- Introduction

- Supply chain management information

- SCM major processes

- Implementing SCMIS using an Agile System Development and ARIS framework

- ARIS framework

- Applications to model SCMIS with ARIS framework

- Technical considerations

- Real-time benefits of SCMIS in inventory management

- Inventory management software

- Works Cited

Introduction

Supply chain management (SCM) entails adding value to a product or service through integration of activities related to making of the product or service. A relevant definition of SCM covers the integration of business processes in a bid to ensure that products and services conform to customers’ orders (Handfield and Nichols Jr 5).

In this regard, understanding of the making process of the organisation’s product and other essential processes is critical for SCM. Production and distribution of goods are positioned either at upstream or downstream of the company’s supply chain. In addition, SCM is integral in ensuring that the organisation’s focus on customers’ satisfaction is fulfilled with utmost convenience.

SCM is important for streamlining the cost of production and ensuring that information flow between business processes is efficient. Manufacturing organisations are known for using SCM to guarantee the inventory cost is reduced through demand projection and effective production scheduling.

On the other hand, management information system (MIS) is a broad term used to describe a computer-oriented system that manages the flow of information within an organisation (Haigh 19).

MIS exists in the form of software and is the recent development in information management. MIS has become an integral component in decision-making processes since it uses computerised applications that manage and control projects, resources and data on managers’ behalf.

Supply chain management information

An effective SCM must consist of essential aspects that will facilitate its integration with MIS. In this regard, information and analytical tools used by the organisation must be considered. In addition, algorithms and other methodologies should take the factors for an information system (IS) into account together with other information including techniques, methods, or procedures.

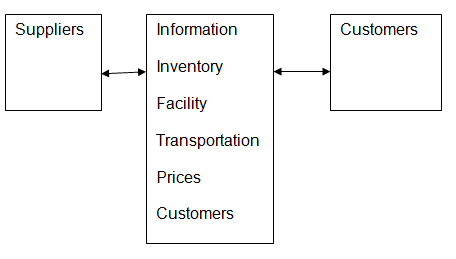

The mentioned data should be related to integral activities or aspects of the electronic manufacturing company. These aspects cover inventory, transportation, price, production cost, suppliers and customers.

Fig 1.0 Organization aspects and SCM interfaces.

SCM major processes

The electronic manufacturing company’s SCM major processes comprise the Supplier Relationship Management (SRM) in charge of supply and design collaboration processes. It should also be stated that strategic planning is an integral activity for the Internal Supply Chain Management (ISCM).

Other activities from the same process are demand planning and field services. Customer Relationship Management (CRM) processes entail sales and marketing, order processing, and customer services (Lambert 28).

All the above processes are to be integrated to form a comprehensive Supply Chain Management Information System (SCMIS) that should be easy to use among the organisation functions, and its performance should be reliable, cost-efficient, and adaptable.

Implementing SCMIS using an Agile System Development and ARIS framework

The Agile System Development is important for creating a SCMIS that is dynamic and involves all organisation’s stakeholders. An example of a SCMIS application that is integrative and collaborative in a business is the Dynamic System Development Method (DSDM).

ARIS framework

Architecture of Integrated Information Systems (ARIS) provides an insight on how SCMIS can be developed. ARIS framework performance in an organisation’s information system is supported by five aspects among which organisation, data, control, function, and output should be considered (Radwan and Majid 7).

Organization aspect. The ARIS framework requires the organisation’s hierarchical structure, network concepts, computer resources and all organisation’s technical requirements in an information system.

Data aspect. ARIS framework demands the organisation’s data details and data models, as well as the data access path. ARIS is also dependent on a data memory usage.

Function aspects. ARIS framework utilises organisation’s application programs by implementing module concepts and programming language suitable for end-user usability.

Control aspect. ARIS framework requires details of an organisation’s entire internal business processes. The relationship between the processes should be documented in a systematic manner. In this regard, the control aspects describe the processes involved in the production of products and services, in the mentioned organisation.

Output aspects. ARIS framework performance demands a description of the organisation’s inputs and outputs. A description of physical, non-physical products and information is vital for integration of an effective SCMIS.

Applications to model SCMIS with ARIS framework

Using the inventory of electronic manufacturing company as a major aspect in the SCM interface, the following entities can be put into consideration. The organisation’s chart can be represented in SCMIS model using individuals’ details. Understanding individuals’ responsibilities within organisations is critical for this process as it gives clarity on how information flows using authority lines within the organisation.

The data entities of an organisation can be modeled using an IDEAF1X computer application, which can only detail data using attributes, codes and keys while awaiting implementation and commissioning of the SCMIS.

A computer-based application is best suited to represent the function aspect, for example, the IDEF0 application. The output aspect of ARIS framework requires necessary details of both input and output required in an SCMIS.

Technical considerations

The active user of the information system must be involved during the designing of the organisation’s aspect of the SCMIS. Security concerns of the SCMIS should also be taken into account during the design and implementation process.

The security problems such as system hacking can be addressed effectively using the ARIS framework that has the capacity to deter virus hacking. Outcomes specification is needed in determining the output of a process. This can be detailed and represented using an ARIS framework.

Real-time benefits of SCMIS in inventory management

The ARIS framework is an essential concept in ensuring that there is the detailed visibility of inventory in an organisation’s store. This is made possible through real-time integration of data of the exact stock levels in the inventory.

Moreover, the SCMIS can assess inventory trends and the frequency of re-ordering. Evaluating the supplier’s on-time performance is measured through a real-time SCMIS that configures inventory trends and order processing from the supplier’s side (Shang and Peter 273).

SCMIS that focuses on controlling stock levels has the capacity to reduce inventory costs since stock control becomes a real-time measure and allows operational efficiencies on other processes (Shang and Peter 273). It is important to note that stock control measures also govern inventory replenishment.

In this regard, managers ensure that inventory stock does not exceed the maximum levels or minimum levels (Shang and Peter 275). Inventory is only maintained at optimum levels that allow operations to proceed without interruption and under the minimal cost.

An electronic manufacturer can benefit extensively from SCMIS by streamlining assembly processes. Thus, the SCMIS ensures that work orders are efficiently processed using new work schedules and plans.

This can be supplemented by using multi-level assemblies. An efficient SCMIS would guarantee that assembly operations are integrated from the procurement functions to back-office operations. This would result in a smooth flow of information maintained until the products are ready for market delivery.

Inventory management software

Inventory management software is a significant aspect that should be incorporated in a SCMIS (Kim 324). This software can implement a bin and lot management feature necessity in tracking and managing all organisation’s warehouses (Stevenson and Mehran 32).

Moreover, the feature can track any inventory transaction from one point. An effective SCMIS with bin and lot management features is necessary in implementing inventory control policy such as FIFO and LIFO.

Implementing a demand-based replenishment methodology is easily made through an inventory-oriented SCMIS. In fact, this method is efficient for ensuring that the finished goods inventory is pushed to the market.

The demand-based replenishment methodology concentrate on the fact that customers’ demand is replaced by available inventory. This initiative is critical in reducing the total net-landed cost and optimising inventory at the same time.

SCMIS that addresses the effectiveness of multi-location inventory is necessary for several reasons. An efficient SCMIS application like QuickBooks Enterprise Solutions (QES) is instrumental in tracking of bins located in various warehouses. This is made possible through scan barcodes entered in the system, which identify the location of a bin or item and the location of data entry, every time this entry is made.

This method is manageable if bins or items are assigned serial numbers. QES application is optimal in calculating the value of a company’s inventory across various warehouse locations. With QES, inventory can still be accounted for even after moving the same from one location to another.

Works Cited

Haigh, Thomas. “Inventing information systems: The systems men and the computer, 1950-1968.” Business History Review 75.1 (2001): 15-62. Print.

Handfield, Robert B., and E.L. Nichols Jr, (2002). Supply chain redesign: Transforming supply chains into integrated value systems. London: FT Press. Print.

Kim, Soo Wook. “Organizational structures and the performance of supply chain management.” International Journal of Production Economics 106.2 (2007): 323-345. Print.

Lambert, Douglas M., ed. Supply chain management: processes, partnerships, performance. Newcastle: Supply Chain Management Inst, 2008. Print.

Radwan, A., and M. Aarabi. “Modeling Supply Chain Management Information System Using ARIS Framework.” Proceedings of the 2011 International Conference on Industrial Engineering and Operations Management Kuala Lumpur, Malaysia, January. 2011. Print.

Shang, Shari, and P.B. Seddon. “Assessing and managing the benefits of enterprise systems: the business manager’s perspective.” Information Systems Journal 12.4 (2002): 271-299. Print.

Stevenson, J. William, and M. Hojati. Operations management. Vol. 8. Boston: McGraw-Hill/Irwin, 2007. Print.