Introduction

The Itaipu Hydroelectric Power plant was constructed on the Parana River that flows through Brazil and Paraguay to provide power and act as a source of water, is the world’s largest hydroelectric power plant with a capacity of 12,600 Mw, an amount high enough to meet the power demands of London for 3 years. The dam was a joint effort between Brazil and Paraguay at a total cost of approximately $ 18 billion, as a result, a consortium of the two countries known as Itaipu Binacional manages the dam, electricity from this project generates about 72% of the energy requirements of Paraguay and almost 28% for Brazil. Its construction began in 1975 and was completed in 1991 (Civil Engineering Portal, para. 1).

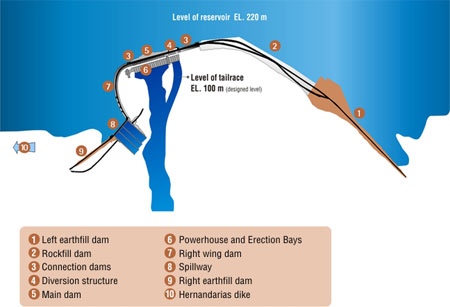

A large number of workers were involved in the construction of the dam; about 40,000 of them coming from all over Brazil, some of whom lost their lives during the construction process. The total length of the dam is 7235 m and is 196 m high, it is made up four different dams. As of 2009, Itaipu had 20 power generation units and each produces 700 Mw.

Construction

In February 1971, the companies contracted by the two countries, IECO (from the US) and ELC Electroconsult S. p. A. (from Italy), began work on the site of the dam. Before the actual work began, its designers decided make the dam so heavy that the high volume of water would not move it- its weight was to be 61 million tones to ensure the floor could withstand the weight of water in the dam.

River Diversion

Actual work started with the diversion of the Parana River, this allowed a portion of the riverbed to dry so that construction of the dam could begin. This was no mean task as River Parana is the world’s seventh largest river with a regular flow rate of 8,790 m3 per second. Construction of the 2.1 km long, 90 m deep (RitchieWiki, para. 4), 147 m wide diversion lasted three years (Engineering News-Record, para. 3). The river’s course was finally diverted to the channels on October 1978 after which cofferdams were constructed to provide a dry floor for the dam’s construction, each cofferdam was 98.5 m high, 540 m in length and 44.5 m wide at the base (USGS, para. 1).

The cofferdam’s stability was checked due to the regular torrential rains in Brazil that could lead to flooding of the River Parana. It was then determined that the cofferdams had to be at least 400 m high in order to realize the targeted electricity output. However, the riverbed was only 50 m deep, the solution was to construct a series of secondary dams across the riverbed for 7 km. The work force for this project was sourced throughout Brazil, and their number was roughly 40,000.

Construction Work begins

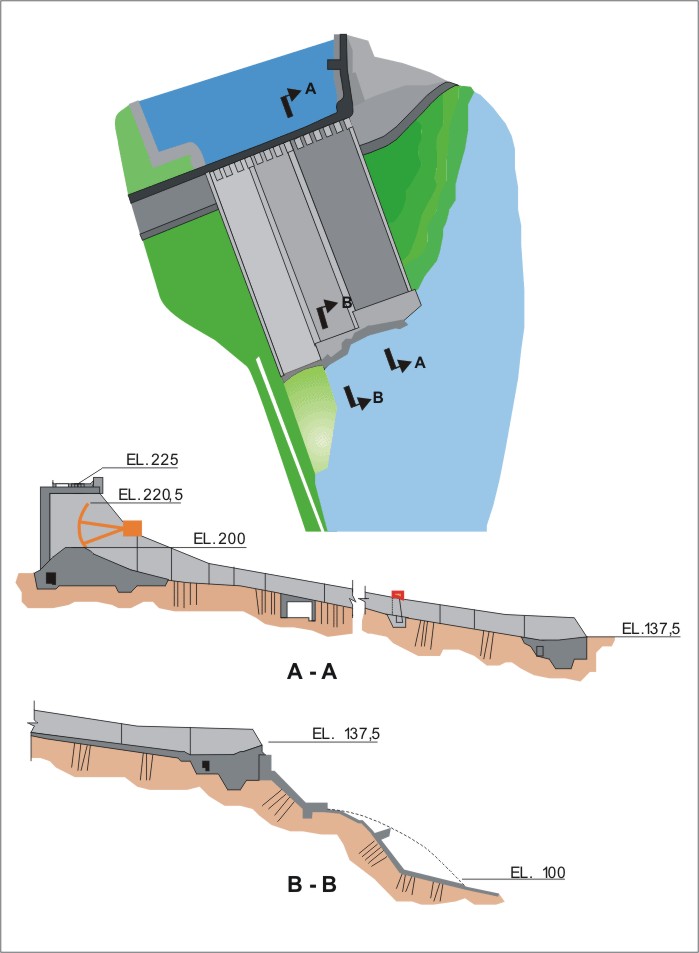

The construction work began in 1982, six million cubic meters of concrete was poured into the floor and the dam linked to spillways through a concrete buttress-type wing dam that flows down the river as a small Cardhfill dyke (Wonderclub, para. 3). Concrete used for the construction was transported to the site using seven cableways filled using monorails from three large concrete sites on each side of the dam, the six plants produced more than 1,022 m3 of concrete per hour. Other equipment used included cranes.

The base of the dam was made wider and stood on very hard rock material, to increase the structural properties of the dam wall, holes were made on them, power generation machines were also fitted onto the walls (South America, para. 5). As construction was in progress in June 1979, a weak layer of rock was found on the bedrock and this would have led to the collapse of the dam due to the weight of the water, hence the weak rock layer was drilled out and the resultant holes filled with an amazing 10 million pounds of hardened concrete. The final stage in the construction was the erection of huge steel structures to be filled with concrete, as the slabs of concrete were very large, they had a high heat of hydration that if released and could create cracks on the concrete thus weakening it, the conditions were made worse by Brazil’s high temperature levels (400c). Sun-dried concrete could not be used as they were weaker, so a cooling system was fitted between the blocks and iced water passed through them. The cooling system was estimated to be equal to 50,000 domestic freezers.

Re-Diversion of the River and Start of Operations

The construction process was finally coming to an end, To prevent an overflow of the dam, spillways were constructed and these could release 64 million liters of water per second, a slope was built at the end of the dam to make the water flow at a high speed. River Parana was re-diverted to its original course and took 2 weeks to fill the reservoir completely up to a depth of 100 m. On May 5, 1984, the first power generation unit began operation on the Itaipu Hydro-Electric Dam.

NOTE: The water passing through the spillway had a high force and if left to flow directly to the river, would have created huge waves and flooding, so it was thrown into the air, engineers calculated the angle of jump using scaled models (Jamal, para. 13).

Conclusion

The construction process was completed in mid-1984 and cost about $20 billion and used more than 12,800,000 m3 of concrete, the dam covers an area of 1,350 km2, equal to the city of Chicago. Its capacity was expanded in 2007 and this led to the start of operation of the last two of the 20 power generating units and this raised the production capacity to 14 Gw (Absolute Astronomy, para. 8). This expansion will allow 18 generation units to run while two will be shut down for maintenance. The dam was elected as one of the Seven Wonders of the World by the American Society of Civil Engineers (The World Wonders, para. 8), this is a testament to how mighty the project was.

Works Cited

Absolute Astronomy. Itaipu.2010. Web.

Civil Engineering Portal. Itaipu Dam. 2010. Web.

Engineering News-Record. Top 125 years in enr History. 1999. Web.

Itaipu Binacional. The world’s largest generator of renewable clean energy. (N. d.). Web.

Jamal, Haseeb. Itaipu Dam. 2010. Web.

RitchieWiki. Itaipu Dam. 2009. Web.

South America. Itaipu Dam. 2010. Web.

The World Wonders. 7 Modern Wonders of the World. 2010. Web.

USGS. Itaipú Dam: The world’s largest hydroelectric plant. Web.

WonderClub. The Itaipu Dam.(N. d.). Web.