Introduction

An excellent ship construction layout employing current cost effective and efficient methodologies, ship construction standards, and ship construction concepts constituted the best approach to modern ship construction of the proposed facility. The basic design requirements and specifications and innovativeness formed the basis of the design.

The report looks at innovative approaches to challenging constraints experienced both in the design and implementation of the ship yard on the physical location of the facility. This was in accordance with the research conducted into ship building methods to optimize production, expertise, budget, and space.

The research incorporates a comprehensive analysis of the 25 metre vessels capacity and the new design approach. The facility will consist of twin 6000 tonne building berths, 450 tonne transporters, equipped workshops, system integration and communication systems for surveillance systems according to international and national standards and conventions.

Methodology

Weight factors were then rated in the order of critically essential, specifically vital, vital, normal, not vital, and undesirable and labeled appropriately with letters. Different activities are incorporated in the production process. The first phase, according to the design incorporated a critical analysis of the available space, land topology, and water depth and the best design for optimal utilization of those aspects (Matulja 2).

In addition expert knowledge, creativity, an analysis of the shape, size, and capacity of the 25 metre vessel capability, its layout and the required infrastructure compared to the current infrastructure, the area to which the facility is to be bounded by sea, and available technology.

Layout and the Rationale Behind

This design incorporates elements of smooth work flow and materials, uniform application of workloads on production tools, and budgetary constraints. In addition the workforce shift capacity, and work flow are part of administrative activities. The rationale behind this layout is efficient space, budget, time, workflow, and site utilization with the available technology and future aspects as envisaged in the previous feasibility study report.

Procedures and the Rationale Behind

Phase One

The methodology focuses on efficient space utilization as detailed in the diagram illustrated below proposed by (Singh and Wang 3). At this stage, the production area was identified based on the aerial map and picture of the construction site. Each production area is numbered, a combination in the process to determine the flow of production of ships. Technologically, weights for the area are critical in determining the flow in the production process. The A, B, C D, E, F corresponding to numbers 0, 1, 2, 3, 4, and 5. The weight factors, in the order of 45, 11, 3, 1, and 0 were correspondingly assigned letters A, B, C, D, E, and F. each weight factor corresponded to a closeness factor in the listed orders as illustrated below. Thus the data was used to design the flow that could provide optimal use of the facility.

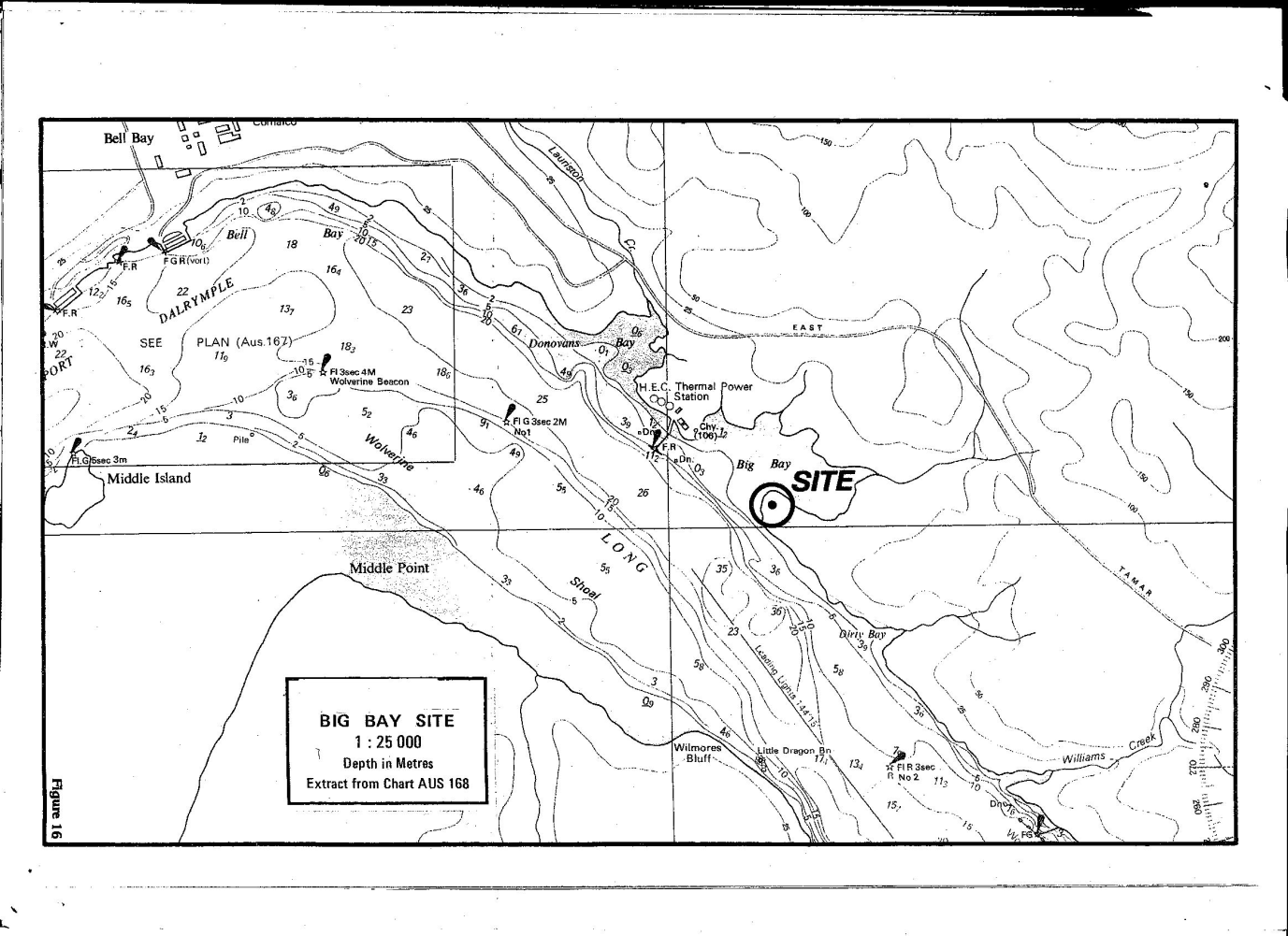

Site Map

The diagram indicates the area for section finalizing, the blasting and section painting, forming, outfitting, and pipe cutting and the smith’s workshop.

Phase Two

These results led to phase two of the design. The flow intensity is regulated among different work positions where all materials flow in the direction indicated in the flow charts (Muther 4). At the design stage, data validation and verification should be incorporated spanning the quantity, routing or direction, the product, specific support, and the time required.

All the working relationships should be clearly identified and be in close proximity to optimize the design and production activities. The strength of the relationships between the activities in the design determines their proximities.

This aspect incorporates future expansion capabilities, space utilization, and clean room requirements that may place additional constraints. An analysis indicated requirements such as the size, shape, relationships between production points, and the approach in organizing the spatial arrangements consistent with the production areas. It’s worthy noting that the use of software in the design drastically facilitated the design process.

The use of templates and CAD were critical components in the design process. A mathematical relationship between the number of closeness (Y), weight factor and closeness (w), the SLP(s) score, and the number of production areas are related in the equation: S= ∑w.Y. To obtain optimal flow and production, the design is made so as to obtain a large value of s.

The design incorporates other constraints such as the available budget, the feasibility plan consistent with the manufacturing target capacity and available human resource personnel and expertise skills and requirements in line with the company’s goals. The best design was arrived at using software tools at the designer’s disposal. The current feasibility plan and future design considerations were factored at this stage since possibilities for future expansion were rife.

Phase Three

At this phase, an Analytical hierarchical Process was used. This structured technique provided critical support in resolving complex issues related to the constraints highlighted above. This design spans the psychology and mathematical relationships between the elements in the production process (Matulja, Fafandjel & Zamarin 36). The criteria for the design included software costs, SLP score, available budget, a feasibility study, and geographical considerations as illustrated on the picture and provided map.

Based on the saaty’s scale, the elements are compared in terms of the strength of the relationship between them. At the top most level is the goal with the hierarchy of the related elements following in order, according to the equation, K (K-1)/2 for each hierarchical level as proposed by (Matulja, Fafandjel & Zamarin 3).

Phase Four

This led the designer to determine the degree of stability of the solution design, inclusion and variations of the hierarchical parameters, and identification of the most critical parameters in the design based on operational research methods. A sensitivity analysis on the data and design based on operational research methods was also done.

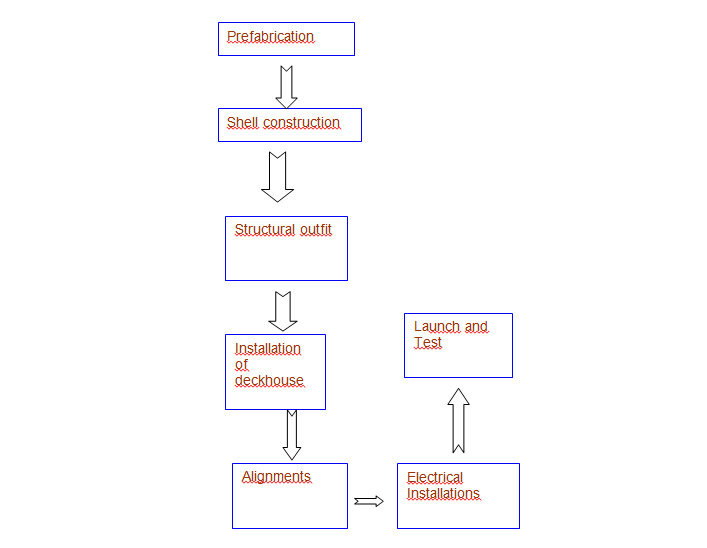

Proposed Construction Process

According to the design, the pre-fabrication activity could involve construction of the mock, appropriate fixtures, and the jigs followed by the cut out plate. The cut out plate and assembly include pre-fabrication activities. The shell is constructed with emphasis on the mock in an inverted construction procedure followed by the structural outfit.

Eyres discuses the deckhouse is install ion to specifically consisting of the pilot house, and the Aluminum pilothouse (8). Other machineries and equipments are installed at this point as critical alignments are done.

Electrical installations are done in the process and other electronic devices such as communication equipments. The ship undergoes final painting and launched. At the launch pad, the ship’s machinery is thoroughly tested, sea trials are conducted, and the final product is delivered on time and according to the budget as discussed by (Ahmad 23).

Discussion

The discussion provides a view of the design and implementation of the ship yard construction in view of constraints such as the budget, manufacturing technologies, materials, the land topology, water depth, and available expertise.

Other factors for the success of the project include excellent work ethics and high productivity. Other success factors for consideration include buffer zones; raw materials supply chain, inventory management and movement, and available technologies. That could make the company realize an optimal facility.

Works Cited

Ahmad, Abdul-Rahim. An Intelligent Expert System for Decision Analysis and Support in Multi-Attribute Layout Optimization. Ontario: University of Waterloo, Canada, 2005.

Eyres, David. Ship Construction. 6th ed, London: Sterling/Butterworth Heinemann, 2008.

Matulja, Tin, Fafandjel N & Zamarin A. Hierarchical as a Basis of the Methodology for shipyard production Layout Design. PhD Thesis, Faculty of Engineering, 51000 Rijeka: Vukovarska 58, 2009.

Muther, Richard. “Systematic Layout Planning. 2nd ed. Management and Industrial Research Publication”. Kansas:USA. Cahner’s Books, 1973.

Singh, Nanua, & Wang M.H. Concurrent Engineering in a High Variety Label Printing Environment. International Journal of Production Research, Delhi: India, 1(994):1675-1691.