PDCA

Safety is one of the main components of food quality. Therefore, quality management systems had received a wide development in food industry. They ensure food safety at all production phases and decrease of the customers’ possible risks. Total Quality Management (TQM) is an administrative approach, which is based on the organization as a system. TQM is a good fundament which can serve the basis for the quality management in all industries, including food industry. PDCA and Six Sigma methodologies are widely used in the food industry as TQM methodologies.

TQM focus on improvement in equipment availability, performance and quality with assuring health and safety of employees and protection of environment (Suresh, 2012).

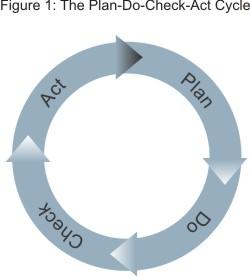

The PDCA (plan-do-check-act) methodology represents the simplest algorithm of the managerial actions aimed at achievement of its purposes in food industry. This methodology helps monitoring the quality of food products, declared by producers and indicators of quality, preferred by consumers.

The Plan-Do-Check-Act (PDCA) Cycle provides a simple but effective approach for problem solving and managing change, ensuring that ideas are appropriately tested before committing to full implementation (Mind Tools, 2013).

The quality management cycle in food industry begins from planning. Planning includes the establishment of the processes necessary for the achievement of the objectives, scheduling on the achievement of the objectives of the process and satisfaction of the consumer, planning of allocation and distribution of the necessary resources.

The “do” phase includes the search for the solution of the problem.

Check includes collection of the necessary information and control of the result on the basis of key performance indicators (KPIs), identification and analysis of deviations, establishment of the reasons of deviations in food industry.

The phase of “act” or “adjust” includes the measures aimed at the elimination of the reasons of deviations from the planned result, change in planning and distribution of resources.

This cycle, which is widely used in food industry, represents the essence of realization – the so-called “general functions of management”. It considers that these functions are directed at provision of the necessary conditions for the creation of qualitative food production and its high-quality use.

The closed cycle of the problems solution in food industry begins with the interrelation analysis between the results of activity and the reasons, causing them. One of the most important moments of the PDCA cycle is the stage of the check of result when any result is significant for the food company irrespective of the success or failure. The further administrative decisions are based on these conclusions. The database of the administrative decisions is gathered in a food company. Thus, the PDCA managerial cycle is successful if a food company’s goals are explained to each employee, and the company’s goals are definite, achievable and limited in time.

Six Sigma

The functional characteristics of the qualitative characteristics of food production are revealed at all levels of the functioning of the “Six Sigma” methodology through its quality management. “Six Sigma” is a statistical concept of measurement of a number of defects in parameters. The introduction of the “Six Sigma” methodology in food industry involves the changes in a corporate culture. After the introduction of this methodology a food company refuses decision-making, based on the subjective opinions, in favor of the analysis based on the real information and application of the statistical methods. “Six Sigma” is aimed at the solution of the problems of quality management in food industry on the basis of the statistical methods with an accurate orientation on indicative monitoring. The application of this methodology in food industry allows food companies to control and monitor the qualitative characteristics of the food products.

According to Larson (2003), the method of “Six Sigma”, widely used in food industry, is based on the following six basic principles:

- A sincere interest to a client;

- Management on the basis of true data and facts;

- Orientation to the process: process management and process perfection;

- Proactive (anticipatory) management;

- Cooperation without borders (a transparency of intracorporate barriers);

- Aspiration to perfection plus condescension to failures. (Larson, 2003).

A food company receives huge economic achievements at the expense of the decrease in all types of losses at the system approach to the introduction of the “Six Sigma” system – an active support and management participation, creation of a necessary infrastructure and technological support.

Table 1. The aims of the “Six Sigma” method and the tools of their achievement.

The food companies, using the “Six Sigma” methodology, achieve excellent financial results and develop more pragmatic plans allowing them to essentially improve the profitability of business and achieve its expansion. The “Six Sigma” methodology is the methodology serving for the measurement and an increase of a food company’s productivity by means of the detection of the defects in the processes of food production.

References

Larson, A. (2003). Demystifying Six Sigma: A Company-Wide Approach to Continuous Improvement. New York: AMACOM.

Mind Tools (2013). Plan-Do-Check-Act (PDCA). Web.

Suresh P.K. (2012). TPM Implementation in a Food Industry-A PDCA Approach. International Journal of Scientific and Research Publications, 2(11): 2012. Web.