Discuss the reasons for Amazon’s evolution of supply chain and distribution systems in the US. Use diagram or otherwise to illustrate and discuss Amazon’s current distribution network in the US. It would be useful if you can extend the discussions to two-tier network distribution where possible

Amazon succeeded due to the benefits derived from simplicity and speed in the US market. These two benefits are instrumental towards the consumer base of its products. Amazon emerged as a very successful bookstore across the globe within a very short time. One of the factors that boosted the company’s supply chain in the United States was the low level of inventories.

In addition, the task of carrying out supply and stock books were left under the care and request of wholesalers. As a result, publishers were also linked closely with the company. The latter were awarded higher discounts than the wholesalers although their efficiency seemed to be rather low.

Moreover, it took a relatively short time to make order fulfillment for customers. The time taken for this procedure was less than one week in most cases. The company also expanded the capacity of its distribution centers in order to facilitate prompt movement of stock from one region to another. The stock of the company in terms of the number of title also grew steadily within the first three years. Moreover, the logistics department of Amazon also grew rapidly due to additional investments.

As already mentioned, the time taken to effect deliveries was significantly reduced due to the expansion that had taken place. However, the fast pace of competition in the online book selling stores prompted Amazon to devise better growth strategies that were in tandem with the market needs. Hence, more distribution centers were established in order to improve the physical infrastructure of the company. On the same note, supplier agreements of the same nature were initiated in order to boost the product range.

The desire to optimize the operations of its networks was yet another important area of focus for Amazon. In any case, both the shipping and stocking activities experienced cost reductions within three years after the above initiatives were adopted. Moreover, there was marked improvement in the delivery of quality services to customers.

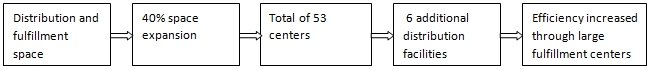

The current distribution network of Amazon in the US makes use of distribution fulfillment space. It has been expanded by forty percent to a total of 53 centers. Other six distribution facilities that were added recently have improved efficiency of delivery. Besides, it has improved the market presence of Amazon due to large fulfillment centers as shown in the diagram.

Q # 2: What is Amazon’s inventory management policy? Do you think that this is the best policy? Give two other inventory management strategies Amazon could use as part of its inventory management policy.

The inventory management policy focuses more on the best method that customers can use to manage their orders. For instance, the company uses refined software that can be used to offer forecasts for demand in the market so that it can meet the expected needs of consumers. This policy is necessary in order to avoid excess supply that may not be bought within the anticipated time.

The allocation of certain amounts to direct vendors and wholesalers has also been established as a buying rule.

The supply management systems have been integrated in such way a way that the systems that handle importation, warehousing and inventory programs are separate, but work as a unit.

The best price from suppliers is also an important policy consideration for Amazon. Therefore, it has executed cascading rules of buying. These rules enable the company to determine the best options that can be adopted to fetch the best price and delivery options for suppliers.

Although the above inventory management policies have been used successfully for a long time, there are other management systems that the company can still adopt in its online marketing business. For instance, Amazon can opt to use a barcode system in managing its inventory.

This system of inventory management system has been proved to be effective due to its high level of accuracy. It has a computerized cash register located at the point of sale. The data obtained from the inventory sales are transferred immediately in the system and later used in the maintenance of user statistics.

The data obtained from the system can then be used to make investment decisions. It is imperative to note that warehouses can also adopt the use of barcode inventory system. The entire incoming inventory can be controlled using a radio frequency identification (RFID) signal installed in the barcode. The flow of inventory within a warehouse is also by a barcode system.

Q # 3: Identify and discuss some of the supply chain management issues Amazon faced in its European markets. What were some of the potential risks faced in its European market supply chain, and how were they mitigating the risks?

There were myriads of challenges that were faced in Europe before the close of 2003. For instance, the desire to reorganize its distribution network was a real cause of concern bearing in mind that the growing demand for its products needed an urgent action to be taken. The management at Amazon saw the significance of embracing business structure and market positioning. There was still a lot of space for improving the supply chain management although the latter had been optimized in most parts of Europe.

The operations of Amazon in Europe were still lagging behind by 2003. In other words, the volume of sales in Europe was far much below the similar operations in the United States. Hence, the product offering was to be expanded and realizing better marketing activities as it was the case with the United States.

However, it was a difficult task to assess the degree of centralization required in adopting new services. For example, it would not be easy to group tasks that were being done separately. Putting these tasks together would require thorough planning. As a result, the operations of the supply chain management in Europe could not easily merge market sufficiency and flexibility within the required time.

Moreover, there was prevailing challenge in the European market in terms of the system of product offering, stocking technicalities in order to attain effective submission to customers and also the methods to use in improving the relationship with suppliers.

Finally, it was also challenging the degree of centralization or de-centralization to adopt. These risks were mitigated by employing strategies used in the US market. However, slight modifications were carried out on the strategies used in the US so that they could be compatible with the case in Europe.

Q # 4: Briefly discuss what are PRM and CRM. Discuss how Amazon used EDI to successful implement its PRM and CRM.

Customer Relationship Management (CRM) in an organization serves the purpose of assisting in the process of controlling and planning activities that deal with the both the post sale and presale tasks. CRM aims at improving the overall relationship between customers and an organization. Some of the important components of a CRM include field service, technical support, marketing; sales force and call center activities. Hence, CRM assists in understanding the behavior and needs of customers.

On the other hand, Amazon has used the Professional Risk Management (PRM) to validate its skills portfolio in managing its risks in the operations of the supply chain management. In other words, the company uses PRM to assess the risk factor in terms of supply and demand of its products. In addition, PRM is instrumental in assessing price levels in the market so that the company does not run at a loss.

Q # 5: What is a push strategy? What is a pull strategy? How would you characterize Amazon’s US and global supply chain strategy? What were the key drivers for Amazon to select the appropriate supply chain strategy in the US, and for the global market?

When products move from one party to another, it is called a push strategy. This term is sometimes linked with the pull strategy to denote exchange of goods between two parties.

Both of them can either receive or send goods to the other party. It is common knowledge for consumers to pull products toward themselves in order to satisfy their needs. On the other hand, pushing of goods and services to the end users by supplies for the sake of optimizing production and volume of sales usually takes place. Hence, the net effect generated is known as the push-pull strategy.

The global and the US supply chain strategy for Amazon indeed follow the push-pull strategy in spite of slight modification. For instance, there are suppliers on one side who push the products to Amazon. In this case, they do not sell directly to customers in the market. After coding and pricing of these products, selling process to consumers takes place.

The company can as well deploy an effective logistics system that can cater for speedy delivery of sold products across the globe. Besides, concurrent engineering can be integrated with supply chain design in order to boost performance.

Q # 6: Identify and discuss the facilitators in the Amazon’s supply chain. Explain how Amazon can apply cross docking strategy with the delivery of its product to its warehouse, or directly to its customers.

The Amazon’s supply chain has several facilitators. Although it has a competitive pricing strategy compared to its market rivals, its facilitators in the supply chain have indeed led to massive growth and profitable of the company. For instance, Eddie Bauer is a retailer who is critical in the supply chain of Amazon because Amazon takes care of its inventory.

In addition, the company also liaises with shipping companies for logistics purposes. Amazon uses drop shipping with certain assigned shipping companies. There are also wholesalers who are key suppliers to Amazon stores. Moreover, Amazon also cooperates with direct manufacturers who sell new products at the huge discount prices.

When goods from a different location are offloaded and immediately loaded into transport vessels without facilitating any system of storage, it is known as cross-docking. Hence, no storage arrangements are organized whenever cross docking is carried out. Hence, Amazon can opt to deliver goods directly to customers without storage in warehouses. This will significantly reduce delivery time and storage costs.