The efficient flow of processes in an organization whether technical or nontechnical define the competitiveness and the ability of the organization to cut costs hence improve its financial health. Developing an efficient working process requires a full understanding of the quantity and direction of the flow of processes to establish sufficient capacities which do not impose restrictions. Again, the capacities created at each stage of the process need not be too high as this may also add to the costs resulting in counter-productivity.

Bottlenecks occur when there exists a stage in the workflow which restricts the smooth flow of work. It occurs at the point where the resource allocated has a capacity less than the demand presented by the workflow. It is a restriction in a process that imposes limits on throughput. Depending on the circumstances, the bottleneck can take the form of a specialized tool, a machine, or even rare but highly skilled labor. These elements present a point in the system workflow where the flow is narrowed to fit within certain parameters. It is akin to a river flowing into a pipe. Many industrial processes though have no bottlenecks (Chase, Nicholas, Aquilano, 2006, p 440).

On the other hand, a nonbottleneck is a resource or facility with a higher capacity than is demanded by the workflow. It is a case of excess capacity and introduces the concept of idle time. There is also the capacity-constrained resource which is defined as the facility whose utilization is almost at full capacity hence could turn out to be a bottleneck if not well scheduled.

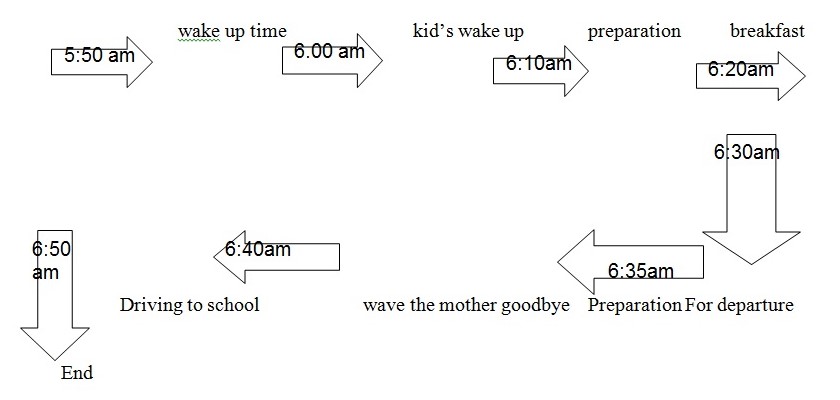

The workflow in consideration is the process involved in preparing kids and taking them to school. The process starts at 5.50 a.m and ends at 6.50 am as shown in the flowchart below.

The process has minimal bottlenecks as the kids can do virtually everything for themselves from preparing themselves up to the time they leave for school. However, a possible area emerging as a bottleneck is the process of driving them to school. This is because the resource in use (driving skills) is possessed by one person only (father). The father also has to be the one to engage the teacher as concerns the performance of the children. As such, all the children even after preparing themselves at different paces must be ready to be driven to school by one person in one car. The entire process is narrowed by the scarcity of the resource in use.

The seasonal factors are the unusual situations that occur to disrupt the system process. The frequency in which they occur is of critical consideration to the design of the workflow model. In the case of the workflow presented above, the stages of the process from waking up to saying goodbye to the mother have rare chances of being disrupted. This is because there are few restrictions likely to hinder their execution. However, the point of driving them to school presents a challenge. There are possibilities that the father may not be available on a certain day due to various reasons ranging from health reasons to work-related issues. The probability of the father not being available puts to risk the entire work process.

The best possible way to solve this situation is by hiring an extra driver hence creating an extra avenue to take the children to school. This removes the constriction of the resource posed by the fact that only the father can drive. The bottleneck is thus effectively eliminated from the workflow and there are thus lesser risks of the children not going to school.

In the application to supply chain demand, as well as the manufacturing process, the focus should be on identifying the areas which present bottlenecks in the processes and finding out effective ways of eliminating them in full consideration of the cost implications on the organization. By finding out the cheapest way to improve efficiency, the organization is set to gain in terms of customer satisfaction through timely delivery of products and more importantly is the ability to effectively control costs.

This is one great source of competitiveness in the market. The efficient manufacturing processes coupled with efficient supply more often than not offer excess capacity. This offers enough resources for use in establishing areas of possible expansion and growth. Once the customers already existing are fully satisfied, the opportunity is always available for the company to search for new customers and establish new links as there is the assurance that there is adequate capacity to offer enough of the required products.

In conclusion, the improvement of the above-described workflow would lead to better management of the school-going exercise for the kids just like it would lead to higher profitability in the case of a business enterprise.

Reference List

Chase, R., Nicholas, J., Aquilano,F., & Robert , J. (2006). Operations Management for

Competitive Advantage. Tata McGraw-Hill.