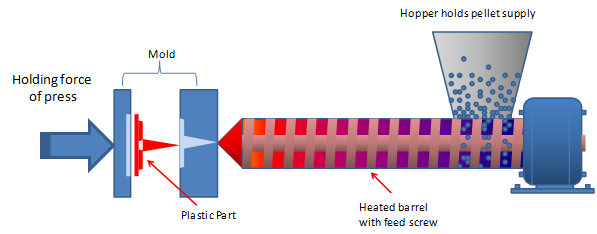

In the context of the explored topic, the technological process of plastic productions should be discussed to enhance the explanation of how human activities influence the environment. The way in which plastic products such as packaging are designed plays a massive role in the way the industry impacts the environment. Most plastic products are made through injection molding, which is completed through several procedures. First, plastic pellets are fed into the equipment to facilitate the heating and liquefication of the material. Second, when the desired shape is achieved, the plastic is cooled and sealed to prevent leakages (see Figure 1). Except for silicones, the majority of plastics have a base of the carbon atom, which is used for linking to other atoms to form chemical bonds (American Chemistry Council, 2018). The transformation of raw material starts from the process called cracking, in which hydrocarbon chemicals are separated from natural gas or petroleum (American Chemistry Council, 2018). During the cracking, raw materials are transformed into monomers that react to forming polymers and subsequently become plastic.

Despite the fact that plastic and its production continue to benefit societies in a variety of ways (including medicine and public health), not all of them are sustainable and can result in efficient recycling. Moreover, plastic can contain harmful components such as endocrine-disrupting bisphenol-A (BPA) or phthalates (DEHP), which have a negative effect on health (Posnack, 2014). BPA has gained a reputation as the most recognized material that causes health problems; as stated by the U.S. Food and Drug Administration, “recent studies provide a reason for some concern about the potential effects of BPA” (as cited in North & Halden, 2013, p. 3). While the lifespan of plastic is extremely long (450 for plastic bottles or over 5,000 years for extruded polystyrene foam), industries such as healthcare as well as general consumers dispose of plastic very quickly since the majority of it is used for packaging, which means that the time between its production and disposal is far less than the time necessary for its disintegration.

Innovation and Alternatives

While there is a variety of alternatives to plastic to facilitate sustainability, it is important to mention that such industries as a healthcare need plastic products to use for packaging due to the material’s durability and cost-effectiveness. Therefore, the key point to consider refers to innovation in the sphere of plastic recycling. As mentioned by O’Connor (2017) from The Guardian, only 14% of plastic products are recycled, which points to the need for tech innovation to solve the problem of not recycling the rest of 86%. It is important to note that recycling plastic can generate from $80 to $120 billion in revenues; however, such high numbers are impossible to achieve without innovation (O’Connor, 2017). Some alternative solutions for addressing the challenge of plastic pollution include plant-based plastic that breaks down without contaminating the environment; although, such alternatives have only attracted smaller companies rather than large corporations, which is a part of the issue.

Innovation in the sphere of plastic recycling has facilitated a range of discoveries. For instance, scientists at the University of Illinois developed a way of transforming used plastic bags into diesel fuel, an Indian entrepreneur mixed landfill plastic to develop asphalt, a graduate from the Polytechnic University in Albany discovered how to use plastic bags to form concrete bricks, and researchers at the University of Adelaide turned plastic into carbon nanotube membranes (Johnson, 2018). These developments point to the massive potential of plastic recycling to reduce the environmental impact and improve societies’ health.

References

American Chemistry Council. (2018). How plastics are made. Web.

Johnson, S. (2018). 5 high-tech innovations taking on plastic bag recycling. Web.

North, E., & Halden, R. (2013). Plastics and environmental health: The road ahead. Reviews on Environmental Health, 28(1), 1-8.

Plastic manufacturing process [Image]. (2017). Web.

Posnack, N. (2014). The adverse cardiac effects of Di(2-ethylhexyl) phthalate and bisphenol A. Cardiovascular Toxicology, 14(4), 339-357.