Introduction to Lean Management

Lean management refers to a style of management that lays emphasis on the decrease of seven wastes namely processing, waste, scrap, waiting time, overproduction, inventory, motion, and transportation. The reduction of waste helps improve the standards and minimize costs and time. The mechanisms that help achieve lean management are “pull production”, mistake-proof and constant process analysis (Plenert, 2007).

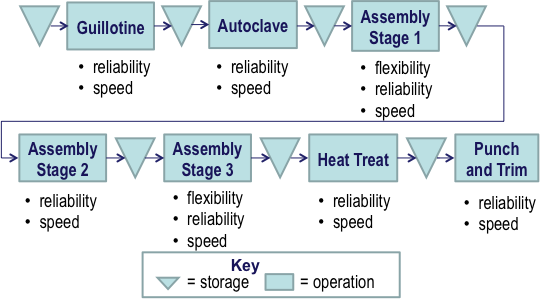

Since it is an integral part of the coursework, the students were required to take part in the lean game, previously known as the JIT (Just-in-Time) game. The entire class was divided into groups comprising 7 students. All the teams were given the common mission of manufacturing four colored widgets and subsequently deliver the same on time as per the requirements of the consumers. The following diagram testifies the flow of the manufacturing supply chain:

It can be clearly understood from the diagram given above that there are in total seven processes in the entire manufacturing supply chain. Each student was assigned the task of overseeing one supply chain and ensuring that the process went on in a hassle-free manner. All the processes are described below with the help of the table:

Process 1: Guillotine

The bases and tops were cut from the raw material sheets with the help of a Guillotine. The Guillotine also took the responsibility of ordering new raw materials.

Process 2: Autoclave

The bases and tops that had been cut with the help of a guillotine were heated in the autoclave for 3 minutes.

During this heating, there was provision for only one machine.

Process 3: Assembly Stage 1

In this stage, the bases and the tops were joined with glue. Just like the last stage, only one machine was allocated to the students. During this stage, there was the limitation of working with tops and bases of the same color.

Process 4: Assembly Stage 2

During this stage, the large red circle had to be attached; a small green circle and a small yellow circle to the top. This stage also involved one JIG machine that was heated and it had a waiting time of 2 minutes.

Process 5: Assembly Stage 3

Subsequently, in the next stage, the small blue and green circles on the top were heated in the JIG machine for a span of 3 minutes.

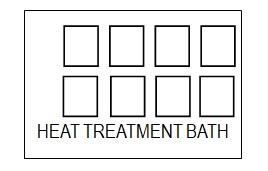

Process 6: Heat Treatment

The widgets then undergo heat treatment. The waiting time for this stage was only till all the 8 baths were filled.

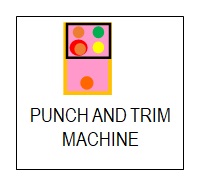

Process 7: Punching and Trimming

Punching and trimming helped fix the small orange circle on the base as well as helped to record sales on-time and late occurrences.

The students had a total of three rounds and once around was over, it was time to review the entire operational strategy (Team Blue) so that they could rethink how to ameliorate the production process. The entire simulation process also involved a test round prior to the three rounds which emphasized the awareness of the market situation and also the procedure at each step of the production process.

Team Manufacturing Chart

Test Round

The students were seated in a row so that each stage of the supply chain was just behind one another. This round did not require a strategy and communication was minimal. But one had to deliver to the best of one’s ability. The supply chain was slow and caused some anxiety and no orders were delivered. Though no delivery was involved, it provided the group with inputs to work on the operational strategy of the process. It seemed best to apply a “leagile strategy” for this process since it satisfied consumer demands and also decreased wastage (Jones, Naylor, and Towill, 2000). It was also found that the group had not taken into consideration quite a few aspects that deferred the process.

Firstly, quite a few processes needed equipment for faster processing. Process 4 and 5 used only one machine and required one more to function better. Also, one new machine was required for stages 2 and 3 to increase the pace of the process.

A lack of coordination and articulation was found in the team and thus stages 1 and 2 were put opposite to one another in order to attain better matching of color order.

Round One

This round exhibited better coordination and articulation and the extra equipment of processes 1 and 2 sped up the supply chain. Thus 5 widgets could be delivered.

This round was better than most rounds and the wastage was also low therefore referring to higher efficiency and an adequate number of machines along with smooth operations and low-stress levels. However, the objective of the group was to further hike the speed of the processes and better our articulation. So, two alterations were done for the next round.

Round Two

Group Blue produced 7 products in this round. However, the level of stress was high and suffered from overproduction and therefore high wastage. The operations were very smooth.

After reworking the processes to attain better articulation among the group members, the problem of overproduction still remained since the structure was more agile than agile. The present structure was such that it waited for the demand to arise since the widgets were ready because of over manufacturing.

Round Three

The production was really high in this round but the quality was low and wastage was rampant. But the group was able to manufacture 16 products and that too on time without ordering additional raw materials.

But the students also had to consider the problem of depreciation. But at the same time, this was required to satisfy the consumers and fast processes. The wastage was lower than the previous round.

Overall Reflection

As mentioned earlier, step 1 had been the smoothest process. Wastage was minimum and greater efficiency as regards manufacturing, group work, adequate number of machines, and low-stress levels. Since the team followed leagile strategy, which comprises both lean and agile strategies (Lambert, 2004), this was deployed very proficiently considering quality, reliability, and speed.

The role-play helped to attain practical knowledge on the working of manufacturing cycles. The way in which speed can be varied, addition or reduction of machines, cost and waste management (damage or over manufacturing), waste management, the significance of quality and consumer satisfaction, and degree of group work in a safe and proper working milieu.

Bullwhip Game

The game was performed in order to assess the practical effects of the Bullwhip Effect (Coyle et. al., 2008). It is defined as the circumstance under which the demand grows from downstream to upstream within the supply chain (Verma and Boyer, 2010).

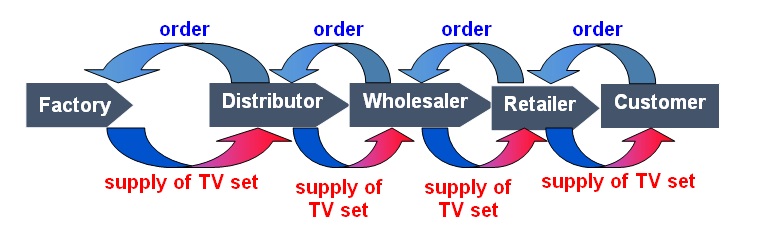

The game made the students a part of a supply chain that produces makes inventories and disseminates television sets. The supply chain for the company is as under:

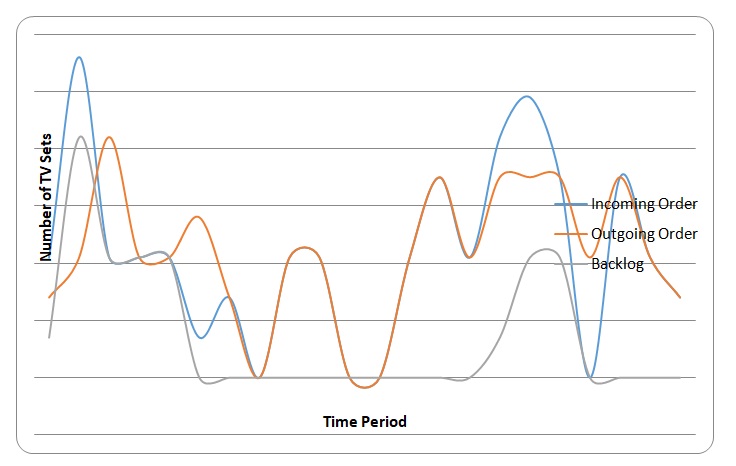

Our group was the works that produced, made inventories, and distributed (via road) television sets to the Distributor. As producers, we did not have any suppliers and thus the storage of raw materials had to be taken care of by ourselves. The forecasting of demand also had to be done so that the factory had enough raw materials for production. The following graph depicts the record of incoming, outgoing, and backlog orders which were kept in the store of the factory.

Chart showing incoming, outgoing, and backlog orders

As seen from the above-noted table and graph, it is evident that there is a lot of variance in incoming orders from the distributor. But the consumer’s orders may be different. Thus the premise of forecasting becomes very important to firms.

The concept of buffer stock is very important in this regard since it allows the factory to be protected against the uncertain rise in demands (Mentzer, 2001). There have been various problems associated with the supply chain during the game.

The constraint of transporting through only one carrier affected the timeliness of the delivery. Since a carrier can only carry a fixed number of television sets, the backlog kept on increasing and required another carrier in order to deliver in a much better and timely manner.

All companies have production processes that are linked to other processes both downstream and upstream. But the flow of information and materials seemed an uphill task since all processes are independent of each other. But the decisions of one of them can influence the other on the other side of the chain leading to the Bullwhip Effect (Bowersox, Closs and Cooper, 2009).

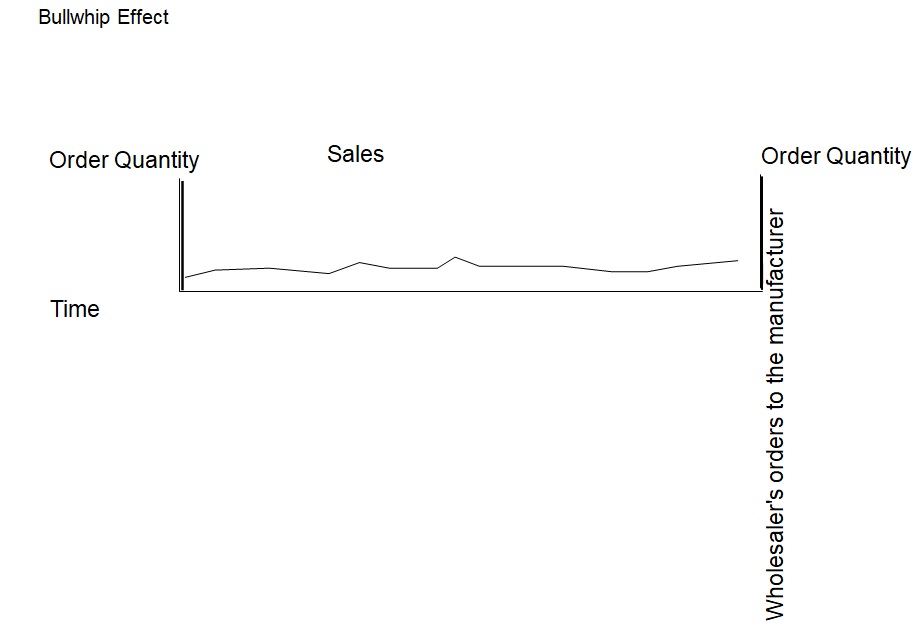

Bullwhip Effect

It can be inferred that the influence of the Bullwhip Effect on the supply chain is very high. It is said that the effect of this phenomenon on the supply chain is negative (Chopra, Meindl, and Kalra, 2006). So it has to be decreased through proper logistics and better operational strategies which are attained through better communication and exchange of information, leaner storage, and better cooperation among the processes.

This will obviously lead to augmented coordination among the members thereby curbing waste and cost. However, this necessitates a high degree of coordination and trust among the teammates for managing the worldwide operations and transportation more efficiently (Jespersen and Larsen, 2005).

References

Benton, H. (2011). Week 8- Bullwhip Effect. Web.

Bowersox, A.D., Closs, D., and Cooper, M.B. (2009). Supply Chain Logistics Management. US, McGraw Hill Higher Education.

Chopra, S., Meindl, P. and Kalra, D.V. (2006). Supply Chain Management – Strategy, Planning and Operation. New Delhi, Pearson, p. 597.

Coyle, J.J., Langley, C.J., Gibson, B.J., Novack, R.A. and Bardi, E.J. (2008). Supply Chain Management: A Logistics Perspective. Mason, South-Western Cengage Learning, p. 20.

Jespersen, B.D. and Larsen, T.S. (2005). Supply Chain Management – in Theory and Practice. Denmark, Copenhagen Business School Press, p. 57.

Jones, R.M., Naylor, B. and Towill, D.R. (2000). Lean, Agile or Leagile? Matching your supply chain to the market place. International Journal of Production Research, 38(17), 4061 – 4070.

Lambert, D.M. (2004). Supply Chain Management: Processes, Partnerships, Performance. Sarasota, Supply Chain Management Institute. p. 127.

Mentzer, J.T. (2001). Supply Chain Management. California, Sage Publications. p. 243.

Plenert, G. (2007). Reinventing Lean: Introducing Lean Management into the Supply Chain. Burlington, Elsevier, pp. 154 – 162.

Verma, R., & Boyer, K. (2010). Operations & Supply Chain Management: World Class Theory and Practice. China: South-Western Cengage Learning.