Current supply chain operation design and the proposed turnkey strategy

- Unlike the current supply chain management, the propped turnkey strategy has internalized the aspect of vertical integration (Andrea 25).

- The proposed change will boasts of a strong backward vertical integration in its industrial organization to ensure that the suppliers meet the expectation of the Elizabeth Arden Company.

- From a single location, the company will be able to control designing, manufacturing, and distribution activities of the suppliers (Bowman 9).

Unlike the current supply chain management, the propped turnkey strategy has internalized the aspect of vertical integration, which involves amalgamation of the production chain to accommodate the different products that company deals in line with the market specific demands (Andrea 25). The proposed change will boasts of a strong backward vertical integration in its industrial organization to ensure that the suppliers meet the expectation of the Elizabeth Arden Company. From a single location, the company will be able to control designing, manufacturing, and distribution activities of the suppliers as opposed to the current operation design, which gives the suppliers more power to control the above processes (Bowman 9).

The changes and suppliers

- Through segmenting and disfranchising the systematic control system that monitors suppliers’ compliance and progress, the proposed strategy will shield the company from market swings (Bustin 34).

- The changes in the turnkey strategy will mean that the suppliers will have to balance the aspects of includes aspect of cost, dependability, speed, quality, and flexibility.

- This aspects can be applied in executing supply functions on behalf of the Elizabeth Arden Company (Worthen 45).

Through segmenting and disfranchising the systematic control system that monitors suppliers’ compliance and progress, the proposed strategy will shield the company from market swings which create fluctuations in the supply chain, in terms of input availability and price (Bustin 34). Therefore, the changes in the turnkey strategy will mean that the suppliers will have to balance the aspects of includes aspect of cost, dependability, speed, quality, and flexibility in executing supply functions on behalf of the Elizabeth Arden Company (Worthen 45).

The changes and various supply chain functions at Elizabeth Arden

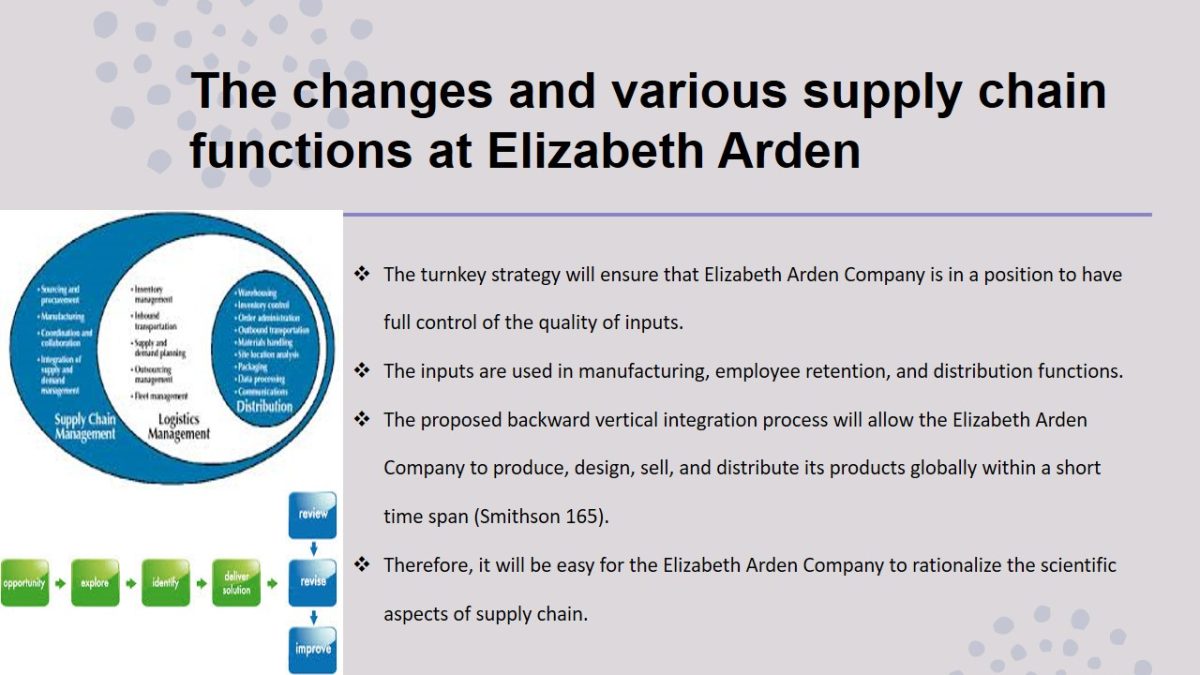

- The turnkey strategy will ensure that Elizabeth Arden Company is in a position to have full control of the quality of inputs.

- The inputs are used in manufacturing, employee retention, and distribution functions.

- The proposed backward vertical integration process will allow the Elizabeth Arden Company to produce, design, sell, and distribute its products globally within a short time span (Smithson 165).

- Therefore, it will be easy for the Elizabeth Arden Company to rationalize the scientific aspects of supply chain.

- Lastly, the company will be able to improve on the decision support system since the proposed turnkey strategy will endeavor to create a decentralized decision support system of different supply chain functions (David 14).

- An improved approach to supply management through decision support will establish a broader partnership with customers, suppliers, and employees.

- Such cooperation will turn supply into a competitive advantage instead of sole cost to the Elizabeth Arden Company.

The turnkey strategy will ensure that Elizabeth Arden Company is in a position to have full control of the quality of inputs used in manufacturing, employee retention, and distribution functions. The proposed backward vertical integration process will allow the Elizabeth Arden Company to produce, design, sell, and distribute its products globally within a short time span (Smithson 165). This is possible due to internalization of a direct and complete control of the distribution and production process for its brands as proposed in the turnkey strategy. Therefore, it will be easy for the Elizabeth Arden Company to rationalize the scientific aspects of supply chain such as use of statistical tools, their application, and evaluation criteria in monitoring and managing the logistics to guarantee efficiency in the supply chain management.

Lastly, the company will be able to improve on the decision support system since the proposed turnkey strategy will endeavor to create a decentralized decision support system that incorporates planning, development, implementation, and discovery of different supply chain functions (David 14). An improved approach to supply management through decision support will establish a broader partnership with customers, suppliers, and employees. Such cooperation will turn supply into a competitive advantage instead of sole cost to the Elizabeth Arden Company.

Works Cited

Andrea, Arnold. “Understanding how Formal and Informal Communication Affect Purchasing, Manufacturing and Logistics Integration.” Advances in Management 4.7 (2011): 22-32. Print.

Bowman, Singh. “Corporate Restructuring: Reconfiguring the Firm.” Strategic Management Journal 1.4 (2003): 5–14. Print.

Bustin, Gerald. Take Charge: How Leaders Profit From Change, Irving, Texas: Tapestry Press, 2004. Print.

David, Fred. Strategic Management Concept and Cases, a Competitive Advantage Approach, New York, NY: Prentice Hall, 2012. Print.

Smithson, Samuel. “Analysing Information Systems Evaluation: Another Look at an Old Problem.” European Journal of Information Systems, 7.3 (2008): 158-174. Print.

Worthen, Ben. Companies More Prone to Go Vertical. 2009. Web.