Introduction

A number of materials may be used to strengthen and stiffen reinforced concrete. For instance, the use of carbon fiber in the form of CFRP (Carbon Fiber Reinforced Polymer) has gained popularity rapidly in civil engineering for the last two decades. Being a cost-effective alternative to steel due to its high strength to weight ratio, carbon fiber has found a number of applications in the construction industry (Roberts, 1989).

One of the common applications of carbon fiber in structures is retrofitting, where the main aim is to strengthen existing structures. In addition, carbon fiber related composites are used as a substitute to steel for the purposes of pre-stressing. In all applications, carbon fiber improves flexural, shear and tensile strengths of concrete leading to increment of the overall structural integrity.

According to Zhou et al. (2013), CFRP is a reliable strengthening element in civil engineering structures. However, the research revealed that the probability of failure with such a beam would be relatively high due to premature debonding. To counter the failure mode, improvement on bonding characteristics has become imperative through restriction of displacement by sliding.

In effect, Zhou, et al. (2013) utilized a technique referred to as FRP-FHB (Fiber Reinforced Polymer – Friction Hybrid Bonding), in which 2 reinforcing fibers are linked into a single network matrix with better bonding characteristics.

Carbon Fiber Reinforced Polymer and Epoxy Resins

According to the postulation made by Al-Amery and Al-Mahaidi (2006), appliances of CFRP strands prevent failures in debonding. Al-Amery and Al-Mahaidi (2006) explained that this prevention arises from the provision of additional strengthening strategies on CFRP sheets. The stand minimizes interface slip placed at the center of sheets and concrete.

Additionally, Riyadh identified that longitudinal strain is variant in accordance to tally of layers permitting a differential strain to traverse the CFRP matrix. Saleh et al. (2009) established the relationships that modified a strategy to calculate interfacial bond stress.

According to Braz and Soc (2006), composite materials based on carbon fiber and epoxy resin have gained popularity in engineering applications, such as aircraft structural framework manufacture, due to their high strength to weight ratio. In addition, epoxy resins are resistant to creep, chemical action and breakage.

Moreover, epoxy resins have been found to exhibit good adhesion characteristics with most of the common engineering substrates. However, a major limitation of epoxy resins (ERs) is their high brittleness after passing through the curing process. However, addition of a small percentage of liquid rubber has been found to improve ERs’ fracture properties that include fatigue resistance and fracture toughness.

Although the addition of reactive rubber improves fracture properties of ERs, it is worth noting that the molecular weight of the selected rubber is a critical factor. In application, only rubber with relatively small molecular weight should be used. Mainly, excessive addition of denser materials in the ER matrix may result into high viscosity that would lead to low process ability.

A possible light-weight rubber that can be employed in this case is butadieneacylonitrile. Butadieneacylonitrile is a carboxyl-terminated copolymer industrially known as CTBN. The liquid rubber is preferred highly due to its high miscibility with ER hardeners. This property is usually vital in the early stages of polymerization.

Although there have been extensive developments in ER processing, little attention has been paid to the importance of Rubber-modified ER systems in the building and construction industry. According to Saleh et al. (2009), the use of CFRP and CTBN has been common in the aerospace and automotive industries. This paper seeks to utilize strength and excellent behavior of Carbon Fiber rubber-modified ER in concrete reinforcing.

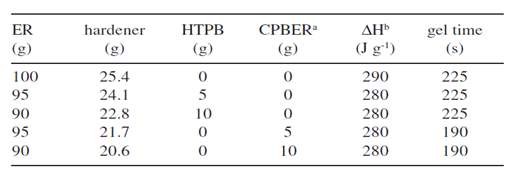

This will improve the strength to weight ratio of the concrete. An overview of rubber-modified ERs with respect to their mechanical properties and the amount of hardener led to a collection of data as shown in tables 3.1, 3.2 and 3.3. For instance, table 3.1 shows various ER parameters and their corresponding formulations alongside rubber-modified ER systems.

Table 3.1: ER parameters and their corresponding formulations alongside rubber-modified ER systems (Braz & Soc, 2006)

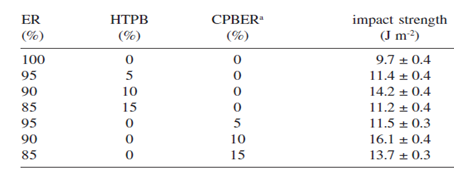

Table 3.2: Mechanical properties of rubber-modified ER networks (Braz, & Soc 2006)

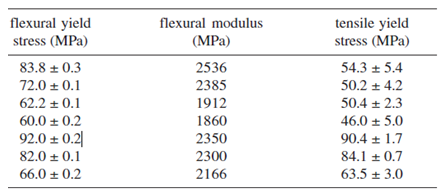

Table 3.3 is a continuation of table 3.2 shown previously. It shows various mechanical properties for various forms of ER.

Table 3.3: Mechanical properties of rubber-modified ER networks (Braz & Soc 2006)

An observation on the mechanical properties of rubber-modified ERs shown in table 3.3 reveals some aspects. For instance, it reveals that both the tensile yield strengths and flexural yield strengths of various ERs are relatively high compared to non-rubber modified ERs. Consequently, decision to employ the material as a reinforcing element in concrete seems to be fruitful.

For instance, the application of rubber-modified ER in concrete straightening will reduce the average weight of concrete and save material cost without compromising strength. Reduced weight implies that the relative sizes of columns and other supporting structures will be reduced in a similar proportion. Concurrently, it leads to saving on material usage at the construction stage.

According the fatigue experiment, Al-Amery and Al-Mahaidi (2006) deduced that a load with a frequency of 15Hz relative to its spectrum in the static experiment varied in accordance to the sinusoidal law when R was 0.2. The researchers delivered a balanced equation for the epoxy resin as shown in the following equations.

Τf(x) = G. ϒxy(x)

Where τf is the shearing stress, G is the shearing modulus

τf (x) = [dFf (x)]/[dx ⋅ l]

Where Ff is the tension force at the end of CFRP

An overview of CFRC (Carbon Fiber Reinforced Composites)

Triantafillou (1992) states that CFRCs are mainly produced from thermosetting polymers such as epoxy resins. The laminated polymers have excellent mechanical properties that include high stiffness and strength to weight ratios compared to the common metallic and plastic materials.

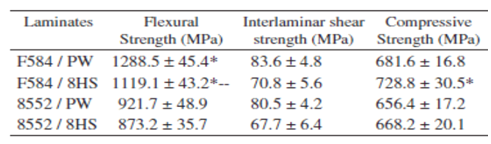

However, modified rubber epoxy resins are preferred over normal epoxy resins due to their low brittleness, high tensile, flexural and compressive strengths. Table 3.4 shows the values of shear flexural and compressive strengths of various rubber modified epoxy resins.

Table 3.4: Shear flexural and compressive strengths of various rubber modified epoxy resins

Epoxy resins are squarely adhesive when compared to polyesters and other varieties of resins. Roberts (1989) pointed out that this resin has double strength and stiffness in comparison to the above distinguished ester. Additionally, epoxy resin has a strong capability to withstand water degradation.

Types of Debonding and Minimization

Roberts (1989) presented two types of debonding in CFRPs that considered crack-induced and cutoff point debonding. The former occurs around the terminal of structural cracks in a loaded structure that is usually close to the point of maximum bending moment. The latter occurs around the cutoff points in which maximum stress concentration is experienced.

Niu et al. (2002) asserted that utilization of fracture mechanics through the study of stress transfer modes and the influence of shear stiffening in a loaded structure is the only key to minimize debonding in CFRPs. The supported techniques include minimization of interface stress to counter cutoff debonding, and reduction of beam spans and loads to avoid crack-induced debonding.

Limitations of CFRP Application in Civil Engineering

The application of CFRPs in civil engineering has a number of limitations. For instance, the cost of CFRPs is relatively high compared to that of its substitutes in the building and construction industry. Some of its substitutes in the industry include AFRPs (Aramid Fiber reinforced Polymers) and GFRPs (Glass Fiber Reinforced Polymers).

While cost remains a significant issue, some aspects like extensive research, exploration of CFRPs applicability in retrofitting, and viable steel alternative are ongoing. Another limitation of CFRPs is unreliability that has been given a long span of time. It cannot endure fatigue at limits. Moreover, many concerns have been raised in question of CFRPs brittle nature.

According to Sato et al. (2000), CFRP has a relatively low endurance limit when subjected to static and other types of loading. Therefore, this material is not highly recommended in areas where seismic waves or any form of vibration may occur.

However, it can withstand static loading effectively without strains incase no strong waves appear. Finally, recycled CFRPs are weak due to shortened fibers during shredding and milling at relatively low temperatures.

Brief research strategies

Based on the nature of the project covered herein, the research strategies to be employed in this paper will involve extensive experimental work and data analysis.

To accomplish this, the author will carry out an extensive literature review in order to capture all the knowledge required for the analysis. In addition, several surveys will be carried out in order to obtain the data and observations made by other researchers on ERs for comparison purposes.

References

Al-Amery, R & Al-Mahaidi, R 2006, ‘Coupled flexural–shear retrofitting of RC beams using CFRP straps’ Composite structures, vol. 75 no. 18, pp. 457-464.

Braz, J & Soc, C 2006, ‘Composite materials based on modified epoxy resin and carbon fiber’, Journal of the Brazilian Chemical Society, vol. 17 no. 6, pp. 1117-1123.

Niu, H & Zhishen, W 2002, ‘Strengthening Effect of RC Flexural Members with FRP Sheets Affected by Adhesive Layers’, Journal of Applied Mechanics, vol. 5 no 3, pp. 887-897.

Roberts, T 1989, ‘Approximate analysis of shear and normal stress concentrations in the adhesive layer of plated RC beams’, The Structural Engineer, vol. 67 no. 12, pp. 229-233.

Saleh, B, Ishak, Z, Hashim, A and Kamil, W 2009, ‘Compatibility, Mechanical, Thermal, and Morphological Properties of Epoxy Resin Modified with Carbonyl-Terminated Butadiene Acrylonitrile Copolymer Liquid Rubber’, Journal of Physical Science, vol. 20 no. 1, pp. 1–12.

Sato, Y, Asano, Y & Ueda, T 2000, ‘Fundamental study on bond mechanism of carbon fiber sheet’, Journal of Material, Concrete Structures and Pavements, vol. 47 no. 648, pp. 71-87.

Triantafillou, T & Plevris, N 1992, Strengthening of RC Beams with Epoxy-Bonded FRP Composite materials’, Materials and Structures, vol. 25 no. 11, pp. 201-211.

Zhou, Y, Gou, M, Zhang, F, Zhang, S & Wang, D 2013, ‘Reinforced concrete beams strengthened with carbon fiber reinforced polymer by friction hybrid bond technique: Experimental investigation’, Materials & Design, vol. 50 no. 6, pp. 130–139.