style,

- revision of listed ideas,

- ranking ideas,

- results compilation.

Referring to these steps, we have conducted a research and have identified the following problems in accordance with the reduction of the importance from the first one up to the last one.

- Health and safety guarantees may be considered as the problems the company faces. Keeping in mind the specifics of the industry, the possibility of injuries is high and the company should consider this problem.

- Meeting environmental standards is another issue the organization faces. It is important that the emissions from the manufacturing do not exceed the stated level.

- The level of occupational illnesses is too high in the company due to the specifics of the manufacturing.

- The quality control is a problem ADWEA usually faces. The company must follow numerous standards and be subjected to the legal acts implemented in the state. Moreover, ADWEA is the company which offers unique services to people. The quality of water and electricity delivery should be on the highest level.

- ADWEA, like any other company, has the purpose to increase the profit and get more money from the projects it works on. The company should pay more attention to the new projects, so planning is considered to be one of the major issues the company faces.

- Control is another key issue ADWEA faces. The control department should cope with a number of different problems, like following the working process in general, keeping an eye on the implementation of the projects and offer support and pieces of advice.

- The work with the human resources may be a problem if the leadership is not properly developed and training programs are not implemented.

- Recruitment of the necessary staff may be the issue due to the lack of highly professional specialists at the labor market.

- Information security may be a great issue if the department fails to work in a proper way.

“Flowcharting” and Its Implementation in Quality Management

Flowcharting is a tool which is used with the purpose to identify, clarify and analyze different events in the process. One of the main reasons to use flowcharting is to see the whole picture of the working process. The advantage of this tool is that it does not take too much time if implemented effectively. Flowcharting is usually used for business improvement. To implement flowcharting in a quality management, one should use the following method,

- Clarify the process which is going to be considered, its progress and the level of specification.

- Identify the steps using brainstorming technique.

- Arrange the steps in sequence.

- Draw the flowchart itself.

- Provide the flowchart testing.

- Communicate about the actions which should be improved (Turner 64).

Pointing to the main characteristics of the flowcharting and its implementation is the quality management, it should be mentioned that the chart should be as simple as possible. It should point to the specific problems which should be considered and to the steps which should be taken is the issues are not addressed in a proper way.

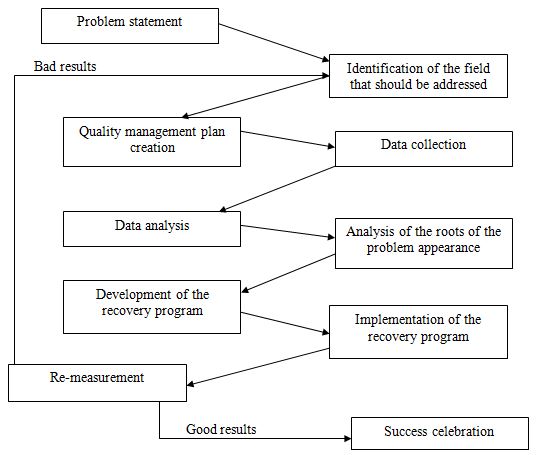

Quality management may have the following look if implemented with the flowcharting.

Thus, it may be seen that the flowcharting is rather important in quality measurement as it helps use the same model for identifying different problems and save time.

The flowchart we have mentioned is the simplest one which just shows the steps which should be completed when the problem appears. There are more complicated quality management flowcharts which point to the specific processes which should be held to promote the quality control and the methods which should be used to make a decision and solve an issue.

Anyway, the main idea of the quality management flowchart is the strict sequence of steps which should be completed before the decision is made or the item is analyzed. The final step of any flowchart in a quality management is the results assessment and their successful implementation.

Gaps in Workflow That Could Cause Problems and Errors in ADWEA (flow chart)

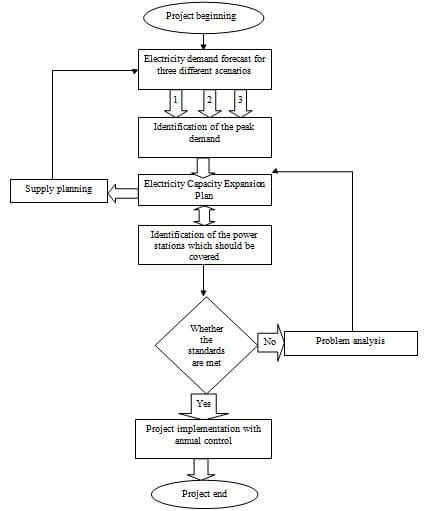

To identify the gaps in the workflow that could cause problems and errors in ADWEA, it is possible to create a flowchart which is going to be a model for the company. We are going to check the possible mistakes and errors in the company workflow on the basis of the ADWEA 5-Year Electricity Planning Statement, a project the company wants to finish in a year.

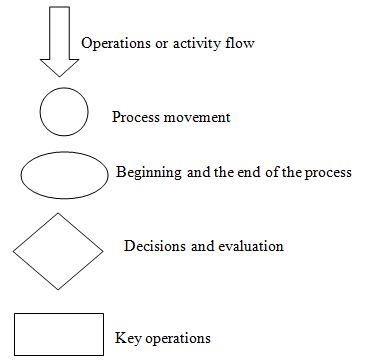

To identify the possible gaps, we should show the whole working process on the project, including its beginning and predicting the end. To make the flowchart easy for perception, the commonly accepted signs are going to be used.

It should be mentioned that three scenarios are the high forecast, the base one (the most likely scenario), and the low forecast (uncertainty in timing). Depending on the Electricity Capacity Expansion Plan and the demand information, the supply should be identified and assessed (5-year electricity planning statement update (2008-2012)).

Looking at the chart, it is possible to say that the control should be implemented at each stage as the project is considered to be long-term and the modern conditions at the international financial market does not allow the company management department leave the project implementation without monthly control.

The flowchart offered above is simple and shows only the most important decisions in the whole projects. Supply, demand and the meeting different standards are considered to be the key issues in the plan implementation. The failure to meet those may lead to the problems which may put the whole project in danger.

Moreover, considering the 5-year electricity planning statement update, we can see that the electricity demand forecast is done only at the beginning of the project. It is wrong. The world is changing. Looking at the price raise on gasoline, the eclectic cars are going to be in demand soon, thus, it may be concluded that the demand on electricity may increase as well.

Conclusion

In conclusion, it should be mentioned that the use of different diagrams and carts for problem identification and quality management is a good idea as it allows a group of people implement different ideas, express personal opinion, discuss and come to the best possible conclusion.

Referencing to the ADWEA and the analysis of the project it is implementing at the moment, it can be concluded that the flowchart system is a good strategy for identifying the possible problems and their discussion. The flowcharts may help solve the problems before they have happened.

Works Cited

“5-year electricity planning statement update (2008-2012).” Abu-Dhabi Transmission and Despatch Company, 2007. Web.

Jacobson, Susan Kay. Communication Skills for Conservation Professionals. Washington, DC: Island Press, 2009. Print.

Subburaj. Total Quality Management. New York: Tata McGraw-Hill Education, 2005. Print.

Turner, Suzanne. The Little Black Book of Management: Essential Tools for Getting Results NOW. New York: McGraw Hill Professional, 2010. Print.