Introduction

Description

The design is aiming at creating awareness of plastic packaging, pose influence and help people cease and think of the amount of packaging they utilize and allow them understand if it is still necessary (Picano et al. 2018). The design intends to inform the youth and the whole of the society as well. The design informs the people that they should pack the future since there is other planet to survive in except earth.

My design task is going to be attractive to capture the attention of the public. The globe has a medium size and can be carried from one place to another (Georgiopoulou et al. 2021). The colors to be used herein are those utilized in the large scale produced globes from the factories. The globe will be made with smooth texture (Lahtela et al. 2020). Course surface will hurt the hands of the people since they will be tempted to feel by their figures. The globe can be used by students and teachers at school. Both governmental and non-governmental institutions that are deal with environmental conservation can utilize it as well.

Initially, before coming up with the design task and idea, I did various considerations in terms of ease of manufacturing, the cost of the raw materials to be utilized, as well as safety. For instance, the materials that I was to use were readily available and did not cost me a lot. Only scissors, marker, bolt, paint and computer heightened the price (Virtanen et al. 2018). I considered my safety while undertaking the task in drilling holes in the bottle tops and cutting one of the 2L bottles.

The general safety of the design task to the users was catered for. The bolt was firmly tightened and thus cases of loosening and harming the user minimized. Again, the manufacturing process of the globe was ease to carry out. The process took less hours and energy to be completed. The manufacturing was environment friendly (Hahladakis et al. 2018). Zero emissions were recorded during the process.

Summary of requirements for this design task

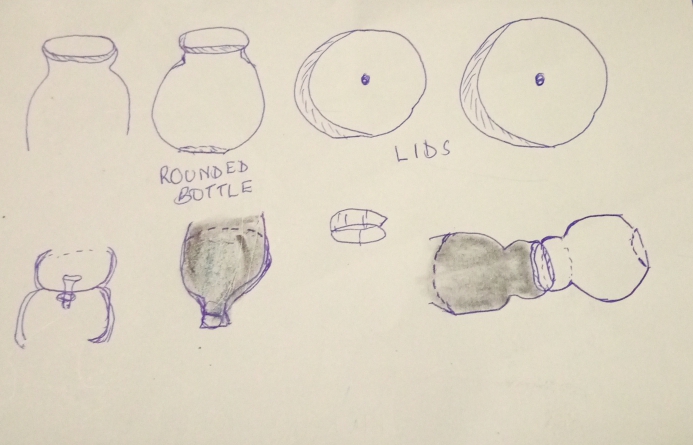

The design needs to be carried out using the following requirements: 2L plastic bottle top, rounded plastic bottle, bolt and washer, paint, paper, scissors, marker and a computer. The control system utilized herein was rotation (Sanchez-Rivera, 2021). The globe had to be able to rotate if the design was accurately done and functional. The design should be able to rotate and indicate various continents that are presenting the actual globe (Dahlbo et al. 2018). This is made possible by ensuring that the lids are flexible and are not rubbing one another intensively.

Research and investigation

Types of research carried out and what I discovered

After undertaking my research on plastic packaging, various websites regards it as extremely wasteful and influences the ecosystems of the earth from which we are dependent (Lacodou , 2018). Because of the poor product design and lack of infrastructure, most of the plastic waste is disposed into the surrounding. Due to the fact that the plastics are non-biodegradable, each particle of the plastic that was ever manufactured dwells in this planet to date.

Meys, Raoul, Felicitas Frick, Stefan Westhues, André Sternberg, Jürgen Klankermayer, and André Bardow in the year 2020 developed a book on recycling the plastic packaging (Ibarra, et al. 2019). In their work, they developed a way through which polymers could be recycled by use of stoichiometric reaction. This however was costly and since it was chemical. Therefore, I decided to use a natural non-chemical way that was cheaper and required lesser raw materials.

Similar existing products that I found

I found that there are various products that resembled mine. Firstly, I found that one could lower the plastic packaging through up cycling of Lotion bottles into charging docks. The process requires cheap and readily available materials such as a lotion bottle, box cutter and a marker (De Marchi et al. 2020). The process of manufacturing a charging using this method is easy and environment friendly too. Secondly, it came to my attention that repurposing of detergent containers for watering cans. This activity is economical and environment friendly since it ensures that plastic packaging is re-utilized.

Different types of approaches and solutions that I found

I found that the world was really in the danger of perishing as a result of plastic packaging (Brower et al. 2018). There was massive destruction to the surrounding which triggered my idea to develop a globe from plastic bottles.

Summary of my research findings

I noted that optimally 35% of the total population in the world use television to watch and learn about the recycling of the plastic packaging.

I found that plastic bottles are heavily disposed as waste into the environment. They contribute up to 55 percent of the total plastic packaging disposed in the environment.

I researched that the plastic packaging is undergoing reduction at a vest slow rate compared to the rate at which it is disposed to the environment.

Development of research ideas

I developed three research ideas. These are described below.

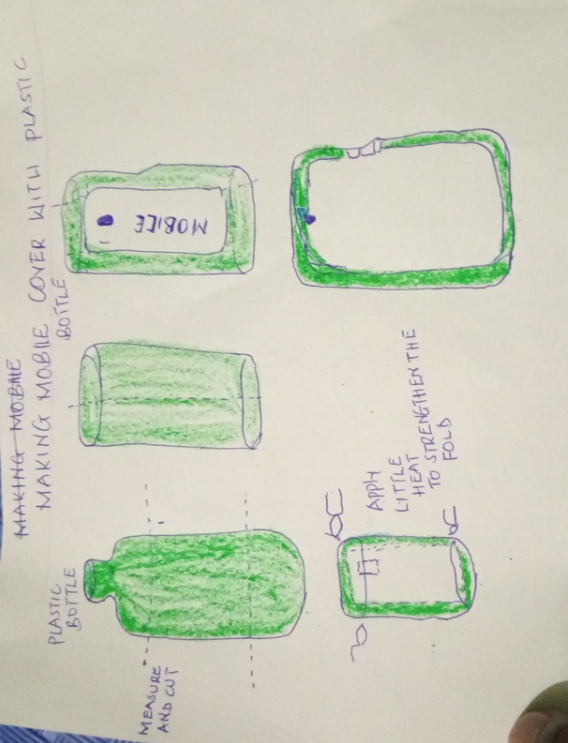

Design idea 1- making a mobile cover from a plastic bottle

I had the idea to design a mobile cover with a plastic bottle. The process of manufacturing involved cutting a plastic bottle and flattening it before fixing it to the mobile phone.

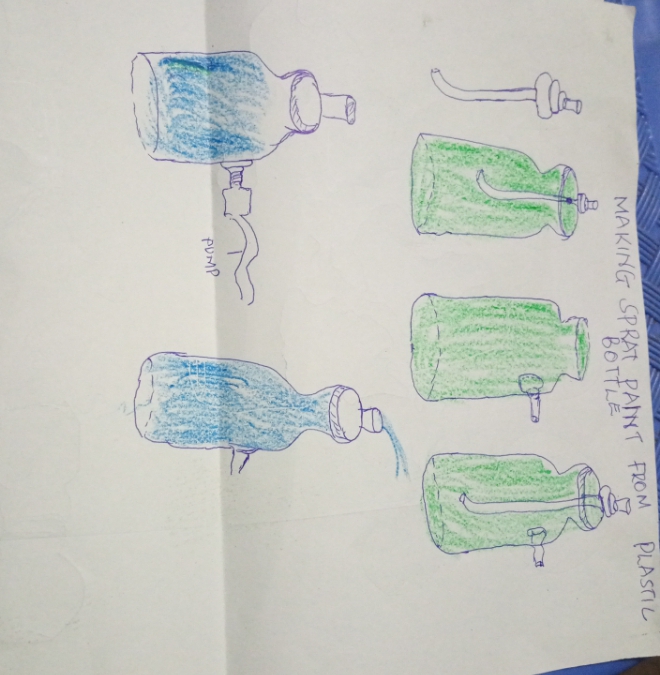

Design idea 2- making spray paint from a plastic bottle

The process requires a plastic bottle, bolt, a trigger and string. The manufacturing involves fixing the trigger after cutting and drilling hole on the top of the bottle. The bottle is holed at the upper part and the top. The pressure tire nip is inserted at the hole on the side part of the bottle. The pressure tire nip is fixed using a rope that is tie on it through the mouth of the bottle. Once the tire pressure nip is tightened and fixed using a nut and rubber in between, the bottle is eventually pressure via the nip with a pressure pump. The ink is poured through the mouth of the bottle before pressure is inserted therein.

Sketches

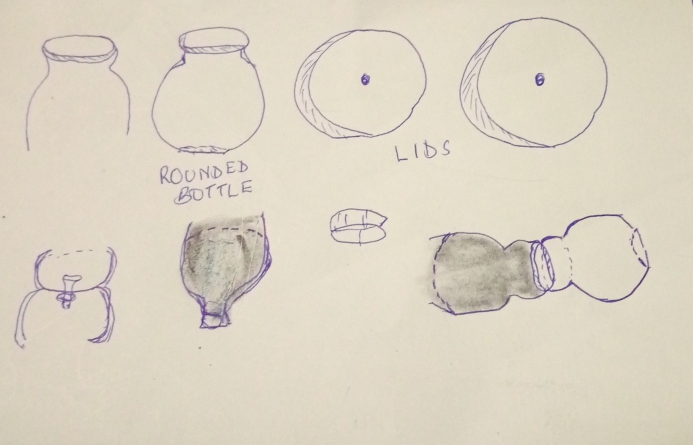

Design idea 3-Making earth globe using plastic bottles

The project requires 2L plastic bottle tops, rounded plastic bottle, bolt, paint, paper, scissors, marker and a computer. The process is cheap and easy to undertake.

Sketches

Selection of design idea

Evaluation of design ideas

I decided to utilize the design idea of making a earth globe using plastic bottles. The idea was far better than the other two ideas because it could be used by many users. Moreover, the design idea was cheaper and easy to manufacture.

Summary- reasons why I chose design idea 3

The design idea 3 could be used by most users compared to the other design ideas.

Design idea 3 utilized highest numbers of plastic bottles hence facilitating the recycling of plastic packaging.

The design idea 3 was the most competent and could impact lives better as well as the environment.

Manufacturing Drawings

2d Drawing of Each Body Part

Drawing of the Final Envisaged Assembled Product

Materials lists and costs

Body parts

Other components required for assembly and finishing

Total cost

The total cost of the materials used in the project = 2,260 Euros

Plan for manufacture

Steps required to manufacture part 1

STEP 1: Use scissors to cut the unrounded bottle at the upper part, 3/4. Preserve the upper part.

STEP 2: Remove the lids from the bottle and make holes at the Centre of both of them.

STEP 3: Paint the rounded bottle into a white color

STEP 4:Paint the base of the cut bottle in to a lovely color (I painted mine black)

Steps required manufacture part 2

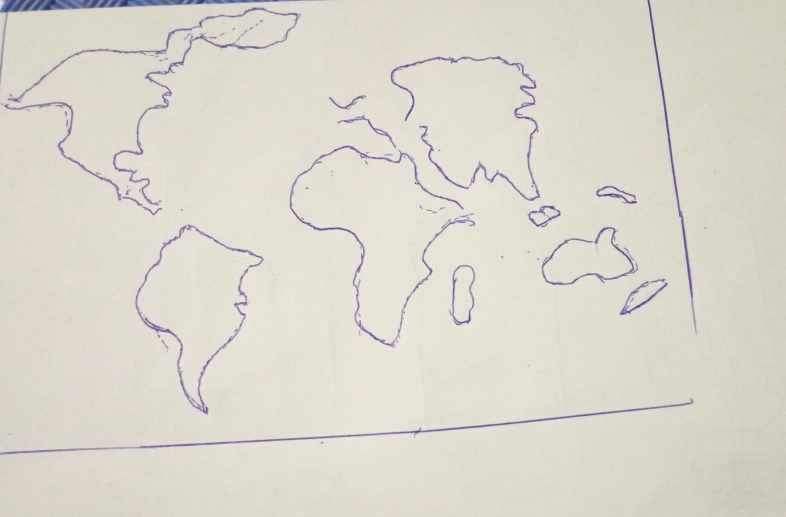

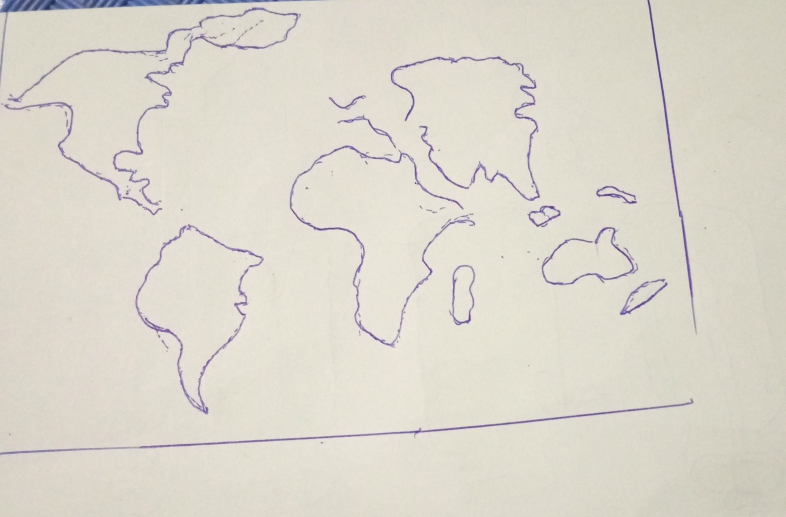

STEP 1: Find a picture of a globe in the internet.

STEP 2: Make a copy of the globe using a plain paper and a pencil.

STEP 3: Use a pair of scissors to eliminate the plain part of the paper.

Steps required to manufacture part 3

STEP 1: Insert bot on the lids and screw the rounded bottle.

STEP 2: Put your picture on the globe (the rounded bottle).

STEP 3: Paint the continents.

STEP 4: Add blue color to make water

Testing

What I changed as a result of testing

Evaluation

What worked well in my chosen design

The chosen plastic and metallic materials utilized made zero emissions

The metallic bolt provided strength of the globe.

A variety of plastic bottles was utilized hence creating a better recycling way of plastic packaging

Possible improvement

I would try to0 use both bigger and small plastic bottles

Improve the base of the goblet create large bottom surface. This would avoid toppling.

Utilizing lesser paints to minimize the general material cost.

What worked well in terms of how I ran the project

The rounded bottle was a real resemblance of the globe.

The blue color was familiar and clearly represented water.

The painting of the continents in yellow distinguished them with water masses.

What I would do differently if I carried the project again

I would prefer bigger rounded bottle to represent the globe.

I would add a better base surface to avoid the toppling of the globe.

References

Brouwer, M. T., van Velzen, E. U. T., Augustinus, A., Soethoudt, H., De Meester, S., & Ragaert, K. (2018). Predictive model for the Dutch post-consumer plastic packaging recycling system and implications for the circular economy. Waste management, 71, 62-85.

Dahlbo, H., Poliakova, V., Mylläri, V., Sahimaa, O., & Anderson, R. (2018). Recycling potential of post-consumer plastic packaging waste in Finland. Waste management, 71, 52-61.

De Marchi, E., Pigliafreddo, S., Banterle, A., Parolini, M., & Cavaliere, A. (2020). Plastic packaging goes sustainable: An analysis of consumer preferences for plastic water bottles. Environmental Science & Policy, 114, 305-311.

Georgiopoulou, I., Pappa, G. D., Vouyiouka, S. N., & Magoulas, K. (2021). Recycling of post-consumer multilayer Tetra Pak® packaging with the Selective Dissolution-Precipitation process. Resources, Conservation and Recycling, 165, 105268.

Guerreiro, T. M., de Oliveira, D. N., Melo, C. F. O. R., de Oliveira Lima, E., & Catharino, R. R. (2018). Migration from plastic packaging into meat. Food research international, 109, 320-324.

Hahladakis, J. N., & Iacovidou, E. (2018). Closing the loop on plastic packaging materials: What is quality and how does it affect their circularity?. Science of the Total Environment, 630, 1394-1400.

Hahladakis, J. N., Purnell, P., Iacovidou, E., Velis, C. A., & Atseyinku, M. (2018). Post-consumer plastic packaging waste in England: Assessing the yield of multiple collection-recycling schemes. Waste management, 75, 149-159.

Ibarra, V. G., de Quirós, A. R. B., Losada, P. P., & Sendón, R. (2018). Identification of intentionally and non-intentionally added substances in plastic packaging materials and their migration into food products. Analytical and bioanalytical chemistry, 410(16), 3789-3803.

Ibarra, V. G., De Quirós, A. R. B., Losada, P. P., & Sendón, R. (2019). Non-target analysis of intentionally and non intentionally added substances from plastic packaging materials and their migration into food simulants. Food Packaging and Shelf Life, 21, 100325.

Lahtela, V., Silwal, S., & Kärki, T. (2020). Re-Processing of Multilayer Plastic Materials as a Part of the Recycling Process: The Features of Processed Multilayer Materials. Polymers, 12(11), 2517.

Picuno, C., Alassali, A., Sundermann, M., Godosi, Z., Picuno, P., & Kuchta, K. (2020). Decontamination and recycling of agrochemical plastic packaging waste. Journal of hazardous materials, 381, 120965.

Sánchez‐Rivera, K. L., Zhou, P., Kim, M. S., González Chávez, L. D., Grey, S., Nelson, K.,… & Huber, G. W. (2021). Reducing Antisolvent Use in the STRAP Process by Enabling a Temperature‐Controlled Polymer Dissolution and Precipitation for the Recycling of Multilayer Plastic Films. ChemSusChem, 14(19), 4317-4329.

Siroli, L., Patrignani, F., Serrazanetti, D. I., Chiavari, C., Benevelli, M., Grazia, L., & Lanciotti, R. (2017). Survival of spoilage and pathogenic microorganisms on cardboard and plastic packaging materials. Frontiers in Microbiology, 8, 2606.

Vartiainen, J., Pasanen, S., Kenttä, E., & Vähä‐Nissi, M. (2018). Mechanical recycling of nanocellulose containing multilayer packaging films. Journal of Applied Polymer Science, 135(19), 46237.

Walker, T. W., Frelka, N., Shen, Z., Chew, A. K., Banick, J., Grey, S.,… & Huber, G. W. (2020). Recycling of multilayer plastic packaging materials by solvent-targeted recovery and precipitation. Science advances, 6(47), eaba7599.