Executive summary

Coca-Cola has a long history that allowed the company to optimise its operations and achieve success on a global scale. Its operations and inventory management are rooted in a framework of operations management that is targeted at increasing the value of shareowners over time. This is done through the continuous cooperation with business partners that help the company distribute its products through a global system of brands. The key to the company’s inventory and operations management is a three-way collaboration between key suppliers, Coca-Cola, and customers that deliver beverages to end consumers.

Introduction: How Does Coca Cola Manage Their Inventory?

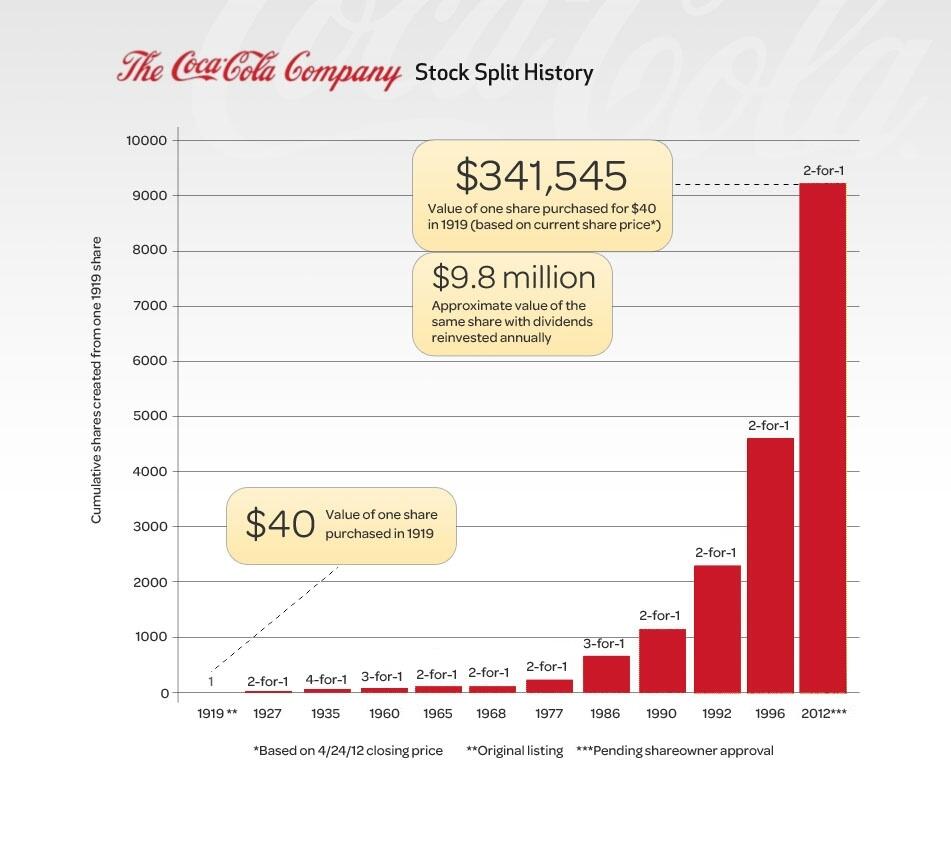

Coca-Cola is a world-renowned brand that produces non-alcoholic beverages. It was first created in 1886 by a chemist Dr. John S. Pemberton, who first used Coca-Cola (at that time, it was called Cola) as an oral medication. However, after Asa G. Candler purchased Coca-Cola, the shift in the marketing tactics led to the domination of the beverage in the non-alcoholic beverage industry of the twentieth century (Figure 1). This was accomplished through the incorporations of the Coca-Cola company in 1892 and the expansion of the distribution of the concentrated syrup used for making the beverage. First marketing efforts were associated with giving away free vouchers on drinks and equipping pharmacies with soft drink fountains that had Coca-Cola branding on them. Today, Coca-Cola is available to people in more than two hundred countries, while the company expanded the selection of products and now owns four hundred brands (Feloni 2015).

Coca Cola Operations Management

Operations management encompasses a range of procedures associated with the use of available productive resources, the system or production, design, product management, supply chain management, as well as other processes. Mostly, operations management is needed for considering the acquisition, development, and use of resources (including materials and ingredients) needed for delivering a product that customers desire. Coca-Cola, being one of the most popular companies in the world, has a complex operations management system, which includes a network of bottlers and production and distribution systems.

Thus, operations management at Coca-Cola is done with the help of multiple players. The company “does not own or control its bottling partners,” which means that the system operates through multiple channels (The Coca-Cola system 2016, para. 2). Coca-Cola manufactures and sells “concentrates, beverage bases and syrup to bottling operations, owns the brands and is responsible for consumer brand marketing initiatives” (The Coca-Cola system 2016, para. 3). However, when it comes to the production of the soft drink and other products that the company owns, it is Coca-Cola’s bottling partners that play the final role in manufacturing, packaging, merchandising, and distributing final products that are delivered to customers.

Regarding Coca-Cola’s 4Ps, the following aspects should be considered:

- The company has a wide product range;

- The marketing mix uses a 2nd-degree price discrimination approach – charging different prices for products in various segments;

- Worldwide distribution network: shops, restaurants, entertainment places, and others;

- Traditional and online promotion strategies.

Usually, bottling customers deliver final products to vendors that then sell beverages to customers. All bottling customers that purchase resources necessary for the production of beverages closely work with convenience stores, restaurants, grocery stores, amusement parks, movie theatres, and other parties that sell drinks to physical customers. Because such operations are localised, it means that the company works in partnership with its bottling customers for executing region-specific strategies.

When it comes to suppliers, Coca-Cola works with businesses that provide materials, ingredients, packaging, as well as other goods and services necessary for producing the final beverage. The company’s Supplier Guiding Principles are focused on maintaining high standards of quality and responsible workplace and environmental policies. At a minimum, the policies and practices established by Coca-Cola’s suppliers must be applicable to their national laws and regulations concerning such issues as forced labour, child labour, abuse of labour, wage and benefits, fair compensation, reasonable working hours, as well as safe and healthy practices of environmental preservations. It should be mentioned that Coca-Cola expects its bottling partners to meet the same standards of quality and corporate responsibility (Supplier and customer partnerships 2016).

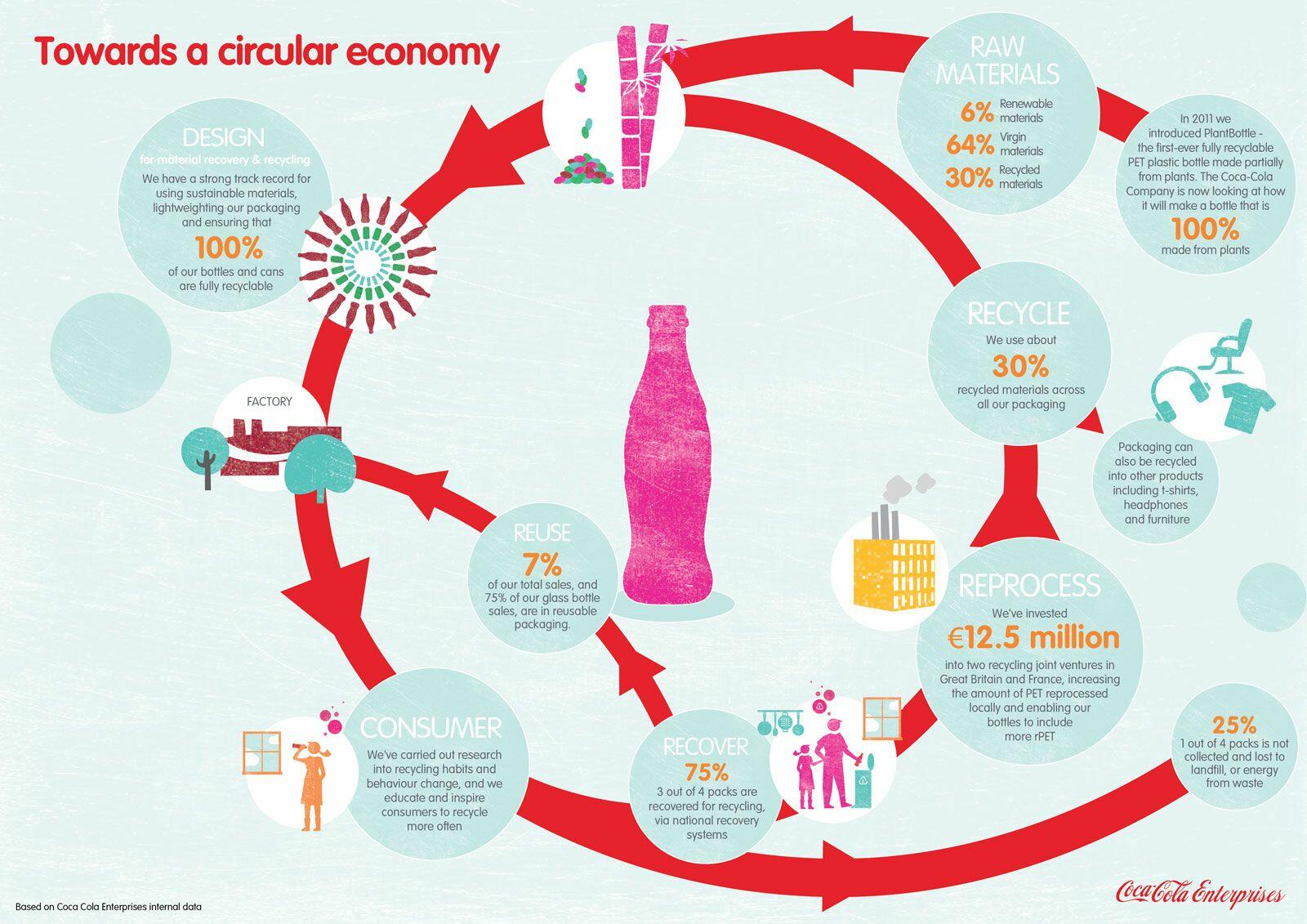

In the discussion about Coca-Cola’s operations management, it is also important to mention total Quality Management (TQM) as a fundamental approach that the company uses for achieving long-term success. Because the company has close relationships with suppliers and customers, TQM is used as a principle that ensures the participation of all relevant players in improving existing processes, services, products, and the overall culture. The global nature of the corporation encourages the company to use The Coca-Cola Management System (TCCMS) for holding all operations at the same high level of quality to ensure smooth production and distribution. TCCMS requires every supplier and customer of the company to establish, implement, document, and maintain high quality and safety standards: ISO 9001 quality, ISO 14001 environmental, ISO 22000 food safety, and ISO 26000 social responsibility (Lambert 2012). It is also important to note that the implementation of TQM has made it possible for Coca-Cola to consider the circular economy system starting from raw materials and ending with reused materials that are reprocessed to make new products, as shown in the diagram (Figure 2) below:

Coca Cola Inventory Management

It has been identified that Coca-Cola itself does not source ingredients and materials, nor does it produce beverages that are then delivered to customers. The established relationship between the company, its suppliers, and customers helps Coca-Cola to focus on marketing and expanding the shareholder value through delegating other responsibilities to its key partners. According to Journey Staff (2016) in the About our suppliers report for Coca-Cola, the company recognises that its suppliers are vital to continued success because it is them that deliver required services and products. Similarly to the relationships that Coca-Cola has with suppliers, the company has also worked with establishing a smooth chain of operations with vital suppliers, without whom the company will have to restructure its entire process of getting products delivered to final consumers. Key Coca-Cola customers include large international retail chains, local and global restaurant chains, as well as small independent businesses. It is important that the layout that Coca-Cola established allows the company to work with both small and large customers on an equal basis for creating a mutual benefit (Supplier and customer partnerships 2016). Overall, the relationships that Coca-Cola created with its key partners is the key to ensuring that the company’s products get delivered to consumers.

Conclusions

Coca-Cola is a company with a rich history and is recognised by consumers around the world. Starting as a small pharmacy brand, it evolved into a multi-national corporation that owns hundreds of brands. The key to the company’s inventory and operations management is a three-way collaboration between suppliers, Coca-Cola, and its customers. Coca-Cola purchases products necessary for the syrup production and sells the recipe and syrups to its partners that produce, package, merchandise, and distribute beverages among retailers, which then deliver beverages to end consumers. Currently, the company is focused on maintaining high standards of quality and corporate responsibility, aiming at reaching a circular economy.

Reference List

Feloni, R 2015, 7 brilliant strategies Coca-Cola used to become one of the world’s most recognisable brands, Business Insider. Web.

Lambert, G 2012, Coca-Cola and management systems. Web.

Staff, J 2016, About our suppliers. Web.

Supplier and customer partnerships. 2016. Web.

The Coca-Cola Company stock split history n.d. Web.

The Coca-Cola system. 2016. Web.

Towards a circular economy n.d. Web.