Abstract

Accelerometers are intelligent electronic sensors that are actively used in many industries in spite of innovative thinking and technological advancements. In this research paper, the focus is made on comparing capacitive and piezoelectric accelerometers and their practical application in real life solutions based on the recent scientific evidence.

It is specifically argued that capacitive accelerometers best fit the importance of measuring static forces, while their piezoelectric counterparts best serve the need of exploring dynamic forces; however, a combination of both is still a valid solution for future implementation efforts.

The advantages and disadvantages of both types are further outlined, following the most applicable industry applications of using accelerometers on the industry scale. Finally, certain constraints are voiced on the future sensor development research based on the case of industries that require future innovation in terms of technological mastery.

Introduction

The intelligent electronic sensors are omnipresent in our contemporary lives. Among the recent industry trends, innovative sensor technologies are represented by the ultrasound, optoelectronic, and laser technologies that transcend our perception of advancement in many commercial industries such as healthcare, automotive, and smart home applications.

The one of such intelligent sensor types are accelerometers, the electronic devices that measure acceleration forces influencing the object to determine its spatial position and monitor related movements. The unit measurement of these sensors is a vector quantity, which is a rate of change of an object’s velocity.

The physical principle behind the operation of accelerometers is measuring two types of external forces. The static forces are those that are constantly applied to the object (for instance, friction or gravity), while the dynamic forces are related to movement and applied to the object randomly depending on the environmental conditions (for instance, vibration). Hence, intelligent sensing of the two types of forces allows better integration with computerized environment and notify users about potential condition changes or collision effects.

For the purposes of this research study, two accelerometer types are compared. The first type is capacitive accelerometers, which explore the change in electrical capacity to determine the extent of acceleration of the object. The second type is piezoelectric accelerometers, which use vibration and shock measurement for sensing acceleration changes. Overall, it is argued that exploring working principles of both accelerometer types is advantageous to understand their practical application and use within specific industries, as well as feasible to determine the best choice from the commercial perspective.

Analysis of Working Principles

Capacitive Sensors and Accelerometers

The capacity accelerometers, also frequently defined as vibration sensors, are designed to sense the change in electrical capacitance, further varying the output of the energized circuit. The capacitance variability is measured using the sensing element that consists of the two plates operating in a differential mode.

The design of such mode suggests the interaction in a bridge circuit, where two fixed capacitors and the oscillator are included in the overall structure to maintain the peak voltage requirement. Additionally, the detection circuits are initiated to control the voltage parameters, further feeding the capacity information to the summing amplifier that transmits an information as a final output signal.

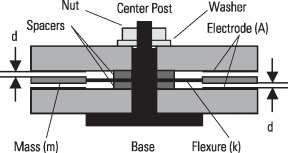

The example of capacitive accelerometer is further shown under the Figure 1. In this case, the sensor uses metal diaphragm and alumina-based capacitor plates. The two fixed plates separate the diaphragm to create two separate capacitors, which allows further movement opportunity for electric sensing. After placing the element in the gravitational field or applying vibration on the test structure, the object experiences a sprig-mass and is further calculated as the one equal to the Newton’s Second Law of motion: F=ma, where F is the inertial force, m is a distributed mass of the spring, and a is the acceleration effect applied to the sensing element.

The spring-mass is further deflected linearly by using the Spring Equation that estimate deflection by dividing the inertial force F by the spring stiffness k: X = F/k

Piezoelectric Sensors and Accelerometers

The piezoelectric accelerometers utilize the effect of certain materials to measure changes in mechanical variables such as shock or vibration dynamically rather than statically. The operational principle of such sensors is similar to the other transducers, where the one form of energy is converted to another and stimulates an electric signal based on the specific property or the object condition. Piezoelectric accelerometers function at either high or low impedance, where the former has a charge output converted into a voltage based on the amplifier or impedance converter capacity, and the latter operate based on the miniaturized charge-to-voltage converter and power supply device to provide relevant output signals to receiving devices.

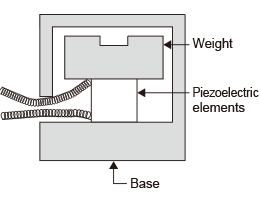

The working principle suggests that accelerometer body is attached to the piezoelectric crystal. When the body vibrates, the mass remains undisturbed because of the inertial principles. As the vibration process continues, the mass stretches to the crystal and therefore creates of force proportional to acceleration in the second Newton’s law. Further, a charge is generated and converted into a low impedance to ensure that electronical devices are capable of providing specific outputs. A sample design is further shown in Figure 2.

The formulas for estimating the effectiveness of piezoelectric accelerometers are similar to capacitive ones, while it is important considering the following adjustment constraints. First, it is important to define the upper usable frequency limits based on the device-specific resonant frequencies to avoid the amplifier limitations for the signal processing. Second, under the condition of charge and voltage sensitivity it is essential to manage acceleration characteristics that appear to be higher for the charge aspect. Finally, there is a principle of the cross-axis sensitivity, which is recommended to be less than 5% when the sensitivity to acceleration is applied in a two-dimensional scenario of along the axis of 90 degrees.

Advantages and Disavantages

Capacitive accelerometers are broadly used in many industries, being particularly advantageous for monitoring the large structures, being able to acquire measurements across a wide frequency ranges, where the static acceleration is essential. They are also anticipated for having exceptional stability, resolution, and sensitivity parameters comparing to other types of accelerometers. However, capacitive devices are susceptible to the temperature changes, humidity, and fragility standards, which makes their use somewhat limited to commercial, large-scale usage.

On the contrary, piezoelectric accelerometers and boast the high frequency response, which allows sensing the parameter changes on the high speeds of processing. Furthermore, these sensors provide more confident statistical outputs related to events detection and generating linear results. The size and rugged construction of piezoelectric accelerometers is also advantageous in terms of providing higher output measured within an electronic circuit.

Nevertheless, comparing to the capacitive accelerometers, the overall output is low and requires connection with external electronic backbone device, which is an example of parasitic capacitance. Furthermore, there is a high impedance level, which means that crystals should be connected to both the amplifier and auxiliary circuit to avoid potential measurement failures. Finally, the design shape of the crystals is highly demanding work procedure, which requires significant testing and resource investments.

Applications and Existing Products

The two different types of sensors discussed in the paper have multiple applications in a real life. For instance, the capacitive accelerometers are frequently used by zoologists to track the movement of the animals in a wild, which provides practical evidence for population distribution and environmental challenges.

Alternatively, capacitive accelerometers could be used by engineers and factory operators to monitor the vibration of the machinery on the timely basis and schedule maintenance procedures more effectively. On the contrary, since piezoelectric accelerometers are based on the principles of vibration and shock measurement, they could be used in a vehicle crash testing to determine the proportional resistance based on the external force level applied to the object.

Furthermore, these sensors perfectly fit the interactive needs of the current handheld devices, allowing to control the level of vibration and reactiveness in phones, tablets, and game controllers. However, this scope of applications is not limited and could be also traced in a healthcare industry, where human activities ad motions are mimicked through the use of artificial simulation tools.

Future Research and Development

The future research for capacitive accelerometers might be focused on the information technology area to support product engineering companies that design handheld devices. It refers to many contemporary industries, including healthcare, entertainment, and home security. Alternatively, given the increasing number of the transportation accidents, the piezoelectric accelerometers could be used in the automotive industry to ensure that vehicle crash tests represent the real picture related to the passenger safety and responsible driving behavior.

However, considering the times of pandemics, the both directions should be explored as an opportunity for remote assistance for the elderly population and educational efforts of using devices that support individual healthcare needs. Practically, it relates to the use of telemedicine tools, remote support services, and delivery of services through the use of embedded sensors in a handheld device leveraging the Internet of Things technologies.

Conclusion

The industry-wise use of accelerometers provides significant advantages for customers and users in times of technology progression. Nevertheless, it is important to explore benefits and bottlenecks to ensure that the choice of particular device or service perfectly fits the intended customer requirements. Therefore, the application aspects of using accelerometers in real life requires further modeling and investigation based on the efforts of fellow researchers and industry recommendations on the most appropriate resource utilization.

References

- S. Kavitha, R. Joseph Daniel, and K. Sumangala, “Design and analysis of MEMS Comb Drive capacitive accelerometer for SHM and seismic applications,” Measurement, vol. 93, 2016, pp. 327-339.

- W. Wu et al., “A precise spacing-control method in MEMS packaging for capacitive accelerometer applications,” J. Micromech. Microeng., vol 28, 2018, 125016.

- J. He, W. Zhou, H. Yu, X. He and P. Peng, “Structural designing of a MEMS capacitive accelerometer for low temperature coefficient and high linearity,” Sensors, vol. 18, no. 2, 2018, p. 643.

- A. Utz et al., “A high-precision and high bandwidth MEMS-based capacitive accelerometer,” IEEE Sensors Journal, vol. 18, no. 16, 2018, pp. 6533-6539.

- M.G. Guney et al., “High dynamic range CMOS-MEMS capacitive accelerometer array,” 2018 IEEE Micro Electrical Mechanical Systems, unpublished.

- H. Qu et al., “Effects of dielectc charging on the output voltage of a capacitative accelerometer,” J. Micromech. Microeng., vol. 26, no. 11, 2016, unpublished.

- Y.-H. Wang et al., “A paper-based piezoelecric acelerometer,” Micromachines, vol. 9, no.1, 2018, p. 19.

- B. Tian et al., “Design of a piezoelectric accelerometer with high sensitivity and low transverse effect,” Sensors, vol. 16, no. 10, 2016, p. 1587.

- S.K. Reguieg et al., “Modeling and enhancement of piezoelectric accelerometer relative sensitivity,” Sensi Imaging, vol. 20, no. 1, 2019, unpublished.

- R-h. Han, J-y. Wang, M-h. XU and H. Guo, “Design of a tri-axial micr piezoelectric accelerometer,” 2016 Symposium of Piezoelectricity, Acoustic Waves, and Device Applications, 2016, pp. 66-70.

- Z. Shen, C.Y. Tan, K. Yao, L. Zhang and Y.F. Chen, “A minituarized wireless accelerometer with micromachined piezoelectric sensing element,” Sensors and Actuators A: Physical, vol. 241, 2016, pp. 113-119.