Introduction

Japanese manufacturing is known for its efficiency and pristine quality of products in practically every industry. Over the past decades, the country has developed and adopted various techniques in lean manufacturing and total quality management that the rest of the world has sought to implement. Poka-Yoke is considered one of the most valuable and highly standardized techniques which can be applied to any manufacturing or service industry.

It is based on the principle of error prevention by ensuring proper conditions exist before each step of manufacturing is executed, identifying and eliminating potential defects early on in the process (Kanbanize, n.d.). Poka-Yoke essentially “fool-proofs” any mechanism or process, leading to the application of the principle in various items and devices that are used by consumers on a daily basis. This report will focus on introducing two devices that include an application of the Poke-Yoke mechanism.

Total Quality Management

As stated earlier, Poka-Yoke originated in Japanese manufacturing and revolutionized the process to the point of high efficiency with minimal errors. It allowed companies to develop an approach of continuous quality improvement that resulted in the production of high-quality goods without significant costs, consequently priced less on the market. This provides any company with a competent application of Poka-Yoke a significant competitive advantage.

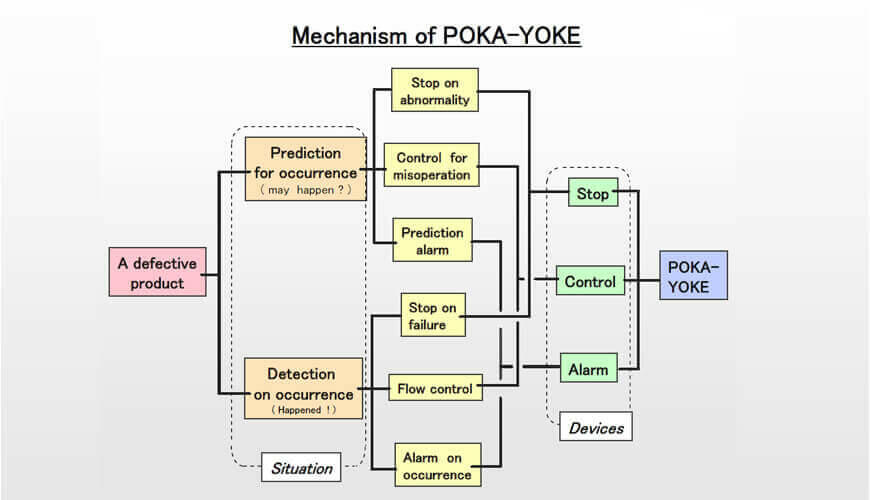

The principle essentially gave birth to the universally applied aspect of total quality management in a variety of given industries and sectors, ranging from engineering to medicine and finance. The Poka-Yoke technique is highly versatile and synergetic, allowing it to be combined with other quality management frameworks such as Six Sigma. Poka-Yoke provides the capability to enable companies to achieving objectives with zero defects (Vinod, Devadasan, Sunil, Thilak, & Murugesh, 2017). Figure 1 below demonstrates the mechanism of Poka-Yoke.

Poka-Yoke is more than a manufacturing term but began to apply to services, techniques, and components of goods which improve quality and prevent errors. Handwashing techniques in hospitals, packaging for screws, and spell-check on word processing programs are prime examples of Poka-Yoke in the application, as they minimize human error by ensuring safety, comfort, or efficiency.

Anecdotal evidence suggests that the implementation of Poka-Yoke in goods or digital services can be as much about being “idiot-proof” as preventing mistakes which may be dangerous, costly, or simply unnecessary, all with the help of relatively simple and innovative solutions (Schrage, 2010). With the modern consideration of a sustainable future, environmentally focused products, and socially conscious homes, devices and processes are becoming eco-friendly and many have features which are meant to prevent errors or waste that affect the environment.

Device 1

One of the primary wastes of energy for electronic devices and household appliances in standby mode when they are not being used but require electricity to continue functioning. While some appliances need to function continuously, others such as televisions and associated systems are continuing to use energy while in standby mode. Furthermore, chargeable gadgets including cellphones and wireless apparel, which many people plug-in overnight, continue to output power once fully charged.

While modern electronic standards have minimized the power which these electronic devices consume, there is still significant energy waste. Some always-on and standby devices such as cable boxes, televisions, water pumps, and microwaves consume more power without active use as an energy efficient refrigerator which is one of the highest energy demanding appliances in a household (Verde Team, 2018). Therefore, it can be argued that over time and in a combination of millions of households, energy waste can reach tremendous levels.

A device that is proposed based on the Poka-Yoke principle is an automatic switch established on all power sockets and strips. After recognizing that the plugged-in device went into standby mode, it would dampen the power output to a bare minimum or potentially eliminate it completely for it to turn on if necessary. With modern smart technology, it would be able to distinguish the type of device or appliance and regulate power output based on this. It would also be able to identify systems of devices, so if television is turned off, the cable box and game systems will be cut off from electricity after a short period of time. Portable chargeable devices will also stop charging after reaching full battery capacity.

For large electronic systems such as lights, water pumps and heaters, and even refrigerators, the switch can be set on a timer, or programmable by a human or artificial intelligence to also lower power waste over time, particularly when no one is home, or such appliances are not in use. The electronic switch would require an insignificant amount of power to operate itself and result in greater energy savings. This Poka-Yoke device would eliminate tremendous energy waste by automatically addressing the common advice for people to unplug devices when not in use (which is rarely done, especially on a consistent basis). Its primary purpose is to provide a practical solution that prevents mismanagement of energy use which can have environmental and safety impacts.

This type of Poka-Yoke device is based on the principle of demand-side management (DSM), which is the future of smart grids and energy use, by allowing to manage electricity loads on various scales ranging from homes to whole cities. The DSM model applies algorithms and prediction software to determine the scheduling of residential appliance use (Javaid et al., 2017).

The benefit of this device is relatively simple in nature and can be useful in homes that have not adopted a range of smart devices and sensors. Its primary benefit is house energy demand optimization which results in financial savings over time for individual households while resulting in energy savings and distribution for municipal energy grids. It can also serve as safety protection against electrical surges which may disable appliances or even cause fires since people often disregard the electricity sockets and plugged in devices. The design and purpose of this Poka-Yoke device can have significant beneficial outcomes for households and the environment.

Device 2

Air conditioning is an integral part of many American buildings and residences, helping to regulate the indoor climate from the scorching heat or, the opposite, cold chill which drastically affects many regions of the country. HVAC technology and service are one of the most vital and successful businesses, providing significant benefits for households and industries alike. However, this comes at a high environmental cost as HVAC units are one of the most energy consuming appliances available.

HVAC is responsible for approximately 40% of total building consumption and 70% base building consumption (Australian Government, 2013, p.1). Dependent on equipment and HVAC system, energy waste can reach high levels as distribution of energy and consumption levels and the cooled air volume the user receives have significant differences. Insufficient air volume controls, lackluster utilization of economy cycles, and poor efficiency measures are some aspects which contribute to the environmental impact of HVAC units.

It is suggested to develop a Poka-Yoke device which prevents automatic turning on of air conditioning or heating based on temperature indicators. It would require manual input, and after notifying the user of energy costs and waste. Furthermore, it would ask the user to set a timer during which the air conditioning or heating may run, limited to no more than 9 hours. During this time, the regular temperature indicator would function as normal as to note when to adjust the inside temperature, but it would not automatically trigger some of its high-powered options either unless by manual input. It can be recommended to limit the high-powered options, particularly with air conditioning to no more than 20-minute intervals.

Therefore, the primary objective of such a device is to eliminate excessive energy use which comes due to intensive and often unnecessary use of air conditioning or heating systems based on such parameters as temperature readings. While these may be an indicator of an indoor climate to some extent, they do not take into consideration external factors such as sunlight/shade, air flow, supplemental fans, and shifts in temperature between night and day. Most of the current systems in residences are basic and this results in poor efficiency and energy waste since people do not have the ability to continuously regulate the temperature settings, especially when not home.

The main benefit of this Poka-Yoke device is initiating a greater control and manual input for air conditioner units which consumer tremendous amount of energy often unnecessarily. This results in waste as the air conditioner units are running at full power at night when no one is home, as well as cooling areas of the residence which may already be cooler than others. Indoor climate regulation is based on an empirical thermal comfort model which considers factors such as inside temperature and metabolic rates. Thermal comfort models need to be reexamined in order to consider physiological constraints, indoor climate, and flexibility of thermal demand. The regulation of these factors would lead to improving energy consumption predictions and greater efficiency in HVAC unit utilization for energy savings (Kingma & Lichtenbelt, 2015).

Summary

Poka-Yoke is a principle in manufacturing that was developed by the Japanese to prevent errors early on in the process and ensure efficiency. It has been adopted worldwide as a standard approach to ensuring total quality management as well as becoming a term symbolizing a “foolproof” component of a certain good or service. Preventing human mistakes in any given process or utilization of an item has significant benefits ranging from safety and efficiency to consideration of costs and environmental impact.

For this assignment, two devices were developed based on the Poka-Yoke principle. The first is an automatic switcher on electrical sockets which would limit stand-by or non-active use power consumption that has significant impacts on energy waste. The second is regulator on HVAC units which would help control economy cycles and thermal regulation, thus eliminating waste of significant energy resources when it is not highly necessary. The background to Poka-Yoke and its fundamental application in this assignment demonstrates that the high-efficiency and error-reducing approach can have potential implications far beyond simple quality-of-life fixes. It is necessary to use Poka-Yoke in a larger number of industries and sectors.

References

Australian Government. (2013). Factsheet: HVAC energy breakdown. Web.

Concept Business Excellence. (n.d.). Mistake proofing – Poka-yoke. Web.

Javaid, N., Ullah, I., Akbar, M., Iqbal, Z., Khan, F. A., Alrajeh, N., & Alabed, M. S. (2017). An intelligent load management system with renewable energy integration for smart homes. IEEE Access, 5, 13587-13600. Web.

Kanbanize. (n.d.). What is the Poka Yoke technique?Web.

Kingma, B., & Lichtenbelt, W. V. M. (2015). Energy consumption in buildings and female thermal demand. Nature Climate Change, 5, 1054-1056. Web.

Schrage, M. (2010). Poka-Yoke is not a joke.Harvard Business Review. Web.

Verde Team. (2018). Truth about standby power. Web.

Vinod, M., Devadasan, S. R., Sunil, D. T., Thilak, V. M. M., & Murugesh, R. (2017). POYSS: A model for integrating Poka-Yoke technique with Six Sigma concept. International Journal of Productivity and Quality Management, 22(2), 223-242. Web.