Introduction

Operations management deals with all the aspects of goods and services production. Operations management involves supervision, design and if necessary redesigning of business processes with the sole aim of achieving efficiency with minimal resources while meeting the requirements of customers.

Management and direction of a firm or organization’s physical functions forms the core concern of operations management (Greasley, 2009, p. 47). Though operations management is wide and includes fields such as equipment maintenance, industrial relations and systems analysis, this discussion will focus on processes related to manufacturing and production systems in a particular industry (Stevenson, 2008, p. 56).

Operations management has increasingly become a critical component in corporate world today. Increased consumer awareness thanks to education coupled by stiff competition has led to major corporations implementing exceptional management systems to ensure maintainace of the market share.

Outstanding performance on a global scale entails heavy investment in both labour and capital-intensive systems in order to maintain relevancy. This analysis will focus on various aspects of operations management and production at Toyota, a leading Japanese car manufacturer with a considerable share in the global auto industry.

The analysis will especially lay emphasis on a brief overview of the company, a somewhat detailed description of Toyota’ s operations management system, an evaluation on the use of teams in its production and operations management and a brief evaluation of the company’s ability to deal with a major crisis.

Toyota Motor Corporation

Toyota Motor Corporation is a multinational car maker with headquarters in Aichi Japan and, also the largest automaker in terms of production. In 2010, Toyota employed slightly over 317, 700 people worldwide. In 2010, the Organization of Motor Vehicle Manufacturers (OICA) ranked Toyota a head of General Motors and Volkswagen, in car sales.

According to the OICA, Toyota sold 8.55 million units representing a market share of 11% while GM came second with 8.4 million units representing 10.9% (Jones & Edward, 2010, p. 35). In 2006, Toyota became the most profitable vehicle manufacturer with $ 11 billion in profits. In the year 2011, Toyota recorded an operating income of $5.2 billion and a profit of $5.07 billion.

Total equity in the same year totaled $128.30 billion with the total assets topping $370.3 billion. From its humble beginnings as department of Toyota Industries, Toyota has grown to become one of the leading brands in vehicle manufacturing and, in the business world. In 2005 Toyota emerged eighth leading world company.

Toyota today has numerous manufacturing plants and dealerships distributed throughout Asia, North America, Europe and Africa. The Daihatsu subsidiary of Toyota has been crucial in establishing a foothold in Asia while the company has struggled to effectively compete in the European market.

Though it faced fierce competition in North America from American auto manufacturers, the effects of the financial crisis on American auto companies have led to a significant rise in the Toyota market share in North America (Jones & Edward, 2010, p. 25).

Toyota’s production or operations management system

Many analysts agree that Toyota’s Production System (TPS) has been the main catalysis fueling the phenomenal growth associated with the company. Experts credited TPS for Toyota solid performance during the oil embargo crisis in the 1970’s (Monden, 2011, p. 89).

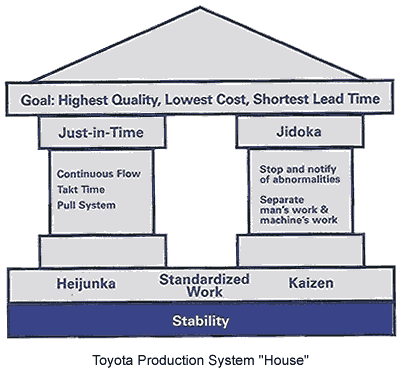

According to the MIT, efficiency of TPS was so high that compared to traditional mass production to an extent that it helped in introduction of a new paradigm “lean production”. Toyota designed TPS with the aim of providing the best quality products at the lowest cost and shortest time. Realization of the above is through elimination of waste.

Two pillars make up TPS i.e. Just in Time and Jidoka (automation). Maintainace and improvement of TPS is possible through standardized work and continuous improvement (Kaizen) through the use of Plan –Do-Check-Act (PDCA cycle) method (Monden, 2011, p. 102).

It is important to note that through TPS, Toyota has been able to produce cars through the “Lean system” whose principle belief is that it is wasteful to use resources for any other goal other than creation of customer value. Toyota production and/ or operations management therefore considers anything that does not meet the above principle “wasteful” hence a target for elimination.

According to TPS value is anything that a customer will be willing to pay for. In a nutshell, TPS translates to a Lean system that emphasizes preserving value with less work effectively a production approach credited with helping Toyota to become the world’s leading car maker (Monden, 2011, p. 104). Currently, Toyota has in place another system it refers to as the Toyota Way which is more or less improvement of TPS.

The illustration below helps put TPS into context.

Figure 1: The TPS system used by Toyota

Use of teams in production and operations management at Toyota

The success experienced at Toyota could not be possible without widespread employment of the teamwork ethic.

According to Liker (2004, p. 1), success of Toyota is largely due to its ability to develop leaders and create teams as well as a supportive culture with suppliers and customers. The Kaizen part of TPS that empathizes on continuous improvement is mainly composed of teams keen on delivering value through the TPS operations management system.

According to Liker (2004, p. 6) Toyota under the TPS operation management system organizes teams from the start to finish of projects. For instance, the design of the brake system is normally responsibility of a single team throughout the design phase to the end of the production system. Enrichment and empowerment of employees is always the goal in the teamwork approach through TPS.

The logic behind it is that challenging but attainable goals and determination of progress towards the achievement of these goals motivate people. TPS mechanisms therefore always make sure that teams are always updated on their progress and on what they should do to reach their targets. Liker further says that under TPS, team members have four tools that they use in designing quality products.

They include: Go and see, analyze the situation, Use one-piece flow and “andon” to surface problems, Ask “Why?” five times (2004, p. 11). Through TPS, Toyota has taken specific steps meant to help in building high performance teams in the production process. The steps include orientation, dissatisfaction, integration and production.

Toyota’s ability to adjust to a major crisis

Despite the quality and efficiency delivered by operation management systems like TPS, it is impossible to predict or avert crisis. In the world today, many crises ranging from economic, environmental, or natural have become common.

Besides terrorism the ever looming threat from terrorism and the 2008 shocks from economic cycles for instance the 2008 financial crisis, natural disasters have hit businesses in recent times with devastating effects (Penuel et al., 2010, p. 298). Judging from the response to such crises so far has been very wanting.

For instance, the recent earthquake and tsunami in Japan affected the manufacturing industry including Toyota leading to a rise in the prices of Japanese cars worldwide.

The preparedness of Toyota has however not been tested given that its plants only suffered minor damages in the disaster. However, safe for the quake specific designs characteristic of most Japanese buildings, there is no evidence of any preparation by Toyota to mitigate calamity of the magnitude described above.

Conclusion

There are as many operation systems as there are business entities. At the same time, it is not easy to determine which one is best suited to deliver desired corporate results. However, the Toyota case study has proven that TPS has constantly delivered at Toyota. In fact many companies have tried to implement TPS with the hope of replicating the success experienced by Toyota.

However, few have equaled the Toyota level of success. The TPS system discussed above, the resultant lean system and the most recent Toyota way are operation systems that have finer components linked together whose understanding may need detailed elaboration.

The most dominant principles however, include avoidance of wastefulness, delivery of value to the customer and customer satisfaction. TPS achieves the above through consistent teamwork and emphasis on continuous improvement as the Kaizan principle dictates.

There is a need however for further research in ways to through operations management systems, in this case TPS can help in mitigating the effects of a disaster. During the Tsunami disaster for instance, Toyota announced the closure of a number of North American plans apparently owing to the effects of the disaster. Such an action is a clear indication of the vulnerability such corporations in face of such events.

References

Greasley, A. (2009). Operations Management. New York: Routledge.

Jones, M. & Edward, R. (2010). Toyota Motor Corporation: Japan’s Industrial Treasure. Chicago: FastBook Publishing.

Liker, J. (2004). The Toyota Way. New York: McGraw Hill.

Monden, Y. (2011). Toyota Production System: An Integrated Approach to Just-in-time. London: Taylor and Francis.

Penuel, B.K. et al. (2010). Encyclopedia of Disaster Relief. New York: Routledge.

Stevenson, W. (2008). Operations Management. New York: McGraw-Hill Irwin.