Abstract

This paper demonstrates the use of real financial performance data to investigate environmental sustainability in the operations Honda Motors Company. The objective is to carry out a broad environmental friendliness analysis and future sustainability. It explores the various techniques and tools used in environmental audit analysis. In the analysis, we use financial data for Honda Motors Company for two years period from 2009 to 2010.

The study is based on a comparative analysis of historical data of the Corporation. The study concentrates on the statistical highlights of the Corporation, ratio analysis, and environmental issues surrounding its functionality. In addition, percentages are used in the analysis to monitor changes over time. Graphs are also used to portray the trend of various variables in the study over the two year period. Finally, the results are interpreted based on ideal situations, and recommendations are made based on the findings.

Introduction

Honda Motors Company is one of the largest motor car manufacturers in Japan. Despite the constant economic swings characterized by hyperinflation and depression, Honda has managed to stay afloat and profitable due to stringent financial models, the top management has assimilated into its operations. Reflectively, in manufacturing, the company has always been active in customizing its products to suit every class from which the company has cut a market niche (Have, Have, Stevens, Elst, & Pol- Coyne, 2003, p.67).

As part of the operation strategy, the company revolves around the philosophy of joyful, creating, selling, and buying. Besides, this philosophical alignment aims at getting and keeping customers through value for their money (Honda Motors, 2011d, p.18). As a result, Honda has an extensive and tight market across the globe, from the third world countries to the developed economic territories (Campbell, 2005, p.23). In the first quarter of the 2010 financial year, Honda Motors has surpassed the forecasted financial performance due to an organization of business operation bundles such as cost-cutting, promoting efficiency, environmental consciousness, and streamlining operations (Have, Have, Stevens, Elst, & Pol- Coyne, 2003, p.67).

As compared to the last six quarter financial earning, the performance for 2010 has been higher in the product range. In the process of achieving the current financial status, the company outperformed the arc rival, the Toyota Company, in sales at an impressive figure of ¥8,579,174 million (Honda Motors, 2010a, p.06). In a bid to stay relevant and improve on its products, the company has come up with complete combustion engines running on gasoline and hybrid gasoline-electric engines (Honda Motors, 2011d, and p.6). This model of the engine is environmentally friendly and cheaper to maintain than the ordinary model.

Though still not fully introduced into the market, the company is in the process of developing biofuel and hydrogen driven fuel cell engines. In appreciation for their continuous environmental concern, Honda Motors was awarded the prestigious honor of being the best environmental sustainability friend for their category in the world (Honda Motors, 2011b, p.15). As shown below, these figures reflect the performance of Honda Motors between 2007 to 2010 financial years.

Summary of financial performance from 2007-2010

Table 1. Summary of financial performance from 2007-2010

Source: Honda 2009 annual report

From the above table, it is apparent that Honda has had an erratic financial performance over the last four years. Despite the threat of declining performance, none of the financial years reported loss. Total revenue peaked at 12, 003 in the FY2008 after which it declined to lowest performance at 8, 579, in the FY2010. Operating income was at its lowest of 190 Yuan in the FY2009 and at the peak of 953 Yuan in the previous financial year. Despite the poor performance in the FY2009, in terms of the net income, FY2010 is characterized by a stabilizing net income, operating income, and total revenue (Wall Street Journal, 2011, p 16).

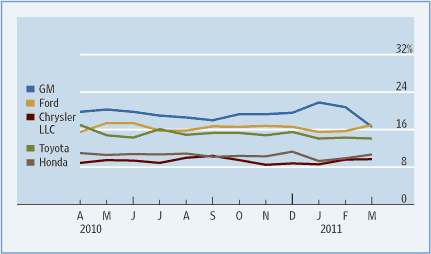

The graph below shows the relation in terms of sales between Honda Motors Company and its competitors.

From the above graph, it is of the essence to appreciate the fact that Honda Motors has remained relatively stable, with the existing discrepancy almost negligible. Though the performance slowed down in the month of January, gains made in the second financial session reflected an upward trend, which assumes a normal curve for the preceding years. Though the competitors may seem to be performing better in their sales, their forecasting orientation is not very stable as compared to that of Honda Motors (Wall Street Journal, 2011, p.04).

Objective of the Study

The objective of this research paper is to comprehensively carry out environmental audit analysis for Honda Motors and draw informed inferences from the results achieved. Specifically, this analysis will concentrate on the outstanding performance of Honda Motors for a two year period of 2009-2010. From the outcome of this analysis, the paper will identify Honda Motor’s sustainable and environmentally friendly production position as a function of Product Development Domain, Purchasing Domain, Production Domain, Transportation Domain, Sales, and Services Domain, Product Recycling Domain, Administrative Domain, and efficiency. In addition, a recommendation would be presented on the viability of investments in the Honda Motors Company based on the final findings.

Literature Review

Honda Motors Company responds to environmental concerns with different comprehensively reviewed policies depending on the geographical location of its plants, national environmental bodies, and business ethics (Ito, 2010, p. 11). For every global operation carried out by this company, environmental sustainability has been its major priority on the facets of sustainable productivity and energy conservation through efficiency. In the contemporary business environment, resource problems, climate change, energy problems, biodiversity, waste management, and pollution control are substances of concern in operating self-emission initiatives (Ito, 2010, p.21).

Honda supplies different products form its long chain of departments across the global market. Since most of these products are ranked in the category of mobility products, Honda regards issues on climate change with great concern. In the production chain, greenhouse gas emission is associated with climate change as a result of global warming (Honda Motors, 2010a, p.22).

An in-depth life cycle analysis reveals that the apparent emission of carbon gases contributes to the largest damage as compared to other gases. In response, Honda Motors Company has set up targets for carbon dioxide reduction across its main domains and geographical regions of operation. Besides, Honda Company has been at the forefront of impact assessment research and alternative production approach to function optimally within the acceptable pollution limits (Honda Motors, 2010b, and p.13).

Across the major domains of Honda Motor Company’s operations, specific initiative have been internalized and fully embraced by their management system through quarter plans which embrace Hi-efficiency production in their engines, Innovative production of hybrid products supported by environmentally friendly technology, and revolutionized green and renewable energy sources(Honda Motors, 2010a, p.18). These policies work concurrently to boost performance standards and incorporate the need for ‘going green’ and ‘appreciating nature’ as reflected in the company’s goal of joyful production to satisfy the customers’ needs.

Environmental Issues Analysis/ Life Cycle Assessment

The outstanding long-time commitment of Honda Company towards the protection of the environment through the production of environmentally friendly products has seen this company earn the prestigious award of being the best eco-friendly manufacturing company. This status resulted from the development of the hybrid CVCC model. The process of maintaining sustainability demands that a company should embrace a life cycle assessment approach to understand and review issues of environmental concern (Honda Motors, 2010d, p.11).

Product Domain Development

Honda Company has a high turnover in terms of the products it produces annually. In the process, pollution as a result of carbon dioxide emission is eminent if not properly managed. To address this concern, Honda company, through its top management team has initiated several initiatives aimed at producing fuel-efficient automobiles, reducing the intensity and volume of exhaust emissions, developing green alternative energy fuels products, reducing noise pollution and adopting the 3R design(Reduce, Reuse, Recycle)(Honda Motors, 2011d, p.18). The success of Honda Company in the 2009-2010 financial years can be attributed to the introduction of the hybrid engine model as part of its assembly of products. This model is affordable, highly efficient in fuel consumption, and produces very low carbon dioxide gases in combustion. In addition, this model has a safety enhancement feature with full manual to its user (Honda Motors, 2011c, p.23).

As a policy resolution, Honda has successfully gone through the ISO certification and a clean bill of health in line with the international environment management protocol for manufacturers (Honda Motors, 2011a, p.07). In appreciation, awards and accreditations have been given to Honda Motors Company, such as UCS greenest carmaker in America in 2007, the best economy rating for EPA fuel in 2005, and the 2010 category for the greenest automobile. Alongside the hybrid engine, Honda company has incorporated electric mechanism in the hybrid engine to enable their customer have an option of switching ignition to charged electric cells to save fuel. In the findings of the National Renewable Energy Laboratory, in a study conducted in 2005, Honda Company score 62% in the efficiency category of Toyota’s 64% (Simpson, 2006, p. 32).

Also, as the world leading producer of internal combustion engines, Honda has reaffirmed commitment and fully subscribes to the set environment regulation protocol in a continuous environmental impact influence aimed at reducing the quantities of carbon dioxide emitted into the atmosphere across its manufacturing plants. In the 3R, Honda has succeeded in maintaining along history of recycling and activities aimed at building harmony as part of the local communities who form part of their market niche (Have, Have, Stevens, Elst, & Pol- Coyne, 2003, p.77).

Tracing back from as early as 1960, the community forests initiative have successfully created a permanent impact on the locals and has encouraged them to adopt effectively in resource use and reuse. This is part of their third priority activities in the year 2009 which categorically states that “We will work to reduce environmental impacts and ensure the effective use of resources through efficiency improvement” (Honda Motors, 2011c, p.02). In addition, Honda Company has contributed towards biodiversity development and conservation following the adoption of technological disseminators of next generation engine development, self-energy producing automobiles, and fuel efficient CVR models.

Purchasing and Production Domain Development

In the production process, raw materials used include water and other components which at the end become wastes. Waste disposal challenge is a reality for most heavy manufacturing companies. Honda Company has adopted green purchasing as an alternative production efficiency. In the management segmentation, environmental management has been created to monitor products supplied by their suppliers who have to sign a ‘zero emission initiative’ pack before being associated with its production line. Besides, Honda has established green factories using solar-powered machines like the one in California. As part of the product domain, energy is considered key in the production and system maintenance. In the words of Honda CEO, Takanobu Ito, the company is planning to refine its brands especially the hybrid model to incorporate the new technological changes and increase the models to five (Ito, 2010).

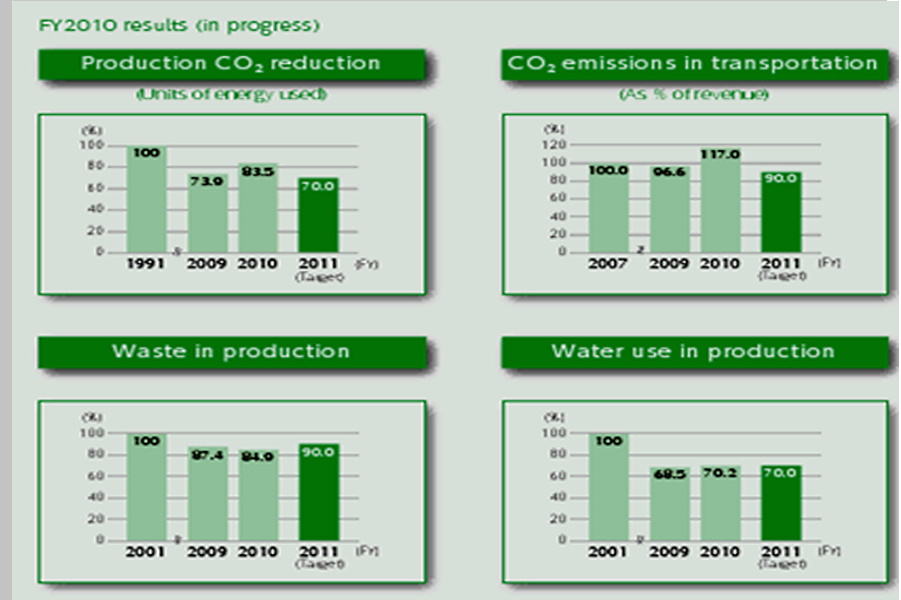

Successful as indicated in the above graphs. Reflectively, carbon dioxide emitted during production process reduced from 93.5% in 2010 to 70 percent in the following year. This can be attributed to the numerous environmental strategies adopted in the same year. The same applies to the amount of carbon dioxide released in the transportation domain. Steadily, the amount water used in production has also reduced due to conservation as a sustainability strategy.

Transportation Domain

Transportation of raw material, finished products, and experimental models demand a fair amount of resources in the form of logistic support and energy. In the process, the automobiles contracted to do the transportation releases green house gases and other environmental unfriendly waste. Thus, there is an immediate need for management of this process within the set environmental business operations protocol. In a bid to handle this challenge, Honda company through the transportation and audit departments have embraced transportation efficiency improvement by lessening packaging material, proper maintenance of the company’s transportation fleet and designing a model which uses the best alternative whenever the company has to transport either raw materials or finished products (Have, Have, Stevens, Elst, & Pol- Coyne, 2003, p.65).

Sales and Services Domain

To survive the unstable economic times, as predicted by financial analysts of the Wall Street, Hondas has responded by concentrating in motorcycle manufacturing as a means of accessing relative and competitive advantage over its competitors. In addition, efficiency has been enhanced in engine production department through continuous technological research, innovation, and streamlining overhead costs. As the new technology embrace the motor market, Honda is not left behind especially on the facets of producing green energy and hybrid engines guaranteeing optimal energy utilization at manageable and environmentally friendly levels (Have, Have, Stevens, Elst, & Pol- Coyne, 2003, p.67).

To minimize the waste associated with service delivery and sustainability, Honda Motors Company has internalized environmental management chart which periodically reviews and make recommendation on technological research breakthrough. The company sells, maintains and may recall any automobile noticed to be performing below the expected. Before the customers access their order, Honda Company has put in place parameters for measuring fuel consumption, efficiency, and performance (Campbell, 2005, p.11). Specifically, this initiative has contributed positively to Honda Company in California where tax exception is practiced for companies producing goods at minimal pollution levels (Harrison & St. John, 2010, p.45).

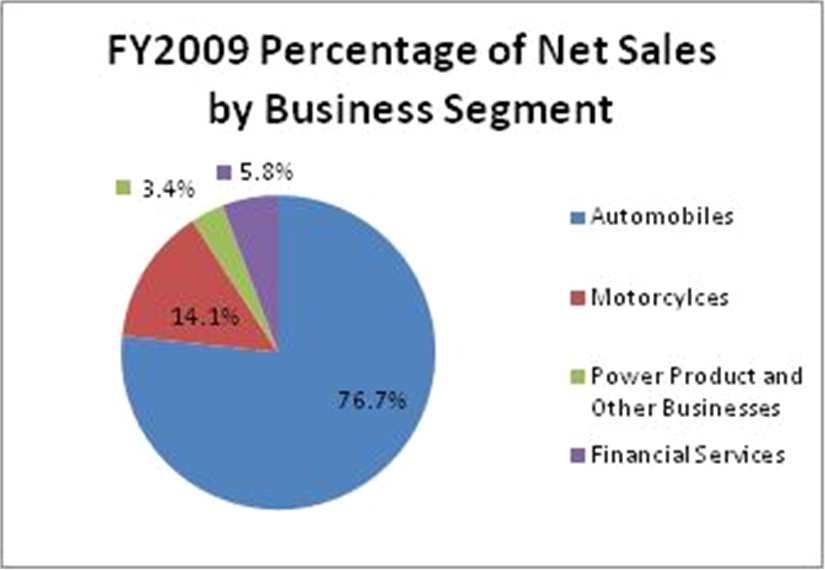

As presented in the chart below, the figures are drawn from the Honda Motors Company website for their 2010 net sales of the different products produced by the company.

From the pie chart, it is apparent that sale of Automobile soared at 76.7% as compared to the motorcycle department sharing 14.1% of the total sales. Besides, power product controlled 3.4% of the annual sale. In the preceding quarter after the first successful segment of the financial year, the profits decline by 56% to 54.2 billion yen mainly as a result of the impact of reduced overall sales of units for the same period. Despite the variance in profits realized, the company adopted efficiency in operations to cover up for the decline. Besides, it hybrid model was sold at zero percent tax as the economic laws dictated.

Product Recycling Domain

In the product recycling domain as part of the environmental concern, the issue of the end of usefulness of a product arises. When such a product disintegrate to unusable level, it becomes a waste is likely to be damped by its final user (Alsop, 2002, p. 19). Such damped automotive parts pollute the environment and is a threat towards sustainable co-existence between mankind and his activities (Gelder, 2005, p.45). Sometimes, the rooting parts of such damped wastes may become a health hazard. Faced with this challenge, Honda Motors Company has formulated a reuse policy for such types of wastes. For instance, it would reward an end user with financial gain when the used up automobile or machines are returned to the plant for recycling (Foster, 2002, p.23). For Honda Company, parts recovery is not limited to the metallic parts only.

Rather, the rubber, aluminum, among others is included in the list of reusable parts. These parts, irrespective of their condition can be recycled and reused for other purposes. Reflectively, this practice has substantially reduced the quantity of harmful disintegrated engine and body part which originated from Honda plants (An & Sauer, 2004, p. 35). For the parts which cannot be reused, the company has developed an initiative and an awareness campaign aimed at enlightening customers on the need for proper disposal of end-of-life products. Depending on the material from which such a product was made of, Honda has established several disposal plants for its end-of-life products. In these disposal plants, the company has recruited experienced technical support team on environmental sustainability and conservation.

Administrative Domain

This domain consists of the management and personnel who are informed and knowledgeable on international environmental conservation protocols in business environment. As a matter of fact, Honda has periodic training sessions for its employees on environmental sustainability and efficiency (Harrison & John, 2010, p.32). United under the umbrella of continuous knowledge on impact assessment, this team is active in functionality of the company’s green offices, energy conservation and optimal use, environmental management, resource use and reuse, and community outreach programs on environment (Cogan, 2006, p.21). As part of social responsibility, Honda Motors Company has in the past 40 years contributed over twenty million dollars in community based initiatives such as the ‘community forests’ and training sessions (Harrison & John, 2010, p.34).

Internal Environmental Audit of Honda Company

To optimize from the favorable business climate created by China, Honda Motors has established an assembly branch which makes good use of the available cheap labor offered by the Chinese government (Bremmer & Stewart, 2011, p. 67). In the first place, Yuan currency is stronger in China and competes fairly with other major currencies like the Euro and the dollar due to economic functionality influence the Chinese government has created to attract trade in Yuan currency (Harrison & John, 2010, p.34).

Besides, several export processing zone are allocated to foreign investors of which Honda Motors is one of them. In a partnership affiliation, Honda Company has established a rapidly growing relationship with Guangzhou SOE to manufacture engines in this region (Ito, 2010, p.65). To create an optimal and sustainable business environment, governments across the globe are in the first late to implement and review business policies to match with the need for environmental sustainability. In response, and to avoid the excessive fines imposed upon exceeding a carbon emission limit, Honda Company has fully embraced green manufacturing techniques which are convenient to its customers (Campbell, 2005, p.54).

Since most of the products form Honda Motors is as a result of customer oriented research, its success have been contributed by the satisfied customers who seem to accept Honda products as social favorite commodity as their expectations are met in the design, operation, and maintainability(Welsh, 2009, p.45). Further, majority of states across America have legalized the need for healthy environment and reduced pollution from carbon emission. As a motivating factor, tax exemptions, clear environment certificates and clear bill of health is issued to agents who have these interests at heart. From the California hybrid plant, Honda Motors has incorporated ethanol production and environment friendly structures in America (Welsh, 2009, p.45).

Since the future of automobile manufacture business is inclining towards sustainability and friendliness to the environment, Honda Motors Company has indicated intentions to invest in technological research and development in line with the forecasted business operation environment. Besides, the company has commenced its strategic plan of remodeling the quality assurance and control to suit the current cyclones of the financial market (Honda Motors, 2010b, p.16). These efforts are geared towards creating a self sufficient production system which can survive in the international market trade.

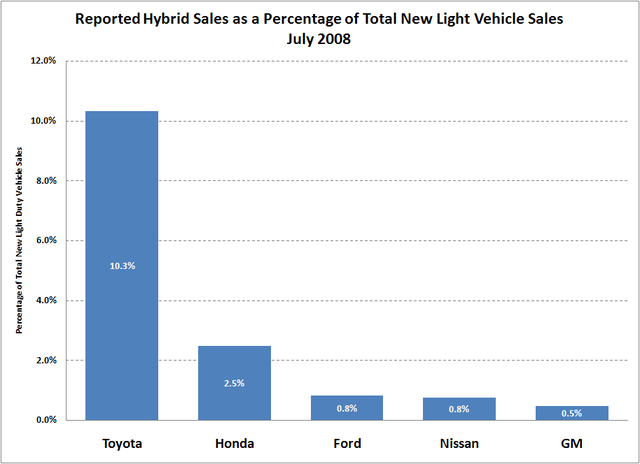

Honda’s Competitive Ranking

As indicated in the above graph, despite these numerous efforts to stay competitive with it hybrid model, Honda’s Hybrid model remains uncompetitive to Toyota’s model. To reverse this, Honda Company seems to embrace functional strategies which consist of sustainable mapping framework, sweep spot analysis, and Triple bottom line functionality (Have, Have, Stevens, Elst, & Pol- Coyne, 2003, p.57). In the first strategy, the company has since identified alternative and efficient energy consuming models for their next generation of the hybrid models expected to come in five different types (Honda Motors. 2011d, p.29). In the sweet spot strategy, Honda has endured to customize its products as required by clients who would prefer efficient and affordable models.

Over time, Honda has managed to survive competition due to support form clients who have always approved of their efforts. Since its inception, Honda Company has managed to hire highly skilled engineers who have overtime combined research, skills, and creativity to come up with exiting models have ensured profit, approval from the people, and friendly to the planet (Shook, 1988, p. 58).

Market Segmentation

In order to remain competitive, Honda Motors Company has considered the possibility of joining the aviation industry as a mean of spreading operation margins and capture new market in line with its expansion goal. Thus this strategy is expected to bring success considering the fact that Honda model has maintained international standards in product quality as expected in the aviation industry (Honda Aircraft, 2011, p.7). Reflectively, market segmentation is also vital in ensuring sustainability (Have, Have, Stevens, Elst, & Pol- Coyne, 2003, p.67). When portfolio balance is maintained within manageable level, the end result is commonly referred to as optimal productivity within minimal cost constraints.

Conclusion

Since its establishment, Honda Motors Company has remained relevant, efficient, and outstanding manufacturer of automobiles and other machines. In the 2010 financial year, the recorded profit stood at over ¥8,500,000 due to the company’s adopting of diversification of products from motorbikes to generators. Besides, the hybrid model whose engine is composed of gasoline and electric functionality was major success among customers shopping for efficiency and performance. Following the approval form American environmental regulation body, Honda has experienced additional unit sales for customers who would wish to associate with the friend of the environment. Introduction of the hybrid model has secured the future survival of Honda Motors Company as the contemporary world slowly but steadily embrace green biodiversity. Unfortunately, the hybrid model is very expensive to majority of the targeted customers.

Recommendations

As global warming grows into a disaster, manufacturers are faced with the dilemma of operating efficient systems in these environments. Manufacturing business has become very expensive and proper strategic planning is of essence. At present, Honda Company is faced with the dilemma of maintaining environmental friendliness production within limited resources and more challenges. Besides, its hybrid model is non competitive to that of Toyota on performance and cost. As the need for environmental system ability hits the climax, Honda Motors Company should heavily invest in alternative energy efficient automobile research and development as forecasted by financial experts.

Besides, the appearance of the Honda insight hybrid should be furnished to appeal to many customers as the current model is just but a prototype. Proper training of staff is a vital aspect of growth for any company. Thus, Honda Motors Company should invest in training of its work force in line with the modern technological know how so as to remain competitive and relevant. Apart form the current range of products, the company should spread its operations to include heavy mining machinery, water boats, aero plane parts, and electric trains.

Reference List

Alsop, R., 2002. “Perils of Corporate Philanthropy tuiting Good Works Offends the Public, but Reticence Is Misperceived as Inaction”. The Wall Street Journal An, F. & Sauer, A., 2004 Comparison of Passenger Vehicle Fuel Economy and GHG Emission Standards around the World. Web.

Bremmer, I. & Stewart, T., 2011 China’s State Capitalism Poses Ethical Challenges. Web.

Campbell, D., 2005. Organizations and the Business Environment (2 ed.), Elsevier: Butterworth- Heinemann.

Cogan, D., 2006. Corporate Governance and Climate Change: Making the Connection. Boston: Ceres.

Foster, M. S., 2002 Nation on wheels: the automobile culture in America since 1945. Michigan: Wadsworth Publishing.

Gelder, S., 2005 Global brand strategy: unlocking branding potential across countries, cultures and markets, London: Kogan Page.

Have, S., Have, W., Stevens, F., Elst, M, & Pol- Coyne, F. 2003 Key Management Models, New York: Financial Times/ Prentice Hall.

Honda Aircraft, 2011 Assembly of conforming aircraft begins. Web.

Harrison, J. & St. John, C., 2010 Foundations in strategic management Ohio: South Western Cengage Learning.

Honda Motors, 2011. Company overview. Web.

Honda Motors, 2011d. Initiatives & Awards. Web.

Ito, T., 2010. Honda CEO speaks at the 27th Thailand International Motor Expo.

Shook, R., 1988 Honda: An American Success Story: Revolutionizing the Art of Management. New York: Prentice Hall.

Wall Street Journal, 2011 “Auto Sales”. Web.

Welsh, J., 2009 “Car Compare: 2010’s Toyota Prius vs. Honda Insight.” Wall Street Journal. Web.