Introduction

The Laser-Induced Breakdown Spectroscopy (LIBS) method of identification analysis, based on a mixed approach, makes it possible to determine the concentrations and nature of substances in multicomponent compositions. The essence of LIBS is specific laser irradiation of the surface area of the analyzed solid object, due to which the ablation of matter takes place. The introduction of a second pulse to the generated plasma allows intensifying the process of excitation of atoms. This paper proposes the development of a procedural methodology for the analysis of thin steel filaments. LIBS is modified with a two-pulse system to increase the excitation effects of atoms in the substance plasma.

Experiment

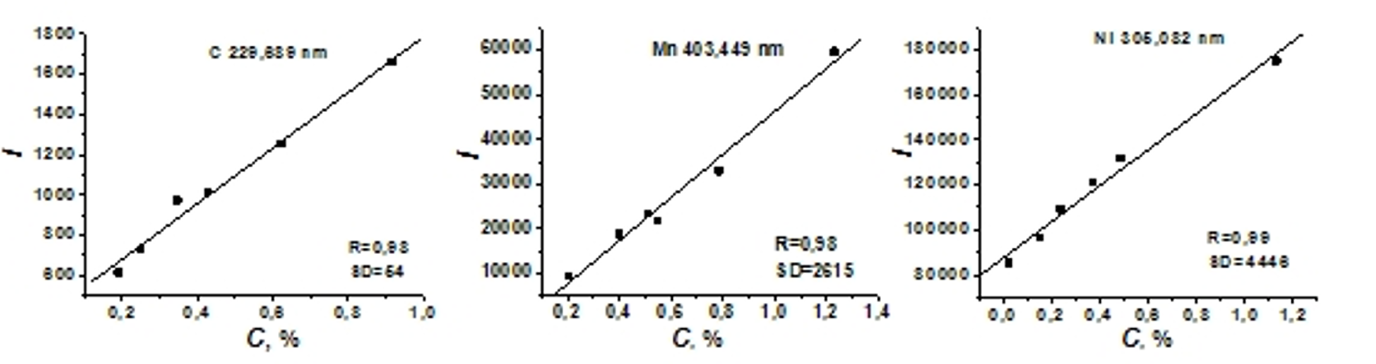

The methodological basis of the present experiment was based on the use of a two-pulse LIBS LSS-1 of Belarusian origin. Two Nd:YAG lasers were used as lasers, the beams of which were focused by means of a mirror system strictly perpendicular to the object’s surface. Standard data on the concentration of components in high-alloy steel were used to construct the calibration curves, as shown in Figure 1. Measurements were taken at room temperature and atmospheric pressure. The basic tuning parameters included the following values:

- Wavelength: 1064 nm

- Pulse duration: 15 ns

- The frequency between pulses: 10 Hz

- Pulse energy: 10-100 mJ

- Inter-pulse delay: 0-30 msec

- Focal length: 100 mm

Table 1: Component concentrations in standard samples used for calibration curves

Results

Carbon (229.689 nm), manganese (403.449 nm), and nickel (305.082 nm) were chosen to construct the calibration curves due to their high spectral intensity in quantitative analysis. An additional reason for the choice was the spectral mismatch between the selected elements and iron, a key component of steel. Analytically, it was found that the maximum intensity of the lines was observed at a maximum laser flux energy of 100 mJ. This does not seem surprising from the context of the explanation of laser ablation theory: as the flux energy increases, so does the amount of ablated matter mass from the surface of the matter.

Meanwhile, it was found that the optimal delay between pulses for carbon was 1 µsec. The need for such a short delay was determined by the desire to minimize potential interactions between the ablated excited atoms and the matter of the surrounding air — in the near-surface area, there is a low-pressure region, the secondary excitation of which prevents unwanted chemical effects. For metals, the optimum delay was determined to be 9-11 µsec: in this case, the optimum was due to a lower ablation rate of the metal atoms due to their higher atomic mass. Selecting a lower frequency between pulses resulted in the secondary signal being absorbed by the plasma and not reaching the material surface due to shielding effects. Thus, the fundamental conclusion is that the frequency between pulses in the experiment must be justified by the applications in the choice of material for analysis. It is noteworthy that if the concentration is determined for both nonmetals and metals at once, the optimal delay should be minimal and be 1 µsec.

Figure 1 shows the calibration curves for the three elements in intensity/concentration (%) coordinates. The figures also provide correlation coefficient values indicating a critically high level of correlation between the variables. For the other two elements, Chromium and Copper, a linear relationship was also found, and the corresponding correlation coefficients were 0.93 and 0.95. Thus, the overall conclusion is that the intensity of the analytical signal increases as the concentration of the substance in the plasma increases.

Conclusion

To summarize, it should be emphasized that the use of two-pulse LIBS demonstrates an excellent signal intensity as the two-pulse system increases the substance concentration in the plasma. In addition, it was found that the delay time between pulses must be adjusted according to the material being analyzed since non-metals require a much lower inter-pulse frequency. Thus, the two-pulse LIBS demonstrates excellent applicability for quantitative steel analysis.

Work Cited

Ermalitskaia, K. F., Y. S. Voropay, and A. P. Zajogin. “Dual-Pulse Laser-Induced Breakdown Spectrometry of Bronze Alloys and Coatings.” Journal of Applied Spectroscopy, vol. 77, no. 2, 2010, pp. 153-159.