Introduction

A streamlined supply chain ensures business efficiency and more productive business processes. Supply chain management involves the management of supply and demand, customer orders, inventory tracking, distribution channels and customer deliveries. Thus, in streamlining the supply chain, integration of all these business processes is essential.

However, the evolving global markets, stiff competition and technological advancements have made quality management in supply chains a challenge to quality managers. Supply chain management aims at enhancing sustainable organizational competitiveness and customer satisfaction.

Often, supply chain management (SCM) emphasizes on customer delivery at reduced prices while quality management emphasizes on quality of goods or services at reduced prices.

The article, ‘Developing global supply chain quality management systems’ by Kuei, Madu and Lin discusses “a conceptual framework for the integration of the two approaches; SCM and quality management” (2011, p. 4457).

The article identifies system, design and decision variables as integral to any global supply chain quality management (SCQM) strategy. By using in-depth case studies of multinational companies in Taiwan, Kuei et al identified four essential themes of SCQM strategy: design, SCM, human resource management and leadership decision-making.

According to Foster, quality management enhances communication in supply chains, which promotes partnerships along the supply chain and enhances customer relationship management (2009, p. 156).

Kuei et al describe the CRM, enterprise-planning systems (ERP) and product lifecycle management (PLM) as systems that facilitate collaborations along the supply chains (2009, p. 4458). Their framework integrates the principles of quality management in supply chains to enhance profitability and customer satisfaction.

The Quality Management Principles

Most multinational companies have adopted various models that incorporate quality management concepts into existing SCM models in order to confront the challenges of globalization. Kuei et al identify five main challenges that affect the supply chains quality: advanced technologies, environment conservation, partnerships, outsourcing and reducing wastes (2009, p. 4459).

These pressures call for the need for quality management in supply chains. Specifically, quality management addresses SCM inadequacies such as leadership in supply chains, creation of a collaborative culture, management of logistical processes and customer cost requirements (Goetsch, & Davis1997, p.148).

The article highlights outsourcing as a viable option to modern enterprises for enhancing quality management in supply chains relative to vertical integration. It influences partnerships, logistics as well as the management of the supply networks and improves core competencies and productivity when properly implemented.

Further, the critical factors in supply chains such as the management of consumer relationships, customer demand and multivendor interface require trust-based partnerships. The article identifies three key issues that can facilitate outsourcing as a SCQM initiative: creation of the CRM, decisions on outsourcing and management of logistics. One of the principles of quality management in supply chains is a cooperative relationship.

According to Foster (2009, p. 144), collaboration among the supply chain participants results to improved performance. People can achieve this through frequent communication and trust-based relationships among the supply chain partners. Therefore, a cooperative approach through teamwork rather than a competition contribute to improved performance of supply chains.

Sustainability in global supply chains is another aspect of SCQM. Kuei et al posit that sustainable economics with regard to environmental protection is essential in today’s market that is environmentally conscious (2009, p. 4460).

As a result, global enterprises should focus on environment protection initiatives such as recycling, inverse manufacturing, ISO 14000 certification and project assessment in order to remain competitive in today’s market. However, launching environmental protection initiatives in the whole supply chain often face leadership challenges.

Leadership in SCM is indispensable in the implementation of quality culture with regard to environmental protection. Gorst, Kanji, and Wallace (1998, p. 102) describe leadership as the base for quality management as they serve as role models to their employees to collaborate to improve the supply chain performance.

The development of a culture of quality and sustainability in the whole supply chain is under the influence of the top management.

Quality management in SCM also requires waste reduction especially during the manufacturing. Kuei et al argues that waste caused by over-production, poor inventory management and inefficient manufacturing processes has a significant impact on the overall performance of the supply chains (2009, p. 4461).

One can achieve waste avoidance through strategic evaluation of processes such as manufacturing, transportation and raw material selection. They argue that people have to manage these processes effectively to reduce wastage. In addition, they identify the six-sigma projects as essential in waste reduction along the supply chain.

Accordingly, Cavinato identifies an integrated process-production process, design process, delivery process and support process- among the supply chain members as critical for ensuring an efficient supply chain and minimizing errors in business and manufacturing processes (1992, p. 11). Thus, effective management of various processes is essential in waste avoidance along the supply chains.

Quality management in operations of the supply chain relies on the development of communities. In this way, the global enterprises are able to respond to customer needs in the era of globalization. Through community development initiatives and philanthropy, modern enterprises collaborate with other supply chain partners in strengthening communities as a corporate social responsibility (Cavinato1992, p. 13).

Thus, by developing communities, organizations must focus on the ultimate customer. According to Cooper and Elliram, customer satisfaction is central to SCQM (1993, p. 21). The customer is the central focus of community development in supply chains.

Another quality management strategy for SCM is the adoption of modern technologies. Modern technologies in managerial, manufacturing and business processes have benefits not only for SCM but also for ERP and CRM as well (Kuei et al. 2009, p. 4461). Modern technologies facilitate decision making and planning to meet customer demands and establish supply networks.

These technologies allow members of the supply chain to link one another and achieve overall competence and innovation. Cooper and Elliram (1993, p. 18) emphasizes the importance of information exchange along the supply chain especially with regard to improvement in the supply chain operation.

Exchange of product information, demand forecast and information on the supply market facilitates the performance of the supply chain.

The Quality Theory

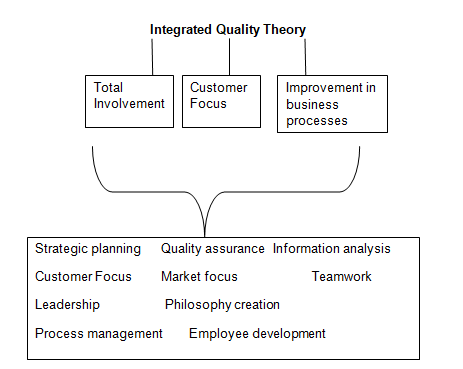

An integrated quality system in supply chains relies on three basic principles: cooperative relationships, customer focus and process improvement. Foster recommends an integrated approach to managing quality along the supply chains (2009, p. 149). He outlines a contingency perspective for integrating the quality principles in a supply chain strategy.

The contingency perspective identifies the aspects specific to a situation and recommends for contextual application of an appropriate theory as a unified SCM theory is lacking. According to Foster, to resolve the differences among the SCM theories, an integrated approach is noteworthy (2009, p. 154).

The integrated view encompasses various variables including leadership, quality assurance, employee improvement and customer focus. From the leadership front, leaders play a critical role through their decisions regarding quality improvement to achieve greater competitiveness.

In the article, the authors identify a hybrid approach to decision-making along different levels. According to them, these are fundamental to SCQM strategy. The article also adopts a contingency perspective with regard to decision-making tools in SCQM. The employee improvement through training enhances productivity and quality improvement in supply chains.

The article identifies three analytic hierarchical process (AHP) levels for quality improvement: tactical, strategic and environmental perspectives. From the tactical perspective, global enterprises must focus on employee attributes along the supply chain. Accordingly, top management must ensure competence development, behavior realization and creation of a quality culture along the supply chains.

Another approach of ensuring quality along the supply chains is through quality assurance. Foster posits that quality design inspection of products and business processes is essential in quality improvement (2009, p. 150).

The article reveals design for six sigma (DFSS) philosophy as a way of measuring and improving business processes. The aim of the DFSS is to prevent defects and reduce waste during business processes (Foster 2009, p. 149). The six-sigma management allows the identification, measurement and elimination of defects in a process to achieve a higher quality level.

Customer focus is another essential approach for quality improvement. Organizations must be customer oriented i.e. understand the customer needs and try to meet them (Foster 2009, p. 151). One can realize this through customer relationship management (CRM) approach (Kuei et al. 2009, P. 4457). The involvement of all members at different levels of the supply chain also contributes to quality supply chains.

Most importantly, strategic planning ensures that organizations manage their processes and activities for improved performance of the supply chains. In addition, continual improvement is essential to the success of the supply chains and achievement of greater organizational competitiveness. Thus, an integrated quality theory should encompass the principles of SCQM and the various variables of quality improvement.

Implications of the Author’s Findings to Practice

Based on in-depth interviews of senior executives, the authors identified four strategic areas with a potential for quality improvement in supply chains. These include the human resource management, the international standards, DFSS and supply chain management that are essential in achieving competence development and business growth.

Further, from the AHP analysis, the authors established that human resource management and global leadership are essential aspects of quality improvement in organizations in the current trends of globalization. This finding recognizes the need for organizations to focus on personnel and leadership development to remain competitive in the future.

The authors identify four aspects of personnel and leadership development: corporate ethics, change management, systems thinking and decision-making. The organizational commitment to personnel development stands out as critical to supply chain quality management in the modern globalized economy.

The authors propose behavior, structural and functional changes as well as competency developments in supply chains as ways organizations can mitigate the effects of globalization. Three issues of design components, hierarchy in decision-making and design in business processes are core to a quality global supply chain system proposed in the article (Kuei et al. 2009, P. 4463).

Conclusion

Global supply chains are essential to large enterprises as they allow them to compete effectively in the international market. However, SQCM is often a challenge to quality managers due to an increasingly competitive global market.

The principles of quality management in supply chains aim at improving quality to achieve profitability and efficiency of supply chains. Kuei et al framework focuses on systems, design and problem-solving variables in achieving SQCM. Thus, framework provides an integrated approach to enhancing the quality in the global supply chains.

References

Cavinato, J., 1992. Identifying Interfirm total cost advantages for supply chain Competitiveness. International Journal of Physical Distribution and Logistics Management, 27, pp. 10-15.

Cooper, M., & Elliram, L., 1993. Characteristic of Supply chain Management and the Implications for Purchasing and logistics Strategy. International Journal of Logistic Management, 4(2). pp. 13-24.

Foster, T., 2009. Managing Quality: Integrating the Supply Chain. Upper Saddle River, NJ: Pearson-Prentice Hall. pp. 156-172.

Goetsch, D., & Davis, B., 1997. Introduction to Total Quality: Quality Management for Production, Processing and Services. London: Prentice-Hall. Pp. 147-154.

Gorst, J., Kanji, G., & Wallace, W., 1998. Providing Customer Satisfaction. Total Quality Management, 9, pp. 100-105.

Kuei, C., Madu, C., & Lin, C., 2011. Developing global supply chain quality management Systems. International Journal of Production Research, 49 (15), pp. 4457–448.