Abstract

The applications of cross-docking have been widely implemented by distribution centres (DC) in western developed countries, especially in retail industry due to its benefits. The advantages include reduction of inventory carrying costs, enhancing the product range, combining the shipments and improving customer satisfaction. In contrast, the use of cross-docking in China is relatively limited.

For example, there are only a few retail goods DC that are practicing cross-docking in China. Despite the growing awareness and potential benefits of cross-docking, many distribution centres in China are still unwilling to adopt cross-docking because of several reasons and barriers. This research aimed to answer the questions: When and in what circumstances should cross-docking be implemented?

What challenges and barriers do distribution centres in China face? Through case studies on six distribution centres in China, this research essay will examine and discuss the challenges and successes experienced by distribution centres in China. P

rimary data collection method was qualitative, namely through interviewing managers and decision makers of the chosen DCs, specifically on their doubts on implementing cross-docking, the difficulties they faced in the implementation process and the success of cross-docking implementation, if any. Data from annual reports and published documents was also used.

This research explored to what extent cross-docking is suitable for DCs in retail industry in China, provided the means to understand the benefits of cross-docking assessed the current status of DCs in China and identified various cross-docking requirements.

In addition, this research aimed to fill in the knowledge and data gap that is necessary in analysing the current utilization of cross-docking in China by acquiring DC managers’ opinions on cross-docking.

Publication of this research would benefit DCs in China, as this research will help managers better understand the technicality and benefits of cross-docking and will make them more competitive in terms of cost efficiency and customer service standards.

The success of cross-docking implementation by DCs in China could improve trust and information sharing among suppliers and manufacturers, which could in turn improve supply chain management as a whole.

Introduction

It is well known that cross-docking used in Wal-Mart has achieved great effect. Wal-Mart’s achieved economy of scale and by purchasing goods by full truckloads, it has avoided unnecessary inventory and handling costs (Stalk and Lachenauer, 2004). Wal-Mart is the first logistics company that established ‘cross-docking’ warehousing and has redefined supply chain management (Stalk and Lachenauer, 2004).

In a typical cross-docking system, goods arriving at a DC from manufacturers are directly delivered to retailers with very little or no time in storage. By not storing inventory, logistic operations become significantly more cost-effective (Reyes, 2006).

Various studies have shown that adopting cross-docking strategy has several benefits, namely lower transportation costs, less warehouse space required, better service level and lower inventory carrying cost (Napolitano, 2008)

In the traditional distribution systems that are still being used by more DCs in China, goods are often managed and stored in distribution centres by suppliers and will be shipped when the orders can make full truckload (FTL) (Gottarna, 1994). On the other hand, some Chinese companies have begun operating cross-docking distribution centres using simple experience-based cross-docking methods.

According to the research done by O’Neill, Scavarda & Yang (2009), only 22 per cent of China DCs provide next day service while almost 70 per cent of DCs in the United Kingdom achieved the same level of service. This represents a 50 per cent gap between UK and China DCs. Futhermore, there are still 15 per cent of China DCs that need over five working days to deliver their goods to customers.

About 55 per cent of the UK DCs achieve the 2-5 days lead-time whereas 65 per cent of China DCs report the same (Baker, 2004). There is also seldom same day lead-time in China DCs, while 20 percent of UK’s DCs can provide same day lead-time.

From the above data, we can see that most DCs in the UK can achieve the delivery tasks in one day. However, most Chinese DCs often take more than two days to deliver after receiving the order. The major cause of this difference in efficiency between China and the UK distribution centres is the poor synchronous exchange of information.

On average a UK DC allocated 18 per cent of their area to goods in/out, whereas only 9 per cent of site area was allocated by a Chinese DC to undertake the same activity. This may also be explained by the presence of cross-docking activity in Baker’s study but the lack of it in China DCs. Without cross-docking, China DCs have no choice but to spend extra effort and resource to achieve ‘fast-moving goods’ and optimise space use.

Baker (2004) noted that on average only 5 per cent of total throughput was conducted using cross-docking in large DCs, indicating that sites utilised space for goods movements from inventory rather than throughput. Apte and Viswanathan (2000) also points out that cross-docking can significantly reduce the cost in transportation without increasing the inventory level or decreasing customer service level.

Emmett & Crocker (2006) pointed out various challenges faced by the DCs in China. One of the challenges is the unwillingness of all parties to share information. Due to lack of trust, retailers are unwilling to vertically share sensitive business information with suppliers and suppliers are also unwilling to share data, especially if other suppliers are also competitors.

The second challenge faced is poor Information and Communication Technologies (ICT). Cross-docking practice requires retailers to have IT infrastructure to implement auto-replenishment process such as EDI and other Web based process.

In addition, retailers face the risk of stock-outs if DCs could not deliver goods on time due to bad implementation of cross-docking. Furthermore, due to the low labour cost in China, most DCs do not consider cross-docking as an imperative need.

There is little or no quantitative data and published works on cross-docking practices in China. Therefore this research will utilize a qualitative data collection method, namely interviewing China DCs managers to identify the benefits they reaped, they challenges they faced and their doubts with regard to cross-docking adoption.

Research Questions

The following questions are used to guide data collection and discussion:

- Why cross-docking is not widely adopted in China? What are the problems or challenges that DCs in China will potentially face if they adopt cross-docking?

- How do cross-docking benefits distribution centres in developed countries? Will China attain similar benefits if cross-docking is adopted?

- Is cross-docking necessary for DCs in China? Is it the right time for implementing cross-docking? What are the requirements and how can a China DC shift their operation style from traditional warehousing to cross docking?

Research Objectives

The following are the research objectives:

- Assess the current practice of cross-docking for distribution centres in developed countries through the media, journal articles and books.

- To find out the reasons why DCs in China are unwilling to practice cross-docking and to identify the challenges of cross-docking for DCs in China through interviewing managers of China DCs.

- To evaluate the benefits of implementing cross-docking for DCs in China through interviewing managers of China DCs.

Scope of Study

The scope of study applies to distribution center of retailing industry operating in China which in this research includes a multinational DC, a Chinese DC that had been partly cross-docking and another Chinese DC that is still traditional warehousing distribution center with medium mechanization.

These DCs provide wide range of products so the research is primarily focused on Fast Moving Consumer Goods (FMCG) which are characterize by quick shelf turnovers and everyday distribution such as dairy products, bread, cake, vegetable, fruit and other foods.

Rationale for the Study

Following global competition, logistics has become more complex and required high level solution capability. How to increase service level and decrease inventory level and the cost in whole logistics process is the major topic on the supply chain. In order to concentrate the core business or make more efficient to do business, many companies has adopted 3PL to help them to manage some non-core business area.

If fact, the market of outsource services in China is estimated to be $84 billion, it will be continue increasing and reach more than double by 2010. In currently, Third-party logistics has been acknowledged that it can decrease traditional logistics costs and help companies to handle complex tasks. Distribution Center Distribution center is the most frequently used logistics service (Gourdin 2006).

There are a number of international retailers who utilize cross-docking in China, such as Cola, Wal-mart and 7-Eleven. However, in China the most common DCs adopt traditional warehousing method. This is the huge gap of utilization of cross-docking between international retailers and domestic retailers.

According to Chopra & Meindl (2004), Cross-docking is appropriate for large demand and can be forecast products. Moreover, DCs also are required that economies of scale in transportation can be achieved on both the inbound and outbound side. It implicate that DCs in China could also consider develop cross-docking as their new competitive strategy.

Literature Review

Current usage of cross-docking in western countries and in China

Hybrid model of target-oriented & source-oriented cross-docking

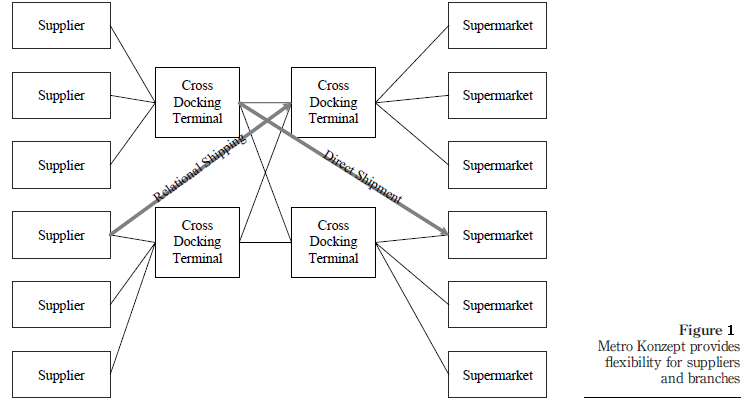

Kumar (2008) introduced a new hybrid of source-oriented and target-oriented cross-docking. It uses more terminals to avoid frequent stops for delivery trucks, multiple drop off for suppliers and under-utilized trucks (Figure 1).

Combing the advantages of two traditional models, the new hybrid model realizes that suppliers can ship products directly to retailers everyday and retailers can order and receive products directly from suppliers daily. It also increases the efficiency of deliveries in terms of dual transportation solution.

Wal-Mart’s current practice

Chopra and Meindl (2004) introduced the current practice of Wal-Mart who first invented cross-docking distribution system. Wal-Mart delivers about 85% of its merchandises by using this system. When it receives products from suppliers, firstly the product is held in inventory temporarily at the DC because the lot size on the inbound side is much larger than the sum of the lot sizes for the store served by the DC.

Then DC cross-docks the product on inbound trucks by breaking each inbound shipment into small shipments that are then loaded onto trucks going to each retailer. It is a distinguishing feature of cross-docking that each inbound truck contains products from a supplier for several retailers while each outbound truck contains products for a retailer from several suppliers.

Status of DC in China

According to research of Chin, Tummala, Leung and Tang (2004) there are 300 large and main distribution centers across China but distribution from suppliers to retailers is very immature. Those large DCs that have more than 40 vehicles, however,only 13 per cent of vehicles (171.31 boxes) were used in transferring goods to large retailers and subsidiary transferring stations.

Tang (2004) specifically noted that ‘vehicles are used inefficiently, as the average loading across types is 61.12% per trip’. This indicates there is an opportunity to improve distribution system and transportation efficiency by utilizing cross-docking.

In China most common and traditional DCs have warehousing function more than cross-docking. Jonsson (2008) criticized that traditional warehousing DCs play a consolidating role to deliver products and control inventory. Such kind of DCs only has a medium level of mechanization.

Benefits of developing cross-docking

Time saving

The DC cross-docks the product on inbound trucks, thus when product packages arrive at the DC, they are sorted and consolidated, and reloaded to go to retailers immediately (Stalk & Lachenauer, 2004). It minimizes the handling and sorting activities and the unnecessary waiting time at the cross-docking terminals because the product does not have to be moved into and out of storage.

All products can be sorted and loaded on the trucks (Kinnear, 1997). Cross-docking is usually used in a large distribution system where numerous vehicles are engaged in delivering and taking products at any time, thus it can decrease order cycle time (Sung and Song, 2003).

Cost saving

Jayaraman and Ross (2003) proposed that cross-docking is the best way to reduce cost in terms of minimizing the costs to transport multiple shipments of products from suppliers to retailers, making sure vehicles be a fully-loaded-truck and having efficient production and logistics schedule. It also minimizes warehousing and scale of inbound and outbound flows.

Low inventory

Luton (2003) indicated that cross-docking needed little inventory to be held in the DC because the product could be shipped from suppliers to retailers directly without storing in the DC. Specter (2004) also mentioned similarly that inbound flows are directly transferred to outbound flows with little warehousing.

Waller et al. (2006) introduced cross-docking with echelon inventory position to the DC because the system-wide inventory levels as a result of cross-docking could improve the inventory control of retailers.

Economic benefits

Firstly, with cross-docking, product flows faster in the supply chain. Cross-docking favors the timely distribution of products and a better synchronization with the demand of retailers where the distribution center essentially acts as a high throughput sorting facility (Luton, 2003).

Secondly, Waller et al. (2006) proposed that cross-docking will achieve the target customer service level in terms of the amount of shelf capacity that was impacted by store and distribution level of the DC.

Thirdly, as mentioned above, cross-docking leads to the reduction of order cycle time, thereby improving the flexibility and responsiveness of the distribution network. Sung and Song (2003) considered cross-docking and an integrated distribution network design as a strategic solution to compete with rivals.

Why few cross-docking DC in China

Despite these proven benefits, there are still not many DCs in China are cross docking today. Even for those large DCs, cross-docking only occupies a small percentage of their shipping volume. One reason is the difficult anticipation of demand. Due to little inventory, suppliers have to manufacture products according to retailers’ orders, which asks the retailer to accurately anticipate the customer’s demand.

This task is a big challenge for the manager of the retailer (Napolitano, 2007). Zhang and Huang (2004) mentioned that it is very difficult for supervisors in the DC to change their way of thinking. For example, supervisors need to transfer labor from warehouse to trucks.

Most of supervisors still cannot operate the cross-docking. Many of managers of DCs still think that traditional distribution center is more suitable for small DCs and retailers because handing operation is more flexibility for them to change order and they do not need to worry the unpredictable demand fluctuations (Napolitano, 2009).

Challenge of implementing cross-docking

Developing the cross-docking seems necessary to improve exist distribution system in China. Report by Maltz and DeHoratius (2004) indicates that the trend is towards more added value services and cross-docking activities. But there are several unavoidable challenges in the process of transferring to cross-docking distribution centers.

Suitability of Cross-docking

According to study of Yan and Tang (2008), there are two types of cross-docking model for new cross-docking DCs: pre-distribution and post-distribution cross-docking. In pre-distribution suppliers process and package the product and then load them onto truck at the dock to deliver to retailers directly. While in post-distribution, the DC need to process and package the product and deliver.

For those DCs that just begin the cross-docking, pre-distribution is a good option in terms of the DC take less responsibility and cost less. However, the retailer prefers the post-distribution cross-docking because it could pool the risk during the period from the supplier to the cross-dock.

The suitability of cross-docking should be examined by analyzing the decision making process based on the expected cost, and comparing the performance with the DC system.

Volatile marketplace

Rapid changing marketplace brings about three problems: the first one is difficult to predict the customer’s demand, which is a risk for the DC manager (Christopher and Towill, 2002). Cross-docking asks little inventory and storage in the DC, which cause suppliers do not have enough products to respond to unpredictable demand peak (Baker & Halim, 2007).

The second problem is asks the DC to focus on its service, and in particular responsiveness to support retailers to satisfy their customers and bring feedback of products to suppliers or producers (Mason- Jones et al., 2000). DCs not only need to cross-dock products, also cross-dock information in today’s marketplace.

Thus the third problem is that cross-docking asks information shared in the supply chain where partners can facilitate their abilities to jointly meet the users’ needs (Spekman et al., 1998). However, due to serious competition in China, suppliers and retailers are unwilling to share any information on business (Stank and Goldsby, 2000).

Dock door assignment

Vis & Roodbergen (2007) concerned the dock door assignment as an important planning problem in cross-docking centers. One of the important benefits of cross-docking is saving time, thus the DC needs to set up dock door to assign incoming and departing trucks as efficiently as possible, in order to avoid congestion and minimize workers travel time and waiting time.

Due to different area distant, product settlement and product processing between cross-docking and traditional warehousing DC, design of dock door is also quite different, which means transferring to cross-docking probably ask the DC to change the building design, location of products and even the location of the DC (Bartholdi & Gue, 2000).

Truck dock assignment problem

Miao, Lim and Ma (2007) noted that one of the key activities at cross-docking is the dock assignment for trucks. Trucks are assigned to docks for the duration of a time period during which the cargo and trucks are processed. Dock availability and times of arrivals/departures for each truck usually change due to operational contingencies such as accidents and traffic problem.

Such changes have lead to delay of other trucks because docks may become unavailable when required. For most of new cross-docking DCs, it is a usual situation that docks are occupied and the arriving trucks have to wait. In order to avoid this situation, it is necessary to schedule these docks well in order to increase the utilization and achieve better performance of the transshipment network.

Research Methodology

The research methodology is using qualitative data: interview and review of published documents to gather the data and information for analysis.

The research looks into the improvements in supply chain because of cross-docking systems adopted by retailers in China and reports on the results of a qualitative study, employing the case study method.

In an attempt to clarify the nature of the problem, identify the relevant variables, and show relationships among variables, a case-study methodology was deemed appropriate in order to dig deeper reasons of refusing cross-docking and current realistic difficulties in some specific DCs in China.

Interview is also an important approach in this study to reach the real thought and worries of DCs’ managers in China. Semi-structure interview is more open and flexible than questionnaire to find out the more issues in DCs in China. The interviews conducted with the managers of the six distribution centers present the basis for a theoretical framework, which provides the scope for further research.

Data and information obtained from the interview and documents will be summarized and formulated the current status of cross-docking of retailing industry in China. Then the results will be discussed with exist theories and research and compared with developed countries.

Once the cross-docking is adopted by DCs of retailing industry in China, it is an opportunity for supply chain management in Chain to improve their strategic SCM such as share information, customization. A design suggestion will be developed by incorporating the findings from the interview and the document information collection.

Interview Question design

The researcher will collect all operation data from DCs’ annual report and distribution department. Interview will be conducted during the case study. Any questions on case studying will be interview questions. These questions are separated into two groups. Group I is for DCs that is using cross-docking, the other is for those never uses it. Two groups are consisting of questions on the scope of the centre, profits, and staff.

Target population

Given the range and diversity of destinations, many would have represented suitable case material for this study. This project would choose three type DCs. One DC has relative complete cross-docking system in order to study its operation and benefits of cross-docking in China. This DC must be a branch of any multinational distribution centers. Another one is a DC that is beginning cross-docking.

The process of their decision on usage of cross-docking and their analysis of cost-benefit would be helpful for studying DCs’ future in China. Last one would be a DC that never thinks about cross-docking. It must be a small distribution center and even with lots of handling work. This DC would bring the realistic difficulties for those small DCs and answer that whether only large DC could use cross-docking.

These three types of DCs would be compared on cost and benefits. Although clearly different in terms of distribution channel, they share severe competitive conditions in their retail industry in China and all of them have similar suppliers with a strategic imperative to enhance existing distribution performance.

Data-collection method

Initial contact will be established with chosen DCs, and thereafter a process of “snowballing” will be used. The complexity and dynamics of the service, and the need to obtain a holistic overview of the implantation of cross-docking in China, a qualitative approach is deemed particularly suitable. One-to-one, in depth interviews will be conducted with representatives and suppliers and retailers of the six DCs.

The thematic priorities for the interviews will be derived from an extensive review of the literature and the field experience. The interviews will be semi-structured and conducted in an informal manner by the author of this proposal.

All interviews will be tape-recorded and transcribed with analysis of the research findings. All interviews will be conducted in the same time period and be subject to identical briefings, prior to and after the interviews had taken place.

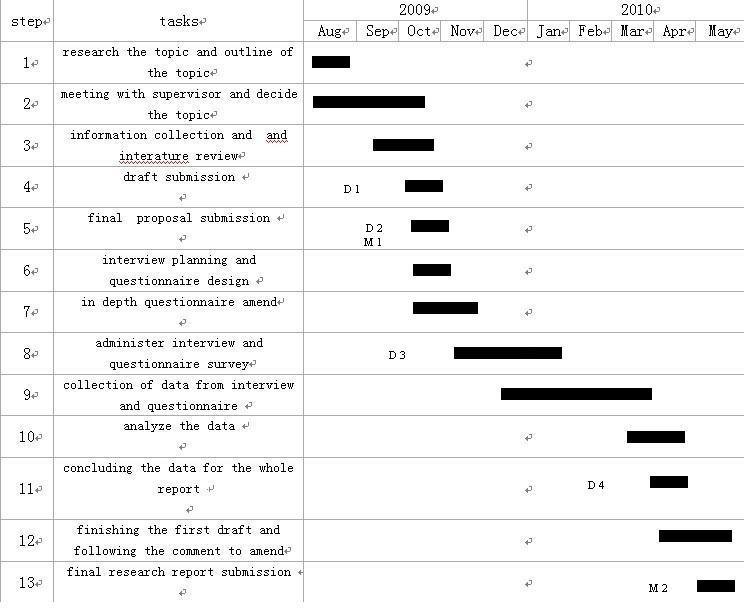

Implementation Program

This research consists of tasks and activities from information collection to the formal report writing. The tasks can be spread over to different parts as the data collection and interview need to be arranged by the target companies. The length of completion ranges from a few days to several weeks.

The Gantt chart in the following page describes the main activities, schedule and progress of this research program.

Deliverables:

- D1 First Draft of Research Proposal

- D2 Final Research Rroposal

- D3 Administer Interview and Questionnaire survey

- D4 First Draft of Research Paper

Milestones:

- M1 Submit Research Proposal

- M2 Final draft of Research paper submitted

Results

The objective of this chapter is to present the findings of the current research on the adoption of cross-docking in the retail industry of China and its challenges. The research also covered the improvements observed in the industry because of the adoption of cross-docking.

Cross-docking (Andel, 1994; Kurnia and Johnston, 1999) is the method that is being used in the retail industry for the distribution of goods from a large number of manufacturers to a large number of customers through a centralized distribution center.

As an innovation in the field of supply chain management, cross-docking illustrates new approaches to improve the efficiency of the supply chain and reduction in buffer stock keeping by the retailers. The research on the status of cross-docking in China was evaluated using qualitative research method of interviewing the managers of some of the distribution companies operating in China.

The retail companies were chosen in such a way that some of the companies have already adopted the system of cross-docking either partially or in full scale and realized the benefits of it. Some of the retailers were still using the traditional pick and pack method of handling their merchandise.

The interview questions were designed in such a way that the managers were able to provide complete information on the system of handling stock items in their respective organizations.

The interview questions covered areas of logistics and inventory management, business processes in the chosen organization, inter-organizational relationship with the suppliers, deployment of cross-docking method and changes in the product specifications for making effective use of cross-docking method.

Companies using Cross-docking Method

The questionnaire used to interview managers of the selected companies is presented below.

Interview Questions

The following is the topical guide for the interview conducted with the customer organizations with respect to their cross-docking activities.

- What is the policy of your company in respect of inventory management and the extent to which you can get the cooperation from the suppliers in managing your inventory efficiently?

- Does your company follow cross-docking system? If yes, how does your company plan the transportation and delivery schedule of the product items and to what extent the delivery of the product items depend on the ability of your suppliers to deliver in the right package size and in time?

- What is the system of purchasing currently in practice in your company? How do you choose your suppliers to meet the requirements of cross-docking?

- What is the policy of the company in involving the suppliers in implementing the cross-docking method in managing your product items?

- What is the level of communication from the suppliers; is it adequate in your opinion to enable you to implement cross-docking?

- How the effectiveness of supply chain management measured from the standpoint of the suppliers’ role and responsibility; Has the company established any benchmarks to measure the performance of the suppliers?

- How soon and effectively the suppliers are able to perceive the changed requirements of the individual store units, and what is the process of communicating the changed requirements to the suppliers?

- What is the time lag between the changes in demands of individual store units are communicated and the changed product is delivered by the supplier?

- Whether the changes in the structure and culture of the company are communicated to the suppliers; Do the suppliers in turn communicate the changes in their organizations to the company?

- Does the company insist on the suppliers to bring about changes in their organization corresponding to changes in your own organization; what is the response from the supplier organizations?

- Do you think adopting the cross-docking affect the supply chain relations; If so how and to what extent?

- Is there a program of training the suppliers to make them suitable as your supply chain partner to meet the cross-docking requirements?

Six companies, which have adopted the system of cross-docking were contacted for interview, for choosing three of them to respond to the request for interviewing. Out of the three selected companies, one was a distribution center and is a subsidiary of a super market chain.

The other company was a Chinese largest home appliances and consumer electronics Retail Chain Enterprises and the third one was operating in the food industry. Thus, the three companies represent all sectors in the retail industry.

Hualian Distribution Center

The Hualian Distribution Center is a subsidiary company of the Hualian supermarket. This distribution center is meeting the product requirements of 162 supermarket chain stores functioning under the banner of Hualian Supermarket in the Shanghai region. The logistics manager of the company represented the company in answering the interview questions.

Based on the interview with the logistics manager it was observed that that most of the retail locations of the supermarket were having individual warehouses to stock the goods. The warehouses were of the area of 100 square meters and the smallest one having fifty to sixty square meters.

The retail locations used to store different products for a longer time and this led to the product items becoming unusable because they catch mildew. The rate of damaged was much higher and the goods lacked freshness leading to customer dissatisfaction. When the warehouse size is larger, there was bound to be more overstocking and higher number of products damaged.

In order to obviate this difficulty, the company adopted the system of cross-docking. The company adopted substantial changes in it’s approaches towards improving the efficiency of the supply chain so that the company would be able to derive the best advantages of cross-docking. Originally, the company was taking centralized decisions on ordering and purchasing and the policy decisions were taken at the corporate head office.

The company had to change this policy for adopting the cross-docking. In effect, Hualian changed the system from “supply chain” to “demand chain”. This system implies that there would the “pull” from the customer for products rather than the “push” of the products by the company in to the system. The customers are in a position to order the goods, when and where needed.

When the company used the system of cross-docking, there were tremendous improvements in the operations of the company. The company created the new distribution center to handle the individual product requirements of all the retail locations. Hualian Distribution Center is functioning with an operational area of nearly 20,000 square meters to handle the cross-docking of the products.

This warehouse area uses the shelf stacker to store the goods and a computerized tracking system for the location and quantities in stock. This system enables easy identification and delivery of the requirements from the individual store locations.

Apart from the warehouse area, the distribution center has also a sorting field operational area of 4,500 square meters with more than 200,000 boxes of stock with more than 8,000 stock keeping items. The computerized system of inventory management manages storage of goods, registration, selection and statistical information on the product items.

The distribution center is equipped with 61 delivery vehicles to meet the delivery demands of the individual stores. With years of practice, the supermarkets and the stores management has improved largely to economize on the warehousing cost of the individual stores.

Because of the adoption of the cross-docking system, the Hualian distribution center was able to reduce the lead-time for delivery of goods from three days to 24 hours to meet the requirements of the individual stores. The distribution center was also able to meet the small quantity requirements of the stores.

The efficiency in the operations of the distribution center was enhanced following the setting up of a picking operations group. Depending on the requirements of the retail store locations of different product items the number of employees would be allotted to repack the goods and arrange for delivery to the individual locations.

With the changed strategy for managing the inventory, the company made drastic changes in its ordering pattern and instructions to the suppliers. The suppliers had to redesign their packages from bigger packages to smaller packages. There was a sharp increase in the number of suppliers to 400 catering to the requirements of more than 1400 product items requiring smaller package.

The adoption of cross-docking had also helped the company to improve upon the profitability of the company by reducing the inventory turnover days. The inventory turnover days were reduced to 15, while the international standard for the retail industry is 18 days.

Suning Appliance Company Limited

Suning Appliances Limited is one of the largest electronic retail stores in China operating through its franchised retail units. The company supplies electronic goods like color televisions and audio and video products.

The product items include other household items like washing machines, refrigerators and small household electronic items. The company also deals in air conditioners, telecommunication equipments and a wide range of electronic items. As of December 31, 2009, the company operates 941 retail stores throughout the country of China (Wright Reports, 2010).

With its operations extended across China, Suning found value in cross-docking. The growth of the company has been a factor that enabled the company to adopt the system of cross-docking. The company was under pressure to seek new ways of adjusting to increased customer demand and at the same time the company did not want to increase the inventory at the retail locations.

Being bulky in nature, the products of Suning required large storage space and with the keeping of inventory at the store level increased the cost of keeping the inventory. As an ultimate result, cross-docking provided the company a significant prospect of reducing cost of its supply chain and speed up the speed of exchanging inventory.

Cross-docking enabled the company to get its products to the customers more quickly and economically. The method has helped the company improve its supply chain, reduce their risk profile, improve the services to the end customer, and enhanced their earnings. The company has opened the first circulation of the second-generation logistics base.

The industry characteristics like introduction of newer varieties, different traditional commodity circulation requirements, bulk nature of the household appliances, hybrid models, store delivery high requirements, work intensity and other characteristics made the appliance distribution industry focus on the domestic logistics and introduced cross-docking as the response to meet the increased shift in customer demands.

According to the logistics manager in charge of Zhejiang, Hangzhou, the second-generation logistics base covers an area of 50 acres. The warehouse is located in about 10,000 square meters. The total investment runs to thousands of Yuan. The second generation of the logistics consists of three-dimensional mechanical shelves and electric pallet trucks.

In order to help the cross-docking process various equipments like hydraulic pressure cart, hydraulic platforms, folder lock vehicles and other advanced automatic machine tools are used. The efficiency of the cross-docking system is enhanced by the use of integrated information management system platform.

The company has procured and implemented SAP’s WMS (Warehouse Management System) inventory management system to manage the cross-docking and distribution. The company has also installed GPRS, the unified global vehicle positioning system.

In order to bring cross-docking into practice, the company had to face a number of challenges in terms of making sweeping changes in its ordering and purchasing system. Originally, the company has been following a centralized system of ordering and purchasing making an estimation of the likely demands of different products from the customers.

With the increase in the number of franchisees, product items and increased number of customers the company found it difficult to make precise estimation of the demands of the customers. Because of this, in certain years the company had to carry a huge inventory of various household appliances resulting in heavy cost of carrying the inventory including warehousing costs and interest on the cost of inventory.

Apart from the inventory-related issues, the company was facing th issue of delays in customer deliveries leading to customer dissatisfaction. The company was under pressure to find a suitable alternative method to reduce the inventory level and meet the customer demand swiftly.

The company realized that by cross-docking the products there is the possibility that the products can be delivered directly to the customers without having to warehouse the products.

For accomplishing the introduction of cross-docking the company changed its ordering and purchasing to become a decentralized affair and authorized the retail location heads to order their requirements directly to the manufacturing locations.

By creating five distribution centers to cater all the 900 and odd retail locations the company could successfully implement the cross-docking in the company which not only helped reducing the inventory cost but also in improving the revenue and earnings for the company.

To make the cross-docking system efficiently the company had to invest heavily in the inventory management system and on improving the communication among the retail locations and manufacturing locations. The company acquired the sophisticated SAP’s WMS (Warehouse Management System) to take care of the information requirements of cross-docking system.

The company made suitable arrangements in the manufacturing locations to combine smaller packages to be delivered in one large package to the particular distribution center catering to the retail location, which ordered the product items. Initially this involved more work at the manufacturing locations.

Once the systems were established and they came into practice, it was lot easier for the manufacturing locations to combine the orders and deliver to one common distribution center. Earlier they were shipping to different retail locations involving more number of shipments increasing the paper work at the manufacturing location.

With the introduction of electronic data interchange, the passing of the information on the shipments and sending the documents electronically has become much easier reducing the work load at the manufacturing locations as they have to make only one shipment to the distribution center.

General (Xiamen Tongan) Food Industry Company Limited

There has been a rapid change in the retail food sector of China with the increased demands of the consumers for convenience and quality in food products. This has resulted in the emergence of a highly competitive food retail sector, which features modern supermarket chains offering wider choices in products and branded items.

The continued evolution of the retail sector in China has important implications for both the foreign and domestic retailers to reach the consumers. The complexity of the food distribution system presents its own challenges to even large players in the industry.

The efficiency in the logistics system has been the main source of competitive advantage of General (Xiamen Tongan) Food Industry Company Limited. The company’s growth and success depended entirely on the distribution of its merchandise partially using the cross-docking method. The adoption of cross-docking has enabled the company to restrict its inventory growth.

The company was in a position to keep a comfortable in-stock position and fill the store with a number of new products. While the company’s revenue increased by 30% during the year 2009, its cost of managing inventory went up only by 3.8% during the year.

The company can realize most of the success by making investment in creating a distribution center, which provides ample scope for the growth in the business. The company has heavily invested in the cross-docking inventory system. Cross-docking has enabled the company to achieve higher economies of scale, which ultimately resulted in significant reduction in the costs of its sales.

With the cross-docking system in practice, the company was able to deliver products to the stores within 48 hours of receiving the requirements and the company was able to deliver the products without having to inventory them in its distribution center.

This enabled the company to provide new product items in the stores, which is approximately three times much faster than the competing businesses. The company was able to exercise its buying power through its bulk purchases and arranging for the distribution of the goods on its own.

Companies that has not adopted Cross-docking

In order to select three companies, which have not implemented the cross-docking system, totally eight companies were contacted for conducting the interviews. Finally, only three companies preferred to respond. The managers of these companies were interviewed based on the questions

The following are the interview questions for the customer organizations who have not adopted cross-docking with respect to their logistic activities.

- What is the policy of your company in respect of inventory management and the extent to which you can get the cooperation from the suppliers in managing your inventory efficiently?

- What is the system of purchasing currently in practice in your company?

- What is the policy of the company in involving the suppliers in managing the delivery of your product items to individual stores?

- What is the level of communication from the suppliers; is it adequate in your opinion to enable you to deliver the products in time to the customers?

- How the effectiveness of supply chain management measured from the standpoint of the suppliers’ role and responsibility; Has the company established any benchmarks to measure the performance of the suppliers?

- How soon and effectively the suppliers are able to perceive the changed requirements of the individual store units, and what is the process of communicating the changed requirements to the suppliers?

- What is the time lag between the changes in demands of individual store units are communicated and the changed product is delivered by the supplier?

- Whether the changes in the structure and culture of the company are communicated to the suppliers; Do the suppliers in turn communicate the changes in their organizations to the company?

- Does the company insist on the suppliers to bring about changes in their organization corresponding to changes in your own organization; what is the response from the supplier organizations?

- Do you think adopting the cross-docking affect the supply chain relations; If so how and to what extent?

- Is there a program of training the suppliers to make them suitable as your supply chain partner to meet the delivery requirements?

The findings from the interviews conducted with the three companies are presented in the following sections.

Shanghai LOTUS General Merchandise Store (GMS)

Shanghai LOTUS General Merchandise Store is one of the popular retail chain stores in the Shanghai region having 21 stores in Shanghai and 77 in the China mainland. The business of the company is to provide merchandise including groceries, fresh vegetables, clothing and furniture.

The retail stores of this chain keeps stock of all the items dealt with by international retail chain stores catering to the demands of the domestic customers. The company strives to provide high quality products at competitive prices.

The company manages its inventory needs of all its store locations through a distribution center located in Shanghai. The distribution center has 50,000 square meters area to handle the logistics of all the product requirements of the stores. The distribution center handles all the commodities including fresh goods.

With the sophisticated information system the company is maintaining, the distribution center will be able to know exactly the number of stock items in any retail store including the quantities. The information system known as the “retail link system” also provides the company sales information about the quantities and value of goods sold during any day or week.

The company prefers to work with the existing system without opting for cross-docking method. The purchases are centralized and the company enjoys the economies of scale. According to the purchase manager interviewed, when the company decentralizes the system of ordering and purchasing at the individual store level, the company would lose the economies of scale, as the company may not order bulk quantities.

The interviewee pointed out that there would be increased transportation costs when the distribution center has to make so many shipments in a week. This cost is more than the cost of carrying the inventory in the distribution center. In addition, the company has to maintain a fleet of vehicles to carry out the transport of the goods to various stores. Then only it would be possible to maintain the time schedule of deliveries.

If the company is going to depend on outsourcing the transportation of goods, the distribution center may not be able to maintain both cost and timelines in deliveries. There is increased cost of labor to handle the combining of the goods or segregating the merchandise to different store locations. This increases the cost of handling the goods.

Thus, the interviewee is of the opinion that despite some advantages, there are some drawbacks associated with the method. The cost of transporting the merchandise would increase for both the supplier and the retail organization in the course of time. This is because there is the need to transport the goods to various destinations for more number of times.

In addition, the transportation system has to be efficient and faster; otherwise, the company will lose the advantage of the cross-docking. It is essential that the transport organization provide a proper response and should avoid any delay in the delivery of merchandise to different store locations.

This method entails a larger risk on the part of the retail organization and the retailer is no more able to pass on the risks to the manufacturer. Those retailers having large distribution network alone can make use of this type of cross-docking. This method becomes useful in situations where there is the necessity to deliver the goods within a short span of time.

However, the view of the interviewee cannot be accepted as a modern distribution center will cost about $80 million in general. When this DC supports about 120 stores in radius of 150 to 300 miles, the benefit will be showed. Under such circumstances, the distribution center cannot only reduce costs, but will increase the logistics costs for the company.

DTW Logistics

Originally, the company was established in the year 1992 as a freight forwarding company which was later converted in to a full service logistics company in the year 2003. The company started domestic “Less than Truck Load” (LTL) transport service and invested large sums of money in the creation of China-wide transportation network.

This network has a large number of hubs, an advanced information technology system to provide superior quality customer services. “The goal of DTW is to become the largest and most professional less-than-truckload (LTL) service provider in China.”

The DTW Contract Logistics Division was established in 2002 and first operated a 6,000 square meters site in the Shanghai Wai Gao Qiao export processing zone. Since 2002, the Contract Logistics Division has expanded rapidly and now operates sites in six major cities in China, namely Shanghai, Suzhou, Shenzhen, Guangzhou, Beijing and Tianjin.

In total, the Contract Logistics Division operates sites with more than 79,000 square meters of floor space. All sites of the Contract Logistics Division are C-TPAT compliant and are equipped with material handling equipment, racking and other systems to perform to very high standards.

The Contract Logistics Division has developed its own IT system to manage warehousing activities and to manage the provision of value added services,” (DTW Logistics, 2010)

Apart from the contract logistics division, the company is also providing one-stop “supply chain management” services. By providing this service, DTW manages the non-core business activities of the clients and help them to optimize their supply chain. “Clients are operations are more efficient, operations costs are reduced and clients can focus on their core competence.”

When interviewed the manager of a branch of this company expressed the opinion that by nature of its business, the company cannot work on cross-docking. The principal business of the company is contract logistics and therefore the company on its own cannot involve in any consolidation of the clients’ merchandise nor it can work on breaking the merchandise of the clients to be sent to different destinations.

Mostly the company can arrange for the transportation of the merchandise from one destination to another as a contract logistics company. Any type of cross-docking efforts is to be undertaken by the clients at their place and once the shipment is handed over to the company, they can organize efficient and speedy transportation of the cargo to the desired destination.

The company has installed sophisticated information technology system to track the shipments and advise the clients the whereabouts of the cargo booked by them. With the large number of available fleet of vehicles, the company is able to organize quick transportation of the cargo to the desired destination.

Kwok Hang Holdings Limited

“Kwok Hang Holdings Limited, Chinese Retail Operations comprises 50 retail stores, which engages in retail sale of luxury clothing and non-apparel accessories for men, women, and children. The stores are located in 30 cities in China, including nine stores in Beijing and four in Shanghai. The stores are located in China,” (Bloomberg, 2010).

The logistics manager of one of the retail stores of this company, who answered the interview questions, reiterated the need for an efficient supply chain management in meeting the demands of the customers in time. The interviewee was of the opinion that considering the nature of the products handled by his organization, there was no need to adopt the cross-docking.

However, the company has strengthened its supply chain by installing a sophisticated information and communication system, through which the company is able to know the status of its orders with the suppliers precisely. This ability to gather the information enables the company to plan its delivery to the individual stores of their requirements.

The company makes centralized decisions on purchases of the requirements and maintains close contacts with its suppliers. The suppliers are given adequate lead-time so that they would be able to deliver the products without any delay.

In fact, the company at the time of placing the orders discusses the time required by the suppliers for completing the production and delivery and fixes the delivery dates based on the commitment of the suppliers. The company follows this system to avoid risks in delivery delays. Once the order is placed the company closely follows the status of the orders with the suppliers and get periodic status reports from the suppliers.

The company uses an advanced information system which enables the company to get linked to the production status of the individual suppliers and this information system provides the company the warning on any possible delays in the supply.

Based on the information the company takes steps for alternatives. This company is not large enough to adopt the cross-docking method and therefore would do well with the traditional pick and pack system of inventory movements.

Discussion

The results of this research strongly support the views expressed by Croom (2001) where the effective customer-supplier relationship is dependent on both operational and relational competence. Croom (2001) observes, “The exploitation of new technological developments or improved operational capabilities is founded on the effectiveness of the interaction process”.

In addition, based on the conceptual framework of the supply chain management, it is observed that the efficiency in delivery of the products in time forms the basis for an effective collaboration, which the customers are expecting to achieve.

Further, this collaboration results in the creation of closely-knit inter-organizational relations. It is established that the customers consider the impact of these inter-organizational relations as the source of competitive advantage by enhanced flexibility, innovation and improvement in business processes which requires higher levels of efficiency and communication.

It is necessary that the retail organizations have to adopt new business process design in order to keep up with meeting the market demand. Ronald H. Ballou et al (2000) advocates that the processes of those activities involved in the value-added activities in supply chain management can be managed by resorting to these three concepts;

- functional coordination inside the business,

- cross functional coordination inside the business

- coordination across different organizations that are part of the supply chain.

According to this view, the scope of supply chain management would cover the coordination and cooperation of value added activities in the form of cross-docking within the functional activities of the firms operating within the retail industry and such activities would help in enhancing customer satisfaction by timely delivery of the demanded products.

Application of Cross-docking

Cross-docking is resorted to put in practice “hub and spoke” arrangements where the incoming materials are transported into one central location, to be sorted out for delivery to a number of different locations. The process of cross-docking is also involved in consolidating smaller shipments by combining them into one single large shipment. This leads to considerable economies in the cost of transportation.

Cross-docking is undertaken in deconsolidation arrangements where a single large shipment is broken down into a number of smaller lots for effecting easier delivery.

Irrespective of these practical applications, cross-docking has not been viewed as a conceptual strategy, but as the application of physical facility where there is the need to optimize the size and shape and internal operations to maximize the efficiency (Cook, Gibson, and MacCurdy 2005; Eyestone and Torch 2000; Tsui and Chang 1992).

This dimension of cross-docking enhances the knowledge on the specific areas where the concept can be used beneficially; but it does not contribute to the advancement in the general ideas about the strategic importance of the concept of cross-docking in enhancing the efficiency of the supply chain.

There are various factors affecting the use of cross-docking. Generally, the location of the customer and supplier affects the use of cross-docking; particularly in case of a single corporate customer using multiple points of purchase. The freight costs for the transportation of the commodities and the cost of inventory in transit also have significant influence on the use f cross-docking.

The complexity of loads involved and the handling methods for different products being transported have an impact on the extended use of cross-docking. Use of logistics software integration between different parties involved in the transactions and tracking of inventory in transit also have large influence on the use of cross-docking.

Another drawback in the existing research studies on cross-docking is the lack of agreement on the elements that lead to success in cross-docking method. For example, Johnson (1998) observed that successful cross-docking requires substantial understanding among the parties involved and reliable operations apart from ensuring quality of the products, which raises the confidence and reliability of the suppliers.

Precise timings of supply is another important success factor. Napolitano and Gross (2000) identify different variables affecting the success of cross-docking operations. They find that correct items, reliability of supplies, swift communication, affordable cost and efficient people constitute the ideal conditions for success of cross-docking.

It may be observed that there are significant variations in the elements of success as defined by different practitioners. Therefore, the lists need to be compared to arrive at the agreeable success factors. Elements like teamwork and others mentioned by Johnson substantially vary from the other elements listed by Napolitano and Gross.

Moreover, the authors have not given any specific reasoning as to the applicability of these elements for the success of cross-docking. Some of the elements have not been made explicitly distinctive as these elements also affect the efficiency of the working of the warehouses.

This research observes that since there is no commonly accepted definition of cross-docking and no clear indications about the types of cross-docks, no consensus could be reached on the set of success factors in the use of cross-docking.

Because there are various elements affecting the success or cross-docking suggested by the literature, it has been the practice to choose the convenient factors for implementing the cross-docking. Similarly, the existing research works are not in a position to identify the causes for failures of many of cross-dock based supply chains.

Based on the responses received from the selected samples a series of findings were arrived at and a detailed analysis of the findings is undertaken in this chapter.

Directions of Cross-docking

The efforts undertaken by the organizations responded to the questionnaire were at different levels with respect to the adoption of cross-docking as a part of their supply chains. This was evident from the level of strategic programs undertaken by them to address the issue of cross-docking and improve its effectiveness.

Out of the six organizations, only one company had fully implemented a strategic cross-docking system, while two others are in the process of implementation of cross-docking. Three of the companies participated were not in favor of the adoption of cross-docking.

Despite the variations in the degrees of efforts in this direction, due to competitive pressures all of the participants have indicated their focus at significant levels of attention on improving their supply chains either by adopting cross-docking or through any other method, as a sustainable source of competitive advantage.

While in the last two decades the retail organizations mainly look internally into their own capabilities for improved performance the recent changes in the business environment with the volatility of the market forces and hyper competition forced organizations to seek greater efficiencies by making an assessment of all business processes with the perspective of respective value additions.

The impact of this for the development of supply chain through adopting cross-docking was evident in the outsourcing of the logistic activities that did not result in added value either because of lack of economies of scale or for other reasons.

The resultant logistic outsourcing activities had led to a proliferation of suppliers and a consequent rationalization of the supply chain. As a result, the retail organizations expected to have a total solution within the context of their own facilities. Cross-docking is found to have the capabilities to fulfill this need of the retail organizations.

While assessing the performance of the retailer stores in the area of reduction of inventory costs and meeting the demands of the customers, a decisive approach towards rationalizing the ordering, purchasing and transportation activities appear imminent to remain competitive. In the case of organizations responded to the questionnaire the focus for efficiency was on quality and on-time delivery in general.

However, in some cases the organizations have considered the qualitative aspects of intensity of responsiveness, degree of flexibility, level of communication, service capabilities, and other relevant aspects.

In view of the difficulties in measuring these qualitative aspects, in addition to the quantitative information on the quality levels and on-time delivery subjective judgments on these qualitative factors were also considered while evaluating the practicality of cross-docking in the case of retail organizations in Chinese context.

In the case of some smaller suppliers, cross-docking services cannot be adopted due o lack of certain strategic capabilities and services, which those smaller suppliers could not provide.

In the process of rationalizing the delivery options, some of the organizations could identify and assess the risks associated with cross-docking and the existing methods of meeting the individual store requirements and some of the retail organizations like Wal Mart were able to evaluate precisely the dependency and strategic contribution of cross-docking and adopt the system for their betterment.

Where the firms could identify lack of resources to implement cross-docking and standardizing the procedure for delivery they have to decide against the adoption of cross-docking.

However, based on a long-term assessment of the benefits arising from the adoption of cross-docking, the firms have decided to incur the initial investments and take advantage of the system in improving the customer satisfaction and in improving the firm performance. The capabilities and supportiveness of the respective firms have a large impact on the introduction of this method of dealing with the store deliveries.

There was a consensus among the participants that cross-docking or other “supply chain management improvement” system would greatly enhance the effectiveness of supply chain management by providing more flexibility to meet the customer demands, increase the transactional efficiency and to allow for increasing the competitive edge of the retailers in catering to the customer requirements.

Expectations of Customers from Suppliers

The customer-supplier relationship is continued and strengthened with the degree of quality of the products, levels of performance with respect to the time of delivery and the competitiveness in pricing. Since all of these parameters are demonstrable and can be compared easily against benchmarks created and the quantitative and qualitative assessments, these elements were considered to be a part of the customer-supplier relationship.

The evaluation of retailer thus required the smaller firms to offer something extra and often the customers purchasing their requirements from these smaller firms evaluated the offerings of the smaller firms through timely deliveries and quality of products apart from the prices of the products. This kind of evaluation and the resultant assessment forms the basis of the continued relationships.

This may also reflect the involvement of the smaller retail firms in the provision of any improved customer service. The participants to the interview consider cross-docking as one of the tools to enhance the retailer-customer relationship.

Thus, the key elements the retailers looked into the activities of their suppliers are the asset specificity and reduction of uncertainty. The asset specificity in this case is the capabilities of the suppliers to provide any unique product or the ease of interactions with the suppliers and their service levels.

Similarly, the firm foundation of relationship between the suppliers and the retailers is laid based on the performance, quality of products and comparative cost efficiency resulted in the longevity of relationship and thereby reduced the uncertainty factor.

Especially in the case of retail organizations adopting cross-docking, the efficiency of the suppliers is an important element in improving the benefits of cross-docking. The participants to the interview confirmed that unless the suppliers perform to the expectations to the retailers in respect of both quality and delivery, the implementation of cross-docking may not be able to provide real benefits to the organizations.

While considering the activities expected from the suppliers, the firms expected the suppliers to perform to provide for higher quality and service for the present or even better costs.

This may involve the indulging by the suppliers in inventory management, consignment stock arrangements, line delivery to cater to the just in time concept of inventory management and other efficient inventory management programs to reduce the cost of inventory. This called for a self-evaluation of the supplier capabilities in these areas.

Another area where the suppliers were expected to perform is the inter-organisational information and communication. Customers often expect the suppliers to provide timely and adequate information though better communication means, to allow them to draft contingency plans to address potential production issues.

Failure on the part of the suppliers to live up to the expectation of the customers may cause deterioration in the relationship. “The degree of information sharing and communication was also a key in developing relationships of trust and collaboration, to allow benefit and risk sharing, and to support innovation and continuous improvement.”

Requirements of Supplier Competencies for Efficient Cross-docking

The development of stronger organizational competence on the part of the suppliers especially the suppliers to larger retail organizations is of vital importance to meet the competition in the changing business environment. These calls for the suppliers to make additional investments in activities that are quite different from establishing the customer relationships traditionally.

Since the study has identified the quality and performance are the key factors that contribute to the development of a continued relationship, any existing competencies must be improved to achieve higher level of standards in these areas.

Once the base is created then it is the capabilities of the supplier firms, which will determine the differentiation in the service level of the larger retail organizations, adopting the cross-docking method.

While the suppliers were expected to deliver continuous improvement in the existing product lines and service levels, they were also expected to provide sufficient value addition to the products. This would require an understanding of the changes in customer preferences and more responsive and solution based approach from the supplier which results in an increase in the scope of activities being undertaken by the suppliers.

This necessitates the suppliers to exhibit a high degree of innovative approach and also technical and process related solutions to the problems envisaged in the delivery of products by large retail organizations. With every change in the product specification and delivery requirements, the suppliers were expected to react quickly and demonstrate flexibility.

This requires the existence of a flexible business process and a clear understanding of the customer requirements. Also the supplier should be competent to exercise two ways formal and informal communication that is capable of undertaking multilevel and multi functional customer interactions which provides for faster resolution to problems, innovations in product areas and continuous improvement in the production processes.

Changes in Organizational Culture due to adoption of Cross-docking

It was not evident from the research that whether the organizations participated in the survey was keen on leading and supporting the changes in the inter-organizational relations. It could be inferred that the customer organizations involved themselves in the change of the context of the relationships but expected the suppliers to adapt themselves to the changes by increasing their competency and performance levels.

Moreover, it was also observed that the prevalent culture within the supplier organizations act as barriers to acquire new competence levels by the retail organizations purchasing the customers’ requirements and these could be overcome to develop new competency levels.

Developing Appropriate Competence

From the research, it could not be observed that whether the customer organizations were serious enough to take adequate efforts within their organizations to resort to the development of appropriate competencies to resort to cross-docking in the retail environment. However, it appears that the organizations are keen in the development of their business processes.

Implications for Retail Organizations

It is clear and evident that the capabilities of the retail organizations in China to increase their competence in the supply chain networks can be improved only when they address the issues of their own organizational and interactive competencies and make faster development there on.

It is also observed that the retail organizations have distinct advantages in implementing cross-docking, when they adopt changes in their organizational forms and communication mechanisms. However, it is also true that all the retail organizations are not equipped with the resources to react quickly to adopt high level of changes within the short period.

Moreover, it was also found that major structural barriers exist in most of the retail organizations that prevent the happening of faster development activities in the area of adoption of cross-docking. In addition, most of the domestic retailers have very little expertise in improving their current organizational capabilities and there are no tools available to them for improving flexibility, innovative capabilities, and relational competence levels.

Thus it is concluded that despite the availability of abundant opportunities for the retailers to take part in the integrated supply chain management through cross-docking, problems of change in the organizational culture, evaluation of competence levels and development of the required competencies pose significant barriers to retailers.

Because of these problems in the implementation of cross-docking they are unable to offer themselves as reliable organizations, fulfilling the expectations of the customers.

The ideal supply chain to be more efficient should remain highly integrated material flow and information flow and through the maintenance of the supply chain should be able to provide identical information to all the supply chain members.

Frentzl (1996) is of the view that through information sharing the efficiency of supply chain management is bound to maximize and the efficient flow of information forms the basis of an efficient cross-docking system.

Efficiency of Supply Chain and Impact on Cross-docking

Supply chain encompasses the agencies and organizational activities, which are needed to design, make, deliver, and use a product or service. Success of any business firm largely depends on its ability to organize its supply chain to ensure an uninterrupted supply of materials and services.

The concept of ‘supply chain management’ developed in the late 19080s and firms started to make a widespread use of the concept from the 1990s. Previously the function was described as “logistics management” or “operations management”.

Chopra & Meindl, (2003) define supply chain as “A supply chain consists of all stage involved, directly, or indirectly in fulfilling a customer request. The supply chain not only includes the manufacturer and suppliers but also transporters, warehouses, retailers, and customers themselves…”. (Chapter 1)

“A Supply chain is a network of facilities and distribution options that performs the functions of procurement of materials, transformation of these materials, into intermediate and finished products, and the distribution of these finished products to customers.” (Ganeshan & Harrison, 1995)

“Supply chain management is the coordination of production, inventory, location and transportation among the participants in a supply chain to achieve the best mix of responsiveness and efficiency for the market being served.” (Hugos, 2006)

Supply chain differs from the function of logistics in that logistics refers to those activities occurring within the boundaries of a single organization, while supply chain encompasses the activities of companies operating as a network and coordinate their actions to deliver a product to the market.

Therefore, supply chain management encompasses logistics function. It also includes other functional areas of marketing and new product development. Supply chain management can be extended to finance and customer service functions.

As a management discipline, supply chain management evolves continuously with a growing impact on business performance. Therefore, the development of supply chain management as a core competency of the business cannot be developed easily. It demands a conscious and continuous effort on the part of the management (Cohen & Roussel, 2005, p 123).

The formation of a supply chain steward acting as a liaison between the production team and supply chain will drastically improve the effectiveness of supply chain and thereby enhance the productivity of the firm. This would ensure a precise aligning of the objectives of manufacturing units dispersed in various geographical locations with the global marketing strategy.

Strategic supply chain management involves the creation of a unique supply chain configuration, which drive the strategic objectives of the firm forward. There are five different configuration components, which need to be considered for deriving the maximum benefit from the supply chain.

They are:

- operation strategy,

- outsourcing strategy,

- channel strategy,

- customer service strategy

- asset network (Cohen & Roussel, 2005, p10).

Until the last decade, companies have been addressing these components informally. Alternatively, companies used to take decisions in respect of these components in an isolated way relating them to basic functional strategies. At best, the decisions were made relative to functions like sales, purchasing or manufacturing.

This approach was considered as ineffective in improving the organizational performance, as it is the process of putting disparate organizational functions under single-pint accountability and leadership. The major shortcoming of this approach is that it does not allow the measurement of the performance of the supply chain and identify the weaknesses for improvement.

Effectiveness of supply chain management can be improved with a simultaneous improvement in both customer service levels and the internal operating efficiency of the agencies and firms in the supply chain. To have effective supply chain capabilities companies need to take decisions in the areas of (i) production, (ii) inventory, (iii) location, (iv) transportation and (v) information (Hugos, 2006).

Chopra & Meindl, (2003) identify these areas as performance drivers, which can be managed properly to produce the desired capabilities of an effective supply chain. An understanding of each driver and the way it operates will lead to an effective management of the supply chain, since each driver is capable of affecting the supply chain directly and enable the supply chain to have enhanced capabilities.

Effective supply chain management is about improving the business processes and each business process has either an internal or an external customer to be served by the process. Some of the common business processes include

- new product development,

- identification of new customers,

- purchases of materials, parts and components and services,

- inbound logistics,

- production planning and control process,

- manufacturing and other production processes,

- sales,

- customer order processing

- outbound logistics.

Improving all these business processes is at the core of an effective supply chain management. Unless properly maintained the performance of most of the business processes are most likely to deteriorate over time. In case a firm does not improve its business processes, it is sure to lose its market share to the competitors who work on improving their business processes on a continuous basis.

With the increased expectations of the customers, there is the increased need for the firm to improve its business processes resulting in higher level of customer satisfaction. Different techniques have been developed and are being adopted by firms for brining improvement over the business processes.