Generating Value

A. When discussing the Nissan case study, it is important to mention that the company placed emphasis on diversity, with offices including employees of numerous cultures and nationalities and extensive experiences in the overseas operations. Moreover, Nissan implemented a build-to-order and build-to-stock approach in order to streamline the processes and simplify the products manufactured. According to the beliefs of the management, the adoption of the build-to-stock and order strategy made a positive influence on the increase in sales.

Compared to key competitors, Nissan introduced a simplified line of products with a view to compliment the key strategies (Schmidt & Simchi-Levi, 2013). Therefore, this allowed the company to overcome unpredictable challenges and change the way Nissan usually responded to emergencies and risks.

Nissan also focused on the importance of the supply chains within the context of increased globalization of the automotive industry. Importantly, Nissan leveraged a decentralized structure of supply chains and later imposed central control and coordination in cases of crises (Schmidt & Simchi-Levi, 2013). Apart from contributing to the developing of the corporate culture, the flexible organization of the supply chain was efficient in the process of management of the major global operations through the valuing of the executive team.

One of the critical components of operations management functions is the production of vehicles that are of high quality but reasonably priced. In addition, it enables the company to ensure the rewarding customer experience by furnishing considerate customer care and manufacturing reliable and environmentally friendly cars that correspond with client’s needs (Schmidt & Simchi-Levi, 2013). Moreover, the enterprise cherishes and promotes the diversity. The multi-nationality that characterizes its workforce allows meeting the requirements of the diverse markets in which Nissan functions.

- Trying to become more competitive in the automotive market that offers very vast competitive opportunities is hard for many companies. According to the research conducted by Toma and Marinescu (2013), Nissan used 13 cross-functional areas that represent the core of the company’s functional spheres. Following the logic of the cross-functional areas, Nissan focused on the global strategy that accounts for the quick expansion of the process of globalization. Therefore, Nissan has to be a proactive multinational and transnational company that has considerable resources (Toma & Marinescu, 2013) for sustaining a competitive advantage in the automotive industry where every manufacturer is faced with great struggle and thus the requirement to implement global strategies for competitive advantage to at least survive.

- Service operations and manufacturing operations have both similarities and differences. The main distinction lies in the tangibility of the output. In the first case, the output is intangible (for instance, purchasing a vehicle from Nissan and its maintenance). In the second case, operations produce physical goods (for example, car manufacturing). Nissan brings value to the clients by addressing all the customers’ needs so that they do not have to turn to other companies for service provision (Pyzdek & Keller, 2014). The main similarity between the two categories is that labor and location are needed for both of them.

To achieve the competitive edge, Nissan has decentralized the supply chain structure. At the time of the natural disasters, the company was already prepared to mitigate the possible disruptions through strong central control and coordination (Hill, Hult, Wickramasekera, Liesch, & Mackenzie, 2016). This strategy enabled the enterprise to recover from the crisis faster than the rivals and bring the value to the clients rapidly. As stated by the company CEO, “most of the steps we have taken in response to the March 11 disaster have been continuations of strategies priorities and plans that were already in place” (Schmidt & Simchi-Levi, 2013, p. 7). Therefore, the emergency response strategy was centered on the decentralization of supply chain.

Theories and Techniques

MRP calculations must be accompanied by the development of product structure, building a gross requirement plan, as well as building a net requirement plan. MRP is a dynamic system that changes according to how company changes. The calculations for gross to net for MRP is the following: Gross Requirements – On Hand Inventory = Gross Requirements. The input files needed for a successful MRP are master production schedule, production cycle, bill of materials, customer focus, and supplier lead times.

It should be noted that PERT (Program/Project Management and Review Technique) places emphasis on timeframe and planning. CPM (Critical Path Method) centers on the cost (O’Brien & Plotnick, 2015). In terms of the company under analysis, the first system would be more advantageous since the occurrences that took place were unpredictable. In addition, this approach enables determining the minimum amount of time needed to furnish the task as well as the activity in general. Regarding CPM, Nissan could utilize it in everyday occupations or when cutting down the expenses in particular project parts.

The steps of forecasting can be concluded to the following: defining the operation that needs it, determining the items, and specifying the timeframe (range of the forecast). Then, Nissan could choose the approach and utilize a qualitative method to produce the new commodity. Regarding top-selling product line, the enterprise will be able to address clients’ requirements better. It will be achieved through ensuring supply chain visibility. The major risks and reduction practices can be concluded to two main categories. They are currency fluctuations and financial risks (Abe & Ye, 2013). The company could employ flexibility in manufacturing decisions and decentralization to remit the possible negative manifestations (Mahutga, 2012).

Priority rules usually dictate the sequence in which jobs are works. Priority rules make job-processing times and due dates crucial information pieces. There are four types: “first come, first served” (FCFS), shortest processing time (set), the critical ratio (CR), and earlier due date (EDD). Earlier due date can be the most effective priority rule for Nissan since it implies that jobs are processed in accordance with due dates, with the earliest due dates first. Because the company is trying to become more sustainable and operate within the just-in-time framework, it can be useful to fulfill tasks that have the earliest due dates to ensure that customers remain satisfied.

Theory of constraints (TOC) is associated with the process of mitigation and identification of bottlenecks within systems. The five steps of the TOC process include the following:

- Identifying constraints within the system – finding the part within the process that limits the goal from being achieved;

- Deciding on how to exploit the identified constraints – using improvements to get the most out of the existing resources (Dettmer, 2000);

- Subordinating other components to the decision – adjusting the rate of activities to support the decision;

- Elevating the constraints – considering further actions for eliminating the constraint;

- Going back to the step 1 in the case if the constraint has been broken at previous steps – avoiding the constraint in the future (Goldratt, 1999).

According to the case study by Schmidt and Simchi-Levi (2013), Nissan experienced some financial difficulties in the process of risk management, which suggests that this area could benefit from the application of the theory of constraints. However, supply chain management is the most challenging process, with which Nissan has to deal, so it is important for the company to identify the constraints within the process and decide how to elevate them for achieving maximum performance.

There are seven steps that companies can use for developing a cohesive forecasting system: identifying the utilization of the forecast, selecting items for the projection, determining the timeline, choosing a forecasting model, gathering data, forecast creating, and implementation. In the case of Nissan, it can use quantitative prediction that is based on the history of sales to input into the forecast. A forecasting system can bring positive results with regards to reducing waste and only producing as many products as customers will be willing to buy.

Risks associated with the effectiveness of the supply chain are differentiated into two categories: internal and external risks. With regards to external supply chain risks, there are the following types:

- demand risks, which occur when there is unpredictable or misunderstood demand of customers;

- supply risks, which are caused by the interruptions in product flow within the supply chain;

- environmental hazards that occur externally in the supply chain and are usually associated with social, governmental, or economic factors;

- business risks, which are caused by factors such as the processes within supplier companies and their stability with regards to management or finance;

- plant hazards, which are caused by the circumstances within the physical facilities (Identifying supply chain risks, n.d.).

Internal supply chain risks are easier for companies to manage because they are usually within the control of the business. Five types of internal supply chain risks are the following:

- manufacturing risks, which occur as results of processes’ and operations’ disruptions;

- business risks, which take place due to the disruptive changes in personnel or management as well as the shifts in the ways suppliers and purchases communicate;

- control hazards, which occur due to the inadequate planning procedures and the lack of effective management;

- risks of mitigation and contingency that are caused by the absence of alternative solutions in cases when something does not go the right way;

- cultural risks, which occur as results of the cultural tendencies of businesses to delay or hide negative information, which contributes to the slower reactions of companies to emergencies (“Identifying supply chain risks,” n.d.).

Supply chain resilience is targeted at risk reduction and can be used by companies even in cases of natural disasters. With regards to resilience, a company should regionalize. Regionalization is often effective in helping a company reduce costs and contain the impact of natural disasters to a specific geographic region (Chopra & Sodhi, 2014). By implementing the regionalization approach towards the distribution of manufacturing facilities of Nissan, the company will be able to design a cohesive plan for the mitigation of natural disaster risks since usually one region is more prone to such incidents than others. For example, through identifying the most disaster-prone areas on the map, Nissan will give more priority to those regions to respond to risks as quickly as possible.

Just-in-time (JIT) is a manufacturing and inventory strategy that companies use for increasing efficiency and decreasing waste by receiving goods only when they are needed in the process of production (“Just in time – JIT,” n.d.a). Toyota Production System (TPS) is based on making vehicles that customers order in the most efficient way for delivering them as quick as possible (Toyota, 2017). TPS aligns with the ideas of just-in-time inventory and lean.

Lean manufacturing is an approach that is based on finding the most efficient approach for removing any wasteful steps that do not add value to the end product (MT Team, 2017). All three concepts are related in a way that they enable manufacturers to focus on efficiency and removal of waste without compromising the quality of the end product. On the bright side, JIT, TPS, and lean reduce inventory costs; on the downside, it requires manufacturers to be extremely accurate when forecasting demand.

With regards to Toyota, just-in-time, TPS, and lean encouraged the company to pull materials forward when they were needed, with components produced and received in small lots. On the other hand, the overall system was not risk-free (Schmidt & Simchi-Levi, 2013). For instance, if there were disturbances in the information or material flow, the manufacturing stages can be significantly undermined.

Total quality management (TQM) is an approach towards management for achieving long-term success through ensuring customer satisfaction (ASQ, 2017). Seven TQM tools include check sheets, scatter diagrams, cause-and-effect diagrams, Pareto charts, flowcharts, time-function maps, value-stream maps, and process charts. In the case of Nissan, the management can use time-function maps to identify processes that limit the company from achieving an effective just-in-time framework of manufacturing. Process charts, on the other hand, can be used by Nissan to distinguish between processes that add value to the just-in-time framework as well as those that only produce waste.

Data Analysis

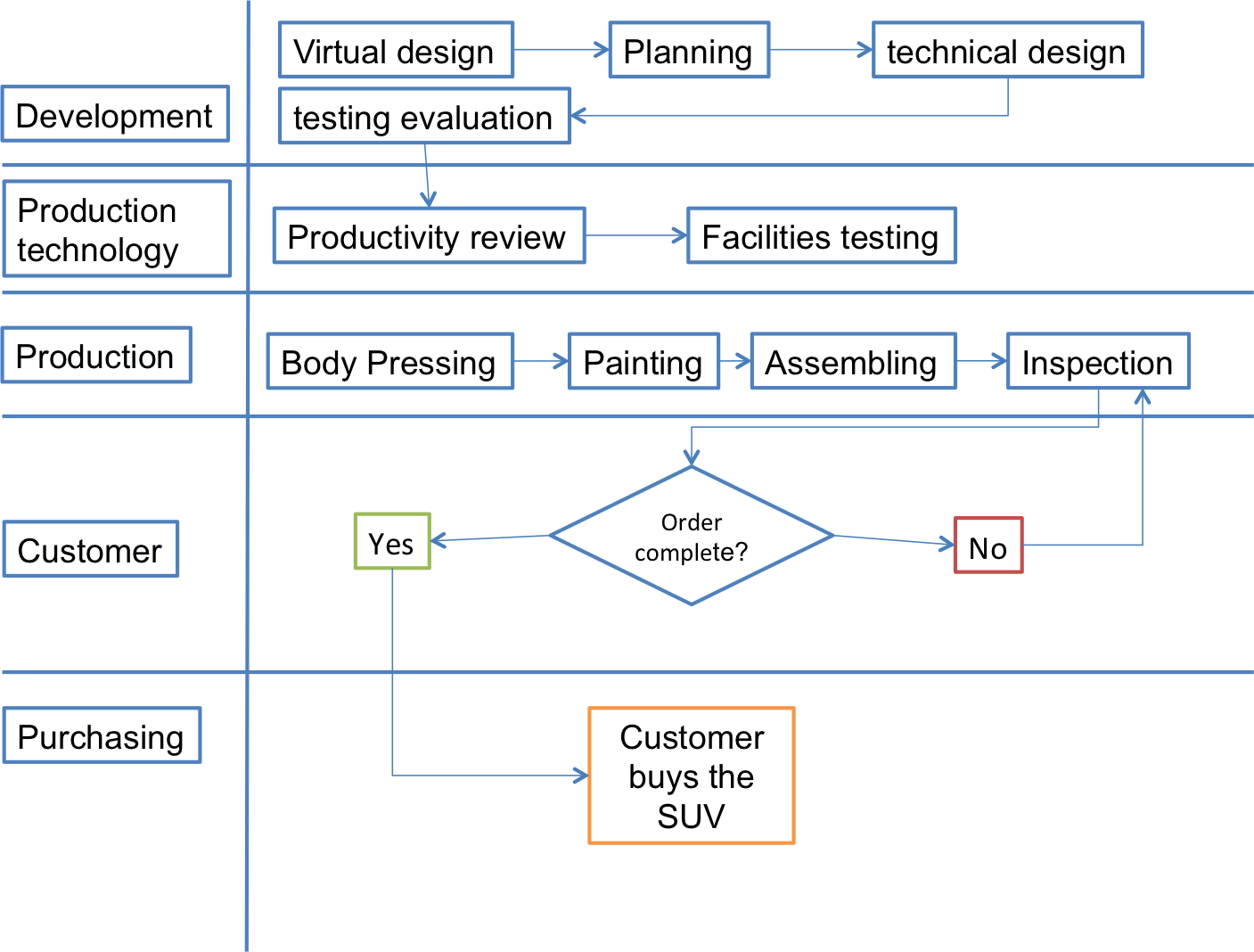

The process map for the new model of X-trail SUVs is presented in the diagram below. The process map can be used for multiple purposes. First, an operations manager can use this value map for checking the current state of the production process. Second, it can be used for assessing the future possibilities. Third, it can be used for complying with the requirements that arise during the process.

X-trail SUV Process Map

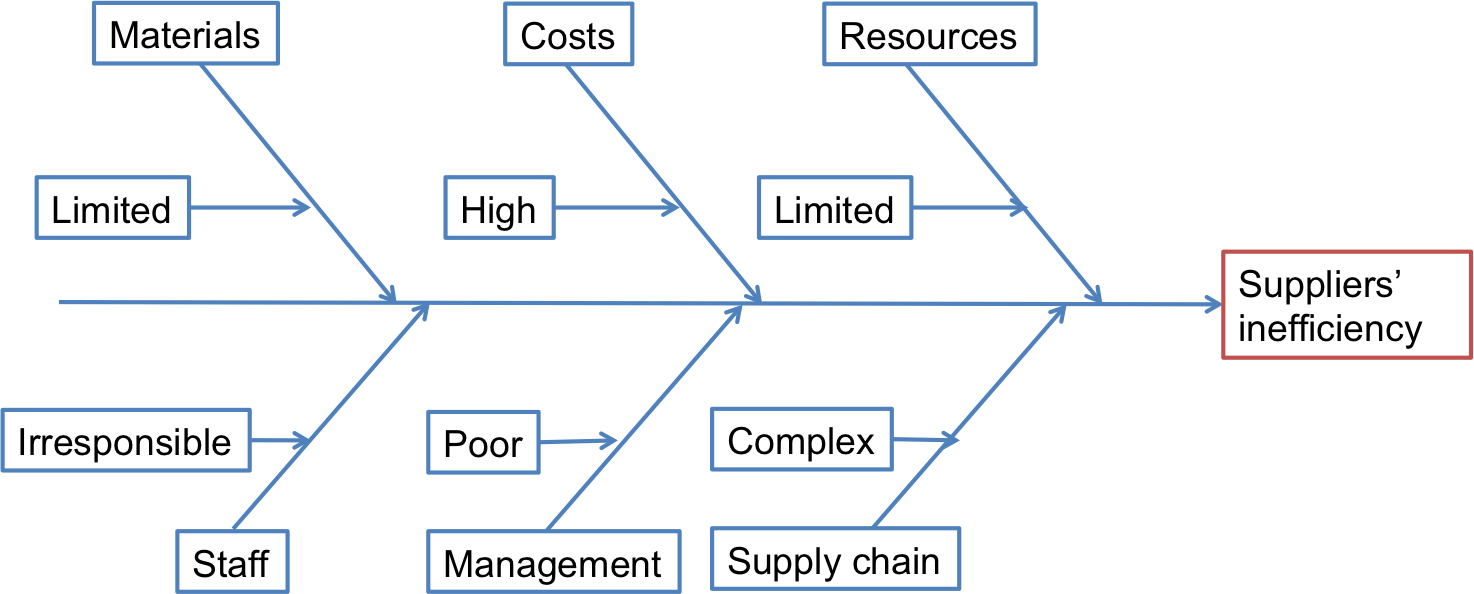

Causes of partners’ struggle are shown in the diagram above; the most prominent are complexity, high costs, and lack of available resources. The constraints partners experience can be mitigated when Nissan addresses the mentioned causes.

According to the calculations above, the two locations got almost equal scores. Although, since the rental and labor costs as well as taxes are lower in South Carolina, it will be a rational decision for Nissan to open a plant there because labor productivity is lower only by two points.

D. Using the ABC inventory classification can allow a business regular its cost control of the materials stored in warehouses. Within the model, materials that make up 70% or more fall under the A category, 20% and below fall under the B category, while materials that are 10% and below in total value fall under the C category. Thus, the framework suggests that even though there are more of some materials, they have less quality compared to those of greater need but of less stock available.

The application of the ABC inventory matrix will allow Nissan to generate a cohesive framework for determining on which materials to focus and on which to not. The calculations for the annual dollar volume, percentage of annual dollar value, and the assigned category for each item are presented in the table below:

Sustainability

- Triple Bottom Line (TBL) is an accounting framework that includes tree performance dimensions: social, environmental, and financial (Slaper & Hall, 2011). Three Ps are the dimensions of the TBL: people, planet, and profits (Slaper & Hall, 2011). To enhance operations management in Toyota, the management should address its three dimensions. First, there should be a shift of focus on the fair treatment of employees by enacting favorable practices. Second, Toyota should implement sustainable practices and reduce its environmental impact. Such practices can range from recycling programs to the usage of only sustainable materials (“Triple bottom line,” n.d.). Third, the company should align its financial bottom line with the sustainable practices and social responsibility since the largest consumer demographic is willing to pay for sustainable goods (“Triple bottom line,” n.d.).

- The ISO 14000 standards provide manufacturers with measurements for dealing with their environmental impact by integrating the environmental considerations into the production process. With regards to Toyota Motor Corp., the company identified hundreds of substances and chemicals that the suppliers must not use in their manufacturing process (Gilbert-Miller, n.d.). The alignment with the ISO 14000 standards allows the company to follow the Triple Bottom Line framework to promote the agenda of sustainability and social responsibility to show customers that Toyota cares about reducing the environmental impact associated with the process of vehicle manufacturing.

- Integration of corporate social responsibility in a technology-oriented company comprises of knowledge exchange with customers, maintaining sustainable agreements with suppliers, developing employee code of conduct concerning ethics and knowledge dissemination, protecting the interest of the company with regards to protecting the corporate government decisions, and creating a social action plan to benefit local communities (Guadamillas-Gomez, Donate-Manzanares, & Skerlavaj, 2010). Among the mentioned principles, exchanging knowledge with suppliers and customers is the most effective since it will allow the company understand the demands of the public with regards to vehicle manufacturing and get an idea about what suppliers can and cannot do to adhere to the practices of environmental sustainability and social responsibility.

References

Abe, M., & Ye, L. (2013). Building resilient supply chains against natural disasters: The cases of Japan and Thailand. Global Business Review, 14(4), 567-586.

ASQ. (2017). What is total quality management (TQM)? Web.

Chopra, S., & Sodhi, M. (2014). Reducing the risk of supply chain disruptions. Web.

Dettmer, W. (2000). Constraint management. Tuscon, AZ: Quality America Inc.

Gilbert-Miller, S. (n.d.). ISO 14000 becomes a prerequisite for suppliers to stay in the game. Web.

Goldratt, E. (1999). Theory of constraints. Great Barrington, MA: North River Press.

Guadamillas-Gomez, F., Donate-Manzanares, M., & Skerlavaj, M. (2010). The integration of corporate social responsibility into the strategy of technology-intensive firms: A case study. Proceedings of Rijeka School of Economics, 28(1), 9-34.

Hill, C., Hult, T., Wickramasekera, R., Liesch, P., & Mackenzie, K. (2016). Global business today. New York, NY: McGraw-Hill.

Identifying supply chain risks. (n.d.). Web.

Just in time – JIT. (n.d.). Web.

Mahutga, M. (2012). When do value chains go global? A theory of the spatialization of global value chains. Global Networks, 12(1), 1-21.

MT Team. (2017). Lean manufacturing: Working more efficiently. Web.

O’Brien, J., & Plotnick, F. (2015). CPM in construction management (8th ed.). New York, NY: McGraw Hill.

Pyzdek, T., & Keller, P. (2014). The six sigma handbook (4th ed.). New York, NY: McGraw Hill.

Schmidt, W., & Simchi-Levi, D. (2013). Nissan Motor Company Ltd.: Building operational resiliency. Web.

Slaper, T., & Hall, T. (2011). The triple bottom line: What is it and how does it work? Web.

Toma, S-G., & Marinescu, P. (2013). Global strategy: The case of Nissan Motor Company. Procedia Economics and Finance, 6, 418-423.

Toyota. (2017). Toyota production system. Web.

Triple bottom line. (n.d.) Web.