Aircraft is a powerful and expensive machine that needs regular maintenance to prevent damages that lower their life expectancy. Cleaning aircraft helps minimize problems such as licks on the underside and water drains, maintaining safe working conditions. Moreover, thorough cleaning improves passengers’ confidence that the plane is in good condition. Synthetic detergents and emulsion cleaners are appropriate cleaning agents for aircraft (Al-Kasasbeh, Abudayyeh, and Liu, 2021).

Wet wash removes carbon deposits, while dry wash removes dirt accumulation, and polishing maintains the luster of the painted and unpainted areas. Air transportation drives global mobility, necessitating quality requirements to ensure safe operations. The air transportation industry has been negatively affected by the COVID-19 pandemic and contributed to the redesign of aircraft to incorporate modern sanitation needs.

Aircraft standard cleaning and cabin disinfection serve significant aircraft maintenance aspects after every flight to minimize safety, security, and operational challenges. Therefore, this study focuses on a project scope statement which discusses project objectives, major deliverables, project scope descriptions and identifies two significant risks accompanied by matrix and mitigation steps to minimize the rapid spread of infections.

The research illustrates the project controls such as financial and document management that play an essential role in the success of aviation companies. Moreover, EASA established safety directives for its associates and for that country operators running commercial air transport of travelers inside and around regions that were subject to the giving of the Treaty on the performing of the European Union. The SDs decree the disinfection of airplanes after every flight from vulnerable regions to protect travelers from secondary contamination.

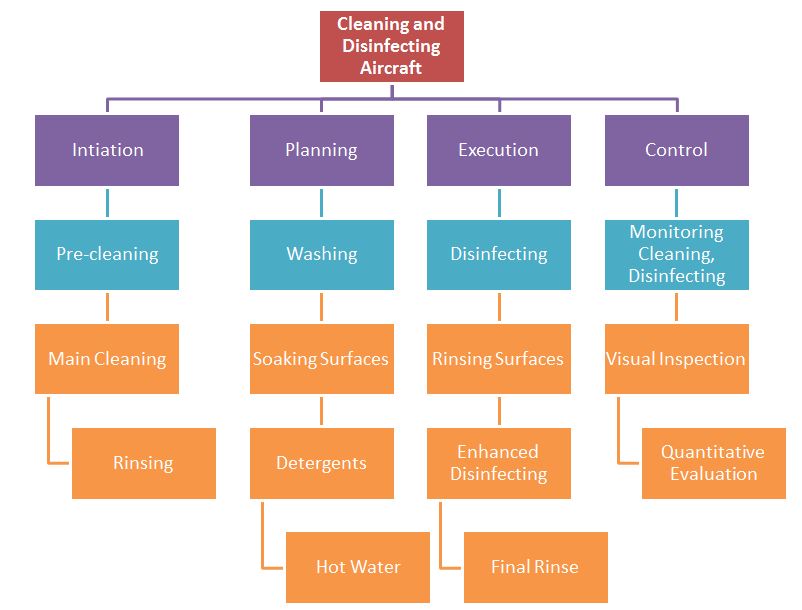

In 2020, EASA developed more SDs that supplanted the previous ones that ordered the cleaning and disinfection of airplanes that took place in commercial airline transport of travelers around Europe twenty-four hours before any long-haul flight (Amankwah-Amoah, 2021). During cleaning and disinfection procedures, aircraft should be outside hangar buildings if weather conditions allow. Given the complexity of aircraft maintenance, cleaning and disinfection activities necessitate vital skills, materials, and awareness of handling infectious diseases that rapidly spread during air transportation in addition to mitigation steps (see Figure 2).

The Project Scope Statement

The project will ensure standard cleaning and disinfection of airlines with the ultimate goal of helping aircraft to attain quality levels of hygiene and reduce the spread of infection. Employees’ competence and proficiency during cleaning activities will support safety efficiency. Moreover, the project aims at developing an emergency response plan to aid in recognizing emergency circumstances (see Figure 1). Emergency plans will protect workers and passengers because people’s safety is a priority during emergencies. All cleaning personnel should be educated on COVID-19 pandemics and infectious diseases (Deng, Santos and Curran, 2020). Airlines staff should ensure that aircraft are comprehensively disinfected and cleaned after every flight.

The aircraft cleaning crew chief should confirm whether it has been cleaned and disinfected to quality standards. Regular maintain ace will improve the engine’s working capacity, ensuring efficient aircraft performance and no flight delays. The robust performance will improve passengers’ satisfaction, enhancing the company’s overall growth (Gössling, 2020). Chances of engine failure are minimized, thus experiencing less downtime and repairs. Avoiding downtime, which eats into business profits, will be beneficial as it lowers spending on air. Repairs are more costly than maintenance; therefore, focusing on plane maintain ace will save time and money, ensuring streamlined operations.

Major Deliverables

The cleaning and disinfection program incorporates accessibility routines and procedures for timely airline training by the counted personnel. Essential aspects include cleaning after every fight, suitable cleaning and disinfecting agents not harmful to airplane materials, applicable personal protective gadgets, and sufficient learning for the designated individual (Piric et al. 2019). Such a critical aspect ensures that Aircraft passengers are at lower risk of infection. Schedule and processes for routine and efficient airline cleaning and disinfection measures, when exposed to high-risk regions, are paramount in sustaining hygienic surroundings.

Project Scope Description

The project will ensure transportation hygiene maintenance, most notably cleaning and disinfecting aircraft after every flight. COVID-19 pandemic prevalence has heightened the spread of the virus through aircraft traveling, which attracts interaction of multiple people and serves as the primary vehicle for disseminating transmissible infections (Razab et al. 2018). Therefore, maintaining a hygienic environment in the airline industry will minimize exposure risks. The aircraft maintenance detailing project will accommodate overhead storage bins, sanitizing aircraft tray tables, and disinfecting seats and seatbelts. Generally, the project focuses on ensuring quality aircraft cleaning and disinfecting to achieve a healthy environment.

Work Breakdown Structure

Network Plan

Major Risks and Response Strategies

The risk of spreading droplet-mediated diseases on an aircraft can multiply due to a lack of exclusive cleaning. Factors such as passenger and crew movement and contact heighten the spread of infections. Contact with contaminated surfaces and infected individuals during cleaning, boarding, and disembarking from the airlines spark transmission of infectious viruses. Lack of national awareness regarding the spread of infection has increased surface contamination, thus lowering cleaning and disinfection efficiency.

The strong matrix plays a vital role whereby the aircraft manager initiates knowledge promotion on infection prevention and sets measures such as passenger distancing to mitigate the spread of diseases (Zhang, Zhao and Hu, 2020). Further, as the most potent decision-maker, the aircraft manager establishes coordination between public and personal sector actors to develop mitigation steps. The first step begins with distancing the aircraft and blocking the middle seats (Al-Kasasbeh, Abudayyeh, and Liu, 2021). The second step involves the free flow of information about disease awareness from the manager to the cleaners. Situational awareness is an integral aspect that involves activities such as sparking and spreading periods of the disease.

Situational awareness offers smooth monitoring to recognize the course of the disease and if the intervention strategies are effective. It supports policy decisions by tracing down if and where the disease transmission occurred (Zhao et al., 2019). As a result, a suitable technique is detected to minimize transmission, such as vaccines to minimize the spread of infections. Additionally, aircraft’s inner surfaces should be disinfected by spraying chlorine with high frequency.

Chemical damage to the airline is a safety risk that severely influences the aircraft and engine integrity. Utilizing inappropriate cleaning agents on airlines is a risk accompanied by negative and costly results. Such agents lead to white corrosion, which necessitates extensive maintenance to renovate structural integrity—for instance, cleaning products containing acetone on windshields result in long-term damage to windshields made from Plexiglas (Razab et al., 2018). Frequent use of acetone cleaners necessitates for constant replacement of the windshield. Moreover, paper towels and various abrasive clothes scratch windshield surfaces leaving damage marks. Therefore, a balanced matrix will aid in maintaining open communication between cleaners and their leaders concerning the longevity of the aircraft and the best cleaning agents to use.

The airline department and the director coordinate and communicates to the cleaners about maintaining high cleanliness and tidiness by using wet cleaning to avoid the suspension of dust. The first step includes identifying the suitable cleaning agents by adhering to test criteria to qualify the best cleaning agents on aircraft products. Aircraft should follow federal aviation advisory guidelines, which ensure cleaning agents do not degrade airworthiness (Al-Kasasbeh, Abudayyeh, and Liu, 2021). The commencement of sundry grades of nonwoven abrasive pads has led to the rise of clean, less costly materials that can effectively eliminate corrosion and more light abrasive requirements. Abrasive papers used to clean plane surfaces should not have sharp abrasives capable of embedding on their own on the cleaned surface.

The abrasives should not erode the cleaned surface to extend the materials’ life. The pads are usable on metals through a single pad for one metal to appropriately remove dirt products. Additionally, impregnated cotton wadding cleaners can be implemented to remove exhaust gas marks and polish corroded aluminum coatings (Amankwah-Amoah, 2021). It can also be applied on other metal surfaces to give out a high reflectance. The second step involves personal protection from chemical disinfectants by wearing rubber gloves. Moreover, working staff should maintain good health by wearing masks and disposable gloves. Such working garments should be disinfected by soaking them for half an hour in chlorine-based disinfectants to improve cleaners’ safety. The third step is appropriately using suitable cleaning agents to maintain the aircraft surfaces and cleanliness, especially the cabin, which should be disinfected by spraying chlorine with high frequency.

Most aircraft windshields are made from curved acrylic panels, so awareness of the effect of cleaning agents on the product integrity is essential. Therefore regular use of warm water with soft towel risk response strategies for cleaning helps maintain the aircraft surface and original color4. Moreover, sandwich corrosion test implementation will help determine if airline structure aluminum alloys are vulnerable to frequently applying cleaning products. Consequently, it measures the corrosion capability of cleaning agents when trapped on two faying surfaces as it is applicable for dry granular and liquid products (Gössling, 2020). There should be limited use of frameable disinfectants on small surfaces and implemented in well-ventilated areas only. Solvent and emulsion cleaning agents should be used for general cleaning purposes. Solvent emulsions are specifically beneficial when implemented to clean heavy deposits like carbon and oil.

Project Controls

Financial controls serve as a vital element of aviation organization success and survival. For instance, budgeting for cleaning materials and all maintenance product expenses will aid in working with a list of planned costs and revenues. When money is spent, statements are well-run to indicate the amount of money spent, how, and what it was achieved (Piric et al., 2019). The financial budget and reports display the overall performance of the aircraft company, thus capable of formulating fiscal management policies essential for identifying the existence of overlaps from the available information.

Consequently, loopholes are timely detected in the present control framework and eradicated. Additionally, such measures allow cash flow maintenance of aircraft companies; hence, cash inflows and outflows are efficiently managed and planned and contribute to streamlined operations. By ensuring the firm’s general operational efficiency with an effective financial management mechanism, productivity is maximized accompanied by direct, optimistic links with profitability. Therefore, those financial statements are utilized to monitor the aircraft’s progress when reporting to the board.

Document control, such as the Airplane Flight Manual (AFM), is a crucial practice in the cleaning activities of an organization as it ensures information is precise, available, and aligned with the nature of the cleaning. It serves as the lifeblood of aircraft operations because of fostering a smooth flow of information and transparency of plane cleaning activities and aids them in performing efficiently—productivity increases when employees quickly access cleaning documents when the document lifecycle is keenly controlled (Amankwah-Amoah, 2021). It streamlines the workflow from various departments by performing on the document with less labor. Moreover, a noble document control process guarantees that cleaning employees are working on the latest document version.

Since information is a typically precious commodity and the highest priority, security protocols should be set to protect critical information from unauthorized access. Vendor management aids in controlling cost, lowering potential risks linked to suppliers, and ensuring quality services. Researching suitable vendors and obtaining pricing details supports aviation companies enabling them to offer quality cleaning services (Deng, Santos, and Curran, 2020). By applying the best vendor management in place, aircraft will benefit from multiple selections of cleaning materials suppliers, leading to more choices and friendly prices. An airline training schedule and a checklist help ensure that all equipment is cleaned frequently.

Since vendors are incredibly different, managing relationships with suppliers is the key to achieving company-set goals. Therefore, setting standards before interacting with material supplies saves loads of time as well as money used. Aviation managers can overschedule employees with work ambiguity, yield tension, leading to overwork and burnout. Such scenarios necessitate change controls, which include delegation of cleaning duties to prevent timeline delays and increased budget stops. Effective control change leads to increased productivity, the flow of communication, disease resistance to change, and workplace morale, reducing stress and anxiety associated with unplanned work.

Conclusion

Overall, airline maintenance, more notably cleaning and disinfection services, require standard skills to offer quality service and protect passengers from infectious diseases due to lack of knowledge and awareness. The project aims for a hygienic environment for aircraft passengers and safety. Cleaning activities such as vacuuming the seats and scrubbing walls and floor prevents infections such as the COVID-19 pandemic from surfacing. Communication skill is integral to enabling easy completion of tasks and solving of arising issues. Significant risks such as spreading droplet-meditated virus can be mitigated by maintaining cleanliness and tidiness.

Chemical damages caused by inappropriate cleaning agents lead to expensive Maintenance. Therefore, using emulsion cleaners and synthetic detergents will aid in prolonging airworthiness. Highly flammable disinfectants such as alcohol should only be used in ventilated areas and not frequently. Although such disinfectants help kill germs, they are associated with cracking plastic surfaces, which is harmful to aircraft. Schedules ensure uniform delegation of duties as it creates role awareness. Change in the workplace influences works positively as it improves productivity and executes the flow of communication—essential performance indicators aid in attaining goals as it measures progress toward set objectives.

Project controls provide details that support making a timely decision and safeguard from surfacing risks. Document controls ensure that workers are supplied with the most current information, enabling them to provide quality services. Vendors’ management ensures delivering of cleaning material on time as ordered. Contract management helps maintain vendor relationships and service delivery for the efficient performance of aircraft.

Reference List

Al-Kasasbeh, M., Abudayyeh, O. and Liu, H. (2021) ‘An integrated decision support system for building asset management based on BIM and Work Breakdown Structure’, Journal of Building Engineering, 34, p.101959.

Amankwah-Amoah, J. (2021) ‘COVID‐19 pandemic and innovation activities in the global airline industry: A review’, Environment International, 156, p.106719.

Deng, Q., Santos, B. and Curran, R. (2020) ‘A practical dynamic programming-based methodology for aircraft maintenance check scheduling optimization’, European Journal of Operational Research, 281(2), pp.256-273.

European Union Aviation Safety Agency. (2020) Guidance on aircraft cleaning and disinfection in relation to the COVID-19 pandemic. Web.

Gössling, S. (2020) ‘Risks, resilience, and pathways to sustainable aviation: A COVID-19 perspective’, Journal of Air Transport Management, 89, p.101933.

Open Textbooks for Hong Kong. (2022) Example of a WBS. [online] Web.

Piric, S., et al (2019) ‘How does the aviation industry measure safety performance, Current practice, and limitations?’, International Journal of Aviation Management, 4(3), p.224.

Razab, M., et al (2018) ‘A review of incorporating Nd: YAG laser cleaning principal in the automotive industry’, Journal of Radiation Research and Applied Sciences, 11(4), pp.393-402.

Zhang, Y., Zhao, Q. and Hu, B. (2020) ‘Community-based prevention and control of COVID-19: Experience from China’, American Journal of Infection Control, 48(6), pp.716-717.

Zhao, B., et al (2019) ‘Microorganisms @ materials surfaces in aircraft: Potential risks for public health? – A systematic review’, Travel Medicine and Infectious Disease, 28, pp.6-14.