Introduction

An air conditioner (AC) is a home or office appliance that purifies and dehumidifies air in a room. The air conditioner cools the room by taking out hot air from the house and cycling it back as cool air, a cycle that continues until the house attains the desired temperature. The process is referred to as the refrigeration cycle. Normal conditioners use refrigerant gas (mainly Freon) to cool the room, examples are those ACs used in residential buildings and offices, however, conditioners used in large commercial buildings and factories use cooled water (Whitman et al 2008, p. 1222).

The first AC units were designed in the late 19th century and were mostly used for industrial purposes, in 1902, the first electrical AC was manufactured by Willis Carrier in New York. During this period, ACs used poisonous or combustible gases such as Ammonia and propane, which resulted in critical accidents in case of leakages, however, a safer gas, Freon, was invented in 1928 and is still used today in ACs.

The purpose of the report is to offer exhaustive information on the processes that occur in each stage of the refrigeration process, i.e. compression, condensation, expansion, and evaporation. The report will also illustrate the properties of Freon that make it suitable for use as a refrigerant gas.

Body

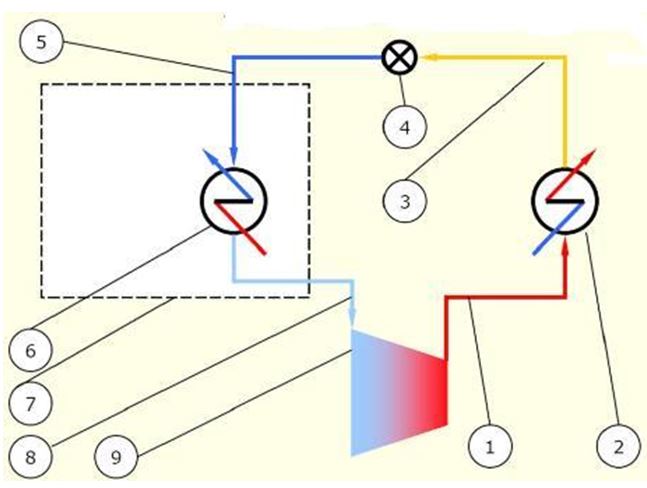

Air conditioners units (ACUs) are divided into two compartments: the high-pressure compartment and the low-pressure compartment as shown in the figure below. (Halder, 2009, pp. 41). Refrigerant gas (Freon) moves between the two compartments during the refrigeration cycle. In order to understand the refrigeration cycle, we must first examine the properties of Freon that make it appropriate for this role.

Key

- High-pressure side

- Heat exchanger (condenser)

- Warm air cooler

- Expansion valve

- Low-pressure compartment

- Evaporator

- Boundary between the sides

- Heated refrigerant vapor

- Compressor

Refrigerant gas. The most frequently used substance for refrigerant gas is Freon. Freon is a mixture of chlorine, fluorine, and carbon hence belongs to a group of compounds called chlorofluorocarbon (CFC). The first ACs used poisonous or combustible gases such as methyl chloride and sulfur dioxide that led to critical accidents when there was a leakage. Therefore, scientists developed a gas that was considered safer. Freon is non-poisonous, odorless, and non-flammable, thus, in case of a leakage, there is no risk of a fire outbreak or poisoning of occupants in a room. However, CFCs deplete the ozone layer and do not decompose easily. This has led to the invention of other types of refrigerant gases, an example is HFC-134a, also known as Tetrafluoromethane, this gas has a shorter life span and contributes less to the depletion of the ozone (Wirz, 2006, pp. 7).

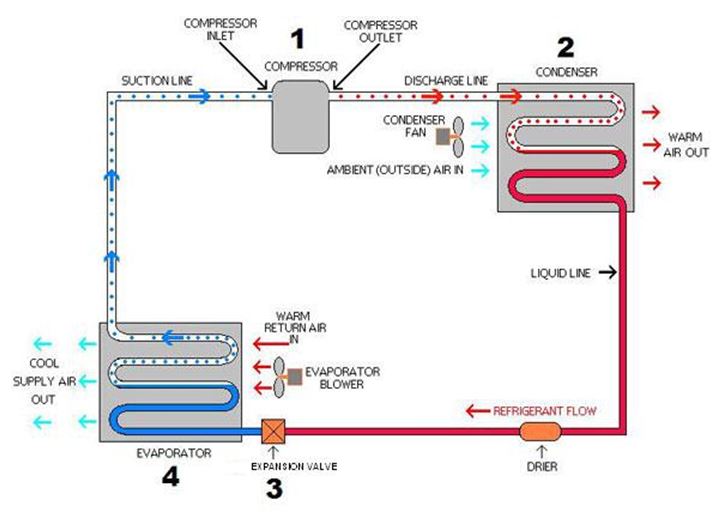

High-pressure compartment

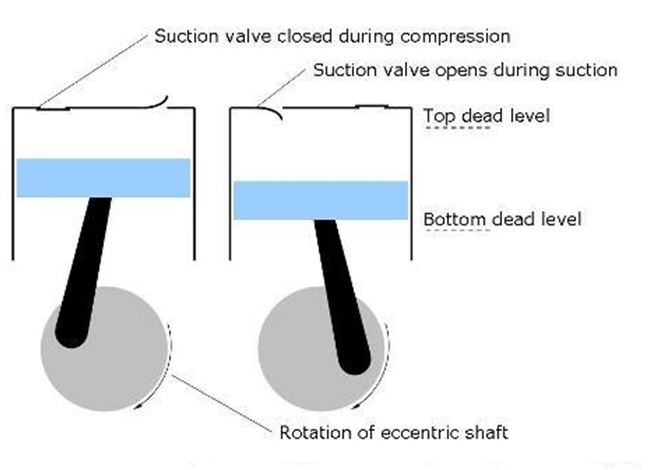

Compression. The compressor applies pressure on the refrigerant gas and it moves out through the evaporator coil. As the electric motor spins, the piston moves in a continuous straight line between two points within the ACU. Two valves are situated at the lower end of the gas compartment; one is the suction valve while the other is a release valve. The suction valve opens only in the direction of the chamber, and the discharge in the opposite direction. As the piston moves, a vacuum is formed and this causes gas to rush in, opening the suction valve, the refrigerant gas moves into the created space (Rajput, 2010, pp. 12).

The piston stops when enough refrigerant gas has moved in and the vacuum no longer exists, this makes the suction valve move forward. The piston moves forward too. Movement of the piston causes compression of the gas, forcing the release valve to open ()Wirz, 2006, pp. 8. The refrigerant gas is then pushed out through the open release valve. The compression process is very rapid, more than 17 cycles can occur in a second.

Condensation. The speedy compression of the gas raises its pressure and hence its temperature to roughly 104 0F. The condenser helps in heat exchange between the gas and cool fluid. The gas turns into liquid form once it gets into the condenser, as this liquid moves above the condenser, it comes into contact with the external cool air and it loses heat. The heat is lost through the condensation coils, fins, and eventually the outside environment. The coils are designed so that the refrigerant gas can take maximum time inside them, allowing for maximum heat exchange. The gas reaches its condensation point.

From the coils, the liquid refrigerant gas passes through the receiver- a compartment for storing and filtering the gas.

Expansion. The gas is still in liquid form and under very high pressure. The expansion valve is a constriction and allows the gas to collect and lose some of its pressure after it moves out of the condenser. This point separates the high-pressure compartment and the low-pressure compartment. The passageway out of the expansion valve is attached to the evaporator, which is also attached to the suction port of the compressor. As a result, the gas, still in liquid form, moves out of the expansion valve, loses its pressure, and instantly changes to vapor (Rajput, 2010, pp. 12).

Low-pressure compartment

Evaporation. In order to complete the heat cycle, the refrigerant gas, now in gaseous form, needs to absorb heat. It will pick up this heat from the surrounding, in this instance a room. A drop in pressure (or an increase in volume) leads to a drop in temperature according to the pressure-volume-temperature relationship. Since the external environment has a higher temperature, the gas absorbs heat to reduce the temperature difference, or, the external surrounding loses heat to the gas. The whole cycle starts yet again at the compressor’s suction (Dincer & Kanoglu, 2010, pp. 407).

The fan that is fitted to the ACU circulates air in the room since motionless air can be unhealthy to room occupants. The fan stirs up the air and drives some of it outside and fresh air moves in the room, therefore, the aid of the fan in air exchange. The rest of the air moves to the air conditioner where it mixes with fresh air coming outside through the ventilator. Finally, an ACU will replace all the air in a room with air from outside, it can exchange air at the rate of 20 to 45 cubic feet for every minute. The size and speed of the ACU motor will determine this rate.

Dry air can cause a person’s skin to be dehydrated and their noses and lungs to become aggravated. To prevent such an occurrence, ACUs add water vapor to the air during cold weather.

Conclusion

The process of air conditioning goes through five main processes, i.e. compression, condensation, expansion, evaporation, and finally heat exchange. These processes work together to clean the air and lower the temperature. The process gives out water vapor as a by-product, an ACU is normally connected to pipes that move the condensed water out of the building. These pipes should be washed out regularly to prevent them from being blocked by algae and related growth. The ACU should have a spare drain pipe for use when the main pipe fails. The ACU usually comes with an automatic cut-off control that turns the system off when the drainpipes are filled with water.

Reference List

Dincer, I., and Kanoglu, M. (2010). Refrigeration Systems and Applications, Second Ed. West Sussex: John Willey and Sons, Ltd.

Halder, G. (2009). Introduction to chemical Engineering Thermodynamics. New Delhi: Asoke K. Ghosh.

Rajput, R. K. (2010). Engineering thermodynamics, third Ed. Boston: Jones and Bartlett Publishers.

Whitman, B. Johnson, B. Tomczyk, and J. Silberstein, E. (2008). Refrigeration & Air Conditioning Technology: Sixth Edition. New York: Thomas Delmer Learning.

Wirz, D. (2006). Commercial refrigeration for air conditioning technicians, Vol. 1. New York: Thomas Delmar Learning.