Introduction

According to Chrismopher, to understand an international supply chain we have to define a simple supply chain. The components of a supply chain involve the parties that respond to a request made by a customer. Here, a supply chain does not only constitute the manufactures and the suppliers. It also constitutes retailers, transporters, customers, and warehouses (14).

According to Logan in the past two decades, the supply chain networks have developed and extended in scope and application. This has resulted to more interrelated as well as complex networks. The reason underlying such development is associated with globalization of the world’s economies. It is the emergence of competitors across supply chains that compete in the international arena for market place dominance.

This competition has resulted to establishment of international supply chains (59). According to Chrismopher, organizations have to establish an international supply chain because of the global business environment that expands on a daily basis. Here, organizations have to respond to consumer expectations that are beyond the confines of their traditional expertise (20).

Background information

According to World Economic Forum, in the past 20 years global sourcing as well as supply has become a reality. According to Logan, the local for local manufacturing patterns have been done away with. In turn, the closing of the local patterns pave way to establishment of a global village (15).

An example is the migration to China that has become the favorable destination. China has become a force in international trade. During 1990, its trade activities increased three times faster as compared to the global economy. Between the year 2000 and 2002, when the world was suffering a stagnated trade it was enjoying a 30% rise in imports and exports (Mentzer 34).

The market today has fierce global competition that entails an excess of supply over the demand. According to Mentzer, businesses undergo such risks because of quantitative anomalies and qualitative effects. The qualitative irregularity comes about because of principal components and biasness in the selection.

On the other hand, qualitative effects come about because of the pressures associated with productivity enhancement, duplication removal, minimization of costs and elimination of waste. Businesses address the risks by balancing these priorities. Employing real time data, risk mitigation strategies, as well as use of analytical tools are some of the strategies a business can use when balancing these priorities (9).

Risks in the international supply chain

Risks in the supply chain are the products of consequence and incidence. Globalization has resulted to a business environment that is complex and interrelated. In turn, the complexity of the supply and demand networks has intensified (Mentzer 10). In reviewing the risks that come with global supply chains, we will review real events around the world that brought about challenges in the global supply chains that brought about risks in the sector.

Political risks

Political instability in North Africa specifically Egypt and the Middle East resulted to short-term hiccups in the supply of oil and natural gases. In Egypt, there was political instability in early 2011 whereby the president Hosni Mubarak stepped down because of military pressure. Demonstrations and protests filled the country advocating for better living conditions and transparency in governance. The region has 61.1% of the total oil reservoirs and 45% of the natural gas reservoirs in the world.

In addition, it dictates 35.3% and 18.8% of the world’s oil and natural gas production and supply (D&B Special Report 2). According to D&B Special Report, when such regions have political strife the world’s markets worry because of the interruptions in the supply of these commodities that are essential in the market. The oil prices went up with a 30% increase over a period of 12 weeks. On twenty forth of January, the prices of oil rose from $95 per barrel to over $125 in April the same year (8).

Source: Logan, Timothy .The global supply chain and the Challenges experienced by small and midsize enterprises. Toronto: Mosby, 2003. Print.

The graph above shows how political conflict has affected the supply of commodities from 1947 to 2011.

Environmental risks

Countries such as Japan have suffered effects of earthquakes, and tsunamis. Such environmental disasters have resulted to destruction and damage of factories. According to Chrismopher, the government of Japan allocated $ 239.3 billion in the reconstruction of the structures destroyed by the 2011 earthquake and tsunami. The manufacturing sectors particularly the electronic, automotive and the agricultural sectors suffered the most (9).

For instance, the North American based Toyota Company cut back on its working hours. This was for purposes of conserving their supplies that they received from Japan. In addition, Japanese companies make about 60% of the world’s silicon wafers. This is a key component in the making of mobile phones. This has resulted to a rise in the price of flash chips because of the threatened technological production. The fear of radioactive waves in the ports of Japan by shipping companies has also disrupted supply chains (Chrismopher 15).

Security risks

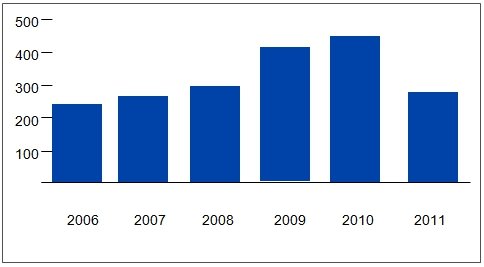

Source : D&B Special Report 2011, Mitigating Supply Chain Risks.

The graph above shows the actual and attempted attacks by pirates from 2006 to 2011. The international maritime forces are responsible for providing security in the Gulf of Aden. Most of the attacks perpetrated in 2008 and 2009 took place in the Gulf of Aden. The success of the international maritime forces has compelled the pirates to move offshore to the Gulf of Oman.

Thirty three percent of the oil transported via the sea passes through the Gulf of Oman. According to Chrismopher, about 20 tankers make their way through these waters on a daily basis. These pirate attacks have caused widespread panic among the shipping companies (10). To make matter worse pirates are not restricted in this area. This has caused problems for areas situated off the coast of Africa on the western side.

Process risks

According to Chrismopher, increases in process risks come about when organizations experience process discrepancies. This comes about when there is utilization of information and communication technologies (ICT) for purposes of systems integration (21). This results to the lack of a business vocabulary between the organizations.

In a survey conducted in 2011 relating to supply chain resilience about 41% of supply chain organizations experience process discrepancies (Chrismopher 23). The increased reliance on these systems has occasioned risks in the international supply chain networks. Governments as well as businesses have no choice but to invest in maintaining information and communication networks that preserve and ensure a high degree of integrity in their data systems (Chrismopher 24).

Mitigating the international supply chain risks

Mitigating the international supply chain risk involves the application of real time data and risk mitigation strategies.

Real time data

According to Chrismopher, organizations that have access to real time data are in a better position to mitigate risks. Real time data provides a clear and visible outlook into the current conditions that have an influence on the objective of the organization (23). With real time data, the supply chain makes educated decisions. Real time data has the effect of isolating issues that are potential risks once they occur. In turn, prevention of negative performance repercussions occurs (World Economic Forum 15). The extensive view of the supply chain integrated with real time data brings about new levels of risk mitigation. In turn, the performance levels rise (Chrismopher 21).

Risk mitigation strategies

According to World Economic Forum, a survey analysis revealed that there are priority areas that need improvement regarding management of an international supply chain. The survey pointed out that the strategies involved in mitigating the international supply risks involve integrating the public and private sector. This paves way to data and information sharing. In turn, organizations are able to understand each other and therefore are able to quantify the supply chain risks (15).

The private and public sector make informed decisions regarding where to put their investments as it involves identification of vulnerable areas. Proactive as well as effective legislative measures will develop. In this respect, the risk management strategies include establishment of trusted networks across businesses and governments, shaping legislation, data and information sharing, use of quantification metrics, and planning a scenario.

Establishing trusted networks across business and government

According to World Economic Forum, for purposes of identifying the risks inherent from the end-to-end global supply chain there is need for collaboration. Businesses and governments should collaborate to identify and manage the systemic risks.

In addition, regulators, professional bodies, suppliers, competitors, and even customers should be part of the collaboration. This is for purposes of establishing a well-managed relationship that entails sharing of information, priorities, and expertise (15). These are fundamental in making pre-disruption as well as post-disruption responses.

The relationships should be formed bearing in mind that the global disruptions bring about excess political, economic, and security risks. The Supply Chain Risk Leadership Council creates an example of such a relationship. This body comprises of supply chain firms that work hand in hand to establish and develop strategies and management practices to curb supply chain risks (World Economic Forum 15).

Shaping Legislation

According to World Economic Forum, mitigating the international supply risk entails aligning the legislation in relation to the modern industry practices. Industry groups should advocate for the simplification of international harmonization as well as implementation of the relevant legislation.

Legislation that does not address this has the effect of worsening disruptions in the global supply chains (15). For instance, there was volcanic activity in Iceland in 2010 that put a halt to all air traffic activities. The inflexible legislation in the region caused further delays and inconveniences.

Data and information sharing

According toD&B Special Report, organizations are able to point out the vulnerabilities in the network when using real time data. In addition, such information assists in establishing back up plans when a disruption takes place. According to World Economic Forum, the results of a survey indicated that 63% of the responds mismanaged shared information and data.

However, the survey indicated that there was need to improve the mechanisms of system flow between the government and the businesses. This is for purposes of preventing the global news from making inaccurate as well as out of context reports (16).

Quantification metrics

According to World Economic Forum, there is need to quantify as well as measure the risks exposed to supply chain networks. Organizations that lack the metrics for this purpose have struggled in quantification of the risk exposure. Here, the development of recognized quantification metrics to address risks in supply chain network is inevitable (15).

The metrics will serve businesses and the governments with information that facilitates a better understanding regarding the risks exposed to the supply chain network. In addition, metrics should be consistent across all organizations for purposes of making comparisons. For instance, a supply failure that has a negative impact on the revenue and gross profits are useful measures in understanding the risk exposure (World Economic Forum 14).

Scenario planning

According to World Economic Forum, scenario planning is a strategy that is useful at the operational level. This is because scenario planning has the effect of reducing risk exposure in the supply chain network. An organization that conducts scenario planning on a regular basis avoids external risks and vulnerabilities.

It allows the organization to have a better understanding of its external environment. Here, the organization has a better view on how to anticipate actions by their network partners (16). For instance, the ABB enterprise in 2010 used scenario planning in the identification of concerns regarding Japan’s earthquakes as well as Egypt’s political strife.

In both countries, the organization trained its management teams on how to face crisis. They tested their systems as well as communication patterns and teamwork through using simulated scenarios. This training was successful because by the end of 2011 they had put it into action. They accounted for all their personnel and got them to safety after each crisis. It also helped them to determine the extent to which the business was affected and the fastest way to return normal operations (World Economic Forum 16).

Conclusion and Recommendations

In conclusion, the international supply chain forms part of the backbone of many local, national, as well as global economies. Here, there is need to ensure constant improvement of supply chain security as well as resilience. This comes about through improving the stakeholder understanding as well as the underlying actions.

The governments should upgrade their resilience standards regarding international and interagency compatibility. On the other hand, businesses should integrate supply chain risks as a major part of governance, procurement, and management process (World Economic Forum 15). The governments as well as the businesses should strive to form and nurture networks of trusted customers, and suppliers for purposes of reducing the risks.

The network should undergo constant improvement with regard to visibility. This comes about where the government and the businesses establish a system of two-way information sharing. In addition, organizations should inform everyone involved in the business regarding the existent supply chain threats. Nurturing such a culture would extend responsibility to all stakeholders (World Economic Forum 16).

Works Cited

Chrismopher, Martin. A taxonomy for selecting Global Supply Chain Strategies. International Journal of Logistics Management 17.2 (2006): 277-287. Print.

Closs, Donald. Logistical Management: The Integrated Supply Chain Process. New York: McGraw-Hill, 2006. Print.

D&B Special Report 2011, Mitigating Supply Chain Risks. Web.

Logan, Timothy .The global supply chain and the Challenges experienced by small and midsize enterprises. Toronto: Mosby, 2003. Print.

Mentzer, John. Supply Chain Management. Thousand Oaks : Sage, 2004. Print

World Economic Forum 2012, New Models for Addressing Supply Chain and Transport Risk. PDF file. Web.