- Executive Summary

- The role of procurement and supply in managing catering service expenditures

- Techniques that ADCO can apply to cater expenditures to improve the added value

- Inclusions for managing future Contracts

- Measures of Selecting Effective Suppliers

- Aspects of Procurement that require Negotiation

- Recommendations

- Conclusion

- Works Cited

Executive Summary

The procurement and supply chain plays a significant role in an organization’s overall performance. This paper represents a sourcing plan, which focuses on five sections to improve the organization’s expenditure management in the provision of catering services. Lack of appropriate strategic procurement approaches has resulted in declining profitability, decreasing competitiveness, bad image, low service delivery, and overall poor organizational performance.

The first section sheds light on the role of procurement and supply in managing catering expenditures. Section two presents novel techniques that can leverage ADCOs efforts in managing expenses in the sourcing plan for providing supplies. Notable techniques include e-procurement, change management, value analysis, and the use of Krajlic matrix. Section three focuses on the leading performance indicators (KPIs) and the RACI matrix as prominent inclusions that ADCO should make to maintain future contractual relationships.

The fifth part dwells on effective supplier selection methodologies, including financial viability, economic strengths, technical capabilities, and stakeholder accountability. The last requirement digs into purchasing aspects such as tendering, contract reviews, renewal, which require the adoption of the five rights of negotiations, and recommendations for the company.

The role of procurement and supply in managing catering service expenditures

Procurement and supply management entails multifaceted activities and aspects of essential sourcing materials, which form the foundation for organizations’ operations. Adopting a responsible supply plan underpins many aspects of success, including quality, performance, reputation, and profitability (Panchal 438). Procurement is a significant embalmer of business in a plethora of ways. Proper execution of the acquisition and supply chain management function can create measurable value and set the pace for change (Brewer and Bryan 190).

Notably, a responsible sourcing plan leads to an appropriate supplier selection process. The procurement function of ADCO is responsible for mitigating risks, driving value for money, improving service delivery, enhancing visibility in cost management, and ensuring relevance and sustainable business for the company. Panchal notes that the catering industry has grown in recent decades, brings novel approaches for managing contractual agreements (441.

We are adopting strategic sourcing strategies in purchasing help to establish a sustainable and transparent supply chain. A streamlined supply chain ensures the sourcing of essential materials occurs promptly (Brewer and Bryan 191).

A robust sourcing process provides a full collaboration between internal and external stakeholders, which relies on participation throughout the product cycle. Procurement aids the catering expenditure through cost-effectiveness (Brewer and Bryan 186). For instance, the processes, procedures, and methods focus on enhancing the attainment of best value outcomes concerning quality, timeliness, costs, and the allocation of resources.

Catering services entail complex and costly activities, which face criticalities such as environment and uncertainty (Ogut 133). The industry involves temporary organizations executing work in temporary sites and many partakers, including owners, designers, manufacturers, and workers (Brewer and Bryan 187). The existence of temporary relationships between the stakeholders can lead to unwelcome shortcomings if the initial procurement phase is flawed. Ass such standard purchasing ensures transparency and information sharing to improve risk management. Notable risks include supplier bankruptcy, natural disasters, political changes, and technological shifts, which could present disruptions to the projects (Ogut 134).

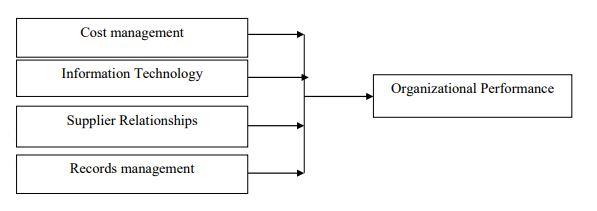

Strategic procurement can help ADCO to integrate different aspects, including cost management, information systems, supplier relationships, and records management, which are the prerequisites to organizational performance. In fact, a growing body of empirical evidence suggests that large companies such as ADCO utilize reverse e-sourcing approaches to cut costs, creating time, streamlining the bidding procedures, and welcoming cross-border vendors (Slaughter and Mukhopadhyay 159).

It is worth noting that companies, which lack appropriate procurement management, are likely to face the challenges of risks stemming from poor supplier relationships (Brewer and Bryan 192). Figure 1.0 shows a conceptual framework of supply, which drives organizational performance.

The procurement and supply management is applicable in assessing service provision. ADCO can lean on purchasing methods to leverage other functions of the organization, including customer relations, branding, and competitiveness. ADCO requires proactive procurement management to source the right materials from viable vendors at the appropriate time. Catering services call for the company’s close attention to quality and cost.

It is important for ADCO to employ an appropriate selection methodology that adds value to the factors mentioned above. A significant role in purchasing entails essential outsourcing materials, which help in administering, sustaining, and managing ADCO’s primary and support activities such as production, transport, and warehousing. The organization relies on procurement and supply and integrates various functions to convert supplies into finished products (Mogerman, Daylath, and Kasun 461). Successful integration of acquisition with different organizational functions determines the level of customer satisfaction and retention, competitiveness, performance, and growth (Rajeh, John, and James 924).

ADCO operates in a fragile industry that depends on multiple macro-environmental factors such as market volatility, political changes, regional conditions, and socio-cultural transformations. As such, it is critical for ADCO to integrate its procurement and supply chain with information market research to gain insight into changes that shape consumption behaviors, technological shifts, and other trends for relevancy.

Purchasing forms a significant part of the procurement process (Rajeh et al. 926). ADCO needs to enhance expenditures on catering materials by adopting various techniques to add value to the acquisition process. In fact, Mogerman et al. regard purchasing as the interface that bridges customers and suppliers through planning, storage, distribution, and obtaining products and services (461). In fact, Jia, Guido, Marco, and Guido argue that purchasing should be part of an integrated organizational structure because it determines the sourcing for essential materials for the delivery of finished goods to end-users (841). ADCO can enhance its procurement functions through integration, which is a leading source of global competitive advantage.

Procurement and supply are critical to effective negotiation with suppliers and stakeholders in the development services, especially in the sourcing process. Negotiation entails taking steps to overcome conflict and hurdles in the supply chain (Hesping and Holger 107). Also, procurement and supply help to evaluate the range of appropriate approaches that are useful commercial negotiations (Jia et al. 843).

A catering supply chain can achieve an added value through supply chain management through reducing costs and prices, enhancing innovativeness, promoting sustainable procurement, and improving delivery timescales to desired markets (Rajeh et al. 924). The functions of procurement and supply in managing catering expenditures include evaluating the financial and commercial potentials of suppliers and assessing vendors’ quotations or tenders to drive added value in tendering of catering equipment and materials.

Also, procurement managers provide consultation concerning the adoption of E-procurement systems, interpreting and advising on stipulations and guidelines that influence the selection of suppliers of building materials. They are responsible for developing effective sourcing plans of materials and establishing proper documentation for efficient tender processes (Hesping and Holger 108).

Techniques that ADCO can apply to cater expenditures to improve the added value

A sourcing plan (tendering/procurement process) begins with drawing up various inventory requirements of both the internal and external users. ADCO should adopt different acquisition techniques to ensure every process of the procurement process adds value. It is important for the company to incorporate sustainability considering many aspects of catering equipment. Notably, ADCO should enhance visibility on efficiency, cost, total cost ownership (TCO), production savings through either existing retaining materials, or refurbishing the catering equipment altogether. The company should make a critical assessment of the actual capacity of the required catering materials (Rajeh et al., 926).

Catering, which is the identified area of expenditure, should entail proper management of resources costs to achieve a similar value addition to ADCO’s business. Added value is the difference between the selling price and the direct or indirect inputs used to create the item for consumption. In this regard, ADCO should take key measures to evaluate its purchasing strategies. Traditionally, the aspect of value addition in the area of expenditure entailed acquiring the right materials at the correct quantity and price and transporting the items to the desired place at the right time.

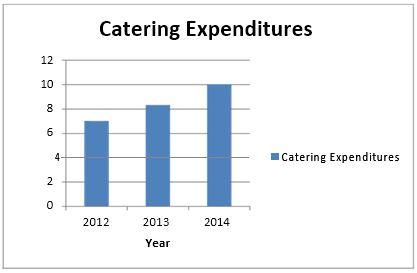

In determining whether the area of expenditure can add value, ADCO evaluates some aspects. The factors include government regulations and controls, financial planning with suppliers, and economic trends (Mogerman et al. 461). Other facets include competitive intelligence, product or service line additions, and product liability exposure. Figure 1.1 shows an illustration of how to the determination of catering expenditures for ADCO.

The costs for the catering services for ADCO have skyrocketed in the past three years. There has been a significant increment increase from 7 million U.S. dollars in the year 2012 to more than 10 million U.S. dollars in the year 2014. These figures are expected to continue to increase in future years if the company fails to change the procurement strategies. It is worth noting that ADCO provides catering services to over 200 employees per site, depending on the size of the field. The chain includes the actual service providers, providers of food items, equipment, workforce resources, labor camps, transportation services, and health safety environment.

Adopting E-Procurement Strategy

ADCO can tap various unique benefits of integrating ICT uptake, such as e-procurement in the entire sourcing plan for catering equipment. In fact, researchers posit that the adoption of technology in the procurement process is a source of competitive advantage. Notable benefits including reduced acquisition costs, increased profitability, supply chain efficiency, organization’s image, cycle times, as well as improved marketing services (Ojha and Pandey 111).

The catering industry continues to witness an intensifying competition as rivals adopt e-procurement. Research shows that the adoption of e-procurement in the catering industry lags behind relative to other manufacturing and retail industries (Rajeh et al. 928). ADCO can create value by focusing on investment in its workforce, processes, and technology, which are the primary components of e-procurement. The implementation of e-procurement is expensive. Besides, it requires a substantial transformation in the internal processes of an organization. Besides, the catering firm stands to benefit from both tangible and intangible benefits, which can motivate the professionals to adapt to new technologies.

An existing body of evidence-based research provides an anecdotal evidence supporting the creation of value through e-procurement (Hesping and Holger 108). For instance, it makes supplier negotiations efficient and effective besides leveraging improved firm performance. ADCO can reap benefits such as reduced employee time, minimizing purchasing cycle time, market expansion, and product innovation enhanced service quality, and cut overall procurement cost (Ojha and Pandey 112). Also, e-procurement can increase negotiation effectiveness through increased responsiveness, quality customer services, and user contention.

In the evaluation of the value of e-procurement to catering organizations, researchers found that a positive correlation between the perceived value of the technology and communication networks, and work processes. In the same vein, the adoption of the technique in procurement reduces paperwork and save time by engaging other suppliers in negotiations. The company can use Internet-based technologies to facilitate communication with its suppliers.

E-procurement accelerates the exchange of data between multiple vendors and the company (Ojha and Pandey 111). Additionally, various articles support the improvement of contract administration and greater organizations’ flexibility. The strategy can help ADCO to reduce inaccuracies besides leading to the efficient execution of procurement roles and responsibilities.

Change management to leverage procurement functions

Research suggests that deploying critical transformative initiatives, which entails a rigorous review and diagnostic measures of the expenditures, can help firms such as ADCO to create an unprecedented value in the purchase and supply of catering equipment. Enhancing procurement transformation requires a robust and continuous sponsorship. The owner ought to communicate and reinforce a clear and compelling goal of the organization’s projects (Hesping and Holger 114).

Also, the negotiation for the appropriate supply of catering materials requires a recalibration of incentives for project managers, who ought to have a high level of control and latitude in supplier selection. The owner should motivate the procurement managers and contractors to embrace change in the consolidated procurement process, which necessitates for motivational models to increase involvement (Jia et al. 848).

Researchers observe that internal transformative initiatives consider a clear delineation of roles, responsibilities, and accountabilities that should be clear to all the stakeholders (Jia et al. 847). It is important to refine the procurement operating model by considering four critical operating pillars that include strategy, workforce, processes, and tools. The four aspects should work in harmony to streamline the sourcing plan. Also, a constant reinforcement should consider change management in the entire organization (Hesping and Holger 110).

The mentioned requirement is possible through proper communication, integrating stakeholders’ feedback to pilot a sustainable momentum for change. The company can improve procurement and supply of catering equipment by defining service level improvement goals (Jia et al. 848). The change agents ought to set expectations between obtaining and the company’s mission and vision. Operations in the business should reflect in critical performance indication metrics that assess cost and supplier effectiveness. ADCO needs to apply sourcing know-how and prowess in procurement to handle the multifaceted catering services.

A growing body of literature shows that many organizations lack the appropriate skills, processes, and infrastructural ability to manage the procurement function effectively (Rajeh et al. 926). As a consequence, profitability reduces in opportunities that are crucial for the growth of the company. For instance, ADCO lacks the essential technical capabilities to manage all the procurement spending categories. Using information integrated systems such as enterprise resource planning (ERP) can help to streamline the supply chain and remove redundant roles and operations (Hesping and Holger 110).

This section provides a good set of contractual and pricing arrangements that can drive the efficient implementation of proactive acquisition strategies, which adhere to a baseline spend analysis through the creation of the firm’s supporting framework, systems, processes, guidelines, and performance evaluation models (Hesping and Holger 112). The primary focus of procurement entails managing the sourcing plan to ensure service delivery, monitoring service providers, and the administration of contractual relationships (Jia et al. 848). ADCO is on the verge of realizing tremendous achievements through its plan to adopt Internet-based technologies to revolutionize its supply chain (Rajeh et al. 927).

Using Kraljic Matrix

The Kraljic matrix technique is applicable multiple industries because of its efficiency in leveraging differentiated procurement strategies. Research shows a limited application of the approach in the catering industry. This portion shows how ADCO can deploy the Kraljic Matrix to achieve added value in the sourcing of catering materials. Procurement projects to great catering firms such as ADCO are often vast and complex because of their uniqueness, risks, and the fact that they involve a broad range of parties and activities. Large companies such as ADCO witness various problems, which result in project delays, disputes, complaints, and counter claims. As a consequence, the company records poor performance and low-profit margins.

The Kraljic portfolio technique created a multidimensional matrix that considers the strategic effect and supply peril vectors. The strategic sourcing approach groups can help organizations to group products and services by similarity grounded on the vendor characteristics (Padhi, Stephan, and Vijay 4).

Categorizing helps the procurement manager to purchase products from a single supplier in the same order (Brewer and Bryan 188). Moreover, according to Hesping and Holger, the matrix allows the company to rate goods depending on the various crucial factors including the number of available vendors, product scarcity, and the total spending on the catering equipment (114). The company can assess the strategic significance of catering materials by the cost, value-added profile, and the profitability profile.

Padhi et al. add that the portfolio approach gives the company an opportunity to evaluate market complexity or supply risks through several factors such as some vendors providing the catering materials, market structure, and the technological capabilities of the suppliers (4). Also, application of the Kraljic matrix allows the company to gain an adequate understanding of the competitive supply market about entry barriers, product availability, and scarcity.

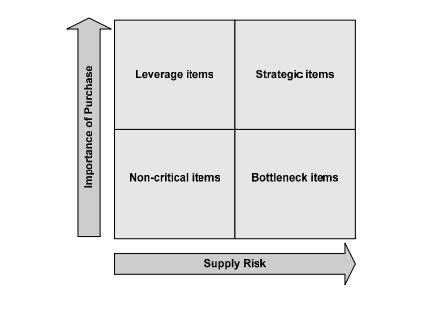

It is critical to note that ADCO suffers massive losses because of delayed supply of equipment and other essential materials. As such, adoption of the portfolio approach can elude future losses and avert adverse consequences of a non-informed procurement process (Hesping and Holger 114). Selection of the right purchasing strategy prevents disruptions and enhances effectiveness and profitability. The Kraljix matrix presents four categories including leverage, bottleneck, strategic, and non-critical. Figure 1.3 shows a representation of the Kraljix matrix for ADCO.

Leverage things are the best-placed units, which hold a substantial business share representing high strategic impact (Padhi et al. 6). It shows a minimized or non-existent risk. Further, the supply process has reached maturity because of a viable establishment. On the other hand, strategic category focuses on the future approach. The group of commodities has a high-impact on the company’s business and attracts a high level of risk (Padhi et al. 6).

In the strategic category, a great necessity of long-term connections with vendors, perpetual plans, and strategic measures is inevitable. According to Padhi et al., the catering company ought to employ a successful management approach to deal with the category of materials, which can imply the difference between relevance and demise of the firm (4).

On the other side, bottleneck items feature elements that catering equipment procurement companies give less attention because of their minimal business impact. However, the bottleneck items have a high supply risk (Brewer and Bryan 190). Sources of the large supply perils emanate from the high likelihood of disruptions, delays, and unavailability among others. The non-critical items have very minimized effects on business as well as a low supply risk (Padhi et al. 8).

The category represents the least significant issues for the firm. However, the key drivers for the small danger in this group include high-performance and low-cost. The Kraljix matrix gives procurement managers an opportunity to choose the most appropriate purchasing strategies, which match the best outcomes depending on the product and market characteristics. The adopted procurement strategy relies on the degree of supply risk while making the best of bargaining and buying the power of the catering firm (Padhi et al. 8).

Benchmarking the company’s bargaining power against the supply market can help a procurement manager to learn essential purchasing approaches such as including exploitation, balance, and diversification. For instance, the directors of ADCO can use the bargaining power to utilize the leverage category through such strategies as target pricing, tendering, and product substitution. The company can put high risky products on the bottleneck group making sufficient the volume insurance, inventories safety, supplier control. (Padhi et al. 8).

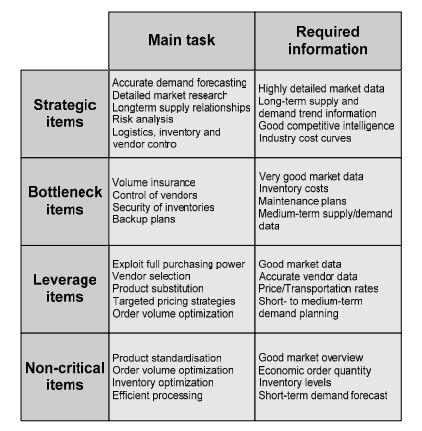

The use of diversification mechanisms can help to enhance the backup plans. The negotiation process of the company and provider depends on the bargaining equilibrium set by the strategic and noncritical items (Ogut 144). The non-critical items necessitate for active processing, optimization of the company’s inventory, standardization of products, and order volumes. Vital articles call for premeditated conglomerates. Figure 1.4 shows standard strategic recommendations on the Kraljic Matrix.

Each quadrant shows a distinct purchasing approach, which relies on critical information to develop a suitable supply strategy for the organization (Hesping and Holger 114). It is worth noting that securing the continuity of supply for bottleneck items at a considerable cost requires the company to reduce dependency on a single supply path and seek substitutes (Padhi et al. 8). Also, the purchasing strategy should consider the principles of competitive bidding for leverage items, which regards vendors as interchangeable.

The company’s priority should entail upholding quality and continuity of supplies (Ojha and Pandey 112). The systems contracting for non-critical equipment and materials should focus on cost reduction, enhancing the simplicity of administration and logistics (Padhi et al. 8). ADCO can attain this goal through product standardization, reducing the number of suppliers, managing vendor inventory for long items, adopting electronic items for catalogs, and e-procurement.

Value Chain Analysis

Value analysis is a viable technique for improving added value. The analysis can help the catering firm to determine the importance of the purchased items. The assessment team should evaluate several factors (Padhi et al. 8). For instance, the required supplies should are essential. Also, the materials should serve the original purposes. If the item is more or less than what is necessary, the company can outsource modified products or negotiate with substitutes.

The primary aim of doing product modification is to improve value. Also, developing supplier relationships is an important framework that can apply to the area of expenditure to improve added value (Ogut 147). Vendor relationships entail the use of multiple tiers of suppliers. Additionally, it encompasses efforts towards reducing the number of purveyors and identifying those that offer the best services at the right price (Brewer and Bryan 186). It is important for companies to maintain more interdependence and stable relationships with suppliers.

Strategic Sourcing and Customer Service

Moreover, strategic sourcing can be useful for ADCO in determining the most critical purchases for its catering operations. Strategic sourcing is a viable approach for dealing with expensive necessary products/services, especially when in large quantities (Gunasekaran et al. 6812). Furthermore, the method can enable the firm to identify the items that are vital to a smooth delivery of catering services, which lead to greater customer satisfaction and optimum organizational performance (Ogut 138).

ADCO stands a prime opportunity to determine the qualified suppliers to the essentials service, which ensures that the registration of providers corresponds to the correct product/service group. Moreover, enhancing the company’s customer service can improve added value by enabling the firm to identify its internal and external clients across all its markets (Ogut 147). The technique is critical in improving cycle times, quality levels, and service delivery. Besides, the method can boost the company’s savings initiatives.

ADCO should regard its suppliers as important by establishing a provider help desk to accommodate vendors’ concerns. Also, responsibilities (Hesping and Holger suggest that customer service plays a critical role in leveraging organization’s competitiveness (109). Also, integrating the internal teams such as stakeholders in negotiation with suppliers can add unique value to the company’s supply chain (Ogut 148).

Inclusions for managing future Contracts

The procurement manager should involve various stakeholders in the definition of contracts, which include critical aspects of role and responsibilities (Hesping and Holger 110). The description should be clear and concise for easy understanding among all stakeholders defined. The documentation of contracts should show the terms and conditions of the concession of all the partakers (Jia et al. 848). The omission of the critical portion such as costs, time frames, or place can render the contract invalid. In fact, Jia et al. claim that an omission of data is a violation the guidelines that govern agreements (848). ADCO should adopt risk management approaches to enhance the effectiveness of managing future contracts to add value and reduce costs of sourcing catering equipment and materials.

The primary objective of procurement organizations entails having a sustainable process that ensures production leads to a continuous improvement in performance (Panchal 438). ADCO should adopt several strategies to manage future contractual activities in the attempt to attain success. This section focuses on Key Performance Indicators (KPIs), Strategic Supplier and Material Segmentation (Portfolio Analysis), and contract management, which can help ADCO to manage future contractual deals.

Key Performance Indicators (KPIs)

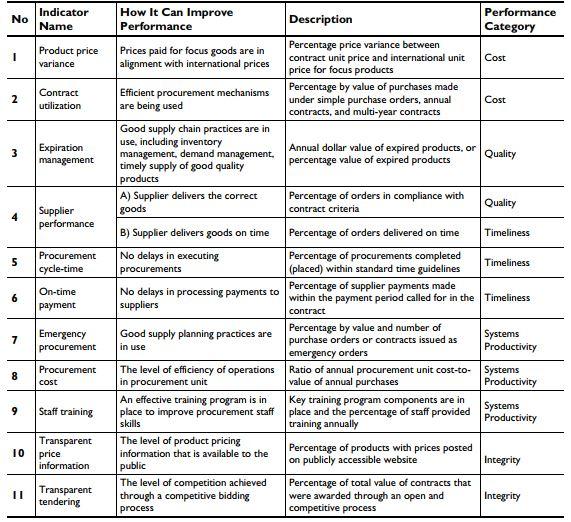

Key performance indicators have gained increased attention of researchers as a crucial tool for measuring progress in the attempts of attaining an organization’s objectives. They are quantifiable measurements set by a firm’s internal and external stakeholders such as procurement managers, suppliers, and customers to assess progress towards various aims of agreement (Slaughter and Mukhopadhyay 1058).

Most standardized activities of ADCO such as procurement and supply are measurable and can be a source of competitive advantage. It is important for ADCO to establish KPIs to provide a direct, which leads to improvements in performance by identifying breakdowns in its supply chain. It is important for a firm to seek what its stakeholders need versus the company’s strategies and future objectives (Jia et al. 850).

The primary stakeholders in procurement include the purchasing department, customers, and suppliers. ADCO needs to know what the stakeholders want, and they anticipate from the company. Once ADCO establishes a mutual understanding of its needs with interested parties, the company should introduce some metrics that demonstrate the progress towards satisfying them. Employee involvement in procurement KPIs is essential to provide a clear understanding of what the stakeholders expect from the company. It is worth noting that suppliers should show consent though signing the KPIs to maintain accountability (Jia et al. 853).

Evaluation of future procurement deals requires the company to introduce a balanced scorecard KPI to measure performance aspects. Notable performance metrics include cost reduction managed to spend and total spend, cost savings, procurement operating cost, return on investment (ROI), seller defect percentage, customer satisfaction, the lead time for procurement, and productivity in purchasing (Ogut 144). Figure 1.4 shows a procurement performance evaluation framework for the future supply chain.

ADCO’s KPIs should have critical characteristics, which are the foundation for improvement. SMART (specific, measurable, achievable, relevant, and time) KPIs should be particular providing clear and concise guidelines to avoid ambiguity among its stakeholders. Also, the firm should set quantifiable KPIs to ensure easy measurement by all interested parties to calculate aspects of progress (Hesping and Holger 110).

KPIs should be feasible and reasonable to accommodate available resources. Meaningful KPIs are relevant to provide information and useful criteria for measuring organization’s performance (Jia et al. 854). KPIs should show a time frame for achievement and evaluation. Figure 1.5 shows procurement performance indicators.

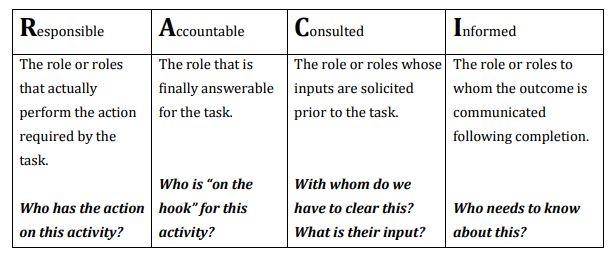

RACI Matrix

The RACI Matrix is a practical framework that helps to assign roles and responsibilities, especially in procurement and contract management. The matrix provides an elaborate description of different stakeholders’ roles in completing particular tasks or deliverables for a contract (Slaughter and Mukhopadhyay 1058). The acronyms stand for Responsible, Accountable, Consulted, and Informed (RACI). The descriptions of the RACI appear in figure 1.5 below.

The RACI matrix describes roles and responsibilities of parties in a contractual agreement. ADCO can increase the value of its supply chain by using the RACI matrix to manage future contracts. The pattern is helpful in coordinating and streamlining the efforts of all the partakers of a procurement contract. It promotes a climate of accountability (Jia et al. 855). It is critical for ADCO to utilize the RACI matrix as a strategic tool for integrating its supply chain.

The most important aspects of the RACI matrix that ADCO’s procurement manager should understand to add value or contract management. First, the manager should designate only a single role as accountable for a unit activity. The purchasing manager should learn that contractual functions can be multiple. Hence, the officer of acquisition should regard each activity as responsible, consulted, or informed. The firm should reduce the number of consulted parties to the possible minimum (Hesping and Holger 115). All roles in the contractual arrangement with the description, ‘accountable,’ should possess the necessary corresponding authority.

Contract administration is a crucial component of the procurement function of the organization. Notably, post-award contract management entails significant activities, which determine the achievement of anticipated acquisition goals (Panchal 438). Appropriate resourcing of post-award contract management is the role of different parties including the organization, the supplier, administrative department, and the operation administration. ADCO should pay a close focus on contract maintenance and change management.

In fact, the manner in which ADCO can manage contract changes that occur in the lifecycle of a contract underpins the achievement of strategic procurement goals such as improved service delivery, enhanced quality, profitability, and performance. The RACI matrix helps to design change strategy eliminating any ambiguity and misunderstanding among stakeholders of their respective roles and responsibilities (Hesping and Holger 114). ADCO’s procurement manager should initiate change control at the earliest stages of the post-contract award. The change control should entail all procedures of the contract documentation with consistent updates, which agree with the involved stakeholders (Hesping and Holger 115).

The flexibility of the systems is essential to allow for possible amendments to the contract, evaluation the impact such as contractual implications, prioritization, and authorization levels, approaches to negotiation and agreement, implementation controls, and managing documentation changes.

Measures of Selecting Effective Suppliers

The election Catering suppliers take place in three stages in ADCO. The first stage is the pre-qualification process, which determines the viable vendors to supply the catering materials. Second, a financial assessment of the pre-qualified supplier is essential (Jia et al. 859). Technical evaluations are necessary to determine the capability of vendors to apply tech-savvy approaches in manufacturing and delivering relevant catering equipment (Slaughter and Mukhopadhyay 1058).

Last, the pre-qualified suppliers should submit their commercial bids, which the procurement managers should screen before further shortlisted following particular performance benchmarks. The fundamental purpose for pre-qualification vetting entails determining suppliers’ capability to meet the procurement goals and the overall firm’s strategic value for money (Slaughter and Mukhopadhyay 1060). The preferred vendor should supply the right equipment and materials needed for running ADCO’s catering services. In this regard, ADCO should exercise caution, patience, discipline, and prove its know-how in the selection process including screening criteria and awarding contracts (Brewer and Bryan 188).

Researchers maintain that despite the challenges that occur in the selection process, working with the right suppliers pays off over time (Slaughter and Mukhopadhyay 1059). The benefits are achievable through consistency and timely provision of high-quality supplies needed in the catering business. Having the feedback from End User will help ADCO management to choose the right performance supplier to do the catering services.

The selection of vendors for ADCO should follow three stages, which include prequalification, technical evaluation, and commercial assessment. The prequalification criteria that the company adopts comprise three aspects including financial stability, commercial capabilities, and technology capabilities, stakeholder accountability. Many companies suffer dire outcomes of supplier non-performance (Mogerman et al. 461). It is important for ADCO to take proactive steps to verify the worth of potential suppliers. The prequalification process prevents cases of non-performance, non-delivery, and nonconformity (Panchal 438).

The secondary objective of the prequalification process is to ensure the supplier assumes responsibility and becomes an active partaker in the contractual relationship. ADCO can adopt a well-designed and administration system to reduce costs stemming from providers and the procurement agency. Lessening the number of contracts that the prequalification system hurdles help to justify the cost of establishing and maintaining it (Hesping and Holger 116).

Financial Stability Evaluation

The organization of acquisition should seek financial information to determine the stability of the vendors and turn down the vendors, who fail do not meet the set criteria. The economic viability analysis helps to assess the ability to remain reliable through the life of the contract time frame (Slaughter and Mukhopadhyay 1059). The company should check whether the competing vendors have the capacity to manage the contract from commencement through to its completion and deliver satisfaction including unplanned amendment needs. Financial stability involves the management and allocation fiscal resources with the aim of developing consistent profitability and capital growth of an organization (Hesping and Holger 116).

The primary indicators of financial viability include surplus income over expenditures, efficient use of money, and the continuous process of service delivery (Slaughter and Mukhopadhyay 1059). Additional financial stability indicators include ratio to cash volumes, structure and conditions of the property, and capital investments (Hesping and Holger 117). The managers of the suitable supplier should demonstrate competence and professionalism by the way they pursue flexibility of economic and monetary policies in response to changes in both internal and external environments. The higher the supplier’s CAR ratios, the stronger the financial stability and the preparedness to absorb procurement risks (Brewer and Bryan 189).

Economic Assessment

ADCO should employ individual approaches to determine whether the supplier to meet operational costs, and ability to satisfy surge capacity. The vendor must showcase professionalism and room to readjust to meet emergent needs of the catering company on short notice (Ojha and Pandey 102). For instance, the supplier’s position to increase delivery quantities in times of urgency is a competitive advantage over the competitors (Panchal 438).

Notably, long-term contracts witness shifting demands despite the high chance of market uncertainty because of unforeseen changes (Hesping and Holger 117). Also, demand for catering materials from overseas can suffer multifaceted factors such as regional politics, global economic conditions, and natural disasters. As such, the supplier must forecast and prepare to satisfy the supply needs in the case of eventualities (Rajeh et al. 925). Additionally, the creditworthiness of vendors is a central focus of many buyers. If the financial resources fall short, the company should be in a position to guarantee continued supply of catering equipment from its credit resources (Hesping and Holger 112).

Technical Capability

The procurement company should choose the supplier, which demonstrate the ability to deploy technology such as e-procurement services, which translate into improved service delivery. Moreover, the provider should show indications of quality (Hesping and Holger 113). For instance, ADCO can require the vendors to ISO 2010 certification, to demonstrate preparedness through sound policies, procedures, appropriate documentation, and continuous training to maintain top-notch services (Hesping and Holger 117). Also, the company’s procurement managers should be to identify areas of fraud such as forgery of certification documents (Mogerman et al. 461).

A check on previous deliveries to several companies, through trade history, can provide crucial information regarding competency. The fixed tangible asset values can provide vital information about advancement or deterioration of a company’s technical capabilities. Technological progress in many areas such as communication, hiring, and procurement is a viable indication of the supplier’s effectiveness in the coordination of the firm’s core business activities (Rajeh et al. 925). In the changing business environment, an integration of information technology is an added advantage for providers to win bids over rivals. Also, technological capabilities are the prerequisites to excellent service delivery, reputation, financial profitability, and cost-efficiency.

Stakeholder Responsibility

The award of contract should consider the level of liability of the suppliers. A successful contractual relationship is underpinned by how the different parties within the provider organization can coordinate the numerous aspects. The relationship management skills of contractors determine the delivery of successful projects. The instrumental stakeholder holds that connections between the partakers of a contract depend on the nature and quality of their relations.

ADCO should select the supplier that showcases the highest level of stakeholder accountability and involvement (Brewer and Bryan 190). Indicators of stakeholder accountability include successful delivery of materials to its customers and letters of recommendation from loyal customers.

Also, suppliers that show a decline in tangible assets such as brand image, customer, and employee relationships could signal poor stakeholder responsibility (Jia et al. 860). Furthermore, Peter and The poor performance of vendors is evident in deteriorating leadership, which is adequate disqualification of such suppliers (Mogerman et al. 461).

Organizations, which demonstrate sufficient level of tangible assets, can attribute it to high financial stability, performance management, proper staffing and employee relationships, customer service value, knowledge management, and customer service. The catering company should dig into leadership qualities of potential vendors that can source of competitive advantage. It is critical to note that poor performance is attributable to the overall management of the procurement organizations (Brewer and Bryan 190).

Aspects of Procurement that require Negotiation

The tendering of catering equipment necessitates for negotiation with potential suppliers. It is important to engage the internal stakeholders in consultation processes to develop a win-win strategy of attaining mutual benefits (Panchal 438). The involvement of providers and end-users will ensure the delivery of the conventional quality materials, enhance performance, and cut procurement costs. Ojha and Pandey and that the buyer can adopt various approaches to convince customers (107).

For instance, in the supply-chain, critical data can be useful in enhancing the scope of work. Research suggests that most procurement managers possess excellent negotiation skills in their attempt to apply rationale and the logic of helping end-users to receive the best service (Ojha and Pandey 104). The best practices in contract development, which lead to successful negotiation involve the primary stakeholders. Notable aspects of negotiation include, before signing the contract, following the selection of a supplier, during contract amendments, and in the case of emerging issues during the contract’s lifecycle (Ojha and Pandey 104).

Tendering Negotiations

The early stages of a contract negotiation strategies such as bidding play a leading role in the entire acquisition process (Jia et al. 844). The supply managers should ensure the terms and conditions include the anticipated level of services, pricing schedule, the company’s motivations, contractors’ timeline of work, the means of performance evaluation, information exchange routes, and guidelines for change control (Hesping and Holger 114).

It is worth noting selection, and rewarding of tenders is easy when the procurement documents provide a clear scope of work. Approaches to successful contracts management should take into account a proper invitation to tender procedures and processes, and ensure the right contract (Ojha and Pandey 104). Additionally, inclusions to standard contracts service delivery and contract administration, contractual agreements, sporadic events and safeguards, continuous improvement, and competency (Hesping and Holger 114).

It is important for the company to ensure that its procurement process leads to the anticipated outcomes through a constant negotiation regarding sourcing of materials and details of supply. Also, ADCO should build a direct and contractual relationship with the actual service providers such as suppliers. A contractual relationship between the company, procurement department (agency), and vendors should lead to timely delivery of materials, quality control, and the supervising of quantity purchases (Ojha and Pandey 103). A legal relationship with contractors gives the parties a suitable framework to sue the supplier directly in case of delays, poor services or other emerging issues concerning the contractual agreement.

The three parties should ensure the procurement addresses various sporadic concerns to safeguard the primary mutual interest of the company. The most significant intermittent issues include but not limited to insurance claims, amendments, call-in performance period, liquidation of damages, and work extension for completion, back charges, termination, and suspension (Slaughter and Mukhopadhyay 1059).

Moreover, the company should seek continuous improvement in quality and cost as an integral part of the contract (Ojha and Pandey 104). The company can attain continuous improvement goals through the use of new technologies, changing the interface between the company and contractors, elimination of undesired parts of the agreement, positive additions, alternative methods of service delivery, and carrying out independent surveys to boost satisfaction (Panchal 438). It is important for the company to improve competency by ensuring the partakers of the contract management possess adequate skills and have a wealth of experience in selecting and managing suppliers (Mogerman et al. 461).

Five Rights of Negotiation

Supplier selection is a competitive process. As such, negotiation with potential suppliers follows the successful evaluation of offers and the identification of the preferred offeror. It is worth noting that consultation in procurement is unnecessary unless the anticipated gains exceed the costs (Ogut 147). In some instances, the discussion is essential regarding the clarification of offers before reaching a final decision of the preferred supplier.

It allows a firm to make informed choices concerning those who seek clarification (Rajeh et al. 936). For instance, negotiation is necessary when the procurement managers seek better terms and conditions on matters such as technical support, financial aspects, risk management, information handling, time frames, and performance incentives (Mogerman et al. 461).

Negotiation in the development of a contract is critical as stakeholders concede on deliverables, deadlines, performance indicators, damages, costs, amendments, and clarifications (Hesping and Holger 113). Also, during the renewal of a contract presents an opportunity for negotiation with suppliers. Things that ADCO should give a substantial consideration include performance assessment to the current date, evaluation of success or failure of the contract, conflict resolution.

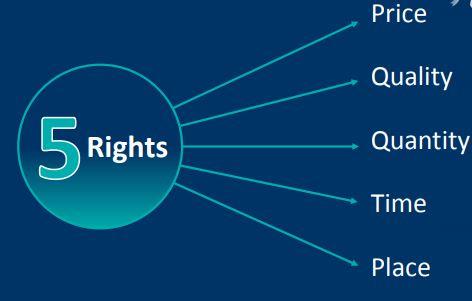

This point of negotiation provides a prime chance for a company to evaluate satisfaction, deliverables, services, responsibilities, and price adjustments. Moreover, contract review involves negotiation with the principal stakeholders concerning an ongoing tender process (Rajeh et al. 940). It is important for ADCO to hold negotiations with the preferred offeror to review the contract on a regular basis. Negotiations at this point can involve budget reviews, vendor performance, program essentials, and other procurement components that influence the contract’s terms and conditions (Hesping and Holger 114). The process should adhere to the five rights of negotiation, which include price, quality, quantity, time, and place as figure 1.5 illustrates below.

Recommendations

In the wake of increasing competition in the business environment, organizational functions such as procurement have gained increased significance as a necessary enabler of business strategy and a preferred way of cutting costs (Hesping and Holger 114). Technological advancement has transformed procurement, which has become a source of success or irrelevancy for many organization. ADCO has been reliant on traditional sourcing plans, which limit the team’s opportunities for exponential growth and managing its expenditures on catering services (Brewer and Bryan 191). This section presents the main recommendations, which can help the company to improve efficiency, increase profitability, and improving the overall procurement outcomes.

ADCO has lost prime opportunities of enhancing value because of lacking a comprehensive contract and supplier relationship management framework. Notably, the company has been stuck in a transactional relationship with its vendors. It requires a balanced approach to managing contracts, which puts a considerable focus on time rather than value for money. Also, ADCO has failed to engage its suppliers in fruitful negotiations that are essential for driving value and performance.

A valid contract and vendor management strategy is a vital enabler of ongoing sustainable value creation (Rajeh et al. 940). The proposed framework relies on segmentation, which entails strategic, operational, and technical performance management frameworks (Hesping and Holger 115). The organization should provide a concise articulation of stakeholder roles and responsibilities. ADCO can create unmatched value from integrating key suppliers into long-term procurement processes. An integrated information system is a viable instrument of driving value through enhancement of communication functions.

Another recommendation entails initiatives that can help ADCO to enhance savings across the value chain. Researchers point out the leading driver of spend leakage in the procurement and supply chain, which is the mismatch between wants and needs of an organization (Ojha and Pandey 104). In fact, researchers argue that supply cost reduction initiatives, which depend on price reduction often get it all wrong. Instead, the purchasing managers should look across the entire value chain which opens greater opportunities. Rajeh et al. give some viable examples of savings initiatives, which include matching wants and needs, employing alternative contract models to deliver the best value for money, balancing demand and supply, and managing the cost of doing business (940).

Also, ADCO should stop relying on poor quality information from general ledger documents or spend by vendors. Instead, it should embrace a procurement spending map that is a unique tool for identifying opportunities and risks, forming the basis of cost reduction, and enhancing value creation from contractors. The strategy can help the company to obtain valuable insights including total spend, who spends on what, the vendors who supply multiple products/services, and the core spend on suppliers (Rajeh et al. 940). A procurement spending map entails category analysis, item analysis, payment analysis, vendor analysis, and contract analysis, which ensure value addition the every unit of the acquisition process.

Conclusion

Procurement and supply is an encompassing process with multifaceted activities, which involve different stakeholders (Brewer and Bryan 192). A sourcing plan for ADCO in its acquisition of catering equipment requires the application of techniques, strategies, and integration of many components to achieving value for its money. The focus of ADCO comprises obtaining high-quality, cost reduction, and receiving value from vendors.

The adoption of various techniques can help to deliver value to ADCO throughout the sourcing plan. For example, the company can use E-procurement strategy to drive unmatched value I entire supply chain. Also, the firm can streamline its purchasing functions through proper change management, which can lead to improved value in the procurement process. For instance, Adoption of the Portfolio Kraljic Matrix and the RACI matrix represents a strategic sourcing approach, which can help the company to mitigate risks while managing many aspects of the supply chain (Ogut 148). ADCO stands a good chance to improve its expenditures on catering procurement if it combines the techniques mentioned above, methodologies, guidelines, and approaches in its entire supply chain.

Works Cited

Brewer, Barry, and Bryan Ashenbaum. “Outsourcing the Procurement Function: Do Actions and Results Align with Theory?” Journal of Purchasing and Supply Management, vol. 20, no. 4, 2014, pp. 186-194. Print.

Hesping, Frank Henrik, and Holger Schiele. “Matching Tactical Sourcing Levers with the Kraljič Matrix: Empirical Evidence on Purchasing Portfolios.” International Journal of Production Economics, vol. 177, no.2, 2016, pp. 101-117. Print.

Jia, Fu, Guido Orzes, Marco Sartor, and Guido Nassimbeni. “Global Sourcing Strategy and Structure: Towards a Conceptual Framework.” International Journal of Operations & Production Management, vol. 37, no. 7, 2017, pp. 840-864. Print.

Mogerman, Aaron, Daylath Mendis, and Kasun N. Hewage. “Project Delivery and Contracting Strategies for District Energy Projects in Canada.” Canadian Journal of Civil Engineering, vol. 12, no. 5, 2016, p. 461. Print.

Ogut, Hulisi. “Factors Affecting Professionals’ Selection in High and Low-Value Online Service Procurements.” Service Industries Journal, vol. 33, no. 1, 2013, pp. 133-149. Print.

Ojha, Shashank and Pandey I.M. “E-Procurement Project in Karnataka: A Case of Public Private Partnership.” Vikalpa: The Journal for Decision Makers, vol. 39, no. 4, 2014, pp. 101-112. Print.

Padhi, Sidhartha S., Stephan M. Wagner, and Vijay Aggarwal. “Positioning of commodities using the Kraljic Portfolio Matrix.” Journal of Purchasing and Supply Management, vol. 18. No.3, 2012, pp. 1-8. Print.

Panchal, Gajanan B. “Multidimensional Utility Analysis in a Two-Tier Supply Chain.” Journal of Manufacturing Systems, vol. 37, no. 1, 2015, pp. 437-447. Print.

Rajeh, Mohammed A., John E. Tookey, and James Olabode Bamidele Rotimi. “Developing a Procurement Path Determination Chart SEM-Based Approach.” Construction Management & Economics, vol. 33, no. 11/12, 2015, pp. 921-941. Print.

Slaughter S, and Mukhopadhyay T.”E-Procurement Infusion and Operational Process Impacts in MRO Procurement: Complementary or Substitutive Effects?” Production & Operations Management, vol. 24, no. 7, 2015, pp. 1054-1070. Print.