History and Background of the Company

Nokia Corporation is a Finland based company that primarily deals with the manufacture of mobile telephones. The company’s brand product is the Nokia phones. The success of the Nokia Company is largely attributed to its best management in supply chain practices.

This project will tend to analyze the supply-chain management practices at the Nokia Corporation. It gives a vivid description of how the company is enhancing its efficiency in a supply chain so as to counteract the impact of reduced market demand of mobile phone handsets.

Nokia is the number one producer of mobile phone devices in the world, and its supply chain has been rated as number six in the ranking of world’s top 25 companies in the world in terms of their supply chain. Nokia Company was founded in 1865 as a paper milling plant, and it was until 1982 that it began producing mobile phones.

Nokia Corporation has 15 mobile manufacturing plants that are spread in nine countries. Their plants are found in the following countries: Brazil, Romania, South Korea, Finland, China India, Mexico, Hungary and Great Britain. Its mother depot is located in Gurgaon.

The mother company provides help in the selection of market partners like distributors and dealers; it also provides monetary privileges to its priority dealers in order to assist in promotion of the Nokia products on a larger scale (Scribd, 2011).

Supply-chain management is defined as the totality of all activities that are involved in the delivery of company products to the customer. This process involves the sourcing of raw materials, assembling of the raw materials to form the finished products, warehousing, distribution and delivery of the final product.

Nokia operates two business groups, Nokia mobile phones and Nokia networks. The company provides wireless communication products and services. Nokia supplies equipment and communication services all over the globe. Nokia is considered as a leading international communication company which focuses its operations on wireless and wire line telecommunication areas (Shah 2009).

It is the pioneer of digital technology and wireless data communications network; its innovativeness enhances its competitiveness and telecommunication network growth. Nokia is listed in four stock exchange markets (Nokia Website, 2011).

Overview of its Supply Chain

Supply chain of an organization is the system of all the activities and resources that are involved in transferring a product from the supplier to the consumers, it is the transformation of the raw materials and the components into finished goods, which are ready for use by the customer. Market analysts associate the success of the Nokia Corporation to its best supply chain practices.

The supply chain of Nokia Corporation is an integrated one with “intertwined suppliers, manufacturing plants, contract manufacturers, sales and logistics service providers and the ultimate consumers” (Kalra, 2011, p. 3). The company has entered into a relationship with its suppliers while supporting them in their processes.

Nokia has been in a better position to keep the prices of its products low due to its efficient manufacturing system and production processes. Nokia Corporation has adopted a hybrid system of manufacturing, which is a combination of both in-house and outsourcing manufacturing. To enhance its competitiveness, the company has incorporated smart manufacturing techniques in its manufacturing facilities.

The company’s distribution network is wide, and this has enhanced its ability to reach the majority of its consumers. Nokia stands far much ahead when compared with other companies, particularly in regional outsourcing and its unique feature of collaborating with the suppliers to form an organized design of the supply chain (Cavinato, Flynn, & Kauffman, 2006).

Nokia has a complex supply chain which has the capacity to handle approximately 100 billion components, together with sixty strategic suppliers and ten manufacturing plants globally.

Nokia Corporation established its supply-chain management (SCM) transformation in the year 1995, and it was aimed at replacing its inventory with information, which could create a pull driven supply chain that was integrated to link the suppliers, production plants, telecommunication operators, distribution partners, sales offices, financial institutions, contract manufacturer logistics providers and ultimately, the consumers.

This was aimed at creating an efficient network of supply that can provide solutions to customer expectations (Nokia Website, 2011).

The secret to the success of Nokia Corporation lies in its creation of value-oriented partnership with the suppliers, which is guided by true information, trust and better leadership, which are realized through its principle of collaboration. Nokia has suppliers all over the world and its base suppliers are in countries like Austria, Belgium, Brazil, Italy, Japan, Morocco and Canada among other many more countries.

Nokia embraces supplier diversity, which ranks top on its corporate responsibility. The company only spends on those suppliers who can contribute to the economic prosperity of the company. The company has developed its set of Nokia Supplier requirements that encompass environmental and social demands and are based on international standards (Kalra, 2011).

Supply chain is an important operation area for Nokia. It is considered as an instrument towards the realization of the competitive nature of the company. Nokia places emphasis on the efficiency of the demand and the supply network which may be significant in the achievement of ever increasing demand for the Nokia products.

Proximity of cooperation between the customers and the suppliers is a central organ of its development principles. Cooperation also promotes diversity in the supply chain (Burt, Petcavage & Pinkerton, 2010).

Organizational Structure

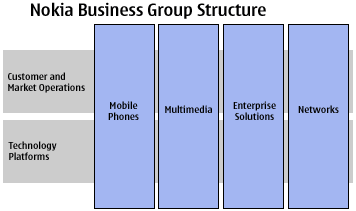

The organizational structure of Nokia is that of four business groups and two horizontal groups. In this kind of organizational structure, the four business groups are: mobile phones, multimedia, enterprise solutions and its networks while the two horizontal groups are customer and market operations and the technological platform.

This organizational structure is illustrated by the diagram below.

(Nokia Website, 2011)

Overview of new-product development Process

The development of new Nokia product in the market can be demonstrated in the following stages:

In Nokia Corporation, it is believed that the life cycle of a market product is two years after which another product is originated and hence the development of a new product is carried out concurrently with the research and the design of the new product.

Stage one: generation of the idea; the idea may be from internal or external source. Internal ideas may emanate from the research and development department, while the external sources of ideas may originate from competitors, customers suppliers or distributors.

Stage two: screening of the idea; in every preceding stage in product development, the price may be high, and it is therefore imperative that any idea that is poor should be eliminated. It is at this stage that all the ideas are evaluated to allow for elimination of unworthy ones.

Stage three: generation and testing of the concept; concept development enhances the creation of the exact version of the idea as explained in meaningful terms. It is at this stage that the consumers are asked to evaluate the concept.

Stage four: marketing strategy; this stage involves mapping out the target market as well as positioning the product in readiness for the market. Consequently, the price of the product, distribution strategy and marketing is mapped out at this stage. All analysis regarding the product is undertaken at this stage.

Stage five: business analysis; at this stage, the sales, costs and the projection of profit are analyzed.

Stage six: product development. The typical development of the product and its testing are done at this stage.

Stage seven: marketing test; three market tests are undertaken at this stage. These are: standard test marketing, simulation marketing and the controlled test markets.

Stage eight: commercialization; this stage involves the presentation of the product into the market (Scribd, 2011).

Nokia Corporation places a lot of interest on the transformation aspect of its production. The Corporation emphasizes on the production of new and diverse products so as to make them competitive in the market. There are circumstances where a phone can be available in more than 170 different kinds.

The operations’ philosophy that has supported the complex nature of its production is to think locally and acts globally, which implies that the company balances localized decision-making with its objective of global planning.

How the Organization Manages Quality of its Products

Quality is at the heart of Nokia products. It is their objective to provide quality products for its customers. Quality brand is a characteristic of the products and services of Nokia Corporation. Nokia Company is linked with the passion for the pursuit of constant improvement to an extent that it will exceed the expectations of the customers.

Since Nokia is a leading telecommunication company in the globe, it is necessary that high-quality standards should be upheld in all aspects of its operations. Nokia has the desire to achieve quality in the following fields: customer services to enhance customer loyalty, products through constant innovation and improvement and quality in its operations by ensuring effectiveness and efficiency in its management.

Analysis of when and how the company can determine whether to outsource or make product in-house

As a global company, Nokia sources materials and components as well as services from all over the world. Its sourcing can be classified into two, namely, direct and indirect sourcing. Outsourcing is considered as one way of reducing costs while enhancing performance. A company can only outsource that service which is not central to the business of the corporation.

Direct sourcing: this is responsible for the material supply of Nokia’s products; these may include the components, product parts, packaging and software as well as research and development of new products.

Indirect sourcing: this is responsible for the capital equipments like furniture and computer. It also encompasses the sourcing of catering and consultancy services.

To be competitive in the market and for profitability, Nokia outsourced its IT services to Capgemini, which is an IT consultant firm of France origin. Outsourcing is necessary to enable the company focus on the supply chain as well as the need to address market efficiency, which has the potential of saving costs and transforming the production process in the chain of supply.

Consequently, the company has also outsourced the production of Symbian software development to a company called Accenture, as part of the deal, Nokia was to transfer 2, 800 of its workers to Accenture. Accenture was to provide software services to Nokia operations in Britain, US, India, China and Finland. In this scenario, outsourcing was necessary since it was used as a measure to minimize the labor force and costs to be able to remain competitive in the market and to catch up with its rivals like Smartphone manufacturers.

How the Organization deals with Issues of Contract

Under its contract with Capgemini, the IT firm was to provide management services like the delivery of goods and making of customer order management as well as invoicing. In this contract, matters facing customers are not entered or covered in the contract. Matters of contract are listed in the supplier requirements.

It is therefore, the duty of the suppliers to best decide whether they can meet the demands and the terms of the contract. When Nokia enters into a contract with suppliers, the following issues are put into consideration; what they are supplying, what they require in order to supply, how long the suppliers will be obligated to supply, their price of supplying it and what they will be held liable in case things do not flow as expected.

All the above factors will define how the supplier will handle the commercial agreement and how business will be consulted under the agreement. It will also make it easy for the supplier to operate under the terms of the agreement. With regards to Nokia’s contract with the customers, the customer would want to be guaranteed of the flexibility of the product to be supplied and the price to be paid for the product.

A short-term of Nokia’s contract with the customers is the bonus factor. Generally, confidentiality is important in contract negotiations and there is also need for boiler plate clauses in the contract.

Production and Inventory Control Measures

When compared with its competitors, Nokia utilizes the life cycle concept of the production process. This involves the manufacturing of mobile phones in two main phases; first is the building of the innards of the phone while the second stage is labeled as fast turnaround, and it is referred as the assembly to order.

Nokia Company has almost ten production units with high productivity and a big production capacity. These units are only in those countries that Nokia has operations. Consequently, Nokia has a better production technology savvy which can produce the products at an amazing speed as well as sustaining mass production.

Nokia Company enjoys very big economies of scale. It is estimated that it averages at $88 making a phone and $129 retailing it; this is an indication that Nokia’s gross profit margin is very high.

The production department of the Nokia Corporation is a central competency of the Company. The company has the potential and the capacity to meet the increasing market demands for mobile phones while enjoying economies of scale because of the massive production of mobile phones. It is the production technology that is utilized by the company that makes it rank as the best and the largest mobile manufacturing in the world.

Nokia Corporation is the leading mobile phones’ manufacturer in the market based on its volume of sales and the quality of its products. This is due to its ability to select best suppliers in the market and also its large production capacity.

Nokia Corporation has one of the best and wide networks of product distribution, which stems from the village market to the remotest parts of the globe where they have stalls to the most advanced markets in Europe and America where they have concept stores.

Joint ventures and cooperation with the supplier has enabled Nokia to utilize its inventory levels. Nokia suppliers who are at times contracted to be Nokia partners take part in the product-development process to satisfy the demands for the future production.

The effective and efficient management of inventory in the Nokia Company is backed up by diversification of supplier location. Consequently, Nokia built its inventory based on demand but there is always minimum levels inventory that should be kept constant.

Relationship between Demand, Supply and Logistics in the Organization

Though it is necessary to match supply and demand in every organization, there are often some difficulties that are encountered in the efforts to match demand and supply. This may include the uncertainties in demand and supply, variations in consumer requirements and the fragmentation of the supply chain.

Logistics is understood as the flow of materials, money and information from the suppliers to the consumers while demand, on the other hand, is defined as the flow of operations from the supplier to the manufacturers’ locations and finally to the consumers. The logistics costs that are attached to the demand supply include the freight costs, warehousing and the interest rates levied.

It is the responsibility of the logistics to find the cheapest and most affordable way of producing a product and the best method of reaching to the consumers. The logistics department must establish the most economical element of supply (Scribd, 2011).

Conclusion

The shortening of the product life-cycle poses problems to the development of a new product by Nokia. Several companies no longer comply with the demand that a product should undergo all the stages from design to launch for it to be made available to the market. This has, however, facilitated faster and active procurement in companies.

Nokia Corporation acknowledges the importance of outsourcing to realize high profitability. Consequently, the company requires its sub-contractors and suppliers to adhere to the stipulated terms of contract to prevent unnecessary legal complications, which might spoil the reputation of the company.

Like any other company, Nokia has suppliers from all corners of the world, and it is the duty of the company to define its requirements for suppliers in wherever they are situated. To ensure efficient and reliable product supply, Nokia has devised a Nokia Supplier Requirements (NSR) that its suppliers must subscribe and comply with.

Nokia stresses the need for openness and trust in its transactions with the suppliers; it is thus two phrases that drive compliance and improvements of performance. This can be assessed through supplier assessments by the company. To enhance supplier confidence and reliability, Nokia undertakes supplier training, which makes it a unique company in the globe.

References

Burt, D. N., Petcavage, S. D., & Pinkerton, R. L. (2010). Supply management (8th Ed.). New York, NY: McGraw‐Hill.

Cavinato, J.L., Flynn, A.E. & Kauffman, R.G. (2006). The supply management handbook. New York, NY: McGraw-Hill Professional.

Kalra, D. (2011). Global supply-chain management of Nokia. Slide Share net. Web.

Nokia Website. (2011). Supply chain. Nokia Corporation. Web.

Scribd. (2011). Supply-chain management in Nokia. Web.

Shah, J. (2009). Supply-chain management: texts and cases. India: Pearson Education.