Sheathing

Definition

This is a layer of fiber material or a board that can be applied on rafters, studs or exterior joists of a particular building to strengthen its structure as well as to act as a water-proof coating to serve the building. Sheathing is applied on walls, corners and the roofs of buildings.

Roof Sheathing

Installation of Roof Sheathing

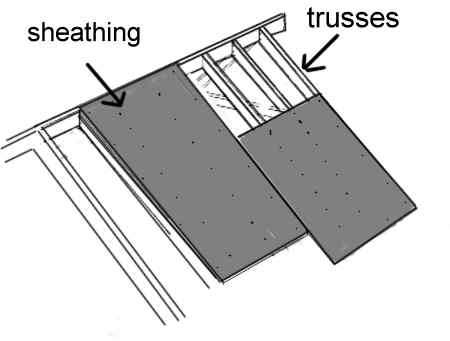

Sheathings are nailed into the roof structure in a fairly straightforward procedure. The illustration below indicates how sheathing is installed. Sheathing, however, needs to conform to the ASTM standard requirements regarding the nails that are applied on the gypsum board (Build Your Own Home 1).

Materials for Sheathing

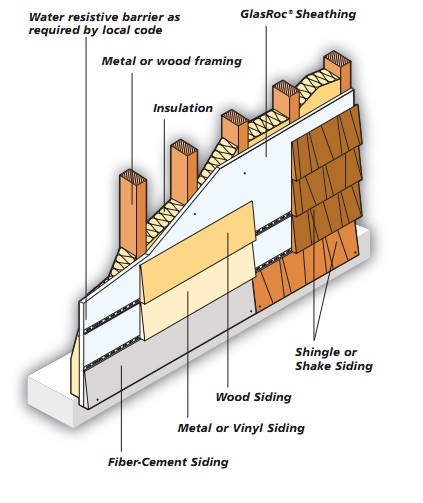

Regarding wall sheathing, plywood, oriented strand, fiber board and the wafterboard are applied since they allow for enough bracing, and they can also resist lateral loads from the wall. Consequently, polystyrene, rigid glass fiber, fiber board and the boards coated with asphalt are used for the exterior coat. Materials for sheathing also vary based on the country since various areas have diverse building codes that are tailor-made to meet their environmental requirements. In this project, glass fiber has been selected as the main material based on the Company Teed.

GlasRoc Sheathing

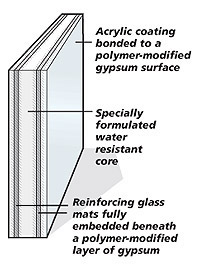

This is a sheathing material that is made by use of glass reinforced gypsum, and the gypsum is made water resistant by placing it under a paperless polymer and an acrylic coated surface. This is aimed at enhancing its durability by helping to hinder the delamination of the glass mat-facer. The GlasRoc board is designed for use in a roofing system that is mechanically attached because it can provide limited irritation and fire resistance as compared to other gypsum boards made of glass mat.

Merits of GlasRoc Sheathing

- Long-term protection to weather exposure for up to six months.

- Powerful water resistant surface that can prevent the penetration of water.

- Outstanding properties of fire resistance with several fire rated assemblies.

- Resistance to mold and mildew.

- High Compatibility with applications and the exterior wall system

- It can easily conform to the requirements of building design and codes.

- It is strong and flexible enough to bend over surfaces that are curved.

- Handling and to installation is carried out easily without any difficulty and this is especially the case with the lightweight sheathing. The sample of GlasRoc layers and exterior cladding is indicated below.

Common Alternatives

Apart from the gypsum board, the fiber board can also be used; fiberboard, otherwise also called black board, buffalo board or gray board sheathing, is considered to be an engineered wood fiber product. Just as gypsum boards, fiberboard is used on the exterior of a building, and it is nailed straight into wall studs. Fiberboard is installed with a plywood panel on the corners of the building to enhance rigidity. Fiber board can provide shear strength, particularly when the requisite nails are used. Despite being good on sound isolation, fiberboard does not prevent mold growth and wood boring insects.

In conclusion, from my analysis; GlasRoc is the best choice necessary, especially in an environment characterized with rain, snow and wind.

Steel Cutting

There are various methods used to cut steel. The normal desired angle should be orthogonal to the surface of steel sheet being cut. The main objectives of sheet cutting are to narrow a cutting slit, minimize energy consumption and to maximize the quality of cut edges as well as to limit the influence of heat.

Gas Cutting

Oxy-fuel is popularly referred to as gas cutting or oxy welding. This process can be used to connect two metals at the same time it can also be used to cut metals. In both processes of cutting and joining metals, heat at high temperatures is used. The high temperatures are obtained by using gas fuel (acetylene mixed in some right proportion of oxygen). The range of the heat produced in this process is 5700-5800 Fahrenheit. This temperature range is hot enough to melt steel among other commercial metals (Bhatia 3).

History

The common ways in which oxy-fuel processes tradition were “brazing, fusion welding, flame hardening, metalizing, soldering, stress relieving, cutting and bending” (Bhatia 3). Currently, oxy-fuel processes are common in the following processes “welding, brazing and cutting” (Bhatia 3).

How it Works

As pointed above, oxy-gas processes can be used both to cut and weld metals. The same apparatus shown above are used to for both processes. The only difference is that attachment. For the welding process, a welding attachment is attached but for the cutting process a cutting attachment is used. The cutting attachment is modified in such a way that it has “an additional tube for high-pressure oxygen, along with a cutting tip or nozzle” (Bhatia 43). The cutting attachment has more modifications as discussed below:

The tip is provided is provided with a center hole through which a jet of pure oxygen passes. Mixed oxygen and acetylene pass through holes surrounding the center holes for the preheating flames. The number of orifices for oxyacetylene flames ranges from 2 to 6, depending on the purpose for which the tip is used. The cutting torch is controlled by a trigger or lever operated valve. The cutting torch is furnished with interchangeable tips for cutting steel from less than one quarter inches to more than twelve inches in thickness. (Bhatia 43)

It is worth noting that depending on the thickness of the steel to be cut, the tip is adjusted accordingly to avoid costly damages. Precaution and double-checking is required when cutting using oxy-fuel process. The table below gives tentative ratios of cutting steel.

Advantages

- Compared to a cut off grinder, oxy-fuel cutting is faster.

- Oxy-fuel cutting can be applied in both thin and thick steel cutting unlike cut-off grinder and water jet cutting which are only appropriate for thin steel.

- Gas cutting can be carried out manually, robotically or by use of machines. The use of robots can make any shape of a cut required.

Disadvantages

The acetylene gas if not properly stored can be self explosive

Water Jet Cutting

Water jet is traced back to the days of coal mining in USSR and New Zealand where water was collected from the stream and directed towards a blasted rock face that carried loose coal and rock. Pressurized water was used to excavate gold rock from the mining surface and it was Russia that first attempted to cut rock with pressurized water where a water canon was used to generate 700 bars. The following is an illustration of water jet.

This is the cutting of steel using machines that can cut solids with a maximum pressure stream of water. This is aimed at keeping the spray coherent, and it was used during the ancient times. Water jet is used to cut thin and soft metals while abrasive jets can be used to cut hard metals. This operates in different modes of pressure ranging from 4.100 bars and 6.900 bars. It is available in two types namely: abrasive water jets and abrasive water suspension jets. Water jets are used in cutting the printed circuit boards, wire stripping, and food preparation, wood cutting and tool steel (Steel Cutting 1).

Advantages of Water Jet Cutting

- No heat generated hence it is used in circumstances where too much heat may alter the properties of the metal.

- It does not produce dust particles when inhaled unlike grinding or machining hence harmless.

- Its width is small hence minimal waste of material during the cutting process.

- It can be automated for maximum production.

- Water cutters are much lighter than the laser cutters.

Disadvantages

- Only small material can be cut economically, and the cutting rate can at times be reduced hence it can prove to be costly.

- It is not applicable in cutting thick parts of the metal since it can compromise dimensional accuracy.

- Taper can also be a problem when it comes to thick materials.

Slab on Grade

Slab on grade is available in two types namely: stem wall and monolithic. With monolithic foundation, you pour as a single structure with a thick perimeter. The perimeter holds the load of the exterior shirt, and it is approximately 8-12 inches thick whereas the interior of the slab is 4 inches thick. The concrete is always poured in single step unlike the stem wall that is poured in parts of three or four. Stem wall can be constructed on a concrete block and can be alternative to pour concrete. The various types of slabs are: the plain concrete slab, slab reinforced for shrinkage and temperature, the shrinkage compensation concrete and shrinkage reinforcement slab post-tensioned to offset shrinkage and slab reinforced for structural actions (Committee 58). Slab on grade is understood to be any concrete slab that is poured on a soil that is excavated as shown below.

Process of making a Slab on Grade

The first step is the preparation and the leveling of the ground area where the slab is to be constructed. The position should be attached with strings. The grid pattern of the channels is made where one of the channels lining on the perimeter of the building. The depth of the channels depends on the frost line and the opinion of the engineer. At this stage there should be an erection of a barrier that can aid in preventing moisture from tampering with the foundation. Furthermore, at this stage, plumbing pipes that pass through the foundation are laid down with a rebar that can strengthen the foundation.

The second stage is pouring the foundation: the quantity of cement poured depends on the size of the house. At this stage, a vibration tool can be used to clear away the air pockets that are applied along the foundation edge. After the pouring, the crew begins to level off the cement, and the final smoothing can be done. The ties are inserted mainly for the sake of sill plate. Tables are kept off the foundation.

The last process is the curing of cement; this varies based on the weather, and quantity of the water used and mixes of the cement. The normal curing time is seven days or one week. Next, the tension cables are tightened, and the forms removed. Since the boards do not leave a smooth finish, it is imperative that butter coat is applied to make the foundation appear smart (Home Inspections 1).

Methods of Approach, Advantages and Disadvantages

There are five methods of designing slab on grade namely: the Portland Cement Association, the Wire Reinforcement Institute, the U.S. army corps engineers, Post Tensioning Institute and the Shrinkage-compensation Technique (Toolbelt 1).

Portland Cement Association

Advantages

- No reinforcement required.

- It can apply computerized solutions.

Disadvantages

- Affected by high temperatures

- Effect of slab discontinuities cannot be included.

Wireless Reinforcement Institute

Advantages

- It can be computerized hence efficient.

- Only loadings on the slab interior are placed into consideration.

Disadvantages

- Expensive

Works Cited

Bhatia, Alex. “Fundamentals of Gas Cutting and Welding.” CED Engineering, n.d. Web. 2011.

Build Your Own Home. “Plywood sheathing for the small-home-plan.” Make My Own House, 2011. Web.

CertainTeed. “Exterior Building Products.” Certain Teed, 2011. Web.

Committee. “Design of Slabs on Grade.” Civil Wares, 1997. Web.

Home Inspections. “How is a Slab on Grade Foundation Made.” Your Houston Home Inspector, 2010. Web.

Steel Cutting. “Waterjet steel cutting.” Steel Cutting, 2011. Web.

Toolbelt. “Slab on Grade.” Toolbelt Building, 2010. Web.