Abstract

Internal combustion engines (ICEs) have served humanity for a long time. Since the invention of ICEs in the late 1800, our lives have greatly relied on ICE machines. However, recent developments in environmental conservation have seen increased pressure for engineers to make IC engines more efficient. This pressure coincides with the global quest to make machines ‘greener’ and more environmentally friendly. From this movement, many engineers have explored ways to improve ICE efficiency.

After exploring ICE types, their application, recent technological advancements in improving the performance of ICEs, and the obstacles that prevent the realisation of optimum efficiency for these engines, this paper proposes the adoption of variable valve timing, turbo chargers, cylinder deactivation, and direct injection technologies as possible ways to increase the efficiency of ICEs. These new technologies advance possible alternatives for improving the internal combustion engine efficiency.

Introduction

The internal combustion engine has attracted a lot of attention among observers for its efficiency needs. Indeed, through the emission of greenhouse gases from internal combustion engines, ICEs have contributed significantly to the global carbon footprint. Apart from ICEs, engineers are developing more fuel-efficient machines.

The process of developing efficient machines bases its principles on two processes – reducing energy consumption and increasing energy efficiency. There are many types of internal combustion engines but Sanguri (2010) demonstrates that all ICEs work the same way. The ICE combustion model characterises the ignition of fuel (by mixing air and fuel) to compress gases and produce energy

ICEs have always failed to provide maximum performance (compared to the fuel injected). In fact, Sanguri (2010) explains that most ICEs are inefficient because users enjoy only 20% of the total energy produced from the burning engine. Fortunately, engineers are exploring new ways of improving fuel efficiency today. Most of these developments anchor on the advancement of computer technology. In fact, computer technology controls most car engines produced today. However, computer technology has not been able to solve most of the efficiency concerns for ICEs.

This paper proposes five strategies for improving the efficiency of internal combustion engines (ICE). These strategies anchor on new technologies used in the past five years to increase engine efficiency. They include direct injection, cylinder deactivation, turbo chargers, variable valve timing, and the use of clean fuel. However, before analysing these technologies, this paper explores the application of ICEs, types of internal combustion engines and the possible opportunities and challenges that exist in optimising engine efficiency.

Application of ICEs

For a long time, ICEs have powered movable machines. Mainly, the application of ICEs has been to propel movable machines. These machines include cars, boats, and aircrafts. Sometimes ICEs also power immovable machines such as generators but the most common application of ICEs lie in powering car engines (Ganesan, 2008).

In fact, almost all car engines use ICEs. A recent trend among car manufactures is to replace ICEs for electric motors. Other car manufacturers are exploring the possibility of merging ICEs with electric motors so that ICEs ignite when electric motors lose power.

Types of ICEs

There are two main types of internal combustion engines: diesel engines and gasoline engines (Gupta, 2006). Sometimes, gasoline engines are called spark engines and compression engines are called diesel engines. Diesel engines and gasoline engines subdivide into two-stroke engines and four-stroke engines.

Two-stroke engines are less efficient than four-stroke engines because the number of strokes realised when fuel burns in four-strokes engines is more than a two-stroke engine (ordinarily, people assume that the efficiency of four-stroke engines is more than two-stroke engines but this is not the case).

Gupta (2006) explains that the classification of ICEs subdivide into reciprocating and rotary engines. Rotary engines are often characterised by the presence of a rotating blade. This rotating blade works to produce power for the engine. Reciprocating engines are more common than rotary engines and they are a popular choice for car engine manufacturers. The spark ignition engine and the comprehension engine constitute the most commonly known types of reciprocating engines (Gupta, 2006).

Engine Efficiency

Several challenges characterise the quest to increase engine efficiency for internal combustion engines. Indeed, the efficiency of the ICE depends on several factors but most importantly, the compression ratio, friction, and oxygen affects the efficiency of ICEs. These factors are also subject to other environmental and mechanical issues, which affect the engine’s efficiency.

Compression Ratio

The compression ratio normally determines the engine power of internal combustion engines (high compression ratios signify high engine power and low compression ratios signify low engine power). In addition, the compression ratio determines engine efficiency because high compression ratios signify improved engine efficiency while low compression ratios signify low engine efficiency (Erjavec, 2005, p. 673).

For gasoline engines, a high compression ratio signifies low engine efficiency but in diesel engines, a high compression ratio signifies increased engine efficiency. The disparities in engine efficiency occur because gasoline does not easily burn under high compression but diesel easily burns under such conditions (Erjavec, 2005).

Friction

In an internal combustion engine, friction occurs through the movement of engine parts. Friction leads to the loss of energy and it acts as a barrier to prevent the realisation of optimum full efficiency. In fact, ICEs may require 20% more energy to overcome the friction barrier (Erjavec, 2005). This lost energy signifies less engine efficiency.

Oxygen

Energy production occurs when fuel burns. This process informs the production of energy from ICEs because the machine transforms chemical energy into mechanical energy (through combustion). This paper already shows that for combustion to occur, fuel mixes with air. Guzzella and Onder (2009) explain that combustion occurs in three stages where hydrogen first burns to form vapour, carbon burns to form carbon monoxide and in the last stage, carbon monoxide burns to form carbon dioxide (Guzzella and Onder, 2009).

Since air contains different compounds, oxygen only constitutes 20% of the air volume. From this small percentage, oxygen may deplete before full combustion occurs. Incomplete combustion may later lead to the formation of harmful compounds thereby reducing the efficiency of the machine (Guzzella and Onder, 2009).

Others

Apart from the above factors, the efficiency of the ICE is still marred by other inhibitive factors such as heat loss (during engine cooling), heat loss from exhaust gases, vehicle drag, imperfect valve timing, low oil viscosity and high energy loss from breaking (among other factors) (Sanguri, 2010). Cumulatively, these factors stand as obstacles to prevent the improvement of engine efficiency through internal combustion.

Solutions

Except for the above challenges (inhibiting the improvement of engine efficiency), several solutions can improve engine efficiency. They include direct injection, cylinder deactivation, turbo charging, variable valve timing, and using clean fuel.

Direct Injection

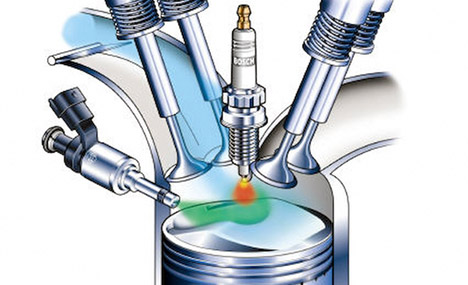

The direct injection technology improves fuel ignition (Graham, 2008, p. 3). Initially, fuel and air mixed in the engine manifold but after the introduction of the direct injection technology, fuel mixes with air in the cylinder to improve engine efficiency (Graham, 2008, p. 3). The following diagram shows how direct fuel injection works

From the above diagram, fuel mixes in the cylinder as opposed to the car’s intake manifold. Through the above technology, there is a better control of the fuel used (but this efficiency also depends on the acceleration and cruise of the engine/vehicle).

Cylinder Deactivation

The cylinder deactivation technology works by deactivating unused cylinders when there is a need to do so. Cylinder deactivation often happens when a car requires less power (Graham, 2008, p. 3). Therefore, the numbers of used engine cylinders reduces on demand. The efficiency of this technology peaks when there is a reduction in energy use. This type of technology has been widely adopted in modern engines such as the V6 or the V8 car engines (Graham, 2008).

Turbo Chargers

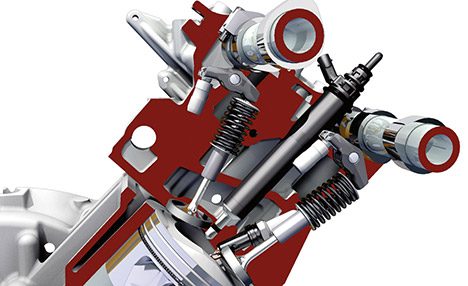

The main technology characterising the operation of the turbo charger is the increase in air compression (into the cylinders) so that more power derives from the fuel used (Graham, 2008). The following diagram shows a turbo-charged engine

From the above diagram, air compression increases in the cylinder to produce more engine power. Fuel combustion increases in this regard and better engine efficiency occurs. Similarly, there is less fuel wastage. These benefits are significant in reducing overall fuel waste but the turbo charging technology has been criticised for failing to be entirely economical.

However, proponents of this technology have advanced the view that this technology improves the efficiency of ICE by giving smaller engines more power (Graham, 2008). Therefore, broadly, turbo charging technologies improve the efficiency of ICEs.

Variable Valve Timing

In the past, it was impossible to vary the volume of fuel (or air) that enters the combustion engine. However, with the introduction of the variable valve timing technology, it has been easy to vary the volume of air and fuel that enters the combustion engine (thereby optimising engine performance with minimal fuel) (Graham, 2008, p. 5).

The variation of air and fuel occur through an optimal timing valve that ensures maximum power from injected fuel. Through such technologies, smaller engines can give more power (as turbo charged engines do).

Clean Fuel

The use of clean fuel increases the efficiency of combustion engines (Graham, 2008). An example of clean fuel is low-sulphur diesel. This type of fuel makes engine combustion cleaner and enables engines to have an efficient combustion. Overall, clean fuels increase engine efficiency.

Conclusion

Graham (2008) explains that internal combustion engines will be around for a long time. Therefore, in the wake of environmental consciousness, it is only wise to adopt new technologies that increase the efficiency of IC engines.

After weighing the findings of this paper, the use of clean fuel, better variable valve timing, turbo charging, cylinder deactivation, and direct injection pose as the best options for increasing the efficiency of ICEs. So far, most of these technologies power modern engines because they provide the best bargain for optimising fuel consumption.

References

Erjavec, J. (2005). Automotive Technology: A Systems Approach. London: Cengage Learning. Web.

Ganesan, L. (2008). Ic Engines. London: Tata McGraw-Hill Education. Web.

Graham, M. (2008). 5 Technologies that Make Internal Combustion Engines Better. Web.

Gupta, H. (2006). Fundamentals of Internal Combustion Engines. London: PHI Learning Pvt. Ltd. Web.

Guzzella, L., & Onder, C. (2009). Introduction to Modelling and Control of Internal Combustion Engine Systems. New York: Springer. Web.

Sanguri, M. (2010). Making More Efficient Combustion Engines. Web.