Introduction

Today, business process optimization is a natural movement towards progress, which is realized through the implementation of effective technological solutions. One of these tools to improve the quality and productivity of work in different directions is an ERP system, an advanced algorithm for planning numerous procedures and operations without human intervention. These systems have a number of valuable features and, despite some shortcomings, are gaining popularity in today’s business environment. This work aims to identify the main peculiarities of ERP platforms regarding their impacts, present and compare the most popular modern digital applications, describe the affected business processes by using the example of one manufacturing enterprise, and assess the prospects for the development of these systems by taking into account the latest Industry 4.0 technologies. ERP assessment makes it possible to describe this software as a valuable tool that minimizes planning errors and can be useful in different areas of work.

General Feature of Enterprise Resource Planning

To carry out day-to-day operational and computing tasks, many organizations implement special software designed to simplify and speed up many procedures. With the advent of computer technology, this process has become widespread, and the optimization strategy through the integration of production resources and different operations was called enterprise resource planning (ERP). Madanhire and Mbohwa (2016, p. 225) give a detailed definition of this technology – this “is the strategic tool which synchronizes, integrates, and streamlines data and processes of the organization into one single system to gain a competitive edge in the uncertain business environment”. This description of ERP emphasizes the relevance of achieving high productivity in dynamic working conditions. In addition, given a wide range of capabilities of such a mechanism, particular attention is paid to multitasking as an aspect that stimulates the introduction of computer algorithms for calculations and planning in distinctive environments to obtain the most effective operational outcomes.

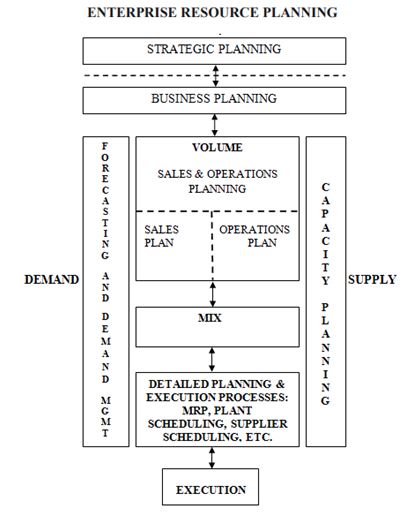

For any organization, the principles of implementing and maintaining ERP sustainability can be individual and differ based on various criteria, for instance, the specifics of the business, the availability of appropriate resources, and other parameters. However, from a planning perspective, there are general principles for introducing ERP into an operational environment, which have evolved from simpler practices. As Šimović, Varga, and Soleša (2020) note, a system called manufacturing resource planning (MRP) was utilized as a technological base to create more advanced strategies and steps for implementing software development and innovation. The first steps were taken in the 1960s when developers began to seek more efficient approaches to controlling the resource base of organizations and monitoring supply as one of the significant aspects of sustainable operation (Šimović, Varga, and Soleša, 2020). As a result, with the advent of digital technologies, inventors managed to create tools that made it possible to control numerous operational procedures remotely. In Figure 1, the main processes realized through ERP are reflected (Santos, 2020). Speeding up and improving business processes are objectively valuable implications of ERP.

Despite the versatility of the application of ERP, there are specific prerequisites that determine the need and relevance of the implementation of this mechanism in the operating environment. Izhar et al. (2018) consider a number of conditions that explain the necessity and value of applying an appropriate digital planning strategy in organizations. One of these conditions is the rationality of the ERP application; if individual processes require standardization or optimization, the transition to advanced algorithms for business control and accountability processes is justified (Izhar et al., 2018). Another premise that the researchers cite is the need to build a long-term development strategy for a particular enterprise (Izhar et al., 2018). ERP is not a one-time system and involves building and maintaining a specific development path over several years. Finally, in view of the ability to allocate resources efficiently and rationally, the need for the detailed monitoring of all financial and expenditure procedures is one of the conditions for the implementation of ERP (Izhar et al., 2018). Corresponding tools help avoid mistakes and enable business owners to establish a sustainable planning regime over the long term.

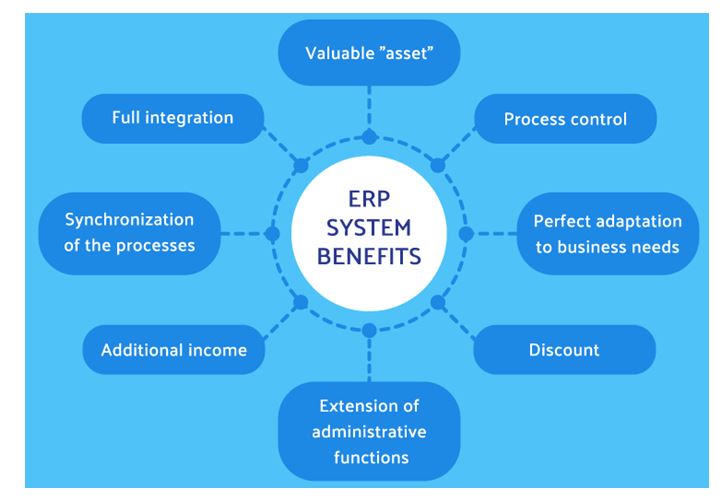

ERP, as a modern and advanced system, has a number of advantages that prove its relevance in today’s business environment for the implementation of significant steps to control all aspects of work, including sales and marketing, production, accounting, materials management, and others. In Figure 2, individual advantages of this system are presented (ERP benefits, 2016). Šimović, Varga, and Soleša (2020) provide a broad list of ERP benefits that highlight the relevance of this strategy to various enterprises. Among the most significant advantages, one can mention the convenience and simplicity of storing and retrieving data within one network, costs reduction due to the unification of procedures, the ease of use due to one software tool for the whole organization, quick access to the necessary information, as well as the accuracy of calculations. In addition, such valuable business elements are addressed through ERP as sustainable logistics, production flexibility, the integration of different departments into one mechanism, stable interaction among participants in supply chains, and some others.

At the same time, despite a wide range of advantages, one can also recall some of the disadvantages of ERP that need to be taken into account to implement such a strategic system into the workflow. Huang and Yasuda (2016, p. 12) note that “traditional ERP is expensive and complex for most organizations to adopt”. This means that to reduce costs, more modern and multi-functional digital algorithms need to be applied. Šimović, Varga, and Soleša (2020) discuss some shortcomings of such systems and mention potential disruptions in operation, high training costs, great efforts from all involved parties at the implementation stage, the need for a detailed analysis of all potential implications, management complexity, as well as risks that the unstable operation of these systems entails. Nevertheless, despite these disadvantages, in the case of competent preliminary work and the necessary procedures to prepare for a change in the organizational environment, ERP is a productive strategic element to accelerate and optimize numerous business processes due to high functionality and advanced control options that facilitate effective decision-making.

The introduction of ERP into various organizational procedures is also associated with valuable user experience implications. According to Eid and Abbas (2017), by utilizing such a technology, users can adapt the working environment to the areas covered by ERP. In other words, the corresponding software shapes the ability to operate with digital algorithms for solving specific problems. In addition, as Eid and Abbas (2017) argue, user experience with enterprise resource planning correlates with productivity directly and helps streamline the range of procedures that an ERP can perform. As a result, the implementation of these systems in the organizational environment requires employee training, and the sustainability and quality of these tools depend on how effectively users manage the technical capabilities of the corresponding software.

Functionality of Modern ERP Systems

The development of ERP as a tool for optimizing operational, accounting, and other tasks involves introducing highly efficient software with wide functionality. However, as Sagegg and Alfnes (2020) remark, some systems do not have sufficient characteristics to cope with all the procedures without exception. For instance, the authors state that not all ERP algorithms are capable of performing a wide range of tasks from an engineering perspective due to limited options, and the corresponding procedures are to be conducted manually (Sagegg and Alfnes, 2020). Haddara (2018) argues that, in some cases, managers are shortsighted and choose those ERP systems that cannot perform planned tasks due to limited capabilities. This, in turn, becomes a barrier to speeding up business processes and increases costs due to the need to purchase additional software with the necessary options. Therefore, a preliminary assessment of the functionality of such tools is a crucial condition for maintaining a sustainable algorithm of strategic optimization.

To assess the capabilities of modern ERP systems, specific tools can be considered to describe their functionality. For instance, the SAP program is software that is suitable for large businesses in different market areas (Haddara, 2018). This product has broad functionality and meets all modern requirements for process optimization due to built-in algorithms of increased productivity (Haddara, 2018). However, such a system is not suitable for small companies due to its high price and too a wide range of analytical functions, which may be redundant.

Another popular program is Microsoft Dynamics that is suitable for all types and sizes of businesses. According to Sagegg and Alfnes (2020), this ERP system is best suited for supply chain management functions as a set of logistics, sales, and other operations involving interaction with suppliers. The artificial intelligence embedded in this software allows combining different algorithms for finding optimal routes. At the same time, its use in the CRM industry is also justified since predicting customer behavior is Microsoft Dynamics’ another valuable option.

ERP system Oracle has several categories that differ in functionality and areas of application. For instance, Sagegg and Alfnes (2020) look at traditional Oracle software that involves manufacturing resource planning, which is an outdated practice. Modern packages of this tool are based on the use of cloud technologies as one of the main digital trends in recent years (Sagegg and Alfnes, 2020). The functionality of this product is suitable for different businesses and allows optimizing a wide range of business processes, including accounting, human resources, supply chains, and other fields.

Odoo, like Oracle, is also suitable for different businesses, although its functionality is mainly focused on CRM procedures, which brings it closer to Microsoft Dynamics. One of the main strengths of Odoo is the integration of applications into the interface that is user-friendly and allows keeping track of the necessary tasks conveniently (Best ERP software 2021, 2021). In addition, this system is relatively inexpensive compared to other platforms (Best ERP software 2021, 2021). This is valuable for small businesses due to the availability of various options, including both CRM and financial management.

EPRNext is a platform that offers ample opportunities to optimize business processes. One of the strengths of this system is a wide range of options for personnel management since, in addition to standard financial control algorithms, this software contains numerous tools for tracking employee performance (Evaluating the pros and cons, 2020). EPRNext has a large set of functions, but one of the main disadvantages is the inability to use it in large businesses, which limits its scope.

Finally, as another ERP system, one can pay attention to Zoho, modern software with a wide range of options, which is similar to EPRNext. One of the main features of Zoho is the ability to use its functionality on iOS and Android platforms, which improves the quality of monitoring business processes in real-time (Evaluating the pros and cons, 2020). This system also makes it possible to control employee productivity as an important performance criterion. The analysis of all the ERP systems considered proves that, despite their similar functionality, they may differ in scope, and this is the reason for the careful choice at the planning stage for the implementation of specific software.

Business Processes in the Context of ERP

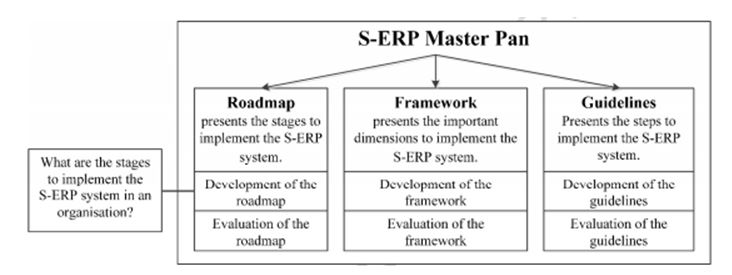

The formation of a stable way of the implementation of an ERP system in a specific business should be accompanied by the analysis of all processes that can be optimized through such a solution. In general, the very process of innovative change presupposes a transition to digital tools with the function of advanced planning. At the same time, as Scurtu and Lupu (2016) note, the mechanism of operation of these systems is multi-stage and meets different requirements, which is reflected in Figure 3. Chofreh, Goni, and Klemeš (2017), in turn, provide a scheme for building a sustainable ERP, which requires both analytical and evaluation work, and this plan is shown in Figure 4.

Based on a relatively complex structure of work, the implementation of an ERP system is to be justified. According to Gunjal and Gogte (2019, p. 105), they are in demand in manufacturing companies that “require an efficient planning and control system that synchronizes planning of all processes across the industry”. By using one of these companies as an example, the experience of implementing an ERP platform will be considered from the perspective of influencing its business processes, in particular, customer management, manufacturing, logistics, human resources, finance and accounting, procurement, assets management, and sales and operating planning.

As a target enterprise, the Spare Parts Company will be considered, an Iranian organization that assembles and sells components for commercial vehicles. Rezaeian and Wynn (2016) describe this organization in the context of the implementation of the HAMKARAN ERP system and its impact on core business processes. The authors note that customer management is improved by collecting and processing information from target clients, which, in turn, provides a comprehensive picture of product sales (Rezaeian and Wynn, 2016). In terms of influencing manufacturing, the ERP system at the Spare Parts Company helps minimize operating costs through the productive planning of all expenses and drawing up an optimal production cycle. Logistics, as an important aspect of the enterprise’s business, is improved through the introduction of the HAMKARAN system as a program to create convenient routes for the distribution and delivery of goods, which, as Ge et al. (2020) state, is also achieved through intelligent planning algorithms. In terms of human resources, this software in the enterprise in question allows allocating responsibilities among employees reasonably and offers appropriate training processes as valuable methods of continuing education to increase the staff’s qualifications.

Processes related to finance and accounting are also addressed at the Spare Parts Company through ERP. According to Rezaeian and Wynn (2016), this software allows preparing reports in accordance with the existing standards of local Iranian law. Since this enterprise is manufacturing, control over procurement operations is a crucial aspect and, as Ullah et al. (2018) remark, allows optimizing facilities management for specific production volumes to maintain stable contacts with suppliers and buyers. Asset management is a business process that involves control over the available resources to plan production efficiently. Rezaeian and Wynn (2016) argue that, in the Spare Parts Company, this aspect is realized by the ERP system due to reports on all critical aspects of the material base, thus contributing to avoid problems and gaps with shortages or surpluses of raw materials. Finally, the process of sales and operating planning is a significant process that is also improved through the implementation of ERP. According to Berić et al. (2018), this tool allows evaluating transactions, recording specific errors, and suggesting optimal distribution channels. All the considered advantages of the ERP system prove its relevance in the enterprise in question.

Critical Analysis and the Effects of the Latest Industry 4.0 Technologies

In the face of high consumer demands and dynamic market activities, companies often implement ERP systems. At the same time, based on the aforementioned comparison and description of their technical characteristics, some programs do not have sufficient functionality and require careful analysis during the implementation phase. Moreland, Parente-Neubert, and Simon-Walters (2019, p. 109) state that “an enterprise resource planning (ERP) system is a common database and offers tools that can be accessed by cross-functional departments such as HR, finance, and supply chain”. Nevertheless, when analyzing these perspectives in practice, employees in these departments may face some barriers. In theory, such software has the ability to integrate core business processes. However, as Gupta et al. (2018) note, in practice, data conversion can be disrupted during transfers within individual departments. This, in turn, leads to the loss of planning accuracy and is a risk to the validity of all calculations. Therefore, despite the potential versatility of such systems, monitoring their operation in a multitasking environment is a must.

Another significant aspect to evaluate is the ability to process data. According to Gupta et al. (2018), ERP systems can process information in large volumes, and theoretically, these programs can replace any additional calculation tools. Nevertheless, while taking into account the individual orientations of businesses and specific tasks to realize, this advantage cannot always be realized in practice. For instance, companies with a wide range of target audiences operate on various resources, including both tangible assets and products of intellectual work. In other words, the type of data can vary, and the processing of such information in a single stream is unlikely since ERP systems operate on built-in algorithms. Therefore, to avoid problems with calculations and planning, business owners should take into account the technical characteristics of such software and the capabilities of digital equipment to involve.

At the same time, when considering the latest Industry 4.0 technologies and accomplishments in this sphere, one can note that, in the future, ERP systems will become more advanced from a functional perspective. Ferrari et al. (2021) assess the prospects for this industry and argue that today, such platforms have begun to process different types of data due to improved analytical options. This means that, in the future, these systems can replace any additional mechanisms that evaluate each business process separately. Majeed and Rupasinghe (2017) also review the advances in Industry 4.0 and note that future supply chains will be strengthened by integrating advanced tracking algorithms into ERP systems. Combining the radio frequency identification (RFID) technology with ERP will make it possible to eliminate any logistics errors and make supply management even more convenient than now (Majeed and Rupasinghe, 2017). Thus, with the development of the technology industry, planning systems will evolve and adapt to the necessary conditions.

Main Reflections

Based on the considered features and advantages of ERP systems, these platforms can be characterized as valuable tools that not only allow optimizing business processes but also contribute to productive learning. Ripamonti and Galuppo (2016) confirm that these tools are effective for HR professionals as the instruments to explore planning modes in the context of personnel management. Chadhar and Daneshgar (2018) view ERP systems as mechanisms that increase the overall level of organizational learning and encourage sustained communication among stakeholders responsible for specific operational tasks. As a result, such platforms create a background for learning, provide valid examples to follow to hone relevant skills, and open up opportunities for professional capacity building.

While taking into account the prerequisites for the implementation of ERP systems, specific learning objectives can be achieved. In Table 1, the key premises are presented, and the main educational implications are reflected based on their relevance to the business sector. Adherence to these conditions of innovative development will expand employees’ professional horizons and make it possible to avoid errors due to the human factor.

Table 1. ERP Prerequisites and Implications.

Conclusion

ERP systems are valuable digital tools that streamline many business processes and simplify the planning of various operations through high-tech built-in algorithms. The evaluation of these instruments from the standpoint of functionality, advantages and disadvantages, comparison of individual platforms, analysis of application at a particular enterprise, and future development prospects in the context of the constantly evolving Industry 4.0 proves that this software is in demand in the modern business sector. With numerous learning opportunities, ERP systems can be helpful platforms to help hone professional skills by acquiring new knowledge and assessing artificial intelligence functions that minimize any planning and operational errors, thereby contributing to the achievement of high productivity.

Reference List

Berić, D. et al. (2018) ‘The implementation of ERP and MES Systems as a support to industrial management systems’, International Journal of Industrial Engineering and Management (IJIEM), 9(2), pp. 77-86.

Best ERP software 2021: top rated ERP systems comparison. Web.

Chadhar, M. A. and Daneshgar, F. (2018) ‘Organizational learning and ERP post-implementation phase: a situated learning perspective’, Journal of Information Technology Theory and Application, 19(2), pp. 138-156.

Chofreh, A. G., Goni, F. A. and Klemeš, J. J. (2017) ‘Development of a roadmap for Sustainable Enterprise Resource Planning systems implementation (part II)’, Journal of Cleaner Production, 166, pp. 425-437.

Eid, M. I. M. and Abbas, H. I. (2017) ‘User adaptation and ERP benefits: moderation analysis of user experience with ERP’, Kybernetes, 46(3), pp. 530-549.

ERP benefits (2016) Web.

Evaluating the pros and cons of ERPNext vs Zoho One (2020) Web.

Ferrari, A. M. et al. (2021) ‘Dynamic life cycle assessment (LCA) integrating life cycle inventory (LCI) and Enterprise resource planning (ERP) in an industry 4.0 environment’, Journal of Cleaner Production, 286, p. 125314.

Ge, J. et al. (2020) ‘Research on the maturity of big data management capability of intelligent manufacturing enterprise’, Systems Research and Behavioral Science, 37(4), pp. 646-662.

Gunjal, S. and Gogte, J. (2019) ‘A study of ERP as a change management tool in manufacturing companies’, Journal of Management, 6(2), pp. 105-110.

Gupta, S. et al. (2018) ‘Role of cloud ERP on the performance of an organization’, The International Journal of Logistics Management, 29(2), pp. 659-675.

Haddara, M. (2018) ‘ERP systems selection in multinational enterprises: a practical guide’, International Journal of Information Systems and Project Management, 6(1), pp. 43-57.

Huang, T. and Yasuda, K. (2016) ‘Comprehensive review of literature survey articles on ERP’, Business Process Management Journal, 22(1), pp. 2-32.

Izhar, R. et al. (2018) ‘Impact and challenges of requirements management in Enterprise Resource Planning (ERP) via ERP thesaurus’, International Journal of Advanced Computer Science and Applications, 9(8), pp. 247-258.

Madanhire, I. and Mbohwa, C. (2016) ‘Enterprise resource planning (ERP) in improving operational efficiency: case study’, Procedia CIRP, 40, pp. 225-229.

Majeed, A. A. and Rupasinghe, T. D. (2017) ‘Internet of things (IoT) embedded future supply chains for industry 4.0: an assessment from an ERP-based fashion apparel and footwear industry’, International Journal of Supply Chain Management, 6(1), pp. 25-40.

Moreland, T., Parente-Neubert, G. and Simon-Walters, J. (2019) PHR/SPHR professional in human resources certification practice exams. 2nd edn. New York: McGraw Hill Professional.

Rezaeian, M. and Wynn, M. G. (2016) ‘The implementation of ERP systems in Iranian manufacturing SMEs’, International Journal on Advances in Intelligent Systems, 9(3/4), pp. 600-614.

Ripamonti, S. C. and Galuppo, L. (2016) ‘Work transformation following the implementation of an ERP system’, Journal of Workplace Learning, 28(4), pp. 206-223.

Sagegg, O. J. and Alfnes, E. (2020) ERP systems for manufacturing supply chains: applications, configuration, and performance. Boca Raton: CRC Press.

Santos, J. M. D. (2020) Best enterprise resource planning (ERP) software for 2021. Web.

Scurtu, L. E. and Lupu, V. (2016) ‘Enterprise resource planning – ERP for business and knowledge management’, The USV Annals of Economics and Public Administration, 16(1 (23)), pp. 145-153.

Šimović, V., Varga, M. and Soleša, D. (2020) ‘Analysis of possible advantages and constraints of ERP systems’, Ekonomija: Teorija i Praksa, 13(4), pp. 41-56.

Ullah, A. et al. (2018) ‘Enterprise resource planning (ERP) systems and user performance (UP)’, Journal of Managerial Sciences, 11(3), pp. 377-390.