Hazard versus Risk

- A possible source of danger that can negatively affect the health and safety of a person.

- The likelihood of an individual being possibly harmed or being exposed to the hazard (Health and Safety Authority, n.d., para. 4).

In order to introduce the topic, it is first important to distinguish between hazard and risk.

While risk is the likelihood of an individual being possibly harmed or being exposed to the hazard (Health and Safety Authority, n.d., para. 4), a hazard is a possible source of danger that can negatively affect the health and safety of a person.

Organization Description

- PR Agency “The Voice”

- 30 in-office employees.

- 10 freelance employees.

- Mondays to Fridays from 10 AM to 7 PM.

- Standard holiday schedule.

- Rented space in an office building.

The organization I have chosen for assessment is the PR Agency “The Voice” which employs 30 in-office and 10 freelance employees. The working schedule is standard – Mondays to Fridays from 10 AM to 7 PM, with a standard holiday schedule. The company works in a rented space in an office building.

Kitchen Hazard

- Kitchen hazards are not just food – appliances and hygiene are highly important (Foster, 2011, para. 1).

- Common accidents in the kitchen:

- Fires

- Burns

- Hazmat

- Electrical Appliances

- Falls and slips (White, n.d., para. 5).

Since kitchen hazard is the issue at hand, it is crucial to know what are the common accidents. Kitchen hazards are not just food – appliances and hygiene are highly important (Foster, 2011, para. 1). Common accidents in the kitchen include fires, burns, hazmat, electrical appliances, falls and slips (White, n.d., para. 5).

The Office Kitchen

- Kitchen in a separate room.

- Includes a fridge, a microwave, a toaster, an electrical kettle, a sink, a coffee machine, cupboards with other appliances (dishware, knives), chairs, and a table.

- Employees bring food from home and put into the refrigerator.

- The kettle and the coffee maker are the most used appliances.

- No stove since employees are not allowed to cook in the office kitchen.

The description of the office kitchen I have chosen for assessment is the following:

- It is a kitchen in a separate room.

- It includes a fridge, a microwave, a toaster, an electrical kettle, a sink, a coffee machine, cupboards with other appliances (dishware, knives), chairs, and a table. Employees bring food from home and put into the refrigerator. The kettle and the coffee maker are the most used appliances.

- No stove since employees are not allowed to cook in the office kitchen, which is an effective safety measure.

Hazards in the Office Kitchen

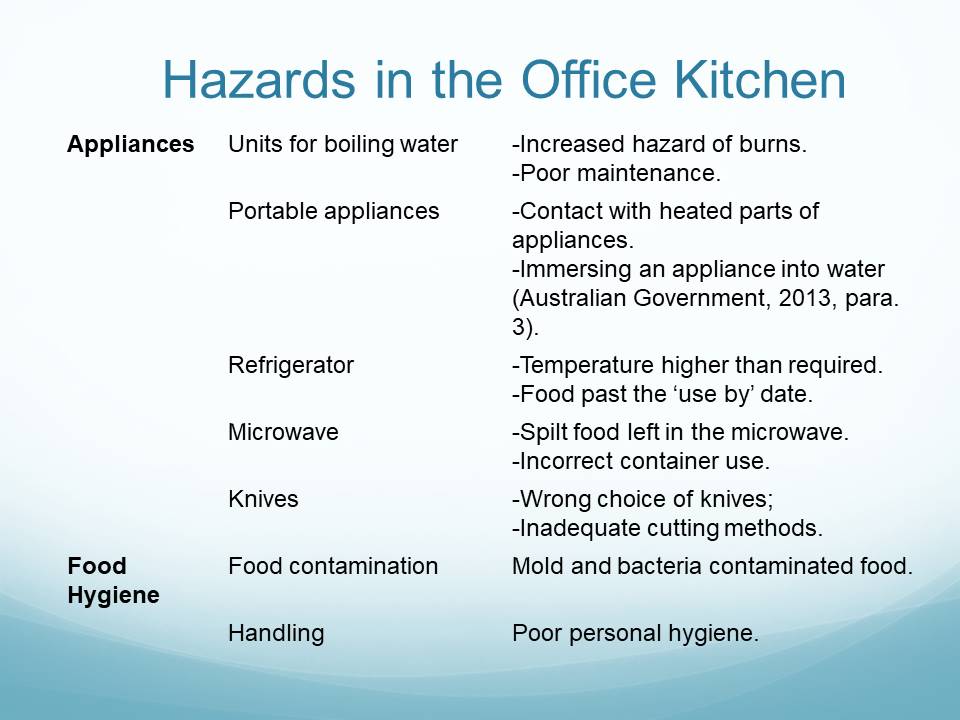

I have identified office kitchen hazards and organized in a table seen on the slides.

There are three categories of potential hazards: appliances, food hygiene, and electricals.

Appliances include:

- Units for boiling water that imply increased hazard of burns and poor maintenance.

- Portable appliances that are dangerous due to the contact with heated parts of appliances and immersing an appliance into water (Australian Government, n.d., para. 3).

- A refrigerator which can operate on increased temperatures and store past the ‘use by’ date.

- Microwave that is rarely cleaned from spillage. Incorrect container use is also an issue.

- Knives are particularly dangerous since some employees are not aware of adequate cutting methods.

- Food hygiene includes the following components:

- Food contamination, namely mold and bacteria.

- Inadequate food handling associated with poor personal hygiene.

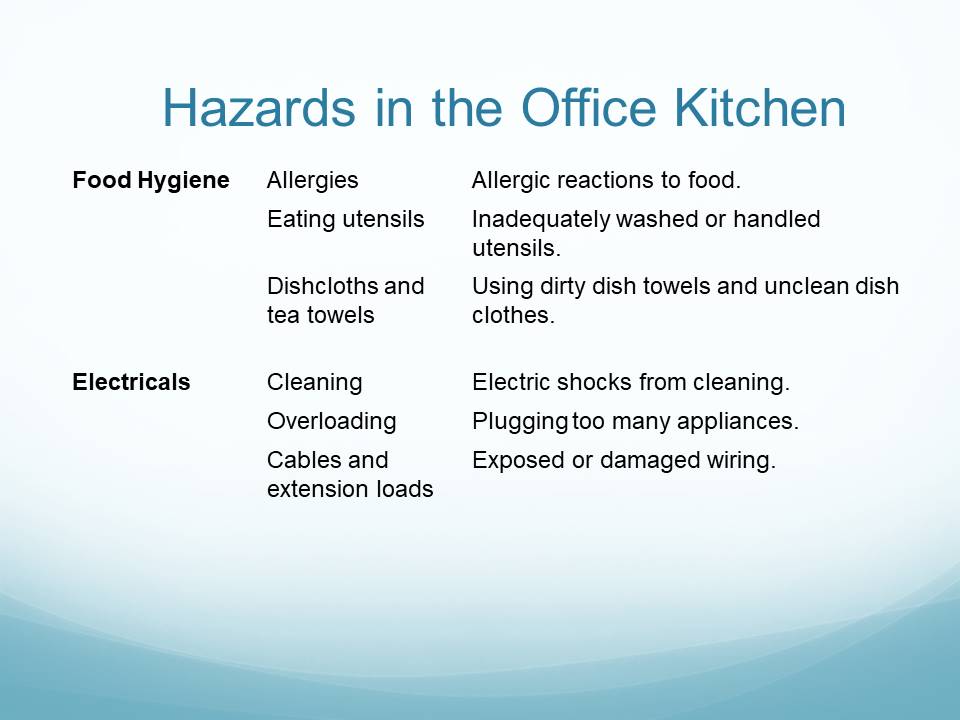

Furthermore, food hygiene includes:

- Allergies – allergic reactions to food.

- Utensils that have been inadequately washed or handled.

- Dishcloths and tea towels that have not been washed.

Electric utensils hazards include electric shocks from cleaning, plugging too many appliances, and exposed or damaged wiring.

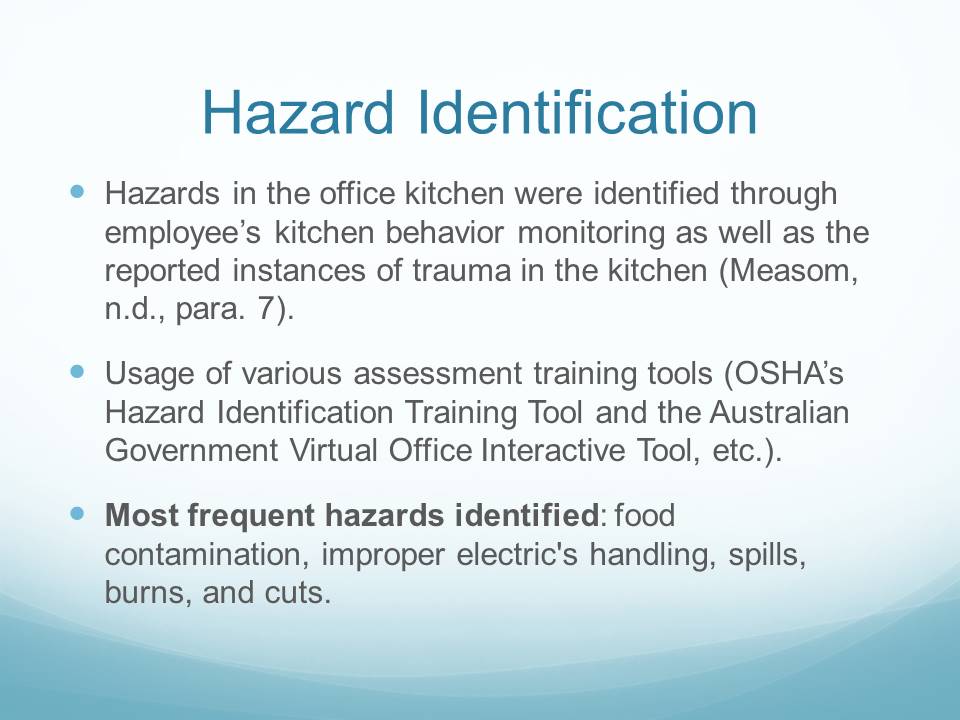

Hazard Identification

- Hazards in the office kitchen were identified through employee’s kitchen behavior monitoring as well as the reported instances of trauma in the kitchen (Measom, n.d., para. 7).

- Usage of various assessment training tools (OSHA’s Hazard Identification Training Tool and the Australian Government Virtual Office Interactive Tool, etc.).

- Most frequent hazards identified: food contamination, improper electric’s handling, spills, burns, and cuts.

I identified hazards in the office kitchen through employee’s kitchen behavior monitoring as well as the reported instances of trauma in the kitchen (Measom, n.d., para. 7). I used various assessment training tools (OSHA’s Hazard Identification Training Tool and the Australian Government Virtual Office Interactive Tool, etc.).

Most frequent hazards I have identified: food contamination, improper electric’s handling, spills, burns, and cuts.

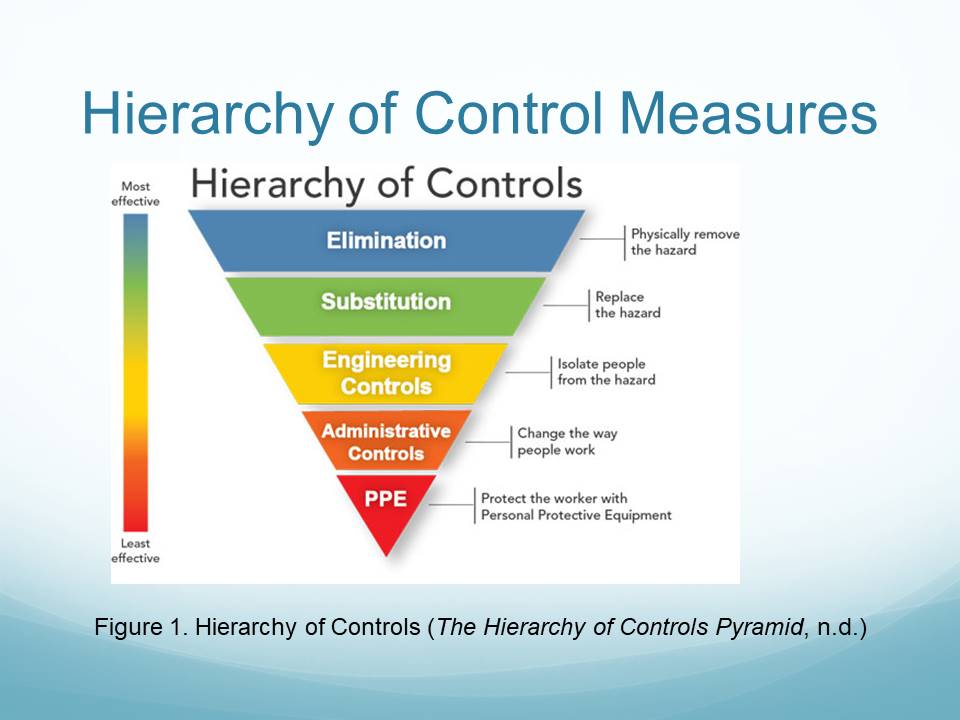

Hierarchy of Control Measures

The hierarchy of control measures is made up from five components that range from most to least effective.

The most effective control measures are elimination and substitution while PPE, administrative controls are the least effective. Engineering controls are in the middle. Elimination relates to physically removing the hazard, substitution means replacing the hazard.

Engineering controls are associated with isolating people from the hazard. Administrative controls change the way people work while personal protective equipment is used for simple protection.

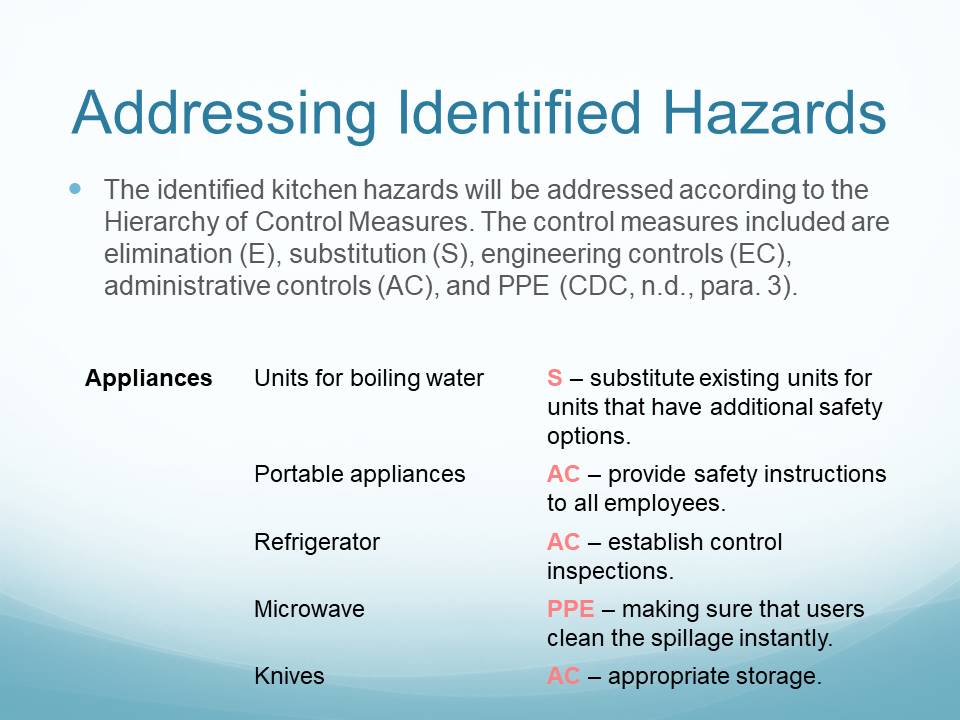

Addressing Identified Hazards

The identified kitchen hazards will be addressed according to the Hierarchy of Control Measures. The control measures included are elimination (E), substitution (S), engineering controls (EC), administrative controls (AC), and PPE (CDC, n.d., para. 3).

The identified by me kitchen hazards will be addressed according to the Hierarchy of Control Measures. The control measures included are elimination (E), substitution (S), engineering controls (EC), administrative controls (AC), and PPE (CDC, n.d., para. 3).

Methods for addressing hazards are organized into a table.

- First, appliances hazards will be addressed through substitutions, administrative controls, and personal protective equipment.

- Boiling water units will be substituted for units that have additional safety options.

- Portable appliances will be accompanied with safety instructions.

- Control inspections will be performed in terms of refrigerator safety.

- Knives will require appropriate storage while the microwave will be cleaned on a regular basis.

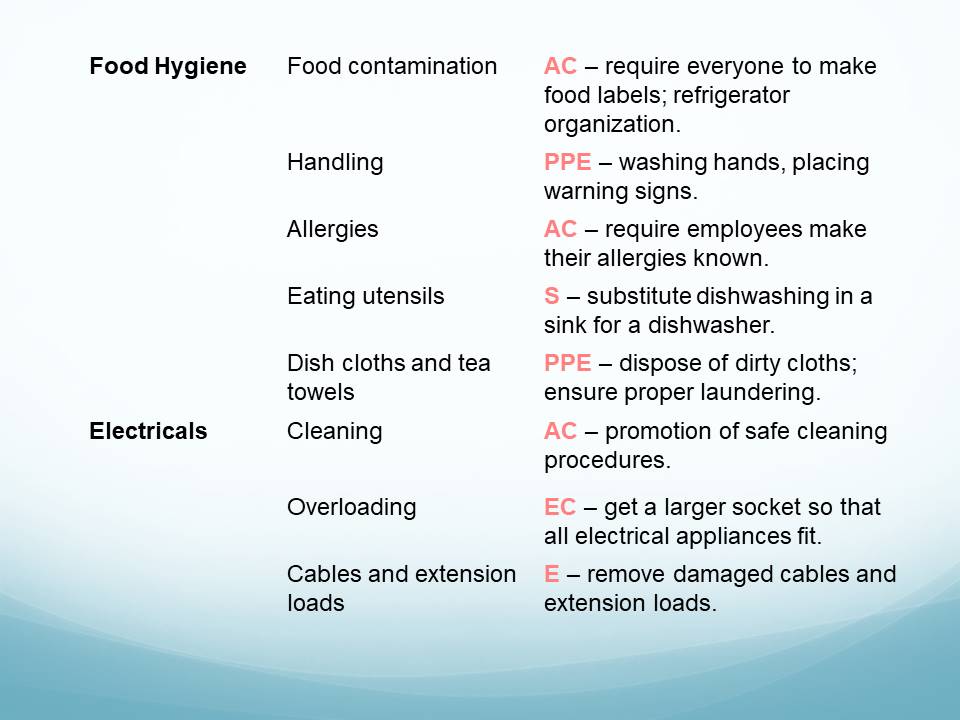

In terms of food hygiene, the administration will require everyone to make food labels; refrigerator organization.

- Food handling will be improved through washing hands, placing warning signs.

- Allergies will be addressed through requiring all employees make their allergies known.

- A sink for dishwashing will be substituted for a dishwasher.

- There will be the disposal of dirty cloths while ensuring proper laundering of fresh tea towels.

- Electrical hazards will be addressed through the promotion of safe cleaning procedures.

- Overloading will be prevented by getting a larger socket so that all electrical appliances fit.

- Damaged cables and extension loads will be removed.

References

Ausralian Government. (2013). Virtualoffice. Ariskmanagementtool. Web.

Foster, S. (2011). Preventingpotentialkitchenhazard. Web.

Health and Safety Authority. (n.d.). Hazard and risk. Web.

Measom, C. (n.d.). Kitchen hazards and kitchen< safety. Web.

The Hierarchy of Controls Pyramid [Image]. (n.d.). Web.

White, M. (n.d.). Kitchen hazards. Web.