Introduction

Quality function deployment (QFD) is an inclusive notion. It has been developed in order to offer an instrument that interprets customer needs. This is done with the intention of elaborating certain procedural requirements that should be followed at every stage of product manufacturing.

Most often, these requirements include marketing policies and novel product proposals. Moreover, the organizations are interested in evaluating prototypes, developing the production process, and increasing sales. A system of QFD was first used in Japan in 1972. The Japanese implemented it in practice as a scheduling instrument and utilized it throughout the process of software development (it was also recurrently used in electronics and healthcare). Nonetheless, it is safe to say that modern organizations use it for food product development as well. In this paper, the authors conduct a comprehensive literature review on QFD.

The literature review dwells on the variety of QFD application methods and their usefulness for the relevant organizations. The paper systematically describes the ways in which QFD was employed in several companies and provides vivid examples of the methodology in use. A representative case of a company producing Spanish olive oil is included. It is important to mention that the literature about QFD that is currently available is insufficient. Nonetheless, the existing literature states that QFD is one of the most appropriate methods available to the food companies that are in need of simplifying their product development methods. Even so, the authors of this research realize that there are numerous points that have not been covered by previous research and refer to several downsides inherent in QFD. Even though QFD is described as efficient and productive, there is not much evidence that supports this claim. In the meantime, the existing literature highlights QFD methodology as a useful instrument in process development in the food industry. According to the majority of the authors, the current QFD should be revised in order to comply with the diversity of present food industry requirements.

Literature Review

In their 2011 research, Zarei, Fakhrzad, and Paghaleh dwelled on the peculiarities of lean production and its connection to QFD and Just-in-Time (JIT). Lean production is one of the most relevant strategies that are currently employed by numerous major companies all over the world. The key objective of implementing this methodology is to reduce costs by using the instruments made available by JIT. In contrast, the food supply chain became the focus of a number of investigators in recent years. This happened due to the fact that the supply chain management strategies and mechanisms are important in the modern context of this field. Zarei et al. reviewed lean enablers and lean attributes and how they are connected. The researchers used QFD with the intention of detecting feasible lean enablers. The latter was meant to be utilized in practice with the purpose of developing the leanness of the food chain. In addition to that, the investigators managed to implement fuzzy logic statements so as to generate verbal verdicts stating the associations and parallels essential for QFD. The researchers present a canning industry example in order to display the implications of the methodology and the ways in which it can be beneficial for the companies operating in the food industry.

In their 2014 study, Chen and Pai were able to review the practical employment of QFD. They stated that the requirements of the current dining clientele transform gradually as they need more specific features compared to those of the previous decade. The food and beverage business faces stiff competition due to China’s economic slowdown. Therefore, it is reasonable to claim that the wants and needs of the clients should be satisfied if companies are to prosper. Quality function deployment is the cornerstone of this research due to the fact that it is one of the best instruments designed to understand the essential needs of customers. This particular study examines the greatest opportunities for increasing service quality. The Taipei Spring Vegetarian Restaurant is the object of the research, and the intention of the investigation is to find ways of improving service quality in the vegetarian industry.

The researchers conducted a literature review on the subject and then interviewed a number of industry experts. On the basis of the interviews, Chen and Pai provided details on a comprehensive consumer questionnaire that mirrored a similar questionnaire presented to other professionals and academics. The researchers were able to utilize SPSS in order to analyze the results of the survey and involve the empirical breakdown of the QFD. In conclusion, the authors of the article identified five key characteristics that were critically acclaimed by the customers. Those characteristics included the trustworthiness and security of the restaurant, the overall quality of the products served in the restaurant, its safety, the courteous and professionalism of its crew members, and its comfortable atmosphere. The researchers were also able to identify a number of important features that were to be updated in compliance with QFD. Those improvements comprised business philosophy, quality of the final product, inclusive service quality, cookery, and the professional skills of the staff.

The key research of this literature review was conducted in 2011 by Erraach, Sayadi, and Parra-Lopez. They associated the major customer preferences (safety and quality) with the attractiveness of the products and sustainability of the olive-oil segment. The preferences were strongly connected to the overall customer demand satisfaction and consideration of environmental issues. The researchers found that QFD is currently one of the best approaches to certifying the fact that the products meet or exceed expectations of a company’s customer base in terms of product development and design. On a bigger scale, QFD can be an influential methodology because of its critical impact on marketing, quality improvement, and customer satisfaction sectors.

Nonetheless, the authors of the article found it interesting that the QFD methodology was not applied to the production of olive oil (considering that QFD has been applied to the food industry for the last 30 years). The authors of the study identified the key consumer requirements and then conducted a survey in order to identify the actual preferences and behavioral patterns inherent in the customers. Erraach et al. involved experts in the process of QFD application and defined the most fruitful agronomic practices that gratify customers in terms of their food preferences. The researchers composed a correlation matrix in order to assess the relative contribution of the crucial elements to customer satisfaction. The implementation of this matrix can be explained by the translation of the needs into agronomical practices that are implemented in order to satisfy these requirements. The findings presented in the article are also beneficial in terms of developing novel marketing strategies projected to expand the attractiveness and affordability of the olive oil produced in Spain.

In 2016, Suryaningrat reviewed the common problems faced by the Indonesian food industry. Particular attention was paid to cassava products. He stated that cassava food producers were unable to improve their production processes. Therefore, Suryaningrat accentuated the importance of improving the quality of processed Indonesian products. According to him, an investigation in this field is necessary to identify the areas of customer satisfaction and define the methods that can be used in order to meet or exceed the expectations of the customers.

The key objective of the current research was to thoroughly assess those basic customer needs that are essential to satisfy if the organizations plan on extending and developing their cassava product supply chain. In his research, Suryaningrat benefited greatly from the use of QFD. He was able to estimate consumer prospects and develop a sustainable cassava products supply chain. The researcher utilized the information he obtained from the suppliers, manufacturers, and industry experts. The outcomes of the study showed that the customers took into consideration the four main characteristics – smell, texture, taste, and color. Suryaningrat decided to consider these features to be the basic elements of a sustainable supply chain of processed cassava products. Overall, the researcher proved that various processing activities and quality control were related to the technical aspect of the production.

Methodology

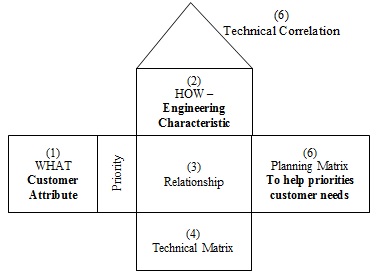

One of the tools of QFD is the house of quality. QFD is a tool to model the dynamics of the design process. QFD is also known by the terms “Customer-driven engineering” and “Matrix product planning”. The whole concept is based on a sequence of operations to translate the voice of the customer into the final product or service. Therefore, the house of quality is a graphic technique for defining the relationship between customer desires and products (or services). Defined as: “House of Quality is a part of Quality Function Deployment process that utilizes a planning matrix to relate customer “wants” to “how” the firm is going to meet those “wants”.”

The methodology used is basically providing details to initial steps in forming the House of Quality include determining, clarifying, and specifying the customers’ needs. These steps clearly define venture and will ensure a process is well thought out prior to any further development. The main aspects to be considered when developing a house of quality are;

- Clarifying Customer Needs – customers buy benefits and producers offer features. It is significant to interpret the voice of the customer into some tangible values that can be turned into engineering specifications.

- Specifying the Customer Needs – after determining what items are most important to the customer, organizations must translate them into particulate specifications.

To build the house of quality for our selected project, the basic seven steps are performed. These steps are:

- Identify Customer WANTS. (What do prospective customers want in this product?)

- Identify HOW product will satisfy customers (Identify specific product characteristics, features, or attributes and show how they will satisfy customer wants?)

- Identify relationships between the firm’s HOWS. (How do our hows tie together? What is the relationship between our two or more hows?)

- Develop importance RATINGS. (Using the customer’s importance ratings and weighs for the relationships in the matrix, compute our importance ratings)

- Evaluate COMPETING products. (How well do competing products meet customers’ wants? (entirely made on research)

- Determine the desirable TECHNICAL ATTRIBUTES. (Desirable technical attributes, our performance, and the competitor’s performance are determined and compared.

The above could be interpreted to the house of quality format. Basic graphic diagram for any house of quality resembles;

Discussion

The food and beverages (F&B) industry are all companies involved in the processing and distributing raw food materials, packaging of fresh, prepared foods as well as packaged foods. Any product meant for human consumption, aside from pharmaceuticals, passes through this industry. So, each F&B industry such as QSRs and/or fine dining should have many varieties of menu items depending upon either the quantities of menu items being added or upon the types of components being added according to the culture. Therefore, each restaurateur will have his own way of making the menu items. We can discuss the way of developing our items as shown in Figure XX. Since we know there are a lot of technical requirements for developing menu items, so we will first draw a chart for displaying the Menu Development Stages. The most important component in designing the product before its final launch is the house of quality Function Deployment.

House of Quality for developing F&B Menu items. The below assumption was made based on our on-going Quick Service Restaurant (QSR) Concept (“Bagels Factory, Ajman”).

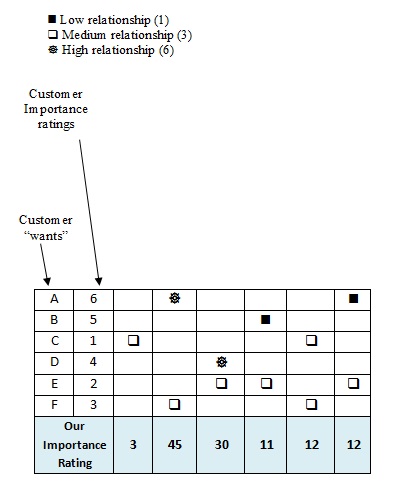

Identify the Customer Wants

Main elements that any customer desires when tasting the newly developed menu:

Table 1: XXX.

So, according to our daily customers’ feedback on social media (Instagram, Snapchat, and others) and walk-in customers, we’ve determined these importance ratings (out of 6):

Table 2: Importance Rating.

Identify How the Product Will Satisfy the Customer’s Wants

In order to satisfy the customer’s wants, owners or managers shall reflect customer’s demand into the industry product. Therefore, the reflected demand shall be considered before making a final product. We intended to deliver the following to meet customers’ wants;

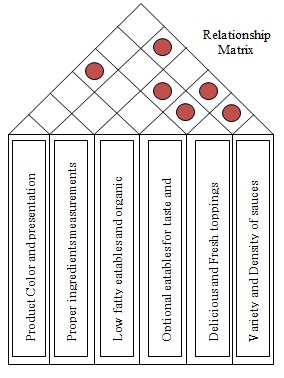

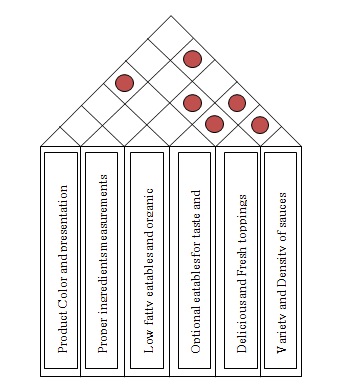

Identify Relations Between Our Hows

After identifying customer wants, we developed a relationship matrix between our ‘HOWS’. Some ‘HOWS’ are related to one another; therefore, according to our figure, we developed the following relations

Develop Importance Ratings

In this stage, we combined the HOWS and WANTS in a matrix and then we determined the importance ratings for the final work to be started.

- Good taste.

- Low price.

- Good texture.

- Low fats and healthy.

- Fresh and hot delivery.

- Appetizing appearance (good presentation).

This step is known as customer market competitive evaluation, we compared features of competing products of other companies from requesting LPOs from common suppliers. This comparison will help the developer position the product on the market as well as find out how the customer is satisfied now. For example, in the market, we saw two companies (Slider Station and By Parker’s) are competing for our products, so, we’ll first discuss and compare their products to ours to get a more comprehensive and detailed report. As per the comparison matrix below, we rate our products from competing companies as Good (G), Fair (F) and Poor (P).

Evaluate Competing Products

Determine the Technical Attributes

This step is considered as technical specifications that are developed into a product with the intention to satisfy the customer requirements. Also, this step aids in determining technical attributes and checking our performance with respect to market products.

Benefits and Drawback of Qfd in Food Industry

As per the study conducted by for food industry review, QFD was not clearly developed for the food industry or the food industry consumers. Therefore, it had its own befits and drawback such as;

Benefits:

- Team empowered to make decision

- Compromise decision about trade-offs

- Working meeting to develop results jointly

Drawbacks;

- Process related improvements are more difficult to achieve the product-related

- More suitable for products that are assemblies of single components

- Benefit service developers that product developers.

Conclusion

The current research was conducted using a methodological approach to the assessment of customer needs and ways to improve the production process. The literature review that was conducted as part of the research presented evidence concerning the key characteristics that generate customer satisfaction. It is safe to say that QFD would be a useful instrument for the organizations that are in need of a structured approach based on the requirements of a company’s customers. The methodologies that were reviewed and elaborated on throughout the process of conducting the research proved that QFD is a universal instrument and can be applied to a variety of industries. The key areas of QFD include organization, processing, supply, promotion, and administration.

The authors believe that the required quality parameters should be clearly determined before the implementation of the methodology in order to achieve the best results possible. Considering the results of the research, the authors of this study believe that QFD methodology should be incorporated into the practice of the majority of the companies that operate in the food industry. This would greatly impact the relevant society, the way in which the customers view the companies, and the approaches that are employed by the organizations in order to comply with their clients’ needs. Nonetheless, it is important to mention that the companies should possess a sufficient level of knowledge in the area so as to apply QFD in the food industry more often. This is why it is important to take into consideration the needs of the customers and make use of the most advanced technological measurement instruments available to the food industry. The current research represented a comprehensive review of the application of QFD in practice and evaluated the upsides and downsides of this methodology.

References

Zarei, M., Fakhrzad, M., & Paghaleh, M. (2011). Food supply chain leanness using a developed QFD model. Journal of Food Engineering, 102(1), 25-33.

Chen, S., & Pai, C. (2014). Using the QFD Technical to improve Service Quality in Vegetarian Foods Industry. International Journal of Academic Research in Business and Social Sciences, 4(2), 162-168.

Erraach, Y., Sayadi, S., & Parra-Lopez, C. (2011). Quality Function Deployment (QFD) in the Spanish olive oil sector. Agricultural Economics and Rural Sociology, 3(11), 1-14.

Suryaningrat, I. (2016). Implementation of QFD in Food Supply Chain Management: A Case of Processed Cassava in Indonesia. International Journal on Advanced Science, Engineering and Information Technology, 6(3), 302-311.

Govers, C.P.M. (2001) QFD not just a tool but a way of quality management, International Journal of Production Economics, Vol.69, pp. 151-159.

Yıldız, M. S. & Baran, Z. (2011b), Application of QFD on food and beverage managements. XI. Manufacturing Research Symposium, “The Evolving Role of Social Development and Production” Presentations Book, Istanbul Commerce University.

Vinodh S. & Chintha S. K. (2011). Application of fuzzy QFD for enabling leanness in a manufacturing organization. International Journal of Production Research,.

Costa, A. I. A., Dekker, M., & Jongen, W. M. F. (2001). Quality function deployment in the food industry: a review. Trends in Food Science and Technology.