Added value that effective Procurement activities can have to a company or organisation

An organisation requires human and physical resources for an effective business operation. Supply chain management is a strategic planning, control and monitoring of processes involved in the material delivery in a company for production of goods and services. Its main aim is to ensure that the end customer gets constant supply of final goods as per their expectations.

Procurement is part of supply chain management with the role of ensuring that a company gets materials from the most efficient supplier at an appropriate cost. It also ensures that materials and machinery for production are available in the right time at an appropriate quality and quantity.

With an effective procurement strategy, a company is bound to benefit. The role of procurement department extends from procuring for raw materials, machineries, office suppliers to developing an effective procurement process (Karp, 2005). This paper analyzes the benefits that effective Procurement activities can have on an organisation.

Procurement

Since the late 1990’s procurement has become an important concerns of different business both in service and product industries. Companies are deploying experts in supplies and purchasing in their efforts to ensure they benefit from an effective procurement logistics. In modern globalized economies, international trade has taken preference giving companies the freedom to procure from different parts of the world.

This calls for an extension of procurement department roles as it has to consider international logistic matters. It would be misleading to state that there is an effective procurement method that can be applied to all business set up and yield good results.

Each business is superior in its own ways and so do the procurement strategies and mechanisms. However, there are common procedures that must be taken for an effective procurement (Ketchen and Hult, 2006).

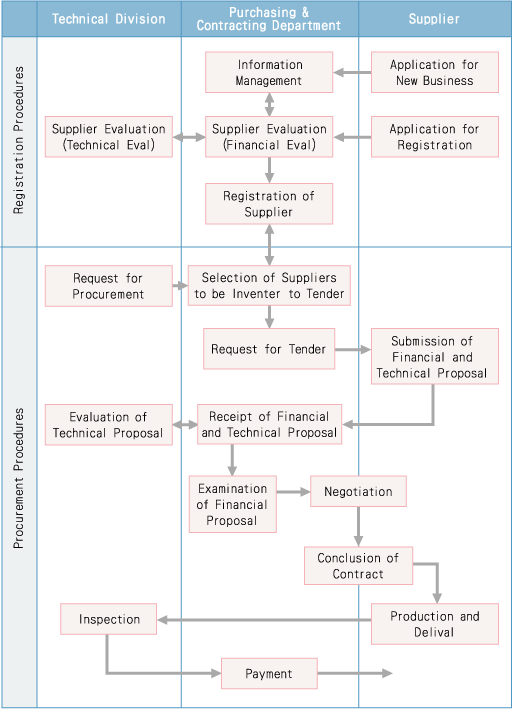

The diagram below shows a standards procurement system:

Chart 1

The above diagram shows basic steps involved in a procurement process, each process has its role in the entire process. In case of a failure in one area, then the entire system is likely not to be effective. It involves three major department or sections which are stakeholders they are technical division which is mostly involved in researching the market and prices of various materials.

The procurement and contracting department consumes information from the technical team and makes the final decision. The supplier is the heart of the process as he conclude the entire procedure. After a successful procurement, data is collected for future procurement decisions.

With the growth of the procurement sector, a number of procurement companies offering outsourcing services have emerged, the major decision that a company should make is whether it will manage the systems centrally or locally or it should outsource these services (Khoo, Bainbridge, Spedding and Taplin, 2001).

Whichever the option, a well managed procurement department and processes are beneficial to accompany in the following areas:

Quality maintenance and value management

The quality of a company’s products and services is subject to materials used in the production. If procured goods are of high quality, then the final products are likely to be of high quality. According to 4ps of marketing mix as developed in 1960 by a marketing expert called E J McCarthy, the quality of a company’s product determine the successes and competitiveness of a company’s product in local and international markets.

Maintaining an effective procurement department ensures that there are materials and other inputs required in production at the right time in an appropriate cost. When appealing for customers to buy ones brands, the quality of the products is of importance, quality is measured by the level of utility that a product gives to the buyer.

At any one time, the quality of product should be high enough that it can satisfy the expectation of customers. Centralisation and having a full department that thinks and gets to the market to collect purchasing data will go a long way in ensuring that a company gets goods at an appropriate cost. Market forces keep adjusting the prices of commodities due to demand and supply forces.

A robust procurement department will be in touch with changes in the market for better decisions. The success of Nokia phone can be attributed to its high quality products that keeps changing with the needs of the environment (Kouvelis, Chambers and Wang, 2006).

Green supplies and company success

Industrialisation, town development and increased population have brought about environmental damage; consumers are getting more interested in environmental conservation. They are increasingly becoming aware and concerned about conservation of the environment; they are more willing to trade with those companies that produce environmentally friendly products through environmentally friendly processes.

With an effective procurement department, is going to analyze the prevailing condition in the market and make decisions that are responsive to the needs of customers. Procurement department is responsible for developing a green supply chain management; it undertakes internal and external audits to ensure that products and processes are environmentally friendly.

It also ensures that goods are produced at minimal or no pollution and the final products do not pollute the environment. When well procured, a company can procure products that can be recycled for environmental conservation. Numerous advantages accrue to a company when it produces via environmentally friendly processes and products.

To have an environmentally friendly production, the process starts with procurement of machineries used in production and the materials to be used in production. A company that produces such goods enjoys an increased customer base and favour from environmental policies activities.

For example, the success of Starbucks have been attributed to its strong environmental conservation has lead to its success in its hospitality industry. The process adopted by the company emanates from procurement department where it ensures that a company gets good from farmers that using an appropriate technology (Larson and Halldorsson, 2004).

Procurement and building a strong brand name

It is the dream of every company to develop and retain a strong brand name. A company with a strong brand name benefit from customer loyalty, minimization of marketing risks, positive responses to changes in prices, and brand-extension. It is also a strong marketing and self-advertising tool.

To fight competition, a company needs to create a close attachment between customers and the company’s products. Products are the results of a manufacturing process that initially starts with procurement.

Consumers are willing to be loyal to those companies whose processes and products meet their need. When procuring, procuring team ensures that, they have the expectation of the customer in mind. This will ensure that the company has a continued supply of customers for an increased profitability.

Toyota Company has maintained the leadership in the automobile industry because of a strong brand name (Manul and Mentzer, 2008)

Procurement leads to good Supplier relation

For an effective production, a company needs to maintain good relation will all its stakeholders. To develop good business relationship with suppliers, procurement department plays an important role. It ensures that orders are procured in the right time and payments to suppliers effected as per the contract of supply.

When a company has good customer-supplier relation, it is likely to get goods at a better price and adequate and reliable market data from suppliers for strategic decision-making.

For example when prices of goods are likely to fall, suppliers may have the information, thus when there are good relations, they will pass the information to the company to control its purchase of raw material.

Information is power thus when there are adequate supplies information, a company is able to make decisions which are responsive to changes in the market. Starbucks has maintained a good relation with its suppliers has ensured the company has constant supply of goods and services.

Procurement assists in maintaining adequate working capital

Working capital is the operating finances at the disposal of a company at one particular point to be use finance different expenses. It is the through operating capital that a business can take advantage of opportunities. It is the difference between current assets and current liabilities; it assists in smooth operation of business. To have a positive working capital calls for management of debtors and creditors (Peltz, 2010).

Procurement department assists a company to maintain its creditors at a minimum rate; credit policy adopted in a company is crucial in maintaining a positive working capital. It is the role of the procurement department to ensure that it has a well-managed credit balance to meet the double goals of paying suppliers in time and maintaining a positive working capital (Hokkaido Electric Power Co., 2010)

With the assistance of procurement department, the company will be able to take advantage of opportunities in created by the market and mitigate against negative effects of suppliers power. The success of Apple Electronic Company is vested in it adequate working capital; it is able to take advantage of changing technological needs (Fugate, Mentzer and Stank, 2010).

Just in time supply mechanism

A procurement system assists a company to save on costs of warehousing; a system of efficiency and effectiveness in the procurement system leads to just in time supply mechanism. A just in time supply system ensure that a company gets materials at the right time for an effective production without necessarily holding stock of materials (Fugate, Mentzer and Stank, 2010).

To have an effective just in time supply system, the procurement department ensure that only goods required in production are procured for and they will be supplied in an effective time. It considers the lead-time of supplies; in times of boom, a company requires more materials that time of low production.

Despite having a just in time policy, the company will adjust effectively to changes in demand of materials. A just in time supply means that at any one point in time, the company is has adequate supply at a minimal costs.

The costs saved by a just in time system include, saving on warehousing costs, stock maintenance costs and handling costs. The reduced cost reduces the cost of production for a company thus, it can sell its products relatively cheaper than companies can in the same industry (Fred, 2008).

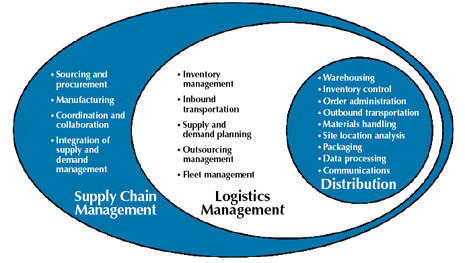

Formation of an integrated supply chain management

Procurement is a major department in the formation of a supply chain system. Supply chain system is a multi objective decision involving internal and external players procurement is the heart of the system.

With invention of computers, integrated supply chain and logistic systems has been developed; for an effective integrated system, the inputs of the procurement department. It provides the developers with information necessary to create lead-times, reorder level and quantity ordering levels. (Darnall, Jolley and Handfield, 2008).

An following diagram interpolates an integrated supply chain system;

Chart 2

It involves integrating all systems in an organisation for an effective collaboration among different departments. Certain lead-time and reorder levels are maintained to assist in making decision on the amount and timing of an order.

Procurement department maintains a pool of data and information regarding suppliers and the product they offer. They also have various credit policies operated by different suppliers thus making a decision on the right supplier at a particular point considering the internal liquidity and needs of good is facilitated.

In modern free market, more than one supplier offers different packages for the same goods can supply goods, an effective procuring department will scrutinize and place an order to the customer who supplies goods at an appropriate cost, quality and can be reliable. All this information is with the procurement department thus it assists in making the right decision on whom to procure (Creswell, 1998).

Procurement assists in international procurement contracts

International trade and globalisation has facilitated the purchase of materials from international market. Although the underlying principle is the same like that implemented in local purchasing, there are special factors that need to be put into considerations.

When buying internationally, customs logistic of importing and exporting country should be well understood to ensure that the company operates within the law and understands all costs involved in international procurement. It is the role of procuring department to ensure that it advices the company on such issues appropriately to facilitate the logistics (Cooper, Lambert and Pagh, 1997).

Some areas that it needs to advise as far as international procurement is concerned include custom laws, duties, rules of origin, trading blocs and any incentives offered by the government to facilitate such trade.

A company without an effective procurement system might make international procurements ignoring monitoring and control policies put in place by a country; alternatively, it may fail to benefit from trade facilitation policies set by national or international bodies. Mearsk limited is successful in international logistic company by understanding international customs laws (Burns, 2000).

Procurement and continuous flow of goods

For production to occur there is need for raw materials and machinery. To have a continuous supply of goods a company needs to have an effective procurement system. It will guarantee the company and ample supply of raw materials when they are needed in the production plants.

When a company has a smooth flow of goods to the market, customers gets confidence with the brand of products, this increases consumer loyalty and preferences.

When developing a strong brand, products should be available to customers when they need them, this can only be effected if procumbent department ensures that production plants are well fed with materials they require to meet the expectation of the customers (Balnaves and Caputi, 2002)

Procurement and waste management

Waste management has been a problem in industries; it can be controlled by using appropriate technology and materials in production. Procurement department undertakes the role of procuring for machinery of the right technology and materials that are likely to produce minimal wastes.

Sometimes a company has the option of using materials that can be recycled; procurement department has the role of ensuring the materials and machinery used emit minimal waste as a process of waste management (Hsu, Tan, Kannan, and Keong, 2009)

In rather an indirect way, procurement can order for goods form companies whose system of production are environmentally friendly. When this is done, then the company will be assisting in preserving and managing the environment.

Although the benefits from such an angle may not be immediate, they will be felt in the future. Honda Motor Company has benefited in the market because of its effective waste management system; this has assisted the company produce its products at a lower cost.

Conclusion

For an effective and continuous production, a company needs to maintain a reliable procurement department. It ensures that there is continuous supply of materials and machineries required for production, at an appropriate cost and of the right quality and quantity. When an effective procurement management is maintained, a company gains competitive advantage.

The effects of an effective procurement department is felt in the following areas waste management, green supplies, just in time supply, cost management , management of working capital and developing good suppliers-company relationship. It adds value to a company in form of financial gain, reputation and smooth flow of functions.

References

Balnaves, M. and Caputi, P., 2002. Introduction to Quantitative Research Methods: An Investigative Approach. London: Sage.

Burns, R.B., 2000. Introduction to Research Methods. London: Sage.

Cooper, M.C., Lambert, D.M. and Pagh, J., 1997. Supply Chain Management: More Than a New Name for Logistics. The International Journal of Logistics Management, 8(1), pp. 1–14.

Creswell, J., 1998. Qualitative inquiry and research design: Choosing among five traditions. Thousand Oaks, California: Sage Publications.

Darnall, N., Jolley, G. and Handfield, R., 2008. Environmental management systems and green supply chain management: complements for sustainability?. Business Strategy & the Environment, 17(1), pp. 30-45.

Fred, D., 2008. Strategic Management: Concepts and Cases. New Jersey: Pearson Education.

Fugate, B., Mentzer, J. and Stank, T.,2010. LOGISTICS PERFORMANCE: EFFICIENCY, EFFECTIVENESS, AND DIFFERENTIATION. Journal of Business Logistics, 31(1), pp. 43-62.

Hokkaido Electric Power Co., Inc., 2010. FLOW CHART OF STANDARD PROCUREMENT PROCEDURES. Web.

Hsu, C., Tan, K., Kannan, V. and Keong, G., 2009. Supply chain management practices as a mediator of the relationship between operations capability and firm performance. International Journal of Production Research, 47(3), pp. 835-855.

Karp, H. R.,2005. Green suppliers network: Strengthening and Greening the manufacturing supply base. Environmental Quality Management, 15(2),pp. 37-46.

Ketchen, G. and Hult, T.M., 2006. Bridging organization theory and supply chain management: The case of best value supply chains. Journal of Operations Management, 25(2),pp. 573-580.

Khoo, H. H., Bainbridge, I., Spedding, T. A. and Taplin, D. R.,2001. Creating a Green Supply Chain. Greener Management International, 2(35), pp.. 71-78.

Kouvelis, P., Chambers, C. and Wang, H., 2006. Supply Chain Management Research and Production and Operations Management: Review, Trends, and Opportunities. Production & Operations Management, 15(3), pp 449-469.

Larson, P.D. and Halldorsson, A., 2004. Logistics versus supply chain management: an international survey. International Journal of Logistics: Research & Application, 7(1), pp 17-31.

Manuj, I. and Mentzer, J., 2008. GLOBAL SUPPLY CHAIN RISK MANAGEMENT. Journal of Business Logistics, 29(1), pp 133-155.

Peltz, E., 2010. Logistics: Supply Based or Distribution Based? Web.