Introduction

Pipeline installations have relied on a number of strategies depending on the location. This article provides a brief description of some of the methods used in pipeline installations. The article reviews the following pipeline installations:

- Pig traps

- Block valves

- Offtakes

- Compressor stations

The designs of these pipelines are not standard. Instead, they depend on the location, function of the pipeline relative to fluid for transportation, temperature, and operating pressure. Pipelines have several points of installations to ensure maximum efficiency during transportation of fluids.

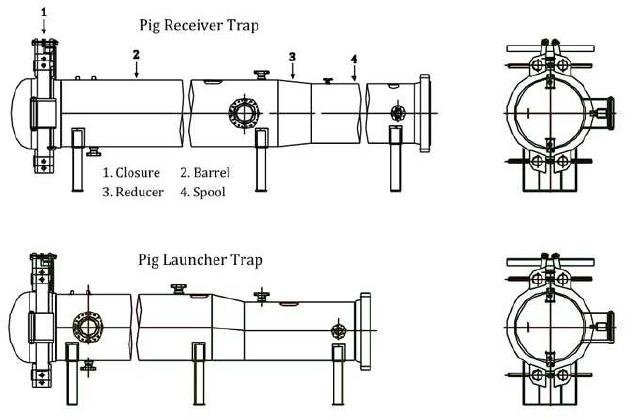

Pig Traps

Pipeline pigging is a method of inspecting and cleaning inner parts of the pipeline using a gadget known as pig. Pig traps are installations used for “inserting or launching pigs into the pipeline and taking them out or receiving them after a successful run without interrupting the process of fluid flow in the pipeline” (Mohitpour, Szabo and Hardeveld, 2005).

A pig trap is like an air lock. The valve separates pig traps from the pipeline. This provides opportunities to depressurise the pipeline in order to insert the pig. Pigs vary in terms of materials and their composition. For instance, there are magnetic flux and air-filled plastic pigs suitable as tools for inspection of leakages.

People who use pig traps load and close the trap in order to pressurise the pipeline. However, the main valve trap remains open so that the pressure can direct the fluid when the pig is behind in order to force it into the pipeline.

Pigging also has a receiving end where the reverse process takes place. It is imperative to ensure that the pigging system is safe and can withstand extreme temperatures, pressure, and inspection of a pipeline can take place safely.

Apart from inspection and cleaning, pig traps are also suitable for separating fluids under transportation and providing information about the pipeline position and size.

Pigging enhance lifetime of pipelines. Inspection and cleaning ensure that debris, wax, and other materials, which cause blockages, do not hinder the transportation of fluids. This enhances efficiency of the pipeline and provides a continuous flow of fluids.

Design

Christian Cloyde notes that design considerations of pig traps “should extend beyond the limits of the pig trap to the boundaries of the pigging station” (Cloyde, 2011). The design must go with the part of the pipeline measurements. Pig traps with mechanical design must match or exceed the design pressure.

In addition, it must also have similar design features, compatible type of materials, apply similar design codes, and conform to temperature requirements just like the section of the pipeline it serves.

Dimensionally, a pig trap must relate to the type of pigging in a section of the pipeline it shall serve. This must take into account the line size of the pipeline and the length of the barrel.

The design must be able to resist pressure as it allows inserting and receiving of pigs. Pigs are heavy. Thus, it is necessary to consider internal pressure for safety of the system and workers.

Pig Trap Design Code

Designers usually use international standards and measurements like ASME. The standard codes include “B31.4, B31.3, B31.8, PD5500, EN13445, and AS2885” (Mohitpour, Szabo and Hardeveld, 2005). These pig traps fit at the end of the pipeline just like extensions. Thus, trap designs can also fit vessel codes.

However, this may create mechanical problems where vessels have thick diameters. This implies that the design must conform to the pipeline and trap ends and must be the same as codes for both ends. In all these strategies, designs must ensure that loading and receiving process remain safe to the user and the pipeline.

Design Pressure

The design pressure must serve as a basis for determining the thickness of the wall of pipeline and pig traps. It is extremely dangerous to use design pressure, which is below the pressure of the pipeline. It is imperative to consider standard design pressure from ASME and ANSI that provide pressure and temperature guidelines.

The designers must subject such materials to hydrostatic pressure tests of 1.25 times more than the design pressure to ensure their safety. However, the code has a significant influence on the design pressure of pig traps. The designer must also ensure extra precaution due to the nature of fluids for transportation along these pipelines.

Temperature

The design must be able to withstand maximum temperature of the fluid. In addition, the design must also take into account both minimum and maximum temperature of the pipeline section and the area.

Materials

The choices of materials depend on the client’s preferences. However, these materials must conform to safety standards set by regulating authorities. Further, such choices must also conform to materials of pipelines and meet the design requirements of the pipeline.

Therefore, designers can only use cost effective and safe materials for installations. At the same time, such products must also be able to withstand reactions from the fluid under transportation. In this light, the designer must consider both metallic and elastomeric materials for the installation.

Selection of materials must also consider other properties relating to chemical, mechanical characteristics, and weld capabilities.

External loading activities require nozzles for attaching the pipe. Thus, the design must also take into consideration effects of external pressure resulting from such activities with regard to the location of the pipeline such as sub-sea.

There are sections of the pipeline that may require frequent pigging activities. Under such cases, the designers must also account for fatigue on the pipeline. They must also consider other factors related to load of the fluid, seismic load, and friction.

Designers must also consider other factor related to the location of the pipeline section, ease of accessibility, and environmental conditions. For instance, the designer must consider risks inherent for sub-sea pipelines and offer additional protection for valves.

Pig traps need adequate space. They must also never be near open flames or sources of ignition. In this case, rules of companies regarding the type of powered gadget allowed near the installation must apply. Designers must ensure maximum care in offshore areas where horizontal space may not be adequate.

In such a case, there should be adequate workspace close to the closure door to allow for pigging activities. Such activities involve “loading and unloading long inspections pigs, removal of liquids and debris from the pipeline and into a waste container, installation, and operation of a temporary separator among others” (Cloyde, 2011).

The layout design must ensure that valves are accessible through different means. In this case, the operator does not need to gain access to closure door in order to perform any activity on the valve.

Designers must also consider safe and efficient operation of the pig trap by taking into account “the orientation of the barrel at the pigging station” (Cloyde, 2011). Therefore, all systems must have adequate space for routine operation and maintenance activities.

The closure door must never face other equipment or place where people may meet. This is necessary to avoid accidents in which pigs can shoot out and cause damages to equipment and people. Designers must pay special attention to the barrel or the oversized section of the pipeline.

The designers must also install dip trays in order to avoid cases of contamination resulting from servicing activities.

Offshore systems must have facilities for loading and offloading heavy materials. Such tools are necessary to locate large pigs into their positions during installations.

Operation

The energy industry is also conscious of the environment. Therefore, activities involved in the pig trap must not cause harm to the environment. Operators must take care to minimise effects of fluids in the atmosphere or water (Goodland, 2005).

Operation of the pig trap involves launching, sending, and receiving pigs.

Maintenance

Pig traps require regular maintenance to ensure efficiency and proper function of traps. Maintenance of the pig trap involves piggability assessments and trap assessments (Cordell, 2003).

Figure 1: Pig trap

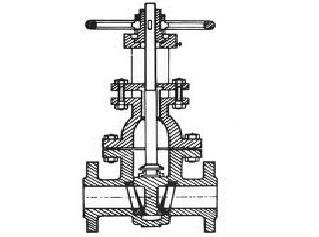

Block valves

Block valves stop the flow of the fluid in one or more directions. Other people consider block valves as tools, which can allow or prevent the flow of fluid without restriction. This may not require a single way valve. In fact, designers prefer gate valves for such purposes.

Operators can fully open or close the valve. In this case, block valves are “useful for separating a section of the pipeline for maintenance” (Daniel Emerson, 2011).

Design

Gate valves are easy to use because they do not need a lot of force to surmount the pressure and friction from the pipeline. This is because their design systems allow the blocking end to move in a crosswise manner against the fluid.

Gate valves also have small sections in the sealing parts. These rings are dependable and prevent any possible leakages. Gate valves are popular because of the following reasons:

- Hydraulic resistance is negligible

- Do not allow reverse flows the fluid

- Suitable for viscous fluids

Designers also take into account factors like effects of pressure, chemicals, temperature, and pressure of the fluid on the valve. They also consider material components of the valves together with driving features. The followings are also important when selecting gate valves:

- Ability to resist the weather

- Ability to prevent any leakage

- Ability to resist extreme forces that may cause bending

- Ability to meet seismic requirements

Operation

The block valve can control flow of fluid in either direction. Designers provide three various methods of controlling block valves. These methods include local, remote, and automatic. However, it is the extent of the leak and volumes of release, which determine the method of controlling gate valves.

Layout

Designers must put block values at pipeline sections where they can provide optimal control of spills and maintenance. Spacing considerations between block valves are also important for onshore pipelines. The aim should be to control flows between adjacent valves. Categories of block valves include.

- Manual gate values, which are in the check valve sections and locally operated. They ensure positive isolation of the fluid.

- Remote gate valves are useful in oil and gas pipelines for protection during accidental failures or damages on the pipeline.

- Station block valves are usually near the pump station to separate fluids from the pump stations during for emergency cases. They are in both the inlet (fluid suction) and outside (fluid discharge) of the pipeline.

Maintenance

Block valves require constant and scheduled maintenance. Block valves need synthetic lubricants and sealant systems. Generally, new valves require constant monitoring than other valves, which have been in operation for over a year.

The maintenance requires constant lubrication in order to lessen the break out torque when in use. Lubrication must spread to the valves gate slabs and seats. Regular adjustments are necessary to ensure that valves have the correct seat seal (Tiratsoo, 2007).

Figure 2: Block valve

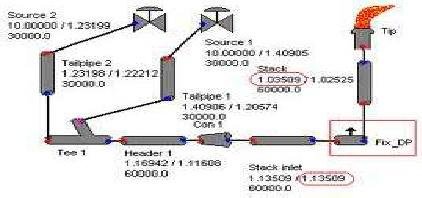

Offtakes

Offtakes are within the distribution and transmission systems. It has a number of gadgets for filtering and managing pressure. At the same time, it performs measurement and ‘odourisation’ of the fluid in order to allow for remote operation of the flow of the fluid.

Within the pipeline, an offtake can be a vessel or pipeline transferring fluid from one section to another or to a larger pipeline.

Design

The designers must ensure that offtakes do not lower the pressure of the pipeline channels. Therefore, designers must consider both internal and external measurements, materials used and the length of the pipeline.

We can only determine efficiency and flow of the fluid by using internal measurements, length, pressure at the ends, fluid characteristics, temperature, and elevation of the pipe from the ground. For safety reasons, the gas from the pipeline system at offtakes must have the minimum pressure.

Designers of offtakes must consider some factors that include:

- Maximum pressure

- Maximum temperature

- Diameter of the header

- Fluid for transportation

- Both hot and cold tie-in

- Available offtake equipment

Offtakes Layout and Operation

The designers must ensure that offtakes have compression stations comprising of enough branches with the mainline. Offtakes require real-time monitoring and performance of analysis using computer systems with high capacities.

Companies normally use SCADA (supervisory control and data acquisition) to monitor and plan their offtake systems (Tobin, 2007).

The designers must ensure that the gas maintains its pressure as it travels throughout the system. In most cases, the pressure of the gas may drop and reduce the pressure. Thus, designers must ensure that the pressure in never low to prevent the flow.

This is why there are compression stations along the pipeline to ensure that the gas pressure does not drop to unacceptable levels (Busby, 1999).

Maintenance

The aim of maintaining offtakes is to prevent the gas pressure from falling to low levels, which are risky. Thus, operators must ensure that they clear any debris restricting the flow of fluids.

Figure 3: Offtakes

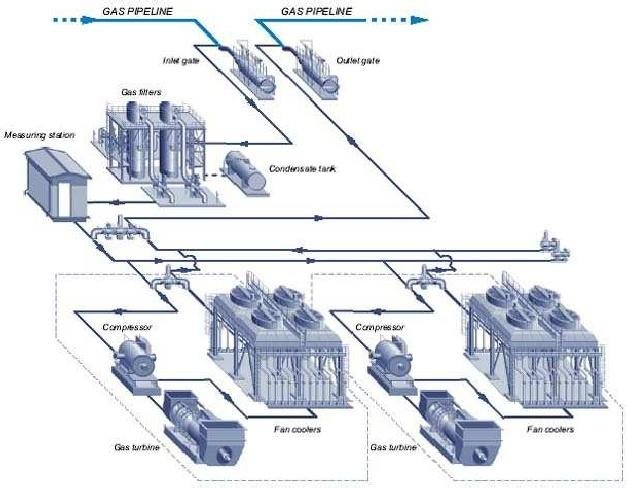

Compressor Stations

The aim of a compressor station along the pipeline is to enhance pressure of the fluid. It uses gas turbines to build pressure for transporting the fluid to the next compressor station. Thus, it increases transmission capacity of the pipeline.

Compressor stations provide the necessary force for the gas to overcome friction so that the fluid can maintain the rate of flow and pressure.

Compressor Station Design and Layout

Designers must consider several factors for compressor stations.

Selection

Selection of materials must consider standard specifications for safety, performance, and life of the system.

Control Systems

The compressor station has four levels of control systems.

- Supervisory

- Station

- Driver and driven components

- Auxiliary control systems

Safety of the Compressor Station

Operators must consider safety concerns related to fire detection equipment, gas leakages, and safety of the relief valves.

Layout

The layout of the compressor station consists of the following.

- Scrubbers that stop fluid from entering the compressor

- Blow down valves and relief systems

- By-pass lines

- Cooler to control temperature of the gas and discharge temperatures

The designers also consider the following factors for the entire compressor station.

- The size of the compressor and its drivers and driving components

- Climatic conditions of the area in which the pipeline section lies

- Accessibility of support services

- Accountability for regulatory requirements involving safety and environmental concerns

- Human occupancy

Designers may build the station using different techniques involving series, parallel, or a combination of these approaches ( Mokhatab, Santos and Cleveland, 2007).

Operation

Compressor stations rely on automatic processes for their operation. Consequently, there are only minimal human interventions. In this case, facility operators must ensure maximum adherence to manufactures’ safety and operational requirements. However, operation activities of the station must consider load of the fluid (Kurz, Lubomirsky and Klaus, 2012).

Operators must engage in continuous monitoring of the station, regulate the mixing activities at the compressor, and ensure efficiency of the system. They must also keep data in every station.

The control systems also have capabilities of remote control of shut-off valves. However, the sensitive areas require ESD controller (emergency shutdown). This is useful for controlling valves and enabling timely reactions to cases of fire or gas detection.

Operators must also note that the main control systems may experience outage due to maintenance or failure. Thus, the system must be under constant surveillance.

Compressor station has three types of shutdown.

- Unit shutdown restartable (USR) reacts in cases where there are low suction or high temperature, pressure, speed, and high pressure of discharge.

- Unit shutdown lockout (USL) shows that the station has a mechanical problem from failure of the lube components, high vibration, and temperature.

- Emergency shutdown is applicable in cases where stations compromise safety of the people. This may result from fire or gas detection. Customer emergency shutdown (ESD) results from failure of the seal components and value failures.

Maintenance

Compressor stations must have a regular monitoring and major changes to their components. Maintenance ensures that the station is safe, works well, and achieves long life. Maintenance of the station must focus on the following areas.

- General cleanliness of the structure and ground of the station

- Monitoring of valves and piping of the station

- Monitoring gas cooler sensors to ensure efficiency

- Ensuring safety of equipment such as fire extinguishers, fire and gas detection systems, first aid materials, and other protective gears

- Ensuring regular maintenance of tanks because of their components of solid sludge

- There should also be regular maintenance of the compressor engine to avoid failure of its blades

Figure 4: Compressor station

Conclusion

Pipeline installation must ensure maximum safety of the people and the environment. This depends on the recommend materials, sizes, maintenance routines, and control of failures detected.

At the same time, the design consideration of pipeline installation also ensures that the pipeline operates smoothly and remains safe to users and nearby facilities and people.

Reference List

Busby, L. (1999). Natural Gas in Non Technical Language. Pennwell: Institute of Gas Technology.

Cloyde, C 2011, ‘Pig Trap Design and Assessment Considerations’, Pipeline and Gas Journal, vol. 238 no. 1, pp. 1-6.

Cordell, J 2003, Pipeline Pigging Handbook, Clarion Technical Publishers, Houston, TX.

Daniel Emerson 2011, Product Datasheet 2011, https://www.emerson.com/documents/automation/user-manual-models-762-763-765-766-gas-loaded-relief-back-pressure-valves-2-to-16-inch-en-55700.pdf

Goodland, R 2005, Oil and Gas Pipelines Social and Environmental Impact Assessment, International Association of Impact Assessment, Fargo, ND.

Kurz, R, Lubomirsky, M and Brun, K 2012, ‘Gas Compressor Station Economic Optimization’, nternational Journal of Rotating Machinery, vol. 2012, pp. 1-9.

Mohitpour, M, Szabo, J and Hardeveld, T 2005, Pipeline operation & maintenance: a practical approach, ASME Press, New York.

Mokhatab, S, Santos, S and Cleveland, T 2007, ‘Compressor station design criteria’, Pipeline & Gas Journal, vol. 7, no. 1, pp. 1-15.

Tiratsoo, J 2007, Pipeline integrity. The Journal of Pipeline Engineering, vol. 6 no. 4, pp. 1-84.

Tobin, J 2007 Natural Gas Compressor Stations on the Interstate Pipeline Network: Developments Since 1996, Energy Information Administration: Office of Oil and Gas, Washington, DC.