Introduction

The following is a scan into the operations of C20. These reports will be concerning part one of this questions. This first part will delve into how C20 manufacturing is all about. It will have representations of pictures graphics as well as other indicators of other C20 operations.

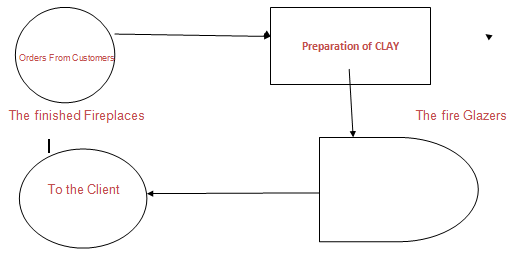

The C20 Manufacturing Process Map

The operations of C20 begin with the management which is made up of the director and under him are twenty employees who deal with how and what should be done in the organization. The manager is in charge of marketing as well as the production activities in the company (Housel 2004). In this part of the report, we will look into the manufacturing processes of the fireplaces in the Century 20.

Findings

The findings in this section relate to the processes of C20. The first process in the manufacture of fireplaces is that of preparing the fire glazers.

Here the materials for preparing the kiln are put in place, during this time the tools and apparatus which are to be used in this process are brought together to ensure that the work will be compatible as well be in a position to handled properly. Some of the materials shown here below;

The second thing after preparing the materials for work in the process of making the fireplaces is setting up the mould for the different kinds of fireplaces required by the clients. In our case of C20 most of the recommended fireplace is the Victorian fireplace.

The Victorian fireplace mold brings out the required fireplace. The moulds not made in C20. C20 Company usually gets these moulds from other manufactures.

Once the mold is in order, the next step involves clay mixing. The fireplace usually made using clay or cement. The company has a clay mixer used in this process. The clay is usually one of the basic materials that C20 considers, as raw material is clay. Clay when used in the process of manufacturing it brings out better moulds.

The clay properly mixed in to dough, then properly inserted in the mould so that it can take the shape of the mould. Once done the clay in the mould goes to the fire glazers. These tools heat the clay at very high temperatures.

A fire expert who in C20 is a permanent employee does the heating in the fire glazers. The reason why it is done by experts is to ensure that the fire in the glazers does not get out of control, also the heat is very harmful and it needed an expert to keep it in control. An example picture of the clay mixer is here.

Once the mixture is dried after the thorough heating in the fire glazer, the next thing which is done is removing the material from the mould which is not very tedious however once the materials now in the shape of the fireplace has been removed the next step is that they have to be furnished.

The furnishing involves brushing the mold to remove the rough surface and also cutting the extended parts of the mould this is done by part time people as it is dependent on the how fast the moulds in the fire glazers are being made.

The finishing part of this process involves having painting the fireplace as recommended by the client. Below is photo of the mold for preparing the Victorian fireplaces in C20.

The next process after the doing the finishing’s involves taking the finished product to the photo room this is where the photo of the fireplace is taken and sent to the client for viewing. This informs the client that the fireplace they asked for is now ready.

The client may take time to come to pick the order, so the product that in this case is the Victorian fireplace goes to the storage room in the mezzanine floor as it waits collection from the client. The storage place also serves as a showroom where properly arranged products that is different fireplaces from different moulds displayed by the C20.

Other than producing the fireplace, C20 shave other products in the line that assists the clients with products such as tiles. They make tiles through the same process however the tiles due to their smaller size compared with the fireplace they require a lot of cutting (Goldratt 2004).

Therefore, after removal from the mold they go to a different cutting machine that cuts the tiles into different sizes as required by the client.

The fireplace is certainly intention is to make the house warm and C20 has noted the need by their clients to have a source of energy. While firewood was what was being used in the Victorian fireplaces in the olden days nowadays it is hard to get firewood.

Therefore, C20 has come up with a mechanism to ensure that they have made a complimentary product, which is going to suit their clients. They make some charcoal improves the fireplace that they sell to their clients.

Recommendation

C20 manufacturing process is not complicated and which makes it easier for them to function correctly. However, speed and the efficiency of production is dependent on factors such as the number of moulds made, and the number of mold made is dependent on the number of orders and the designs received from the clients.

Therefore, their work is usually dependent on the demand in the market. Therefore, for the company to remain productive it has to ensure that there are enough orders to match its capacity.

Summary

With the rising demand in housing, and the homeowners appreciating the Victorian designs such as the Victorian fireplaces, it is imperative for this company to look for ways in which they will handle the increased demand. Either by increasing the number of clay mixers, which is one in the whole factory and would be a cause of bottleneck delay the orders or the products demanded are more than it can handle.

Operations Management in C20

The following is a report that seeks to discuss the part two of the question especially in relation to the issues of capacity and demand as well as discussion on the theoretical aspects of operation management in C20.

The following business report is based on a case study of C20, a company that deals with the production and distribution as well as repair of Victorian fireplaces. This paper will deal with the identification and evaluation of how C20 manages its capacity and demand as a part of operations management.

Operations management, at its basic, is the process in which an organization puts mechanisms in place to enhance its efficiency in the production and distribution of its goods and services.

Findings

This report will base its findings on one of the theories of operations management. C20 assessed based on the bottleneck theory of operations management. Here, the analysis will look at the inactive systems in the company as well as the efficient operations, which perform in this organization.

It will also discuss how the bottleneck theory of operation management works and why it is so important for a company to identify its bottlenecks to enhance the efficiency of its operations as well as increase sales volume.

Increased efficiency directly relates to the increased revenues. This report is all about analysis on areas that require readjustment for the company to attain maximum improvement.

Constraints/Bottlenecks

One operational challenge in this company is about the distribution mechanism that is not well defined. There is a dire need for the company to have a mechanism on accessibility of its products by the people of Manchester. Failure to do this would mean that customers who may want to get the products would not access most of the goods and services if they were away from that location.

The warehouse of the company is certainly another constraint. It is not clear why they chose to place the warehouse in the mezzanine floor. Certainly, a warehouse in the mezzanine means that more work in transporting the goods from it to different locations.

Failure to have a warehouse located in a more accessible place results in more energy and human resources used in transfer of goods rather than in the process of their production. The C20 must establish a formidable supply chain. The company is a conglomerate of facilities performing the tasks of procurement necessary for the production of the final product.

In our case, the final product is the Victorian fireplace. Among the raw materials required, there will be marble, iron ore pellets, and concrete. A realistic supply chain consists of various products. The management part of operations is a very critical aspect of C20 that is constrained. So far, the company has been having only one chain of command, and this has really decreased the efficiency of operations.

Although the details are scanty on the work of management, according to the data provided, it is evident that the manager does all the paper work because most of the staff is in the distribution and production departments of the company.

Theoretical Approach

An understanding of the bottleneck theory is critical for someone who is required to do operations management. This is because it gives the individual a chance to evaluate the system and look for instances which could be a hindrance to a proper efficiency.

The theory derives its name from its resemblance with the neck of a bottle compared to the other parts of the bottle. This means that if the business has some operations that are inefficient, that will be a problem for the entire company because the inefficient program will certainly affect the output (Thompson 1967).

Recommendations

The first operation addressed is that of building capacity, which in this case, refers to an efficient and effective production and distribution to handle the rising demand. As a part of increasing capacity, the company must address the issue of the human resource capacity. According to the video clip, the company currently has eleven employees who handle the production aspects of the enterprise. From the video clip, it is evident that the number

For this organization to be in a position to handle increased demand, it certainly calls for more production. The managerial as part of operation management involves activities like quality control in the production, inventory management, and record keeping as well as organizing and directing the firm.

The management is critical because it is the vision carrier as well as the vision developer in the organization. This means that work done to avoid the aspects that will sabotage the whole organization (Davis & Pine 1993).

Coordination of activities is also a vital aspect of operations management because without a proper coordination, C20 will certainly be a failure. Therefore, to make the company successful, all the operations within it need a perspective to ensure that they are in tandem with organization’s objective, which, in most cases, is to make the highest profit possible.

The company must increase its production if it is going to handle its demand. C20 products are certainly in a big demand, and in order to meet it, the company must manufacture more fireplaces. The organization must have a mechanism due to which it can outsource the raw materials at lower costs to maximize profitability.

The company as a part of its operations management requires having a procurement department, which will handle negotiation with the vendors who sell it the raw materials. This will ensure that the firm gets the necessary bargains that will be of great benefit to the company.

For the C20 to be effective, it must embrace technology in inventory management. It is clear from the video that even though the company is technology conscious, the inventory system is still manual. The inventory needs automation so that there should be censors in the company to indicate the present stock and, therefore, provide an easy mechanism of decoding both the previous and the present stock.

This will save the human resources as well as make the company more efficient. Automated inventory management is vital in having a system that will promote efficiency in any organization (Kidd 1994). With proper inventory management, the company’s success will certainly be phenomenal.

When a business connected with the multimedia, it means that it relies heavily on the various kinds of media for marketing (Frieda & Pierre 1984). C20 is one of such businesses, which do not rely on text alone as a part of its marketing strategy. It relies on the modern type of language and communication.

That is the internet, which incorporates audio and video media. Media is a form of communication that allows exchanging of information between two entities. In this case, these two entities will be the C20 and the client. The multimedia used as a medium by the two parties is the internet. The following is an exploration on how C20 can increase its online presence as a part of its operations managements (Womack 1990).

Referring to the flowchart of C20, there is a missing link in its chain of command. Tim is the overall manager and below him, there are three managers; one is in charge of office operations, such as bookkeeping and customer care, the other is in charge of procurement, and the third one deals with the operations, such as glazing and tiles cutting.

There is another vital department missing in this chain of command because there is no one who is in charge of such vital technological activities as website management and online sales and multimedia streaming. This means that if the website is hacked, no one can replace it within the required reaction time. In addition, if it shuts down, no one will be in a position to repair it. Probably, the company has outsourced this services but one should believe that if C20 is a multimedia-based business, it should have a department or someone dealing purely in website management.

In the twenty first century, we live in an information age, and companies that thrive are those, which include technology as a part of its operations. In our case, C20 has not included a link that means that the company cannot be in a position to respond to their customers with the immediate effect (Stevenson 2008).

The company has another missing link in its operations. Though it has a procurement manager who is in charge of procurement activities in the organization, there is no one who is in charge of driving sales and distribution of the company. There is a big difference between the procurement operations and sales distribution operations.

Distribution operations involve the company having ways of supplying its products to those who are in need of it within the soonest time possible (Taylor 1911).

Without proper distribution mechanism, the company may not be in a position to holly tap its market, and this is one of the challenges, which C20 is facing. It is unable wholly to meet the demand of its market.

The procurement, on the other hand, involves purchases made by the company. The purchases include the raw materials used by the company and make the firm negotiate contracts to ensure that moulds for C20’s customers made properly. Procurement is, therefore, necessary in ensuring that the company buys low and sells high.

The company, however, has some head start in the fact that it is selling products that do not have so many manufacturers to give it a competitive edge. However, this should not make C20 behave as if it has gained a monopoly; rather it should use that situation to improve multimedia communication, in order to develop a closer relationship with its prospects so that it can have more customers who would want customized services.

Customized services mean that the customer gets products, which suit a particular need, but the need may not meet the other customers’ one. Most of the customers have a tendency to want specialized services, so anyone who offers them such services will certainly have an edge over any competition (Kanigel 1999).

Another aspect that C20 should focus on is its operations concerning having a shipping facility, which will help them, deal with orders which are from other countries. For instance, if they had orders from Iran, with a proper marketing, such orders may come from all over the world. To enhance this, there should be someone, probably a part time employee to handle overseas orders. This will include the shipment and cargo forwarding and any documentation required for such transactions (Housel 1984).

Summary

Having counterchecked the performance of C20 against the theory of bottleneck in operations management, one can confidently conclude that C20 is a company which future is bright if it is going to align its operations with the growing needs of the market. These needs certainly have an effect on the overall production. The company requires focusing not only on the production but also on the distribution.

A great company must, therefore enhance its operations by constantly reviewing and analyzing its activities as well as machinery and labour; in order to ensure well handling of bottleneck issues before they affect all other operations. This is a company with a future if through the placement of correct mechanisms to optimize its performance (Goldratt 2004).

References

Davis, T & Pine, T 1993, Mass customization, Harvard Business School Press, Washington.

Frieda, I & Pierre, J 1984, the second industrial divide: Prospects for prosperity, Basic Books, London.

Goldratt, E 2004, The goal, a process of ongoing improvement, North River Press, New York.

Housel, R 1984, From the American system to mass production, 1800–1932: The development of manufacturing technology in the United States, Johns Hopkins University Press, Massachusetts.

Kanigel, K 1999, One best way: Frederick Winslow Taylor and the enigma of efficiency, Viking, London.

Kidd, D 1994, Agile manufacturing: Forging new frontiers, Addison-Wesley, Virginia

Stevenson, W 2008, Operations management, McGraw Hill, Chicago.

Taylor, B 1911, The principles of scientific management, Dover Publications, New York.

Thompson, I 1967, Organizations in action, McGraw-Hill, Chicago.

Womack, P 1990, The machine that changed the world: The story of lean production, Harper Perennial, Cambridge.