Abstract

To create an alternative source of revenue for its economy and avoid over-dependency on oil, the UAE resolved to contract engineering companies and other human resources expertise in the design and construction of the 1.5 billion dollar project. Various formidable challenges were significant in the design and construction process. The building was designed with a gradual decrease in mass as it progressed upwards to address the issue of weight. The central core of the structure was designed to overcome the twisting effects of wind and a cultural theme was incorporated in the design. Specially designed cranes were used to move materials and man up the building and silicone materials specially designed and tested were used to curb and control thermal effects on the building. Water was sufficiently supplied and drained appropriately. The structure was a success.

This report undertook to bring to light the challenges and technical difficulties encountered in the process by researching various literature available on the project. Various problems and technical challenges were experienced.

The Problem: Thermal effects, the movement of materials and man, the force due to the wind, turning effects on the structure, and pressure due to the weight of the building in addition to the curing effect of cement during construction was the main problem.

Results: These measures were overcome through various approaches and conclusively the building was a success.

Recommendation: However, it was worth noting that the human factor, ethics and fair play, and a detailed analysis of materials should be done in any future project.

Executive Summary: To create an additional source of revenue and address the problem of overdependence on oil, the UAE undertook to contract skilled and experienced designers and contractors to design and construct the Burj Khalifa structure. To address the problems and technical challenges faced in the construction of the Burj Dubai structure, special cement was used to reinforce the concrete and steel mixtures. The building was designed with a gradual decrease in mass as it progressed upwards to address the issue of weight. The central core of the structure was designed to overcome the twisting effects of wind and a cultural theme was incorporated in the design. Specially designed cranes were used to move materials and man up the building and silicone materials specially designed and tested were used to curb and control thermal effects on the building. Water was sufficiently supplied and drained appropriately. The structure was a success. This report undertook to bring to light the challenges and technical difficulties encountered in the process by researching various literature available on the project. The Problems included thermal effects, the movements of materials and man, force due to the wind, turning effects on the structure, and pressure due to the weight of the building in addition to the curing effect of cement during construction were the main challenges.

The Project

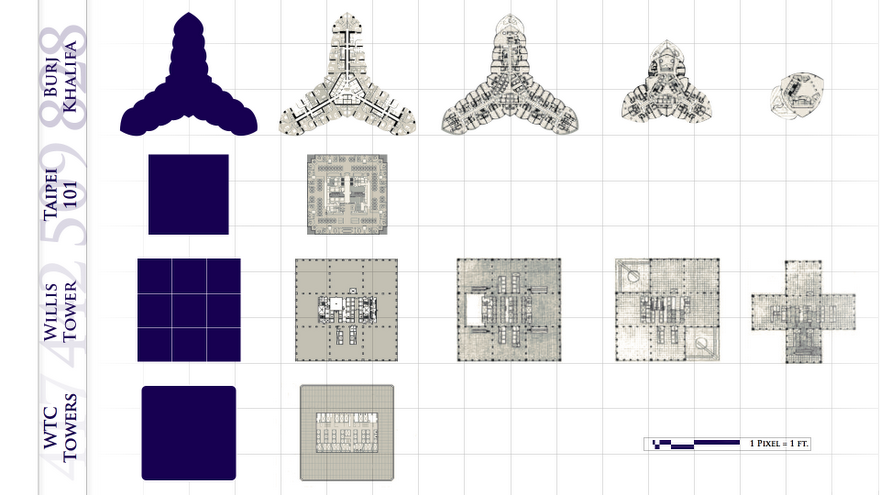

Burj Dubai is a project of its own. Being the world’s tallest building, it spans 828 meters above ground level with approximately 160 stories. It is visible from a distance of 95 kilometers, boasting 3000 underground parking spaces. Sitting on 19 hectares, and with a record-holding capacity of 160 hotel suits, it is a marvel of engineering ingenuity. Designed and constructed with reinforced concrete and steel, its primary structure occupies 45,000 cubic meters weighing approximately 110, 000 tonnes. At the base, the structure is built on a concrete and steel foundation consisting of approximately 192 piles buried 164 feet deep to impress stability in its foundation. Thousands of tonnes of steel and rebar were used in the construction process. The structure, an engineering ingenuity took a whole 22 million man-hours for its completion. The construction of the foundation was materials-specific. Low-density cement with low permeability was the best option (Burj Khalifa Construction 2010)

Built by Samsung Engineering and construction in partnership with Besix, and Arabtec, the project had additional characteristics. It had a high number of compartments that are supplied with highly pressurized air for refreshments and fire safety or disaster safety floors located at every 35 floors in case of an emergency.

Pressures due to the tonnage of the structure are withstood by the use of special concrete mixtures thoroughly tested and evaluated for their structural strength in supporting the massive building to withstand the huge amounts of pressure and force.

The hotel is designed with a central core that structurally reduces with every rise of the building. The core provides support for structure on a hexagonal design with a reinforcement of three buttresses.

Water into the hotel is supplied at a rate of 946,000 liters daily. The structure has an embed system for cooling purposes that exploits the humidity of air from the outside of the structure and condensed moisture from the air. The whole water system is designed for reuse in the park after it’s drained from the building. Cameras and a state-of-the-art information security system are used to keep check of any potential threats to the building.

To ensure thorough and uniform curing of the concrete mixture, mixing was done during the night and the concrete mixture was mixed with ice for additional delays in curing and setting to avoid cracking and breaking of the concrete.

This was done not to mention the deplorable condition of workers who saw the structure span the sky. The abysmal pay, the inhuman conditions they lived in was the sole cause of the high number of injured workers and deaths.

The state-of-the-art design was done by Merill and Skidmore in partnership with Owings. The designers were culturally specific. In an Islamic setting, the design pattern symbolizes Islamic art. The Y-shaped structure was specific for hotels and residency.

The Project Director

Under the able leadership of H.E. Hamad Buamim, the director of General Dubai Chamber, various trained and experienced architects, and engineering companies, the project came to a successful end. Equipped with wide experience and management skills, the directorship of Hamad Buamim was a success. Besides, the designers of the projects were widely experienced in the design of various structures in diverse environments. In addition to that, construction companies were widely experienced in the construction of similar structures and had the right equipment for the construction work.

Purpose of the Project

The purpose of the project was to establish up to 30,000 homes, prestigious hotels, residential areas, and an impressive tourist attraction, and more specifically the Burl Khalifa Lake. The government of the United Arab Emirates purposed to diversify from the dependency on oil as a driver of its economy to a service-oriented and tourism-driven economy. To this end, the government set out the project that could bring it to the international scene. With the formidable challenges that faced the project, UAE‘s government forth the project (Economic Development n.d). UAE is a country dependent on revenue from oil. It is a desert country without any agricultural activities and to supplement its income. In addition to that, the country is situated in a politically volatile region where the possibility of war can impair its oil business. Besides that, oil is not a renewable source of energy and if the taps run dry, the possibilities of an economy collapsing are disastrous.

Engineering Challenges

Every engineering project comes with its challenges. These challenges put to the test Engineers’ experiences and skills in addressing them. That was the case with Burj Khalifa (The Project n.d).

With a budget of 1.5 billion $ and a structure of a height of over 828 meters above ground level, several challenges and technical difficulties were experienced. These included managing thermal effects, the movement of construction materials and man up the structure as it progressed, the effect of forces due to the wind, enveloping the building, internal pressures, and the weight of the structure on its base, security concerns, and labor ethics.

Thermal effects were addressed by engineers’ use of tested and verified materials that could withstand high temperatures, specifically tested to fit in an environment with sandstorms and drastically varying temperatures. To reduce the high risk of pressures, the design incorporated interlocking panels positioned at high points of the structure. According to Baker (2010), the silicone sealant was developed with best-practice standards to ensure high and excellent performance. In addition to that, the curing of cement was addressed by incorporating ice in the cement concrete mixtures and construction piles could be buried to a depth of 164 feet deep to help the foundation support the structure.

The movement of machinery, man, and materials was achieved through cranes designed for the purpose, while special high-density cement was used as discussed above.

Conclusion

Being the world’s tallest building and spanning a height of 828 meters above ground level, with approximately 160 stories, the project was an engineering success. Various challenges such as the force of the wind, cement curing, the weight of the structure, thermal effects, and various other aspects were overcome to see the construction become a success. The purpose to create a center-piece structure was technically achieved amid the formidable engineering challenges faced.

References

Baker W F 2010, Civil Engineering. Engineering an Idea: The realization of the Burj Khalifa. Web.

Barj Khalifa Construction 2010, Burj Khalifa, World’s Tallest Building. Web.

Economic Development. Dubai, World class Infrastructure and a Global Hub for Trade, Transport and Tourism, Web.

The Project. Silicone Solves High Altitude Technical Challenges at the World’s Tallest Tower. Case Study. Burj Khalifa, Dubai. Web.