Introduction

The aim of the paper is to understand supply chain management (SCM) and operations management (OM) as strategies to gain sustainable competitive advantage. A brief review of the two is conducted ton SCM and OM literature.

Then, two case studies –

- supply chain strategy of Wal-Mart and

- operations strategy of Toyota are presented in the paper.

The last part presents a theoretical understanding, with examples, and shows how supply chain and operations strategies can become competitive advantage for companies. The paper also presents the difference between SCM and OM.

Literature Review

Supply Chain Management

Supply chain management is the sequence in which different stages of a process, to fulfill customer need of a product, is satisfied. Metzner, DeWitt, Keebler, Min, Nix, Smith and Zacharia defined supply chain as “a set of three or more entities (organizations or individuals) directly involved in the upstream and downstream flows of products, services, finances, and/or information from a source to a customer.”

The supply chain process is divided into five stages: supplier, manufacturer, distributor, retailer, and customer. In essence, the process of placing an order by the customer and the various stages that occur to deliver that product is exhibited in the supply chain.

This helps in streamlining the process of supply of the product from manufacturing to the customer and enhances distribution performance. Chopra and Meindl showed two basic types of supply chain based on the way processes are formed – cycle view and push/pull view.

The cycle view of the supply chain points out that the five different stages of the supply chain operate in a cyclical manner.

The push/pull view the supply chain with the pull process execution of the supply chain is initiated with the customer order while in case of the push process it is initiated in anticipation of the customer order .

The main advantage of an integrated system where the supply and the demand side are integrated to form a seamless process helps in monitoring and planning the operational process.

This is mutually beneficial for all the stakeholders as the risks and benefits are mutually shared. It enhances coordination among the supply chain members and increases transparency of the distribution process.

A proper supply chain management helps businesses to gain competitive advantage. Competitive advantages are the needs of the customers, relative to its competitors, that an organization aims to provide through its product and/or service offerings.

Organizations can gain strategic fit between their SCM strategy and competitive strategy by three methods –

- understanding their SCM risks and their customers,

- ascertaining the SCM competencies,

- realizing strategic fit.

Power conducted a literature review to understand the SCM practices from a strategic viewpoint. The study demonstrated that it is important to undertake a holistic view of the participation and interaction of the participants of the supply chain.

Operations Management

Operations management is the process of designing and planning the products, processes, and supply chain. It entails undertaking proper planning to acquire, design, and plan resources to carry out a function.

Operations management (OM) is “a set of activities that create value in form goods and services by transforming inputs into outputs” . Leseure pointed out that operations management is essential for the performance of an organization.

Traditionally, the internal performance of an organization’s operations ahs been designed under cost, quality, delivery, speed, and flexibility. The literature on OM is replete with the debate over the importance of operations as a strategy to gain sustainable competitive advantage for a firm.

Bettley, Mayle and Tantoush points out that many researchers (like Michael Porter) have pointed out that an operations strategy is not enough to attain sustainable competitive advantage as operations can be emulated.

Researchers and practitioners have put stress on resource-based approach and they believe only a few “good” companies can sustain competitive advantage using operations strategy . Hayes and Upton emphasizes that the role of operations is much larger than just formulation of strategy.

Further, it helps the companies to position their product. The main question asked by customers while purchasing a product is ‘why should I buy it’.

Operations strategy helps the companies formulate a position for the product based on which the company streamlines the whole of its functioning. Thus, a positioning strategy helps the company identify how it would like to be differentiated in its chosen market from its competitors.

Therefore, by positioning the product better than the competitors and in accordance to the needs of the consumers a company can gain competitive advantage in a market.

Another method of gaining competitive advantage for a company is by executing the existing strategies better than their competitors implement.

For instance, shifting the place of production to a low-cost location may be a good decision in the short-run but to make it a sustainable advantage companies have to be very efficient to continue the strategy sustainable for long-term.

For instance, as a retaliation to Wal-Mart’s strategy to computerize its product procurement and inventory control system, Kmart failed to realize that sampling emulating the act will solve its problems. Soon Kmart realized that their employees were not trained to operate the systems.

Difference between SCM and OM

Often SCM and OM are confused and used interchangeably.

However, both are completely different. SCM is the process of sharing resource information and planning logistic right from the point of procurement of raw material, to manufacturing, and then distributing it, until the product reaches the consumers.

On the other hand, OM is the process of planning and managing the resources required for the production and delivery of the product to the consumers.

In a way, SCM is a subset of OM for the latter is concerned with the production process apart from the delivery and distribution. More importantly, the difference between the two can be further delineated as follows:

- SCM aims to reduce inefficiencies in the complete chain of processes from supply of raw material to delivery to the customer. On the other hand, OM has a broader range of activities in monitoring and planning the wider set of operations regarding the manufacturing of the product.

- SCM deals with monitoring the raw material required for the production and ensuring that the right material is being delivered for production. OM deal with all that is necessary for the actual production process.

- SCM is based on activities irrespective of the nature of the business while OM is concerned with the business the operations are being conducted.

- More broadly, SCM is mostly concerned with the activities that occur outside the organization’s premises such as shipping, warehouses, distribution, while OM is concerned with the activities occurring inside the premises.

Though both are different, both are essential in maintaining a sustainable business strategy. Overall, it can be pointed out that SCM is a part of the OM. SCM looks into the operational logistics while OM looks into the overall picture of the manufacturing of the product.

Cases

Supply Chain Strategy of Wal-Mart

Wal-Mart has used supply chain strategy to gain competitive advantage for long time.

The following case study of Wal-Mart’s supply chain will demonstrate that a successful supply chain can reduce cost of product considerably and enable companies to provide product at highly competitive pricing. Wal-Mart is the world’s largest retailer with highest sales per square foot.

Wal-Mart’s success from a regional discount retailer to an international discount retailer has been mostly due to their efficient supply chain management.

Wal-Mart has assumed a successful leadership position in the global retail market mostly due to efficient management of its supply chain.

The supply chain strategy of Wal-Mart is based on four factors: vendor management, distribution channel management, technology, and integration all the processes.

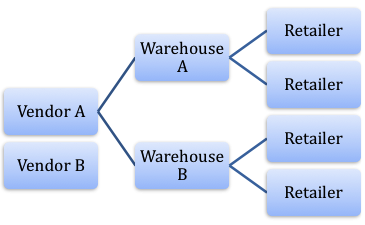

Wal-Mart’s strategy has been to procure their products at lowest possible cost. Figure 1 below shows the supply chain strategy of Wal-Mart. Wal-Mart sources its products from different vendors worldwide and procures the products at cheapest possible cost.

This helps them to sell their products at the lowest possible prices. These products are then sent to the different warehouses at different places, and since then all the products are sent to the retail outlets according to the demand of each retail store.

Wal-Mart follows a push, supply chain strategy wherein the products are first sourced based on an anticipated demand from the customers. In case of Wal-Mart the main issue is sources the large quantity demand and at different places. Further,

Procurement

The first section to consider in Wal-Mart’s supply chain is their suppliers or vendors. For instance, Wal-Mart had problems with P&G as a supplier initially; for the latter’s organizational processes were too complex for Wal-Mart’s efficiency oriented culture.

In order to overcome this problem, Wal-Mart invited its partners to jointly develop vendor management, inventory management, and category management . Wal-Mart bypasses intermediaries to directly procure the products from the manufacturers to minimize cost.

Recently Wal-Mart has also invested heavily in making its supply chain environmentally compatible by choosing more environmentally conscious vendors and supply chain partners .

Distribution

Wal-Mart has its warehouses and distribution centers at different locations of the US and other countries where it operates.

The warehouses have a large inventory of the goods sold in the Wal-Mart outlets and each retail store is replenished with the stock of goods with efficient product demand forecasting system.

The company uses advanced technology such as RFID, hand held computer systems, and bar code, which makes keeping large inventory in the warehouses economical . In 2007, 80 percent of the products of Wal-Mart were distributed through 121 company owned distribution centers.

Only the suppliers for electronic and prescription drug products supplied directly to the stores.

The inventory management system used by all employees accessible through their hand held computers allowed them to access a particular product exactly to its location on a particular shelf increased efficiency considerably.

Logistics

A company owned logistics systems with over 3500 trucks and 75000 employees in the logistics department, who helped the company to replenish its stores twice daily.

Further to reduce the time of logistics and make its supply chain more efficient Wal-Mart uses a technique called “Cross Docking” that allows the company to procure the product directly from the manufacturer and directly delivering it to the customer, almost eliminating the time and cost involved for distribution from warehouses.

Inventory Management

Due to large number of stores and huge scale of operation, Wal-Mart ensures that it uses proper inventory management system to ensure continuous flow of products.Further, it also has to regulate the inventory cost.

For this, since 1980s, Wal-Mart has used satellite communication systems that allowed the company managers to closely monitor the operations within each store and analyze the amount of product that has to be replenished at the end of daily operations.

Further, the company takes precautionary measure to reduce unproductive inventory by use of advanced technology such as RFID and bar code. It also allows the stores to manage the stock allowing small packages and well-timed price mark down.

Operation Strategy of Toyota

The operations management system developed in Japanese, especially that in Toyota has been named as the Toyota Production System (TPS). The lean management system developed by the Japanese manufacturer demonstrates the current state of operations management.

The main point that one must understand before undertaking a study of the TPS is that the company did not consciously adopt it, instead it grew naturally through its operations over five decades.

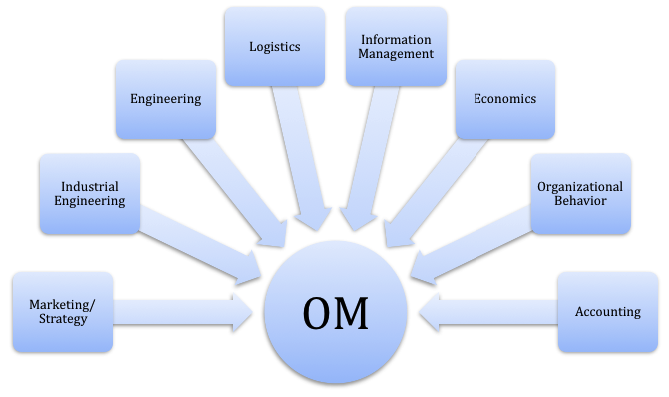

The operation strategy of Toyota is based on a strong interaction of the operations management as the core strategy and other disciplinary interfaces . TPS can be descried through four rules according to Spear and Bowen (1999) –

- All work conducted by the company must be defined in terms of “content, sequence, timing, and outcome” .

- All customer-supplier relation must be direct and consent to accept or reject the order must be defined in a simple yes-no process.

- The way a product is produced and delivered must be simple and direct.

- Employees at the lowest level of the organizational hierarchy make all improvements in the products.

These four rules greatly simplify the operational process and make it extremely flexible. The TPS method ahs been summarized in five steps –

- long term vision,

- continuous improvement (Kaizen),

- going back to the source to find out the facts (Genchi Genbutsu),

- teamwork,

- respect.

TPS is based on two key concepts that Toyota follows – just-in-time (JIT) and stoppage of production in case defects are identified (Jidoka).

JIT emphasizes on the continuity of production with maximum supply of inventory and raw material for continuous, uninterrupted flow of production. Further, the TPS system also aims at elimination of any excess waste such as overproduction or inventory.

Toyota aims for change in the operational strategy and a flexible strategy over a longer period rather than short run cost effectiveness. The total quality management (TQM) strategy employed at Toyota enables it to integrate its manufacturing operations with other disciplines (see figure 2).

The Toyota production line is designed specifically to ensure that once implemented, the plan does not change until the process is specifically redesigned. Therefore, in case of installation of a seat in a car, if plastic bolts are required for fixing the seat, the employee orders it from the specific handler.

The supplier makes request for the bolts with his own suppliers and sends to the designated person.

According to the Toyota operations strategy, the bolts will not be delivered to the next available person or machine but to that specific person, and if he is not available, there exists some problem with the production line and it is redesigned .

The operation strategy in Toyota is not based on one specific aspect but encumbers all the management disciplines to make it a complete process. Thus, Spear points out that it is impossible to understand how TPS works until one immerses oneself in the practical process of the operations .

Sustainable Competitive Advantage

The competitive strategy of a company defines how a company aims to satisfy its customer needs through its products and services . Competitive advantage, therefore, is a means of building competencies in a particular business. Building barriers to prevent imitation of the strategy can help companies achieve sustainable competitive advantage.

Research shows that companies who stress on supply chain strategy as a primary strategy have a high level of sustainable competitive advantage and organizational performance .

The companies that use SCM as their core competency usually operate based on the following aspects: supply chain integration, information sharing, cross-functional communication, and supplier involvement.

Efficient supply chain management is based on demand forecasting, strategic planning, and apposite inventory supervision . For instance, consider the case of the adoption of RFID in supply chain of Wal-Mart. Emulating Wal-Mart, Kmart too adopted RFID for managing its supply chain.

However, the new technology created complexities for Kmart, as the people using the technology were not adept to use it.

Further, Wal-Mart’s supply chain strategy has given the company many other sustainable competitive advantages such as low cost procurement, optimal inventory, and better in-house brands.

The methods that a company must employ to make their supply chain strategy competitive are –

- A company must remember to collaborate with their supply chain partners rather than competing with them. The success of each stakeholder of the supply chain will have a positive impact on the supply chain’s success.

- A company must integrate all the process together and preventing compartmentalization of functions. In case of certain companies, employees loose focus and start identifying themselves with the function rather than with their company. Therefore, integration of the culture of togetherness is important to gain competitive advantage.

- A company has to keep the supply chain as simple as possible to gain competitive advantage out of it. For instance, incorporation of ERP to the supply chain may be helpful to simplify the processes, however, one may be enamored by the technology and add up non-essential tasks to the supply chain making it complex.

- When a problem occurs it is important to look into the issue rather than treating the symptom leading to the problem.

- A company must create constant vigilance to track cost drivers in the existing supply chain.

Organizations can achieve sustainable competitive advantage through adopting proper operations strategy. We exemplify the case of Toyota to understand the issue.

Toyota’s operation management is unique and it is difficult to understand, as it is believed, because it was not imposed on the company but evolved through decades of operation. Emulation of such a strategy is difficult for it does not work on a set formula.

Therefore, in order to achieve sustained competitive advantage out of operational strategy a company must allow it to develop through its organizational culture and integrate it within its system rather than imposing it from outside.

Lean and Agile

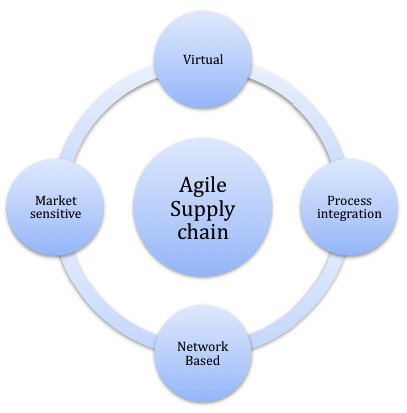

The main criterion of an agile supply chain is the emphasis on time as a competitive advantage. In terms of competitive advantage, it is important for a company to choose between agility and lean (see figure 3).

Figure 3: Agile and Lean supply chain.

Agile supply chain is one which has the four characteristics described in figure 4. An agile supply chain must be market sensitive, implying it can understand the changes in market demand. Such supply chains rely on demand forecast, rather than actual demand .

Use of information technology helps the company to create a virtual supply chain that reduces inventory and increases use of information.

Process integration is essential, as it enhances coordination between buyers and sellers. Further, all the partners of the supply chain are closely linked within the network.

A lean supply chain is one that emphasizes on doing more with less . It is often used to show lean manufacturing, which incorporates just in time approach to manufacturing. One such example is the manufacturing process of Toyota.

Conclusion

SCM and OM strategy have assumed great importance for businesses today. However, the adoption of either or both the strategies is business specific.

For instance, in case of an organization like Wal-Mart an agile supply chain strategy is more conducive as it provides it the agility and flexibility to adapt to the ever-changing demand of the market.

On the other hand, for a manufacturing based company like Toyota with few product offerings but large investment requirement a lean production system is more appropriate.

Either of these strategies can be turned into sustainable competitive advantages by building barrier against competitors emulating the strategy.

References

Bettley, A, Mayle, D & Tantoush, T 2005, ‘Introduction to Theme 1: Operations as a Strategy’, in Operations Management: a Strategic Approach, Sage, Thousand Oaks, CA.

Byrnes, J 2003, Supply Chain management in a Wal-Mart World. Web.

Chopra, S & Meindl, P 2007, Supply chain management: strategy, planning, and operations, 3rd edn, Pearson Education, Upper Saddle River, NJ.

Christopher, M 2000, ‘The Agile Supply Chain : Competing in Volatile Markets ‘, Industrial Marketing Management, vol 29, no. 1, pp. 37-44.

Hayes, RH & Upton, DM 2005, ‘Operations-based Strategy’, in Operations Management: a Strategic Approach, Sage, Thousand Oaks, CA.

Heizer, J, Render, B & Rajshekhar, J 2009, Operations Management, Pearson Education, New York.

Leseure, M 2010, Key Concepts in Operations Management, Sage, Thousand Oaks, California.

Li, S, Ragu-Nathan, B, Ragu-Nathan, TS & Rao, SS 2006, ‘The impact of supply chainmanagement practices on competitive advantage and organizational performance ‘, Omega – International Journal of Management Science, vol 34, pp. 107–124.

Mentzer, JT, DeWitt, W, Keebler, JS, Min, S, Nix, NW, Smith, CD & Zacharia, ZG 2001, ‘Defining Supply Chain Management’, JOurnal of Business Logistics, vol 22, no. 2, pp. 1-25.

Plambeck, E & Denend, L 2011, ‘The Greening of Wal-Mart’s Supply Chain‘, Supply Chain Management Review, vol September/October, pp. 16-23. Web.

Power, D 2005, ‘Supply chain management implementation and integration: a literature review’, Supply Chain Management: an International Journal, vol 10, no. 4, pp. 252-263.

Spear, SJ 2004, ‘Learning to lead at Toyota’, Harvard Business Review , vol 82, no. 5, pp. 78-91.

Spear, S & Bowen, HK 1999, ‘Decoding the DNA of the Toyota production system’, Harvard Business Review , vol 77, pp. 96-108.

Toyota 2012, Toyota Global Vision and Strategy. Web.

Voss, CA 1995, ‘Operations management – from Taylor to Toyota – and Beyond? ‘, British Journal of Management, vol 6, no. Special, pp. 17-29.