A plastic material is among the extensive collection of artificial or semi-synthetic organic materials that are used in the production of industrial products. Plastic materials are characteristically polymers with high molecular mass. In addition, they may contain additional substances that help them to improve their performance and/or cut down the cost of production.

The most likely plastic used

Polyvinyl Chloride (PVC) is the most likely used type of plastic.

Why this plastic is selected

Polyvinyl Chloride (PVC)

PVC is highly reliable because of its durability, light weight, flexibility and low cost. In addition, it has a high resistance to out-of-doors exposure as well as high mechanical strength PVC is also very good in reducing solar heat gain. Depending on the additives, PVC combines strength with transparency or color (Ronald and Baird, 1986). This addition of white and colored additives improves the weathering resistance of the PVC materials and products as well as their process-ability. These are some examples of the huge demands made on Polyvinyl Chloride.

What are some alternative plastics and why?

Some of the alternative plastics that are in use today are:

- Fiberglass (GRP)

- Polyethylene

- Acrylics

Formaldehyde plastics

Fiberglass (Glass Re-enforced Polyester, GRP)

The characteristics of the refined GRP compound material are dependent on a large number of fabrication and compositional factors (Blaga, 1978). Some of these factors include resin formulation, curing conditions, filler, fabrication process, the amount and type of strengthening, workmanship, and coupling agent (Blaga, 1978). Glass reinforced plastic is a polyester resin reinforced with glass fibers. It can be used as a structural material by the artist. Fiberglass can be molded into various shapes which add strength to the work of art.

This material is durable and light, which makes it suitable for delicate applications in works of art. Fiberglass can easily be reinforced by adding more layers to harden it. Although not strong, this material is cheaper to manufacture (Ronald and Baird, 1986). A Glass Re-enforced Polyester material has found use in applications that require corrosion resistant materials at reasonable costs.

Therefore, Fiber glass materials can be employed as lining materials for conventional pipes that are exposed to chemical or galvanic corrosion (Blaga, 1978). GRP materials are non conductors of electricity and are therefore, induction flows do not have an effect on them. In addition, fiber glass materials have high tensile strength, durability, better strength and low density. Also, the materials have very strong stiffness characteristics. Lastly, as a result of their structure, GRP materials have very long life times.

Acrylics

The most popular acrylic plastics type is Polymethyl methacrylate and it is usually tough and highly transparent. It is also characterized by high resistance to weathering and ultraviolet radiation. Polymethyl methacrylate can also be drilled, formed, colored and molded easily. This quality makes it ideal for many applications in art (Dominick, 1993).

In view of the fact that Acrylics do not form crystalline resins when they are heated, however, they are converted into a shapeless blob that is referred to as an amorphous resin; acrylics have a grand “mold to size” capacity but their resistance to chemical corrosion is poor. In addition, they are fragile and easily broken. This is why they are constantly sprayed with certain types of fiber glass materials so as to stiffen them.

Formaldehyde plastics

This material is highly reactive and pure. It is also relatively cheap. Formaldehyde plastics have good Color retention properties, and offer moderate water and heat resistance. In addition, they offer good chemical resistance and have excellent dimensional stability (Whitfield, Brown, and Low, 2007).

Polyethylene

Polyethylene is highly reliable because of its durability, light weight, flexibility and low cost. Polyethylene is also very good in reducing solar heat gain. Depending on the additives, Polyethylene combines strength with transparency or color. A good number of grades of Polyethylene have outstanding chemical resistance and do not liquefy at room temperature as a result of their crystalline nature.

Different from acrylic materials, Polyethylene materials have better elasticity, and would not break before bending. They are closed cell materials similar to Styrofoam, which do not absorb water and emit any gaseous odors or fumes. In addition, they are tough, electrically insulating, offer poor weathering resistance, have low strength, and have a relatively low friction coefficient (Callister, 2004).

What is the most likely process? Used

There are many processes that make it possible for plastics to be changed into a number of useful shapes. These processes, which are employed in the molding or shaping of thermoplastics fundamentally, make the plastic material softer so that its injection into a mold, or flowing via a die, or forming over or in a mold can be done easily. These processes more often than not permit any scrap materials or parts to be chopped into pieces and reused. The most common process that is used is casting.

Casting

Casting is the process of art which involves making of an art form from a hollow mold by pouring molten plastic into the mold and leaving it to harden. This technique can be done in various ways. Lost-wax method of casting for instance begins with coating of the model surface with lacquer among other proactive substances.

The model is then placed in a retainer mold where pouring of liquid elastic takes place. To reveal the negative impression, the flexible mould is gently removed from the model when it solidifies. Application of meted material is done from the inside of the flexible mold. Core of investment material is then poured following solidification of the material. To reveal the wax positive, the two halves of the outer plastic retainer molds are removed after solidification of the mold (Dominick, 1993).

Steps in creating a sculpture using direct modeling method of casting

The process starts by preparing your framework of art. The plastic material is simply poured into a box where the artist wants the artwork to carve from. For this illustration, a human head will be used. To start with, a picture of a person’s head is sourced. The next stage that follows involves building an armature.

This is the frame where building of the sculpture takes place. This can be build from any rigid material such as a steel of a wire. A small welder can also be used to make a basic steel frame. The frame is the essential outline upon which the sculptor holds the materials. To build an armature, the artist can use nails and tacks to build together pieces of woods. The length of the wood should be slightly shorter than the length of the head that the artist intends to make.

The wires are then nailed on a piece of hardboard. To make a round shape as intended, the wires are blended together. The wires are then attached to a central position on the piece of wood. This consists of the basic structure of the head. Knowledge of the right mixing ratios of the plastic material is required for the subsequent stage. This stage involved mixing of the plastic materials.

Mix the plastic materials properly to form a resilient material the moment it dries up. When the plastic material starts reacting chemically and hardening, the next step which involves inserting the hand gently into the mixing materials is started. The aim of this stage is to capture any clumps of solids and breaking them up. This stage also helps by bringing the air bubbles to the surface to ensure uniformity.

The next stage involves completion of the armature. Some old rags are torn into small strips and dipped into a mixer of the plastic. The strips are then twisted around the wire support. This process creates a strong support along the wires, and the sculpture starts to form. The strips are then left to dry. Depending on the humidity in the air, this process takes about an hour. Having done with the armature, the final shell is thrown to form the sculpture.

The versatile material is molded till the general shape of the head is built up. In order to get high quality, significant process control is required in this process. Examples of products that are made using this method are slabs, rods, tubing, and sheets (San Diego Plastics, n.d). Examples of materials that can easily be cast include nylons and acrylics (San Diego Plastics, n.d).

One of the advantages of this process is that the artist can continue to add the basic shape even after the paste has dried up. This is because materials can be mixed and casted onto the areas that the artist feels that some elements have been left out. For example, if the artist feels that the nose is smaller than intended; more materials can be mixed and casted to add up the size of the nose. It is however important to avoid adding up more paste when the earlier one is too dry because it may not adhere well. Grooves can however be cut into the dry paste to increase the level of adherence (Raymond, 1990).

This process is frequently employed in the making of complex and intricate shapes, which would otherwise be uneconomical or difficult to make using other methods (Degarmo, Black, and Kohser, 2003).

The better properties of the products that come from permanent mold casting are usually determined by solidification in the metallic mold. This include: superior mechanical properties, homogeneous chemical composition and grain structure, as well as low gas porosity and shrinkage. In addition, the art forms have good surface quality and low dimensional tolerances (Kopeliovich, n.d).

Alternative Processes

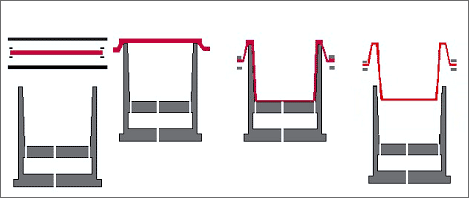

Thermoforming

This process of thermoforming involves heating a cast or extruded sheet, draping it over a mold, in addition to allowing it to cool so as to fabricate a component (San Diego Plastics, n.d).To ensure that the material better conforms to the profile of the mold, vacuum is used to haul the material downwards.

Air pressure can also be used to blow up a shape or a bubble (San Diego Plastics, n.d). On the whole, these two processes call for the softening of the material in order to allow a low force to be applied so as to shape the component (Harper, 1996). Some examples of components made from thermoforming are motorcycle and boat windshields skylights, signs, and bubble packaging (San Diego Plastics, n.d). An example of this process is vacuum forming.

Vacuum forming

Epoxy resin and Crystic polyester can both been used with fiberglass to mold solid castings. Vacuum forming, a method for molding thin plastic sheet, can be used for three-dimensional plastic surfaces. This thermoforming process uses through the application of heat and pressure to mold castings (“Vacuum forming,” n.d).

This is applicable where identical motif is required in multiples for recurrence within a sculptural arrangement, for instance in Oldenburg’s Profile Airflow (1969; New York, Museum of Modern Art); Richard Hamilton also used this procedure to make plastic imitations of the Guggenheim Museum in New York. In the mid- and late 20th century, plastic have been built into a variety of forms of sculpture, assemblage, montage and collage (Edward, 1994).

Vacuum forming (“Vacuum forming,” n.d).

Comparatively deep parts are usually formed when the form-able sheets are pneumatically or mechanically stretched before bringing the sheets in contact with the surface of the mold and before the vacuum are applied (Throne, 1999).

The process of vacuum forming is employed in the production of plastic parts many industries; these include cosmetic, food, medical, entertainment, electronics, toys, household products, automotive, athletic equipment, appliance, clothing, office supplies and packaging industries (“Vacuum forming,” n.d).

Some of the products formed by vacuum forming are inserts, blister packs, clamshells, and trays. This processes’ production time is usually short and this increases the detail-oriented features of production’s time. Many products produced by vacuum forming are sharp and precise detailed, hence making this process a desirable alternative to other molding methods (“Vacuum forming,” n.d).

Some advantages of the process include being economical for petite to medium fabrication units, low cost of tooling, quick startup, and effective prototyping. In addition, there is no need to paint the art forms since texture and color are formed in (“Vacuum forming,” n.d).

Modeling

The modeling is a sculpture process which is additive and it involves materials building up to create/generate a final product/form. It is mostly done on an armature. The sculptor uses their hands to mould the material, which must be pliable.

Matrix molding

This process, which is occasionally referred to as matrix transfer molding, is a practice frequently employed during molding. The process starts with the creation of a firm outer shell. This is then followed by the introduction of a softer and more liquefied molding material into the rigid shell and the model. Matrix molding is regularly used to create intricate shapes from composite materials such as glass/ceramic and glass composites (Mazdiyasni, 1990).

Matched-die molding

According to Mohr et al. (1973) and Agranoff (1975), matched-die molding is among the new processes that are currently in use the process allows for increased automation, and makes use of sheet molding compound (SMC). Molding of complex large art forms is facilitated by SMC.

This includes those that have differences in thickness, sharp radii, molded-in ribs, threads or bosses, comers and inserts. Art forms fabricated by this process have smooth molded surfaces. Many automotive applied products are made using this process (Blaga, 1978)

Injection Molding

Injection molding is a process of art used to make detailed three dimensional art forms (San Diego Plastics, n.d). Placement of the material inside the machine’s hopper (Injection molding machine) starts the process. After the placement, the material is then taken to the melting cavity where it is heated.

Injection Molding (Kailas, n.d.)

When the material melts, it is then taken to the pressured mould, fitting into the cavity’s outline. When the cooling process is over, opening of the mould takes place. Afterwards, the mold is closed and waits for the subsequent shot. During injection, mold clamping is critical since the pressure of the cavity rises to 5,000 psi at times. Usually, the molds are made from hardened steel, epoxy and aluminum and are carefully finished (San Diego Plastics, n.d).

Extrusion

Squeezing toothpaste from its tube can be likened to extrusion. This process brings into being continuous shapes that are two dimensional. The technique is particularly adapted to production of continuous lengths that have constant cross-sections (Gowariker, Viswanathan, and Sreedhar, 2001). Some of these products are gasketing, film, pipe, sheet, and tubing.

The process involves feeding the material into an extruder where it melts and is then pumped out from the extrusion die. The die and the take-off line can control the ultimate aspects and the shape of the cross-section as the material cools. The extrusion equipment is created and regulated to generate melted plastic at very regular pressure and temperature that control the quality and size of the extruded products (Harper, 1996).

Extrusion (Kailas, n.d.)

This process is used to produce bottles, for example the gallon milk bottle (San Diego Plastics, n.d).

Calendering

As noted by Gowariker, Viswanathan, and Sreedhar (2001), the calendering process frequently makes use of four heated rolls that are revolving at slightly distinct speeds. In this case, the material is delivered into the rolls, where it is heated and melted. Shaping of the material into films or sheets then takes place. Many products, commonly made from Polyvinyl Chloride (PVC), are usually fabricated using this process (San Diego Plastics, n.d).

Compression Molding

The process of compression molding usually involves placing a suitable charge of polymer material containing additives into the hollow space of heated male and female mold components (Callister, 2004).

Compression Molding (Kailas, n.d.)

After the material has been poured into the cavity, the mold is closed in anticipation of material cross-linking. Heat and pressure are constantly applied. This makes the plastic material to acquire the preferred mold shape.

Hand lay-up process

The hand lay-up process, which is the oldest technique and the one that calls for a minimal number of equipment, is currently used to fabricate large, hand lay-up and exceptional parts, as well as a fairly small number of miniature components, whose sizes and/or quantities would not validate the cost of production (Blaga, 1978).

This technique entails impregnation of the fiber glass reinforcement using a thermo-settable resin liquid in a gaping mold made from reinforced plastic, wood, concrete, or plaster, and cure is induced at room temperature (Parkyn, 1970; Mohr et al., 1973). A little external or no outside pressure may be applied (Parkyn, 1970; Mohr et al., 1973).

When catalysts are added, cross-linking or hardening of the material occurs at room temperature (San Diego Plastics, n.d).

Filament winding

Filament winding is a process of art forming that is said to be an automated edition of the hand lay-up method (San Diego Plastics, n.d). In this process, support filaments are coated using a resin and subsequently wrap around a mandrel. Layers and orientation’s number is dependant on the component’s bearing weight. Only strong and thin hollow pieces remain after the mandrel’s removal. Some examples of parts made from filament winding are street lighting columns and storage tanks (San Diego Plastics, n.d).

Depending on the size and the intended use of the products, there can be no “perfect substitute” for plastics. Although metals could be melted and cast into several shapes, they are bulky and some are very expensive. Wood can not be a substitute for plastics because it can neither be molded nor withstand high temperatures. All the above materials and processes are environmentally sustainable if proper care is taken when dealing with each one of them.

References

Agranoff, J., 1975. 1975-1976 Modern Plastics Encyclopedia. New York: McGraw-Hill, Znc.

Blaga, A., 1978. GRP composite materials in construction: properties, applications and durability. Industrialization Forum, 9 (1), pp. 27 – 32.

Callister, W.D., 2004. Materials Science and Engineering – An introduction. Sixth edition. New York: John Wiley & Sons.

Cowie, J.M.G., 1991. Polymers: Chemistry and Physics of Modern Materials. New York: Chapman and Hall.

Degarmo, E.P., Black, J.T. and Kohser, R.A., 2003. Materials and Processes in Manufacturing. 9th ed. New York: Wiley.

Dominick, V., 1993. Plastic Encyclopedia and Dictionary. London: Hanser Publications.

Edward, H., 1994. Mechanical Engineer’s Reference Book. London: Society of Automotive.

Engineers, 2001. Polymer Science. Bangalore: New Age International (P) Limited publishers.

Harper, C.A., 1996. Handbook of Plastics Elastomers and Composites. Third Edition. New York: McGraw-Hill Professional Book Group.

Kailas, S.V., n.d. Material Science: Chapter 11. Applications and Processing of Polymers. Dept. of Mechanical Engineering, Indian Institute of Science, Bangalore. Web.

Kopeliovich, D., n.d. Permanent mold casting. Substance & Technologies. Available from http://www.substech.com/dokuwiki/doku.php?id=permanent_mold_casting .

Mazdiyasni, K.S., 1990. Fiber reinforced ceramic composites: materials, processing, and technology. New Jersey: William Andrew Noyes Publications.

Mohr, J.G. et al., 1973. SPI Handbook of Technology and Engineering of Reinforced Plastics/Composites. 2nd Edition. New York: Van Nostrand Reinhold Company.

Parkyn, B., 1970. Glass Reinforced Plastics. London: Zliffe Books.

Raymond, B.,1990. Engineering Polymer Sourcebook. New York: McGraw-Hill.

Ronald, J. and Baird, D.,1986. Industrial Plastics. South Holland, IL: The Goodheart-Willcox Company.

San Diego Plastics, Inc., n.d. Plastics. San Diego Plastics, Inc. Available from http://www.sdplastics.com/plastics.html .

Throne, J.L.,1999. Understanding Thermoforming. Cincinnati, OH: Hanser Gardner Publications, Inc.

Whitfield, R.M., Brown, F.C. and Low, R., 2007. Socio-Economic Benefits of Formaldehyde to the European Union (EU 25) and Norway. Lexington, MA: Global Insight (USA).

Vacuum Forming. Web.