Executive Summary

Construction of structures and technical devices applied in engineering entails the use of different materials. These materials are of different sizes, shapes, textures, and other characteristics, which help in strengthening structures. Selecting the right materials for use in a certain project is essential because they influence the durability, toughness, and hardness of engineering structures. This study explores three hardware materials to understand their characteristics, basic types, and how they are used. The three materials explored are bearings, rivets, and shafts. The report ends with a conclusion and recommendations on what engineers should do to utilize these components fully.

Introduction

There is a wide range of materials available to engineers. Ashby (2010) opined that there are more than 160,000 engineering materials. Therefore, engineers have to understand the best materials suited for their purpose. In such cases, there are various standardization, design rules, as well as previous experiences, applied when selecting materials. Additionally, Ashby (2010) argued that the choice of materials is not independent of the process in which the material is to be shaped, joined, and finished. Other factors involved in selecting the materials include personal preferences such as texture, form, color, and feel, which is evident in automobiles or other appliances used by people.

In the early days, humans used crude materials such as stones, metals, or wood because they were naturally available. However, the growth of innovative design has enabled people to invest in ways of making natural materials stronger quality and in different types, which are used in a wide range of applications like the construction of buildings, bridges, airplanes, automobiles, and home appliances. According to Callister Jr and Rethwisch (2015), solid materials are categorized into six groups that include mechanical, thermal, electrical, deteriorative, and magnetic. For instance, some of the materials, like gears and chains, are linked together to produce the desired motions in rigid structures. This paper examines three engineering hardware components, which include bearings, rivets, and gears. The key characteristics, dimensions, and applications of these materials are analyzed and presented in the subsequent sections.

Bearings

Bearings are commonly used in supporting moving elements in machines known as journals. Bearings permit relative motion between the contact surfaces of the members while carrying the load (Chaudhari et al., 2015). Relative motion between surfaces exposes them to wear and tear because of the present frictional resistance, which can be reduced by applying lubricants. According to Chaudhari et al. (2015), greases, vegetable oils, mineral oil refined from petroleum, and silicon oils are used as lubricants. Lubricants help in reducing friction and improving the rotation of the surface.

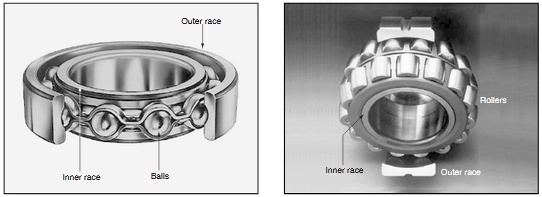

The bearings are classified into four main types. Harris and Kotzalas (2006) explained these types as ball bearings, roller bearings, linear motion bearings, and bearings for special applications. Ball bearings comprise outer and inner surfaces with steel balls placed between the two metallic rings. Ball bearings are useful in reducing rotational friction and support both radial and axial loads. The ball bearings are further subdivided into single-row, double-row, double-row self-aligning, as well as single and double-row angular contact bearings. On the other hand, roller bearings are commonly used in industrial bearings because they carry a load by placing the round elements between two surfaces. The movement of the two pieces rolls the round elements, which helps in carrying the load. Additionally, roller bearings have a higher load capacity compared to ball bearings.

All bearings are expected to meet certain standards to be considered fit for use in machinery and appliances. These standards check the size, finish, and diameter requirements in bearings, among other features. Some examples include AFBMA (Anti-Friction Bearing Manufacturers Association) standards 9 and 11 concerned with load ratings and fatigue life for the ball and roller bearings, respectively (Autodesk, 2019). Figure 1 shows the ball and roller bearings.

Rivets

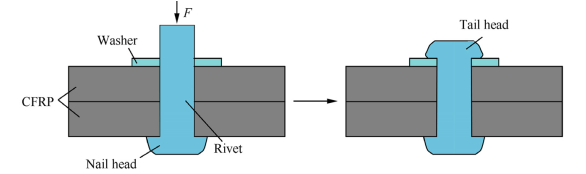

Rivets are used in connecting structural elements, and they are preferred in industries because of their low costs. The rivets are designed as a smooth cylindrical shaft with one end as the head. Common rivet heads include a button, flat, truss, pan, and countersunk. They are inserted into predrilled holes, and the tail section is deformed to expand at least 1.5 times the original shaft diameter (Troughton, 2008). The larger the rivet head, the lower the stresses on the surface because the load is distributed over a larger area. The rivets are cost-effective, especially because of the large volume and high-speed assembly. They are also less susceptible to vibrational loosening as experienced by bolts and screws.

There are several types of rivets each used in different areas. According to Universal Rivets (2020), roller assembly rivets are suited for high-speed assembly operations, and they fasten two or more pieces. Solid rivets are easily deformed with a hammer, and they have used indoor hinges and pulley applications. Structural steel rivets are used in fastening metal structures like aircraft, ships, and buildings. Other types include collar rivets, shoulder rivets, and cross-drilled rivets. Rivets are governed by several standards, such as the ISO/TR 12198:1998, which defines the rivet materials used in aerospace. The ISO 10299:2000 defines the material and metric series on solid rivets in aerospace construction (ANSI 2020). Figure 2 shows a rivet before and after the tail is deformed.

Gears

Gears are machine elements that transmit rotary motion using successively engaging teeth, usually at constant speeds. They are of different shapes and sizes and are classified into three categories. The first category is parallel shaft gears with examples such as spur, helical, herringbone, as well as rack and pinion gears. Spur gears consist of two shafts in parallel with straight teeth that are parallel to the axes of rotation of the shaft (Uicker et al., 2011). They are used in clocks, power plants, clothes washing and drying machines, aircraft, and trains. The second type is intersecting shaft gears that include straight bevel and spiral bevel gears. Bevel gears are used to transmit force between two shafts that intersect at one point. The third type is neither parallel nor interesting shafts consists of crossed-helical, hypoid, as well as worms and worm gears (Zhang et al., 2003). The design, building, and maintenance of gears are governed by certain international standards. The American Gear Manufacturers Association (AGMA) standards specify the tooth thickness and size, relationships between dedendum and addendum, fillet radius, and shapes, among others. Figure 3 shows different examples of gears.

Conclusion

In conclusion, this paper shows that all three hardware are essential materials in the engineering and construction industries. The paper shows different types of these materials and where they can be applied efficiently in different areas, especially in the transportation sector. I would recommend the engineers and contractors to read widely on these three hardware materials because they each provide unique advantages and limitations as compared to their alternatives.

References List

ANSI (2020) Other rivet standards.

Ashby, M. (2010) Materials Selection in Mechanical Design. Butterworth-Heinemann.

Autodesk (2019) Bearing standards.

Callister Jr, W.D. and Rethwisch, D.G. (2015) Fundamentals of materials science and engineering: an integrated approach. John Wiley & Sons.

Chaudhari, C.P., Thakare, B.B., Patil, S.R. and Gunjal, S.U. (2015) ‘A study of bearing and its types’, International Journal of Advance Research in Science and Engineering, vol.4, no.1.

Harris, T.A. and Kotzalas, M.N. (2006) Essential concepts of bearing technology. CRC press.

Troughton, M.J., (2008) Handbook of plastics joining: A practical guide. William Andrew.

Uicker, J. J., Pennock, G. R., & Shigley, J. E. (2011) Theory of machines and mechanisms (Vol. 1). New York: Oxford University Press.

Universal Rivet (2020) Rivet applications.

Zhang, Y., Finger, S. and Behrens, S. (2003) Introduction to mechanisms (pp. 39-245). Carnegie Mellon University.