Abstract

Contractors often juggle the notions of Quality Assurance and Quality Control as they go about their everyday work on construction projects. The construction industry faces challenges in assuring high-quality outputs from the construction phase if neither the owner nor the workforce. To save money, paying close attention to all aspects of material management is essential.

The modernization of construction methods has been made possible by employing cutting-edge tools and forward-thinking methods. Organizations that need to appreciate the significance of new technologies and adapt to new circumstances are, quite rightly, no longer welcome in the mainstream of construction activities. The underlying assumptions regarding the nature of procurement are crucial in determining the type of procurement practices seen as sensible.

Production must be envisioned alongside transformation (T), flowing (F), and value generation, according to standard practice in Lean production (LC) (V). On the other hand, it is required to recognize and deal with the risk of loss of value with the same vigilance as has been shown in dealing with the other difficulties so far. Materials management is a crucial aspect of every project’s organization and management.

Introduction

Quality Assurance (QA) is a collection of systematic and well-planned actions that guarantee a certain standard of quality in the architecture, engineering, and construction (AEC) industry. It ensures that quality is built into the beginning of the project rather than the finish. External factors, such as setbacks in permission, inspection, quality control, availability of raw materials, labor, weather, etc., can cause issues with material demand and ultimately delay the project’s completion date. The planning stages are affected by the fact that each construction phase has its own set of needs and that any delay in the project will have an impact.

Resource and labor availability are two of the most pressing issues in the building industry. To what extent one may participate in a construction project relies on whether or not the process is controlled internally or outside. Job dependence is something that can seldom be avoided. If construction management does not live up to standards for resource management, then a lot of management work and procurement studies could be required. Standardization efforts in architecture, engineering, and design provide the basis for many essential needs. To ensure that all essential materials are up to par with the firm’s quality requirements, the company has established a set of criteria for marking drawings and plans from conception to final approval.

Supply

Inadequate materials for storing are a common cause of problems on websites. The survey results indicate that supply chain and buying managers have a clear window into the financial health of their organization (Keenan et al., 2021). Material requests must be placed at the appropriate times to ensure on-time delivery at the agreed-upon quality. In order to fulfil the supplier’s demand, it was necessary to arrange the desired sports at the optimal times (Faeq et al., 2021). Procurement costs, waste, and other dangers can be drastically reduced when adequate storage space is available at a site.

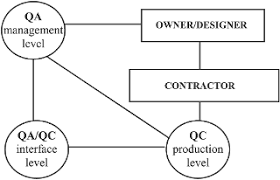

System Architecture

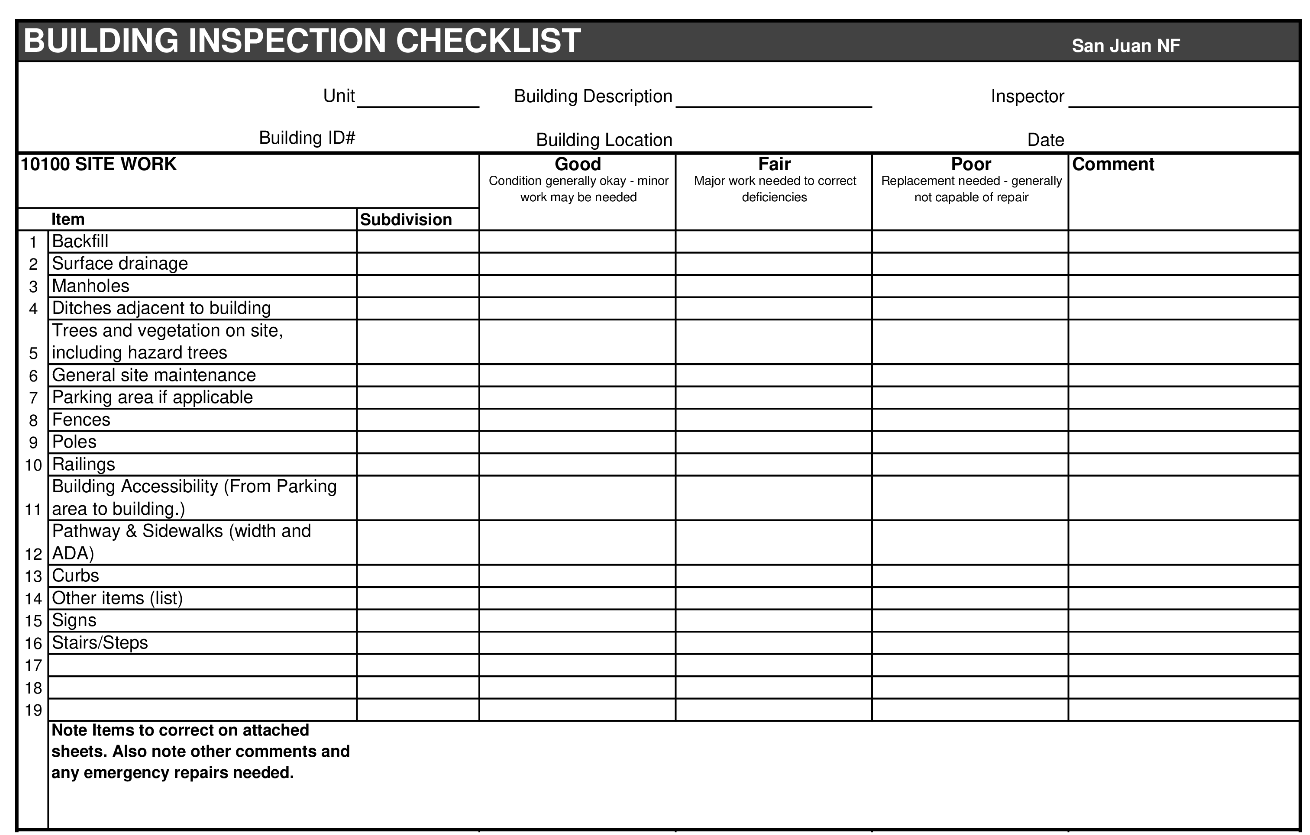

Inspection Checklist

Materials Management

Urban areas and restricted environment sites provide unique challenges when dealing with materials. Manufacturing materials help enhance the overall performance of creative initiatives in terms of triple constraints and productivity (Keenan et al., 2021). Standards for various types of work can be found in the publications of groups like the American Testing and Materials Society (ASTM), the American National Standards Institute (ANSI), and the Construction Specifications Institute (CSI) (CSI).

Standard Specifications for Highway Bridges are produced by the American Organization of State Road and Transportation Officials, while American Welding Society welding standards are issued for specific construction activity (Keenan et al., 2021). Changes must be made to these general parameters to account for differences in climate, culture, materials available, legal requirements, and other factors.

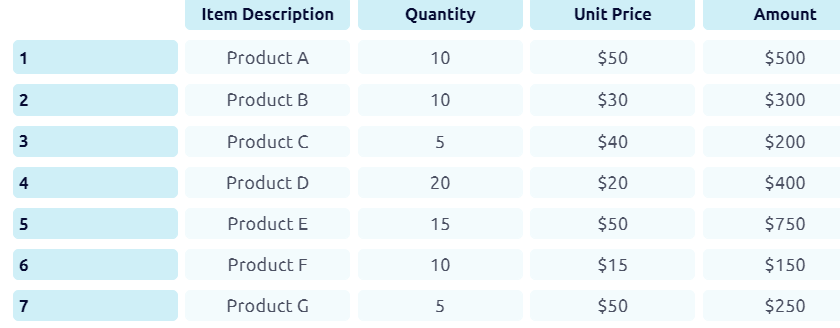

Materials Delivery Form

Methodology

Figure 1 demonstrates the research approach.

Construction Materials and Equipment

Inadequate Access to Necessary Tools and Materials

Cement, gravel, gravel, iron, wood, brick, paint, ceramic, natural stone, and other building materials are some of the many construction materials that fall into one of two categories: the material names themselves and the derivative manufacturing that relies on them. In addition, indigenous and non-indigenous components were used in its manufacture, and it has a uniquely Indonesian trademark rather than belonging to a worldwide franchise network (Luo et al., 2022).

On the other hand, using imported, non-native materials in production necessitates importing methods for getting such materials to market. Indonesia imports materials like metal, metal, and zinc and exports materials like aluminum, copper, and forests (Luo et al., 2022). Even though some resources are brought from Malaysia and China, there is significant evidence that other materials, primarily Portland cement and metal, are unavailable for reasons beyond production or trading difficulties.

About the Software Designed

Benefits of SPSS

SPSS has a wide variety of information and is simple to use—software for managing content and creating edits. Extensive statistical tools should take advantage of SPSS when there is a need for a versatile and adaptable method for getting granular on even the most complicated data sets (Egwunatum et al., 2022). It also frees up more time for the researcher to focus on the most critical tasks, such as recognizing patterns, creating prediction models, and reaching conclusions based on the evidence. Labeling variables and data values explicitly, saving information and documents in system files and documenting enormous datasets thoroughly.

Research Findings

T-Test, Evaluation, and Independence

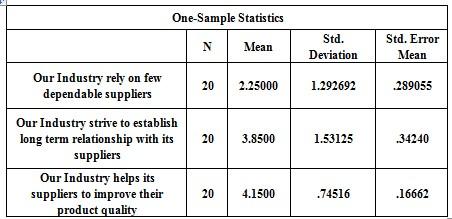

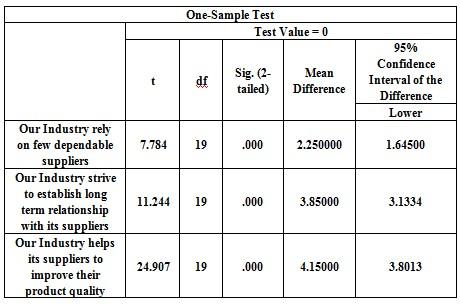

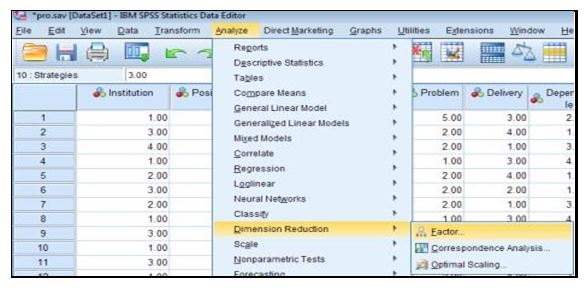

T-test is applicable when a continuous variable has been collected on a sample of persons or products, and the mean value is compared to a hypothetical population means. Because it is based solely on the typical distribution, the one-sample t-test can only be used with numerical and continuous data from the sample (Egwunatum et al., 2022). However, if the information sequence technique became random, it would be reasonable to conclude that the observations were independent. To illustrate, instead of using a systematic sample, we may randomly pick laptop computers (Amusan et al., 2019). This ensures there is no chance of amassing a biased pattern, which could lead to incorrect conclusions. The one-sample statistics are displayed in Table 1.

T-test 1 is displayed in Table 2.

Table 3 shows a one-sample t-test.

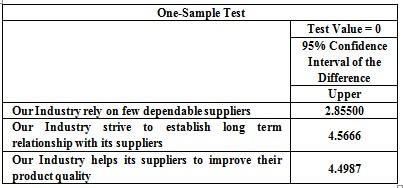

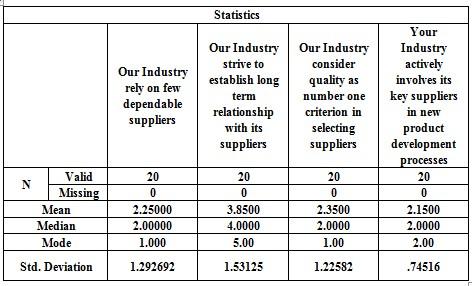

Considering Multiple Factors

The SPSS factor analysis is depicted in Fig. 2.

Statistical Methods for Quality Assurance

All materials and labor in a given facility might be put through a battery of tests as part of an optimal quality control program. X-ray inspection of welds is just one example of a non-destructive technique that can be utilized extensively throughout a building (Amusan et al., 2019). An on-site inspector can verify at any moment whether or not current practices meet standards.

The fact that skilled workers may evaluate their supplies and progress as they go is a huge plus. However, having inspectors perform thorough, or 100%, tests on all materials and work can be very costly. Extensive testing is usually impossible since it necessitates destroying a material sample during testing (Faeq et al., 2021). Therefore, we use sample sizes to determine whether or not to accept a work item or a shipment of materials. In order to conclude the quality of an entire bunch or lot of materials or finished goods, statistical methods are employed to analyze the results of tests conducted on a small sample.

Test results with a limited sample size might be highly deceptive if not correctly interpreted. To illustrate, let us say that out of a batch of one hundred, ten are flawed (Amusan et al., 2019). Out of a sample size of five, the inspector will not identify any defects. Based on these samples, one cannot conclude that there are no defective items in the population. Because samples are selected randomly, there is a wide margin for error in any tests performed (Faeq et al., 2021). Only with statistical approaches can problems like the likelihood of varying degrees of defective parts in the complete lot be thoroughly examined from a relatively small test.

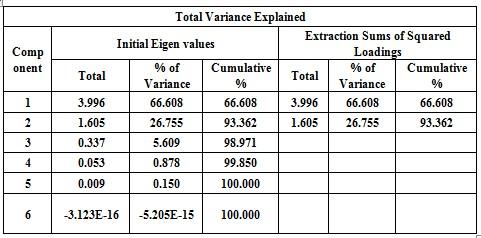

The results of the factor analysis are presented in Table 4.

The Collapse of the Trench

A hole between 12.5 to 18 feet deep was dug along the middle of a four-lane street to upgrade 1,200 feet of the sewer system. The contractor started digging the 12.5 ft. deep trench from the less deep end (Amusan et al., 2019). The contractor then dug a 9′ deep, 4′ wide rebar trench box to hold the soil in place. A trench box is a steel structure with an open top, bottom, sides, and ends. This strategy benefited from allowing two lanes of traffic to remain open during the reconstruction process. The trench box was holding its own in the shallower sections of the trench. However, as the depth of the trench increased, a larger volume of soil was left unreinforced beneath the trench box. In the trench, the soil began to collapse at irregular intervals.

After some time, a parallel six-inch water main gave way, flooding the ground below the trench and causing major soil collapse. The main water replacement was a last-minute addition to the original agreement. The contractor started sloping the trench’s sides, and the whole roadway had to be shut down. The trench box served its purpose for a while, but it soon became apparent that it needed to be more adequate and safer. Accidents from soil collapse were a constant threat to the trench crew (Faraji et al., 2022). Consequences for the surrounding infrastructure, including the parallel water main, were likely. Of course, the sloped excavation that was ultimately chosen over the use of tongue and grooved vertical sheeting for the entire height of the trench is the better option. Table 5 below shows the initial Eigenvalues.

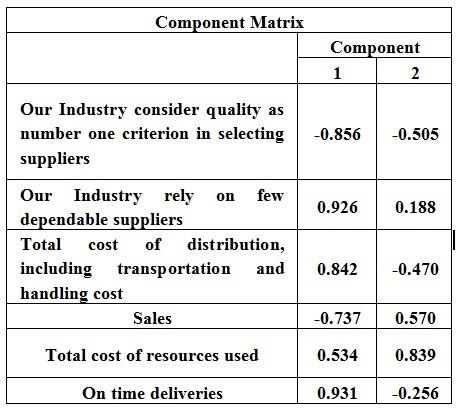

Table 6 shows the component matrix, and the component matrix is shown in table 6 as shown below:

Frequency Analysis

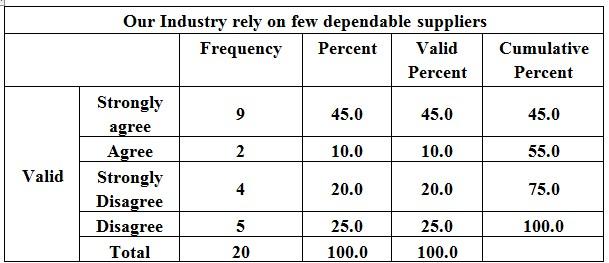

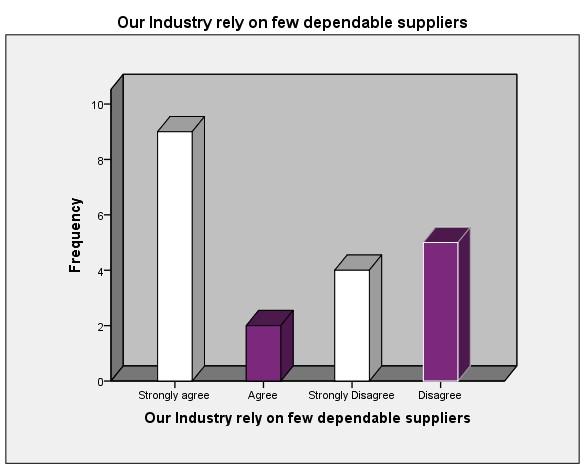

Consistently reliable vendors are analyzed in Table 7.

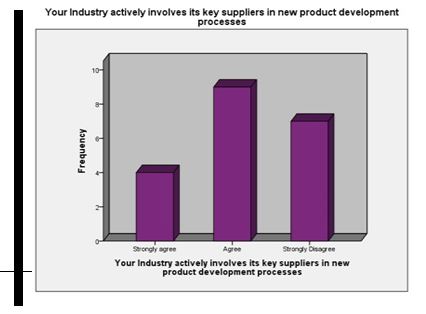

Trustworthy suppliers are depicted graphically in Fig. 3.

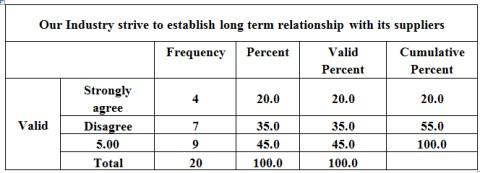

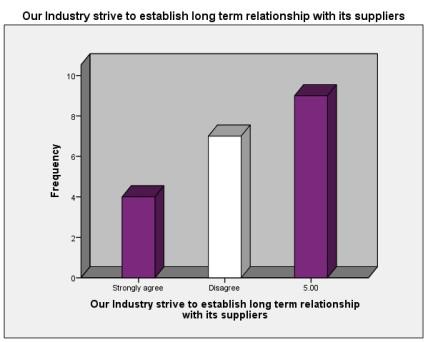

The frequency analysis of the company’s interactions with its vendors is displayed in Table 8.

The connection to its providers is depicted in a graph (Fig.4).

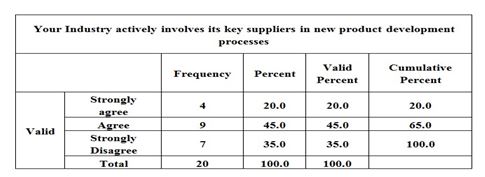

The process of development is analyzed for frequency in Table 9.

The development process is depicted graphically in Fig. 5

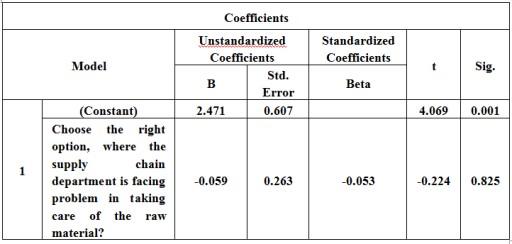

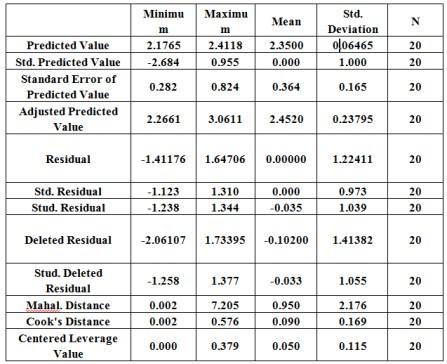

ANOVA

Anova co-efficient data are presented in Table 10.

The residual data are presented in Table 11.

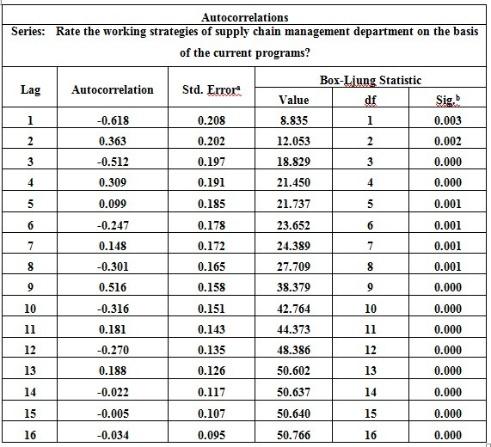

The Concept of Autocorrelations

In order to guarantee the facility performs as intended by design, control, and improvement in construction often involves verifying adherence to basic standards of craftsmanship and materials. Acceptance or rejection of batches of finished work or supplies is often based on random sampling and statistical methodologies to ensure compliance (Faraji et al., 2022). It will be rejected if a batch fails to meet or slightly deviates from its intended design parameters.

The following sections elaborate on the steps in carrying out this quality assurance procedure. These conventional quality assurance methods presume a threshold below which defects are unacceptable (Amusan et al., 2019). If the projected defective percentage falls under the acceptable quality threshold, the inspection of the materials purchased from suppliers or the work conducted by the organization is considered successful. Delivered products with defects are fixed after they have been received.

The objective of total quality control stands in stark contrast to the more conventional quality assurance method. This method entirely eliminates faulty materials from the building process (Faraji et al., 2022). Despite the impossibility of ever achieving it, the objective of zero defects serves as a benchmark for measuring the success of a company’s quality assurance efforts.

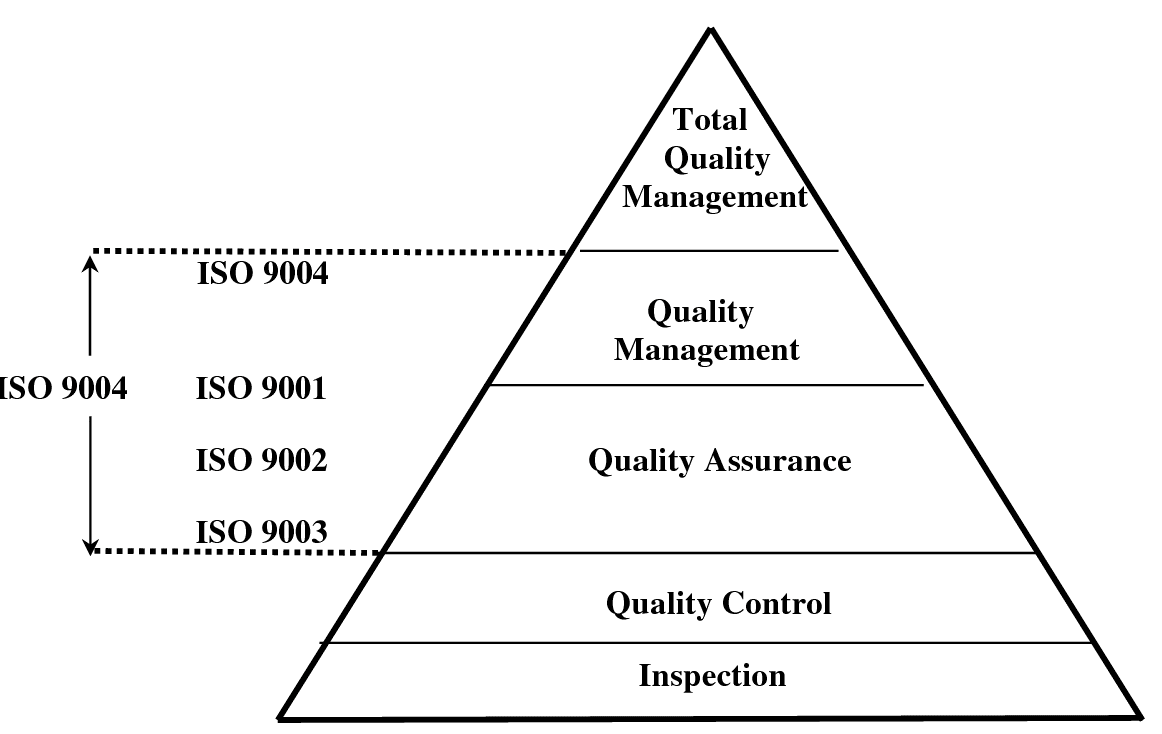

The idea and method of quality control were initially created in Japanese and European manufacturing enterprises but have now expanded to numerous construction firms. The International Body for Standardization’s ISO 9000 standard is the most widely recognized formal accreditation for quality improvement (Faraji et al., 2022). ISO 9000 requires thorough records to be kept alongside established quality standards and regular cycles of preparation, execution, and evaluation.

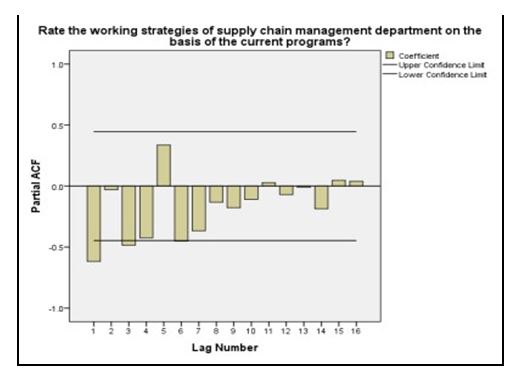

Total quality control, or TQC, is an approach to business that emphasizes excellence in every facet of operations. It is crucial to conduct design reviews to guarantee efficient and risk-free building practices (Abdullahi et al., 2019). Additional factors include thorough employee training, a transfer in the onus for defect detection from quality control inspectors to workers, and regular equipment upkeep. Quality circles are a systematic method of worker participation in better quality control in which groups meet regularly to offer suggestions for enhancing quality. All suppliers of raw materials must guarantee that their products are flawlessly supplied. Certified suppliers can undergo a partial inspection if they have performed well in the past. Table 12 displays the inter-factor autocorrelations.

Control charts

The operational plans control chart is depicted in Fig. 6.

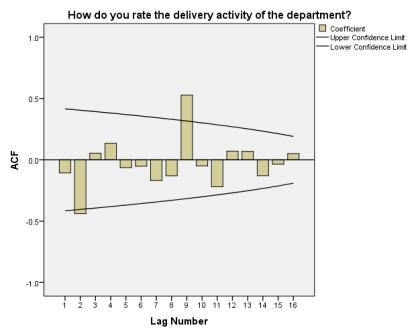

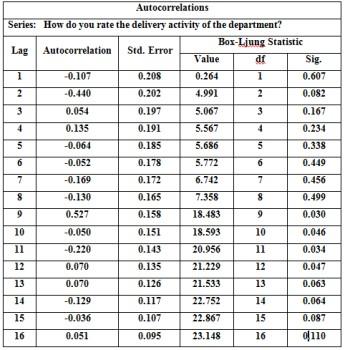

Correlations between deliveries are shown between themselves in Table 13.

The chart for monitoring dispatch operations is depicted in Fig. 7.

Safety

The selection of appropriate technology can also play a significant role in defining the level of safety present at a worksite. The machinery operators can be alerted to problems by safeguards incorporated into the machinery, which can prevent injuries (Abdullahi et al., 2019). For instance, even the most straightforward switches might prevent machinery from running if protection barriers exist.

The availability of onboard electronics and sensors has substantially increased the possibilities for developing sophisticated machine processors and monitors for tools and equipment used in the construction industry. Choices regarding the work procedure and the materials used can impact the level of safety in construction. Replacing asbestos with another material might lessen or even eliminate the risk of developing a condition that manifests over an extended period, such as asbestosis.

It can directly affect workplace safety by educating workers and supervisors on the appropriate procedures and potential hazards. Recognizing the significant financial expenses associated with construction-related diseases and injuries offers significant impetus for education and awareness efforts. On virtually every work site, conducting routine safety inspections and holding safety meetings are now considered standard practices. Pre-qualification of general contractors and inter- and intra about safety is another essential step toward improving workplace safety.

Solution

Evidence-Based Practices (Case Studies) Presentation

Four selected case studies to examine requirement control methodologies, associated problems, and recommended enhancements in depth we used in this study. Details about the projects at hand in the case studies, including the types of projects and the industries served by the clients in question (Abdullahi et al., 2019).

Exact results from the projects’ use of necessity management techniques, including a breakdown of the approaches taken, the people involved in the RSM techniques, the data collection procedure, and some excellent observations on the requirements control of each project, as well as the techniques themselves (Abdullahi et al., 2019). It is important to note that these case studies were designed to provide illustrative insights into the requirement analysis process inside a single project, not to be representative of prerequisites control procedures generally. Case study A was chosen for further examination and description because it has the most in-depth data.

Misunderstanding of Client Wants and Needs

Based on the findings of the semi-structured interviews, miscommunication about what customers want and need has emerged as RSM’s top challenge. Most respondents believed that ambiguities should compromise the accomplishment of the overall mission and the client’s satisfaction (Faraji et al., 2022). Therefore, gathering information about the customer’s wants should be the first stage in developing the project. Inadequate completion of this stage makes it extremely difficult to complete the project successfully and achieve the desired end.

Conclusion

Organizing and controlling the flow of materials is crucial to any artistic endeavor. This study ranked the most significant elements impacting the procurement, distribution, and management of construction projects in India. Experts with more than twenty years of real-world knowledge have identified and vetted various relevant elements from the existing literature. Twenty-eight considerations were listed in their search questionnaire. All we looked at were India’s construction projects, so that is what we did. Information was compiled from general and specialty contractors and subcontractors involved in various construction projects. According to the investigation findings, managing materials is a top concern, even though they need more space or are being stored incorrectly.

References

Abdullahi, U., Bustani, S. A., Hassan, A., & Rotimi, F. E. (2019). Assessing quality management practice in the Nigerian construction industry. Journal of Construction Business and Management, 3(2), 17-25. Web.

Amusan, L. M., Osinowo, S., Osawaru, F. A. I. T. H., Awotinde, L., Adelakun, A., & Peter, N. J. (2019). The building informatics approach to modeling construction quality assurance parameters to prevent the structural collapse of the building. International Journal of Technology, 10(2), 386-393. Web.

Egwunatum, S. I., Anumudu, A. C., Eze, E. C., & Awodele, I. A. (2022). Total quality management (TQM) implementation in the Nigerian construction industry. Engineering, Construction, and Architectural Management, 29(1), 354-382. Web.

Faeq, D. K., Garanti, Z., & Sadq, Z. M. (2021). The Effect of Total Quality Management on Organizational Performance: Empirical Evidence from the Construction Sector in Sulaymaniyah City, Kurdistan Region–Iraq. UKH Journal of Social Sciences, 5(1), 29-41. Web.

Faraji, A., Rashidi, M., Meydani Haji Agha, T., Rahnamayiezekavat, P., & Samali, B. (2022). Quality Management Framework for Housing Construction in a Design-Build Project Delivery System: A BIM-UAV Approach. Buildings, 12(5), 554. Web.

Keenan, M., & Rostami, A. (2021). The impact of quality management systems on construction performance in the North West of England. International Journal of Construction Management, 21(9), 871-883. Web.

Luo, H., Ling, L., Chen, K., Fordjour, A. A. M., & Chen, L. (2022). Digital technology for quality management in construction: A review and future research directions. Developments in the Built Environment, 100087. Web.