Abstract

Aluminum and mild steel were compared in this experiment to determine their mechanical qualities. The fundamentals of universal testing machine functioning were also learned throughout this experiment. Many engineering materials may be tested with the Universal Testing Machine. In many engineering constructions, tensile qualities of materials are employed as a basis for their design. It is possible to anticipate the properties of materials under various loading conditions by looking at the stress-strain relationships of different metals (van Zijl, Slowik, Toledo Filho, Wittmann, & Mihashi, 2016). Mild steel outperformed aluminum in this testing in terms of tensile and yield strength. Because of its excellent strength, mild steel may be used in a wide variety of constructions and engineering projects.

Introduction

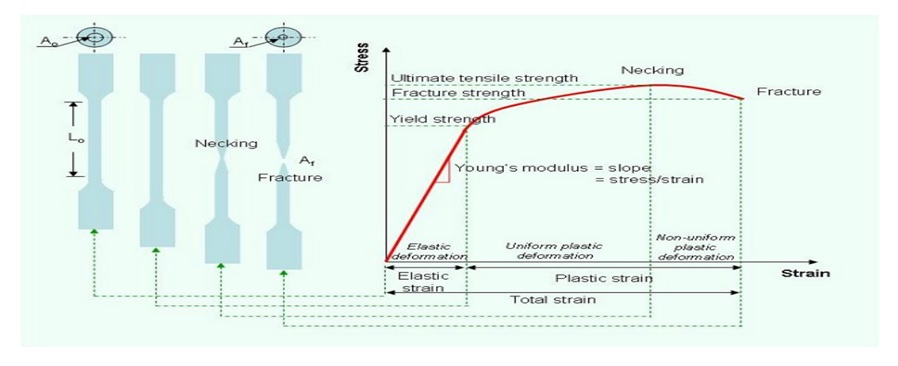

Structural components for bridges, railways, ships, airplanes, and pressure vessels should have their tensile qualities studied to ensure their safety. As a result, the tensile strength of the materials used in structural applications should be adequate. Engineering applications are determined by the metals’ mechanical characteristics. Tensile tests, which apply axial or longitudinal force to a specimen with given dimensions, may be used to estimate a material’s tensile characteristics. Until the specimen deforms and fails, these forces are applied. Using the tensile load and the related extensions, the stress-strain equation of the material specimen is calculated and determined. In addition, to yield strength, percentage of elongation, and ultimate strength, the tensile test experiment may be used to assess additional mechanical properties of the specimen. Keeping track of the initial gauge length Lo, diameter Do, and cross-sectional area can help with future computations.

Theory

In the presence of tensile stress, a substance undergoes deformation. There are two main types of deformation: elastic and plastic deformation. Expansion and applied load are directly proportional in elastic deformations. Engineering stress is defined as the ratio of the applied load to the original cross-sectional area, whereas engineering strain is defined as the change in length (extension) L over the original length L.’s

Hence;

σ=P/Ao

and

ε=∆ L/Lo

Where:

Σ is exerted stress

P is the axial load

Ao is the initial cross-sectional area

Experimental procedure

- By use of Vernier calipers, the thickness and breadth of samples of aluminum and mild steel were measured. The gage length of each material was found to be 80 mm.

- A ruler was used to measure and check the gage length of each sample of material.

- The program for capturing and recording data was enabled, and the substance matching the specimen was chosen in the software.

- By zeroing the load cell, the Instron Load Frame could only be configured to measure just the tensile load on each specimen entered.

- The jaws were altered to accommodate the size of the specimens. This was followed by mounting the extensometers to the shortened parts of the gage specimen.

- To minimize slippage of the specimens, the scroll wheel was utilized in preloading the machine.

- After the specimen was retrieved, the extensometers were set to zero values, and the test proceeded to measure the strain of the specimen.

- The data was recorded by the program on the spreadsheet.

- By inserting each sample in the compression testing machine, the tensile test was done, and the results were stored in the computer. The data was then obtained for computation and display of the graphs.

Results and discussion

Conclusion

Mild steel is often used in many technical applications that call for high tensile strength. It’s because mild steel has a crystalline structure that enables it to handle large axial stresses without breaking before the onset of fracture. Many designs requiring low-density materials, such as aerodynamics and certain automobiles, have found aluminum useful. Young’s Modulus is a factor that governs structural component deflections, and aluminum has a higher rate of ductility than mild steel. In this experiment, tensile strength is shown to have a close correlation to theoretical data.

References

van Zijl, G. P., Slowik, V., Toledo Filho, R. D., Wittmann, F. H., & Mihashi, H. (2016). Comparative testing of crack formation in strain-hardening cement-based composites (SHCC). Materials and Structures, 49(4), 1175-1189.