Introduction

Background

Technology has advanced some of the world’s biggest industries today. Not only has technology been used to enhance processes but it has also been used to push each industry forward. Carvajal, Maucec and Cullick (2017) argue that the industry of the oil and gas is the world’s largest sector in terms of dollar value. There are several states that are known for their crude oil exports. Today, the US is the largest exporter of crude oil on earth.

More states that have mined large oil reserves include Saudi Arabia and other countries in the Middle East, states in North Africa, nations in Europe, Canada and the US. It is very essential to note that oil and gas industries are located in both developed and developing nations. However, much of the digital transformation has been driven by First World. This can be attributed to First World’s strong economies and accessibility to funds for research on technology. Interestingly, technology in oil and gas has been distributed to the different countries that produce the valuable natural resource.

Carvajal, Maucec and Cullick (2017) explain that the near equal distribution of technological advances in the field has allowed the growth of the industry. Despite this, it is ironical that many of the nations that have oil reserves are also considered Third World. Unlike other industries that have observed direct value creation from technology, the oil and gas industry use to be and remain affected by complex factors that have in turn made it a complicated sector. In fact, as Longde et al. (2015) observe, the complexity of the sector has led to the association of nations that produce oil and gas as cursed since oil-producing nations are either poor, at war, or both. One can argue that despite the challenges, the oil and gas industry can redefine itself through the use of digital transformation (Shukla & Karki 2016).

It is arguable that a large percentage of people working and making decisions in the oil and gas industry are from generation X. This means that they will be seeking to retire in the near future (Carvajal, Maucec & Cullick 2017). The upcoming generations are dependent, to some extent, on digital developments. It is critical that the generation that is in management right now lay foundations for the future leaders in the industry of oil and gas.

Since technology is already a big segment of the oil and gas industry, the current generation should strive to standardize the processes in the sector to make it easier for the next generations to manage the field appropriately. The additional fact that the industry is expected to decline in the coming years puts pressure on the use of digital transformation to, first, maintain the current reserves, and, second, prepare for transition.

This project report will determine how the mentioned digital transformation is currently influencing the industry of oil and gas. A global outlook will be adopted to cater for all the different technologies that are being used in the industry. As mentioned previously, the industry has incorporated technology in various processes and services. This report will, however, only focus on technological expertise among the current staff working in the industry. A literature review will be included to highlight similar studies that have been done. The research project will suggest the use of both secondary and primary data collection methods to advance the research objectives.

Motivation to Study the Topic

The motivation to study the topic stems from the importance of the oil and gas industry. Currently, there are many sectors that fully depend on this industry to function. Its importance is more prudent due to the fact that technology has made it more efficient. The inclusion of AI and other types of technology have made it easier for the parties involved in the industry to efficiently and effectively control the mining and use of oil, gas, and their by-products.

Gap in the Literature

One of the gaps in literature that was noted during the compilation of this report is the fact that there is relatively little research that has been done on the impact of AIs on the industry. Whereas there are many studies that have been conducted in regards to how general technology has been used, very few have focused on the impact of AI in the sector.

Aim/Research Question and Objectives

The aim of the research is to investigate how digital transformation has affected the oil and gas industry.

Research question

How has digital transformation affected the oil and gas industry?

Research objectives

- To establish the different ways digital transformation has impacted the oil and gas industry.

- To investigate how digital transformation has affected both internal and external communication in the oil and gas industry.

- To discuss the relevance of digital transformation in research and development in the gas and oil sector.

Overview of Methods Adopted

This study will use both primary and secondary approaches in collecting and analyzing data. The secondary data will be collected through desk top research. On the other hand, primary data will be collected through a questionnaire made up of 21 interview questions. The questionnaire was developed through secondary data and the gap in literature that was observed during the development of the literature review. The use of the secondary data allowed the researcher to identify some of the questions that similar studies had asked and also some of the gaps and areas of possible research suggested by previous scholars. It is also important to note that the study used formal approaches to ensure viability of the results.

Structure (Outline) of the Chapter

- Background

- Motivation to Study the Topic

- Gap in the Literature

- Aim/Research Question and Objectives

- Research question

- Research objectives

- Overview of Methods Adopted

Summary of the Chapter

The first chapter of the report focuses on the introduction of the topic. The chapter gives an overview of the background of the topic. Ideally, the industry has changed over the last couple of decades. This is attributed to the fact that the natural levels of both gas and oil have been depleting over the years. This, and the fact that the industry has largely been accused of supporting environmental degradation due to the adverse impact of mining have ensured that although the oil and gas industry is one of the largest in the world, it is also one of the most contentious sectors. This argument serves as one of the elements of motivation to do the study. Additionally, motivation stems from the growth and impact technology has had on the industry.

Literature Review

The digitization trend is widespread and in demand in various areas. Coreynen, Matthyssens, and Van Bockhaven (2017, p. 44) define this concept and note that it implies “the growing use of digital technologies for system, connecting people, companies, services and products”. In relation to the oil and gas industry, this course is relevant today, when many states sell these natural resources actively and, in many respects, form the domestic economy and budget due to them, improving the principles of extraction and production is an essential task. Shukla and Karki (2016) note that introducing innovations in this field is a demanded activity. Therefore, a focus on digitization and connectivity are the crucial aspects of the industry of the oil and gas.

Advantages of Digital Transformation in the Industry of the Oil and Gas

The digitization of industrial facilities in the industry of the oil and gas is inextricably linked to the issues of ensuring production safety. Innovative IT solutions aimed at speeding up the automation process and optimizing many production processes in enterprises have found wide application in the market. For instance, according to Longde et al. (2015), the impact of digital technologies is becoming wider, which allows improving not only production processes but also other significant aspects, for example, increasing the organizational efficiency and quality of employees’ operation.

At the same time, innovations in production and processing, the digitization of workflow, and other activities are strategically important steps for any company on the path to its digital future. Koplos, Tuccillo, and Ranalli (2014) evaluate the success of the Baker Hughes company and give the statistical results of introducing digital technologies in 2012. According to the results of the assessment, during that period, the corporation drilled “36,824 oil and gas wells”, which was a significant step towards leadership in the industry (Koplos, Tuccillo & Ranalli 2014, p. 45). Therefore, the provision of manufacturing with high-tech equipment contributes to productivity and the expansion of market influence.

It is essential to bear in mind that for the oil and gas industry, security is a key issue that digital technology can solve in many ways. As Siebel (2017) points out, using predictive analytics eliminating the technological failures of production assets or costly equipment downtime, as well as minimizing the human factor, contribute to the normal operation of all systems. The functions of modern digital devices that help the work of the oil and gas industry serve as the tolls reducing people’s participation in the monitoring process, thereby automating the monitoring of activities and allowing employees to focus on the ways of increasing production results (Siebel 2017; Longde et al. (2015). These advantages prove the relevance of implementing high-tech equipment in this area.

Another essential advantage of digitization is technological solutions that are used throughout the world to improve production efficiency and the current operational activities of employees. This is important since, for instance, at those enterprises where flammable chemicals are part of the environment, sparks caused by the operation of mobile phones or other portable devices may provoke emergency situations. According to Longde et al. (2015), even the temperature of their surface can be dangerous for both employees and enterprises as a whole.

The authors argue that, as companies are increasingly merging with digital technologies, their most important system functions in the near future may directly depend on the availability of computer solutions (Longde et al. 2015). The reliability and durability of such equipment are the key factors for successful work. Therefore, equipping employees with mobile devices that are suitable for work in high-risk enterprises will allow them to collect, use, and access information in places where it was previously impossible, and will also help companies save and optimize operational data and generate business ideas.

Digitization and Automation

With reference to the oil and gas industry, such terms have become common as oil production digitization, smart wells, processing automation, and other aspects of activities. The key role is traditionally given to minimizing a human role and making the processes of formation and transmission of information and data computerized. However, the considered examples of using information technologies in the oil and gas industry meet these goals.

In order not to confuse the two concepts, it is essential to consider their features. Carvajal, Maucec, and Cullick (2017) offer to draw attention to the digitization concept and compare this principle of work with automation as one of the varieties of advanced production. As the authors point out, both directions are related to increasing the role of information technologies; nevertheless, a qualitative difference is formed in the depth of their application (Carvajal, Maucec & Cullick 2017).

Automation, as a more traditional method, includes information technology into the production, thereby reducing the cost of the manufacturer. At the same time, a specific business model remains unchanged – making a profit by selling products. Digitization is the result of the enhanced implementation of information technology until the moment of a qualitative change in business (Carvajal, Maucec & Cullick 2017). As a result of increasing the level of the application of modern technical mechanisms, the transformation of the business model of an enterprise occurs, which causes modernization. Ventures change their operating modes from the sales of products to the provision of services with the use of technologies that include manufactured products.

In relation to the oil and gas industry in the conditions of a new paradigm and, in particular, the Baker Hughes company, natural energy resources are not the final product. With the classical methods of work, suppliers’ responsibility ends at the moment of transferring the resource and receiving payment. In this case, automation facilitates the internal processes of a manufacturer, reduces its cost, which, in turn, may affect consumers by reducing prices.

The notion of digitization goes further because, as Kapitonov et al. (2017) state, the use of information technologies creates values for buyers, which means that the commercialization of modern equipment is performed. In this case, a manufacturer is to expand the area of responsibility and penetrate into the needs of customers, thereby selling not raw materials but, alternatively, the final result of utilizing and processing it. The use of information technologies offers opportunities for such interpenetration. At the same time, smart devices installed in wells, security systems, and other areas do not affect buyers of the fuel and are tools of manufacturers’ internal costs (Kapitonov et al. 2017). This mechanism explains the relevance of digitization from customers’ perspective.

In its classical definition, the oil and gas industry, in specific, the extraction, processing, transportation, warehousing, and sale of mineral resources, hardly suits the concept of digital innovations. Vorob’ev et al. (2017) argue that the transition to a new regime means forming a fundamentally new service sector, as well as non-standard value-added chains and pricing. Nevertheless, the issues of the automation of the raw materials economics are relevant and significant in the context of modern modernization practice.

According to Kapitonov et al. (2017), implementing automation processes in the oil and gas industry proceeds gradually but steadily. For instance, the rapid exchange of data with the exception of the human factor allows creating a transparent market for supply and demand and (Carvajal, Maucec & Cullick 2017).

Some suppliers are in competitive advantage, in particular, those who are able to maximize flexibility to meet the needs of energy buyers, while optimizing production risks associated with uneven consumption (Carvajal, Maucec & Cullick 2017; Kapitonov et al. 2017). Therefore, the concept of digitization as the final stage of the modernization of the oil and gas industry has many conventions and certain nuances affecting contemporary innovations.

Existing Digital Technologies Utilized in the Oil and Gas Industry

Combining the main production structures in the oil and gas industry with the help of telecommunications into a single system allows monitoring all the technological processes of exploration and production of valuable energy resources. Digital innovative technologies developed to date include a wide range of devices and mechanisms that contribute to more productive mining. Since the Baker Hughes Corporation occupies one of the leading positions in this sector, the introduction of appropriate technologies helps the company to develop steadily and maintain market competition by involving the necessary tools and instruments.

According to Harthy et al. (2018), in the field of exploration during development, passive well monitoring is applied, which is a successful technique for analyzing the volume of potential resources. Also, the authors note that for ecological protection, environmental monitoring in real time is utilized (Harthy et al. 2018). This operation allows preventing destructive effects on the environment through the preliminary assessment of the impact of drilling and production regimes, thereby taking the necessary safety measures. All these digital technologies serve as valuable tools in promoting the growth of the oil and gas industry.

Organizing the management of oil production from remote centers by using electronics means not only improving production or expanding the use of digital technology but also changing the direction of work. Hajizadeh (2019) notes that the integration of data collection and management systems concerning the state of wells and other components allows exploration and mining organizations to make effective decisions.

This opens up the possibilities of analyzing the current situation, developing an optimal management strategy, and reducing inevitable costs. Kamsu-Foguem (2016) also confirms the relevance of these mechanisms but, nevertheless, note that despite the advancement of technologies, manual inspection is mandatory to avoid unforeseen situations and eliminate errors. This recommendation applies, in particular, to the field of extraction.

In general, technologies for optimizing production and forecasting help prevent accidents. According to Hajizadeh (2019), such a direction as machine learning is in demand in modern realities. The author provides statistics on the progress of this field and argues that, by 2018, the number of studies in this area has increased significantly (Hajizadeh 2019). Therefore, both manufacturers and researchers are interested in studying innovations in the oil and gas industry.

Predictive Analytics as a Component of Digitization

Oil and gas companies conduct out maintenance work regularly due to different reasons, for instance, the improvement of activity stages or combination of technologies. However, the reliability of equipment may remain low, and the overabundance of maintenance personnel may entail undesirable costs. In order to solve these problems, Davis et al. (2017) offer to pay attention to the predictive analytics system. Installing sensors and automating the monitoring process can reduce the number of repairs, minimize tools downtime, and determine the optimal number of employees required to perform the specified work.

In addition, as the authors point out, with the help of modern technologies, it is possible to study a field at all stages of its development remotely (Davis et al. 2017). Therefore, such a predictive activity is relevant to the industry under consideration.

Specialized mobile applications allow controlling equipment modes remotely and obtaining deep analytics, including the analysis of products, regularity, and quantity that corporate and retail customers buy. According to Schäkel, Janssen, and Brecher (2019), when relying on these data, one can increase the efficiency of gasoline supplies to retail networks of gas stations or the fleets of industrial companies.

Oil and gas companies, in particular, Baker Hughes, actively introduce mobile applications for retail consumers (Koplos, Tuccillo & Ranalli 2014). Such tools can also be issued for corporate customers to check the availability of manufacturers’ products and redundancy. Stakeholders may consolidate the accumulated data on demand and distribution with data on production and processing. The efficiency of all the processes will increase under the conditions of complex rather than scattered digitalization and competent personnel management.

Many processes at oil and gas fields depend on qualified specialists, and their permanent presence there is not necessary. Nevertheless, in case of emergency situations, companies are forced to constantly keep on the platforms a large number of employees. To bring them there if necessary is an unreasonable decision since their delivery, as a rule, to hard-to-reach deposits, is financially costly. The augmented reality technologies that Yu et al. (2015) describe allows employees at oil and gas fields to interact with an expert remotely, consult on the ways of troubleshooting, and perform other significant tasks.

The authors note that wireless technologies have rather compact designs, which, at the same time, is an advantage in the conditions of limited space (Yu et al. 2015). Therefore, this method of remote access is an important phase of a predictive control practice.

One of the most debated fact is the inclusion of artificial intelligence (AI) in the oil and gas industry. This is not a common occurrence although there are studies that support the incorporation of AI in oil and gas industry foundation on the impact it has had in other industries.

Fattouh, Poudineh and West (2019) argue that the inclusion of AI in the oil and gas industry has been embraced by few companies due to the sensitivity of the industry. for example, bakerhughesc3.ai has advanced the energy sector. This is a a joint venture collaboration between Baker Hughes and C3.ai which was announced by the two companies 2nd half 2019. This newly established JV is aimed to enhance the production of oil filed using Al to convert the oil and gas industry in several ways. Additionally, one of the commonly referred AI in the oil and gas industry is Sandy, a cloud based AI that was built for BP company.

The AI was tasked to interpret geophysics and project information for efficient and fast decision making. This goes to show that AI and digital transformation as a whole can be used to connected difference components of the oil and gas industry (Ajaero et al. 2017). Additionally, the UK government launched the National Data Repository, an AI, in 2019. Arguably, the future of the oil and gas industry is in AI. The reality that there is need to document the management of the oil reserves necessitated the development of the National Data Repository in the UK. This just goes to show the importance of digital transformation in the industry.

One of the reasons why AI has become so important in oil and gas is the fact that it is a depleting industry. Despite the fact that national reserves are low all over the world, the industry has to adapt to the changing circumstances as the industry is still valuable. The push for digital transformation is based on two main ideologies. The first is that an AI will offer more effective efficient ways of managing the industry. Thus, even with the depleting national reserves, AI’s can be able to calculate the number of years natural oil and gas will exist in the world (Pagani & Pardo 2017). Secondly, the AI will also be able to diagnose other possible ways of stretching out the remaining reserves to last the maximum time possible.

Siebel (2017) agrees that AI’s are able to run many possible diagnostics at the same time. Thus, they save time and costs that human resources would have otherwise spent doing the same task. This is critical in the oil and gas industry as the industry is tied to other social factors. As stated previously, the oil and gas industry became and has been blamed largely for environmental degradation all over the world. The mining procedures combined with the effect of the by-products has led to severe degradation of the environment. It is arguable that the use of AI in the industry will help lower chances of such happenings in the future and give the oil and gas industry more advantage in helping to save the environment.

The issue of knowledge management and communication is also enhanced by the use of artificial intelligence. Hansen and Mahmood (2017) confirm that there are two main reasons why knowledge management should be tied to AI in the oil and gas industry. The first reason is to ensure proper management and retrieval processes. Khodabakhsh, Ari and Bakir (2017) denotes that the retrieval of needed documents and project information should be timely if they are meant to be effective.

Due to the large amount of data (big data as it is called these days) that has already been collected in the industry, it takes a lot of time for human beings to retrieve the needed information for a project or for critical decision making. AI’s are not only efficient as they sought the data and information, but also because they can easily retrieve the same on command. There are several other examples of the utilization of digital transformation in the oil and gas industry as well, which include the ability to product failures, enhance efficiency, utilize best practices and many others.

Also important to note, AI has recently been used for production optimization. Like all other industries a lot of the raw materials end up as waste due to poor production optimization. Shukla and Karki (2016) explain that using AIs can change this as they can ensure effective and efficient use of all raw materials. The suggestion here is that the AI would also be able to detect new by-products that can be used. Therefore, digital transformation can reduce the percentage of waste developed through the production process.

According to the secondary data collected, digital transformation can also enhance customer relations. Currently, many companies are using chatbots in their websites. However, there are very little companies in today oil and gas industries that have adopted this technology. The assumption is that clients of oil and gas companies in this industry do not need to chat with the companies. Pagani and Pardo (2017) explain that this is a wrong assumption as all types of consumers prefer fast and direct interaction with the companies they are buying from whenever the need arises. The use of chatbots in the oil and gas industry drive transform how these companies interact with their clients. In turn, with better end user relations comes better profits and more added value.

Ideally, there have been suggestions on how AI can save businesses and lives. Hajizadeh (2019) explains that the use of AIs can help reduce the number of fires in gas stations significantly. One of the leading causes of fires in gas stations is cigarette smoking. Hajizadeh (2019) explains that AIs can detect cigarette fumes and ether notify the attendant in the gas station or turn on the alarm immediately. This warning can lower the lives and properties lost due to gas station fires. Currently, there are some companies that use AI powered cameras to detect any dangerous activities to ensure they are stopped before they become hazardous.

Hajizadeh (2019) argues that the most important link between AIs and the oil and gas industry is the ability of the AI to explore new opportunities within the industry. Again, as mentioned, investors in the industry are being pressured to stop mining natural oil and gas due to their depleting reserves. Apart from proper management of the reserves, AIs can be used to effectively seek new places where oil and gas can be mined and how to optimize and find new ways to maximize production from exacting fields. Additionally, other opportunities for resources that work the same as oil and gas can be easily sought out with the help of AIs.

Despite the numerous advantages that AI has in the oil and gas industry, very few companies are currently using the technology. One of the reasons for this is the cost of installing AI in the businesses. Hajizadeh (2019) confirms that the incorporation of the AI into a company’s processes and operations can be very costly. However, the one-off cost of installing the AI will save the company a lot of money in the future. It is critical to note that the AI will need maintenance, and this is part of the costs companies have to bear. Any company in the oil and gas industry that seeks to invest in digital transformation has to be willing to constantly maintain the AI in order for it to be effective.

The predictive nature of digital transformations and AI also make them a great addition to the oil and gas industry. As stated earlier, the AI is able to run hundreds of possibilities and diagnostics at the same time. Thus, it is able to come up with the maximum possibilities a business can face in its near future. This information is important for fast and efficient decision making. It also ensures that the company using the AI has a competitive advantage over its rivals.

It is important to point out that digital transformation has its limitations. Some companies have adamantly refused to use any form of AI in their processes due to some of the limitations and possible challenges associated with the use of this advanced technology. The first cause of concern is the cost of investing in AI. As stated, it can be very costly to both incorporate, maintain an AI and having the right resources who can operate such advance technology in an efficient way which have an added value to the company. A second limitation of the technology is that it replaces human workers.

Arguably, this is an ethical concern as people have lost jobs due to the proper functioning of AIs and other digital transformation innovations. Unlike human beings who get better with experience, AIs can only be improved through updates and different versions.

This can lead to loss of critical organizational knowledge that would have also been important in decision-making. Whereas creativity is not a big concern in the oil and gas industry it also worth noting that the use of AIs might also lead to lack of creativity in the industry.

Additionally, AIs are computer-based systems, therefore, can be hacked. Siebel (2017) notes that this is the biggest fear of companies that are using AIs and other digital transformation strategies in the processes and operations. Hacking of AIs can lead to loss of data and also expose the company’s strategies. Such an act would leave the affected oil and gas company exposed to its competitors. Technology experts have argued that there is very minimal chances for AIs to be hacked. This is mainly due to the fact that the artificial intelligence will realize immediately anyone tries to hack them and also the current increase use of cybersecurity.

The system will then send the administrator a notification and suggest possible actions to ensure safety of data and other information. Additionally, the technology experts stress that just like other computer software, AIs have to be constantly updated and maintained to ensure they do not lose any critical data and project information.

The questioner using the primary data collection shows that there is a quite good understanding from the employees’ participation in the survey at Baker Hughes Company toward the need of AI and digital transformation in the industry. This also come with the fact that the company is moving toward becoming an energy technology company leveraging a big portion of its change moving in the direction of Al and digital transformation, a clear move in this direction is the established new JV of bakerhughesc3.ai which focus on this path of AI to improve reservoir recovery and optimize production.

The survey result support this outcome and confirm the direction from the feedback of the participants. It is clear that Baker Hughes as a company is moving solidly and aggressively in the direction of digital transformation leveraging AI to support its progress internally, with their customers and be ahead of the game when it come to new technology adaptation and implementation in the oil and gas industry.

The survey also highlighted that the biggest challenge for Baker Hughes Company in moving more in the digital transformation from the view of the participants is Lack of funds to set up technology needed for digitalization, when discussing this further with the participants, it was clear that this is due to having proper justifications from the requester side to the management to move with the fund. The company is welling and have the full motive and interest to move toward digital transformation with more effective AI implementations, however this needs to be controlled in a way to make sure that the resources needed and which will be deployed for such transformation is placed in the right place and investment and spends are managed wisely.

Key Advantages and Challenges

When summing up the findings of the presented academic sources, the results of the review may be grouped on the basis of the criteria of merits and difficulties. Digitization in the oil and gas industry is a complex and multi-stage process that is characterized by many nuances. Despite the large number of benefits that both suppliers and buyers receive due to innovation in extraction and production modes, difficulties occur inevitably. Table 1 presents the types of main advantages and challenges that arise in the development of digitization in the oil and gas industry.

Table 1. Advantages and Challenges of Adopting Digitization.

Theoretical Framework

There are several theories that can be used in this research project. The first is the stakeholder theory which was advanced by Klaus Schwab. The theory explains the relationship between a business and its different constituencies (Davis et al. 2017). According to the theory, there are several constituencies that make up the structure of any business. These constituencies are customers, investors, suppliers, creditors and surrounding communities among others (Bechtsis et al. 2017). Arguably, it is these constituencies that grow an industry. Additionally, such a system works like a machine, where individual segments have to work together in order to sustain the business. The theory can be applied in the discussion on digital transformation in the oil and gas industry.

Koplos, Tuccillo and Ranalli (2014) explain that the technology that has so far been used in the industry has been to make production of oil and gas and their by-products more efficient. In line with this, the quality of the products has also been positively affected. Therefore, looking at the mentioned constituents of a business according to the stakeholder theory, it is clear that all will be affected by the digitization of the industry’s processes (Willow 2016).

Since the cost of doing business will be lowered, the different companies in the sector will be able to pay off their debts easily. Additionally, oil and gas products will be more affordable and of higher quality for the consumers. Suppliers will have an easier time getting their product orders and payments afterwards as well as a seamless digital system will allow the industry to prioritize better.

A second theory that progresses the discussion on digital transformation and ues of AI in the oil and gas industry is the diffusion of innovation theory. Guseo, Mortarino and Darda (2015) clarify that the diffusion of innovation theory suggests that a product will eventually spread to a specific group of people if the right circumstances are ensured. There are several things that would make this possible. One such factor is communication and knowledge sharing, which also ties to the first objective of this research project. Communication refers to how the target group of people receives information about the new product that is to be launched.

Arguably, efforts by both technology experts and oil and gas experts are required to make a viable technological advancement. However, the way these experts communicate the importance of the product to the industry will determine whether it is adopted or not. On the same note, the way the knowledge gained is distributed to all relevant parties will determine the success of the product.

It is important to note that the diffusion of innovation theory does not cater for the constant need of refresher trainings in the target population. Capello and Al-Humoud (2016) explain that digital transformation requires a constant understanding of the changing needs of the industry. These changes might require new technology or a refresher of the same. It is these changes that also denote the need for software and other technology updates. Notably, the oil and gas industry has entirely embraced technology and its advancement and it is for this reason that it is considered the fastest growing industry in the world (Perronsa & Jensen 2017). The diffusion of innovation theory is also important in this discussion as it depicts the importance of assessing the right target audience for any oil and gas industry technological product.

The third theory that ties closely to the discussion is the techno-centric knowledge management theory. Cooper (2018) defines the techno-centric theory as a philosophy that highlights the importance of having the right processes for information flow. Arguably, this is the most relevant theory for this discussion. Indeed, technology has enhanced how communication and information flow happen in the oil and gas industry. For example, there are several applications that are currently being used to share and store information related to the industry.

The techno-centric theory of knowledge management places technology in the middle of a business. Siebel (2017) explains that corporates, governmental and non-governmental agencies all depend on proper knowledge management to advance their core businesses. The fact that the oil industry combines all these different stakeholders together makes knowledge management that more crucial. Since oil and gas are a natural reserve, they are owned by the different states where they are mined. However, corporates are invited to build the factories and industries that mine and produce the by-products of the oil.

On the other hand, the non-governmental agencies hold the other two parties accountable for the impact of the mining, including the advancement of both the industry and the communities around the mines. Ideally, best way to ensure that all the information collected and even shared with these three parties is safe and secure for future use is through technology.

Research Methodology

Research Philosophy

A research design is a method of collecting and analyzing data in research. There are various types of research designs. This study will use both primary and secondary approaches in collecting and analyzing data. The primary approach will involve the use of a questionnaire to gather required data. On the other hand, secondary sources will involve the use of literature and previous studies to satisfy the research objectives. There are four main reasons why these two methods were selected for the research design, two for each approach.

Khodabakhsh, Ari and Bakir (2017) explain that bias in the collection of primary data can occur due to several factors. First, the interviewee can show bias based on the fact that they feel pressured by the interviewer’s presence to state what they assume is the right answer. Additionally, the interviewee might want to prove a point to the interviewee by providing answers they believe are correct. On the other hand, interviewers can be biased based on the interviewee’s appearance and manner. It is important for the interviewer to develop a comprehensive method of choosing the sample population in order for him or her to trust the opinions and beliefs of the target audience.

The removal of bias in any research project is critical in ensuring valid results. This is especially so if the results are to be used as a reference in the future. It is important to note that the researcher managed bias based on the fact that the research was done in one company by identifying, separating and interviewing the sample study at the same time. This is one of the reasons the research assistant was needed.

On the other hand, secondary data collection involves the collection of secondary sources on the same topic. The literature review done is part of the secondary collection of data. Whereas the literature review highlights some of the studies done in regards to digital transformation in the industry of oil and gas, the discussion part of the project report draws conclusions from the highlighted points. One of the benefits of the collection of secondary data approach is that it allows the researcher to understand what has happened in the industry in the past. This sets a foundation for the research project.

Secondary sources can either support or critique the arguments and recommendations given in a research project. For this particular research project, both critiques and supportive debates will be highlighted. This also ensures that the research project has minimal bias. Hansen and Mahmood (2017) goes further to explain that this approach ensures that the public trusts the study done.

Research Context

There are two main things that have to be considered when talking about the research context. The two are the transitioning of the oil and gas industry and the effectiveness of skill and knowledge transfer in the industry. The world has been transitioning from the oil and gas industry over the last couple of years. One of the reasons for this is the point that natural oil and gas reserves have been lowered tremendously due to unsustainable mining.

Hansen and Mahmood (2017) explains that the main producers of oil, that is the Middle East and North Africa region, has been encouraged by economists and environmentalists to significantly reduce the amount of oil and gas they produce. This transition makes it necessary for people to understand the lessons learned by the countries on mining these natural resources. One can argue that the transitioning of the industry has been positively impacted by technology. Therefore, there is need to also determine how this digital transformation has affected the industry.

Importantly, there are new states and regions that have taken up oil and gas mining due to recent developments. Debatably, the industry can only grow with the new mining areas protected sustainably through digital transformation. One of the common innovations that is being utilized in the recent mining for oil and gas measures the natural oil reserves to allow calculations on how to sustainably mine the resource.

Additionally, such countries that are realizing oil deposits can learn from others such as the MENA region. An effective way of ensuring learning is through digital means. Jacobs (2019) explains that sharing of knowledge has been made easier through digital platforms such as eLearning platforms and so forth. It is critical that nations that have already gone through the process of mining oil and gas document their knowledge clearly and share the same widely for the benefit of the entire industry.

To fully capture the two objectives of the research project, the study was done in Baker Hughes Company. This is the world’s only full stream company in the oil and gas and is moving forward as an energy technology company. The company was selected because it has been using several digital transformation approaches in its daily processes. Secondly, the company has a good number of accessible employees who will be targeted for the primary data collection. The research used a sample population of 10 people. The sample study was made up of 3 women and 7 men. The reason why there was a difference in gender is the fact that more men work in the industry as compared to women. Due to this, gender was not used as a variable as any point of the study.

Additionally, the research sample was made up of people between the ages of 23 and 60. This was so as to see the difference in digital uptake between people of different ages. It is important to note that the sampling done to capture the right people to be interviewed was random. This means that a computer generated software was used to identify the people who were interviewed. The random sampling ensured that there was no bias in the selection of the participants.

Research Approaches

The research study uses inductive research approach, where the researcher seeks to develop a theory as opposed to testing one. In line with this, the researcher seeks to take the specific observations offered by the sample size and applying those to get a larger and more general observation.

Research Strategies

The study will use the survey research strategy. This is both a qualitative and quantitative approach, thus, makes it a great choice for the study.

Time Horizons

This research study will be cross sectional due to the fact that it is a one off. The participants will not be engaged further after they give their responses to the questionnaire created.

Procedure

The study took a formal approach to ensure viable results at the end. First, the researcher prepared the secondary data through desktop research. This research then informed the literature review of the study. It is essential to note that all the sources that were used in the literature review were carefully selected to ensure reliability. Secondly, the research prepared the research proposal which was then approved for the study. At this point, the researcher prepared the research questionnaire that was used to collect the primary data. The process of preparing a good questionnaire is complicated as it involves a lot of consultations. The end result was a questionnaire with 21 questions that sought to get answers on the research objectives.

Before data collection, the researcher selected one research assistant who was well versed with the academic research process. The assistant was used so as to allow the whole process to be done in the shortest time possible considering the length of the questionnaire. The research assistant was trained on how to conduct research without bias. They were then given a sample population of 3 people to test the questionnaire and research design. It is critical to point out that the testing was to ensure that the questionnaire was well understood among the target population and that no data was missing from the collection tool. A few changes were made after the testing to create the final questionnaire (Appendix 1).

The researcher then conducted the research study with 10 staff from Baker Hughes Company. After the study, the data tools were collected and data analysis was then conducted. This process analyzed the given data based on the research question and objectives that had been set out at the beginning. A report was then written to compile all the data that had been collected and the data analysis done. This report incorporated the previously done literature review and drew out conclusions of the study.

Data Collection Methods

As mentioned there are two data collection methods that were used in the study. The two are secondary and primary data collection methods. Each of these methods has its advantages and disadvantages. Secondary data collection was used to set a foundation for the study. The initial readings allowed the researcher to draw out the research proposal and even come up with a viable research question. These were then used to develop the research objectives. One advantage of secondary data collection is that it is not costly. The desktop research did not require any budget to complete. All the resources were found online in the forms of books and peer reviewed journals. This was a critical decision due to lack of organizational or sponsored funding for the project.

Another advantage of secondary data collection is that it offers other scholar’s experiences dealing with the same topic. The different studies that were conducted previously ensure that the secondary data collected lacks bias. The additional fact that the secondary data has already been analyzed and conclusions drawn ensures that little time is required to validate and even use these sources. One way of ensuring reliability and validity of information is checking whether they have been peer reviewed. This is the primary reason why only peer reviewed journals were used as secondary sources of data collection. Additionally, secondary data serve as a basis for comparison.

This is in line with the primary data that the researcher will collect. Towards this end, one can also argue that secondary data helps make primary data specific. This is due to the fact that the secondary data shapes the vision of the researcher to a more specific direction.

On the other hand, primary data offers the researcher an opportunity to get raw data on the actual beliefs, experiences, concerns and opinions of the sample population. One of the advantages of primary data collection is that it is specific. The researcher can develop questions used for primary data collection that revolve around the topic of discussion only. Additionally, the specificity of primary data allows the researcher to prove their research hypothesis.

Secondly, primary data collection is more accurate. This can, however, only be achieved if the right questions are asked. The drafting of, for example, a questionnaire, has to include all the right questions in order for the right data to be captured. Additionally, primary data collection ensures current and up-to-date information is used in the research study. Since secondary sources of data are done in the past, their results have to be compared with current results in order to establish any growth, changes in opinion and other similar advances in the field. Additionally, primary data collection makes the researcher the owner of the information.

Therefore, the researcher can use the information in other projects as long as s/he does not break the confidentiality clause of the first primary data collection. It also ensures that one’s work is used as a reference for other works done in the same field.

The combination of both secondary and primary data collections ensures that no bias is recorded in the process. Secondly, it also ensures that the strengths of the two approaches are enhanced for the benefit of the research study. None of the approaches is superior to the other as they both offer great benefits for the data collections and analyzing. The next unit will discuss the different questions that the target audience was asked.

Discussion of questionnaire

How the Questionnaire was Developed

The questionnaire was developed using previous knowledge that was attained through secondary research. Additionally, the gap in literature that was previously identified also allowed the researcher to develop the questionnaire.

Data Analysis

There are various data analysis approaches that were considered for the study. However, two approaches were selected due to their reliability and also the structure of the study. The two data analysis methods selected were the quantitative and qualitative approaches. Each of the approaches has its advantages and disadvantages. One advantage of the quantitative design is that it summarizes the data into numbers. This makes it easier for decision-making and drawing out conclusions of the study. Additionally, it also allows for statistical testing of the data to ensure they are reliable and factual. Unlike common belief, the quantitative approach is very descriptive as well.

The second advantage of the quantitative approach is the availability of various t-tests that can be used to analyze the data. This is important as it allows a researcher to get different analyses of the same data. The analyses that come up similar are proven to be viable for the study while new angles can be worked out at the same time.

A third advantage of quantitative approach is that it can be used on a large sample population. The term “large sample population” refers to studies that involve over 300 people, are done across different organizations or represent a larger target population. The study used a sample of 10 participants. However, it is critical to note that this is a representation of a wider population that could not be easily accessed at the time. It is due to this that a combination of both quantitative and qualitative was used.

On the other hand, the qualitative approach of data analysis was used as the sample population was relatively small. This makes it easier to draw out conclusions in the qualitative design. Additionally, since the sample is significantly small, the researcher does not need much time to analyze the data collected. It is prudent to note that the qualitative approach to data analysis highlights the characteristics and opinions of a subject. This is essentially what the research question and objectives are trying to do, making this approach superior.

Unlike quantitative design, qualitative design analyzes routines, needs, and human behavior as well. The researcher sought to document these in order to understand the need in the industry for data transformation. One of the assumptions of the study is that there is a great need for data transformation in the industry and some of the impacts of the transformation enhance this need, this is can be noted in the way the industry is moving and the bush from customer in this direction to enhance the operations both for internal company use and external customer benefit. It is upon this premise that the argument of knowledge sharing and proper documentation is based.

The flexible nature of the qualitative design also makes it applicable in this study. This is due to the fact that the questionnaire, as mentioned, uses a semi-structured format. The format allows for some questions to be determined from the beginning of the survey while others are determined as the interview progresses. Importantly, the semi-structured design also collects different variables that were not initially included in the study. This is especially the case for the open ended questions used. Overall, it is important to note that the combination of the two approaches also minimizes their weaknesses and limitations. This ensures a superior data analysis design that can be trusted by peers and can be considered a reliable approach.

Validity and Reliability of Methodology

There are several things that the researcher uses to ensure validity and reliability of the methodology. The first is the inclusion of team discussion and assistance to help with the study and the direction of the result. One crucial reason why this is important is the fact that it lowers chances of bias by all involved in the study. If the researcher were to do the study with no consultancy, then personal biases and beliefs might have affected any of the phases of the study. Also, if the team involved in the discussion were not fully aware of the subject to be studied and how to be part of a reliable outcome of the study, the same result might have been realized.

Additionally, the use of team discussion ensured that the researcher had enough time to complete the study. Although the sample population is small, the research process is complicated and long. Additional discussion ensures that all phases are carefully drafted and completed to allow for a reliable and valid study.

A second factor that was used to ensure validity and reliability is the pre-testing of the questionnaire. As mentioned, after the draft of the questionnaire, the research discussion team tested it on 3 people. It is prudent to note that these 3 people were not included in the final 10 sample group that was used for the study. The main purpose of pre-testing a data collection tool is to minimize any chances of bias that might arise during the study.

Secondly, the phase ensures that all required data is captured in the tool. For instance, in this study, one of the critical questions that was asked was the need for knowledge sharing through digital platforms in the oil and gas industry. Whereas the initial questionnaire asked this question, it did not ask the participants what are some of the digital platforms for knowledge sharing they have been using so far.

Thirdly, several consultations were done before, during and after the study to ensure validity and reliability. Before the study, consultations were done to ensure reliable selection of the methodology based on the research question and objectives. These consultations were also important as they allowed for an unbiased secondary data collection that informed the literature review. Consultations that were done during the study informed the structure of the data collection tool.

Additionally, it validated the use of that specific tool based on the objectives of the study. Also, the consultations ensured that the data analysis method selected was complementary to the data collection approach selected. Ethical concerns were also addressed during the research study and proper consultations guided the researcher on how to address the said ethical issues. Again, there were consultations done after the study to ensure the correct interpretation of the data collected.

Notably, the combination of two data analysis approaches can be identified as a way of ensuring validity and reliability of the study. As discussed previously, the study used both the qualitative and quantitative data analysis methods. First, the combination enhances the strengths of the two approaches ensuring that a reliable approach is adopted. Additionally, the approach minimizes the biases and weaknesses of the individual approaches to boost the adopted methodology. Whereas no approach is better than the other, both have significant limitations that would have otherwise affected the reliability and validity of the study.

Findings

Secondary Sources Findings

One of the key findings realized from the secondary data is that there is a need to digitalize various elements of the oil and gas industry, not just automate the processes and systems. Research and development and even communication are key elements of the industry that would benefit significantly with digitalization. It is important to note, in comparison with the literature analyzed earlier is that the development of both the systems and processes has helped push the industry forward. Indeed, the oil and gas industry are part of the world sector for energy.

Additionally, secondary research has revealed that the use of AIs in the industry has been associated with security risks and this is one of the reasons why some parties in the field have adamantly refused to digitalize their operations. The fear of hacking in the highly competitive industry has put a halt in further digitalization of processes. It is debatable that the automation of systems and processes has been encouraged due to the fact that it ties directly with the effectiveness and efficiency of the industry.

Primary Sources Findings

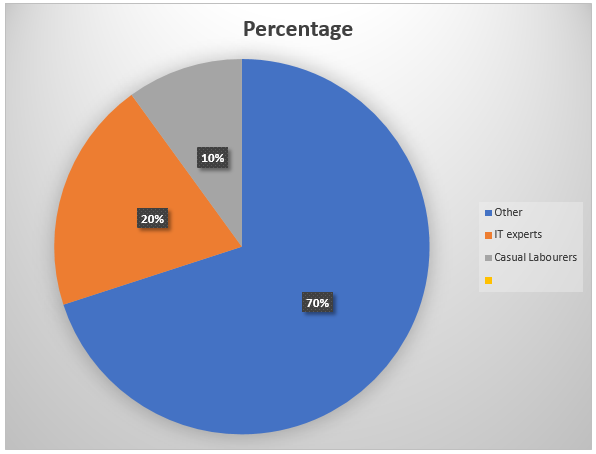

Several findings were realized in the primary data collection. As mentioned, the first section of the questionnaire looked into the participants’ general information. The first questioned revealed that a majority of the participants, 70%, identified their jobs as “other”. 10% of the participants identified themselves as casual laborers while the remaining 20% stated that they were IT experts. None of the participants were engineers. The second question in the section looked into whether the participants had any experience with digital transformation. 100% of the sample population stated that they had experience with digital transformation. The chart below summarizes some of the findings:

The fourth question in the section looked into how long the participants had worked in the oil and gas industry. The data collected showed that 60% of the sample population had worked in the oil and gas industry for three years or less, while 10% had worked there for five years or less. The remaining 30% had worked in the oil and gas industry for more than five years. Additionally, 60% of the participants had worked in Bakers Hughes for three years or less while 20% had worked there for five years or less. The remaining 10% had worked in the company for more than five years.

Interestingly, 60% of the sample agreed that they had heard about ERP, Facebook Workplace and the Intranet as knowledge transfer tools. 20% agreed that they knew about ERP and the intranet while the last 20% knew all the tools that had been listed as answers. 40% of the sample agreed that digital transformation has helped in knowledge transfer in the oil and gas industry This is an above average rating of digital transformation in knowledge management in the industry. Also important to note is that 80% of the participants believed that digital transformation had helped in making communication more efficient between the different departments of the company.

The third section of the questionnaire starts by asking the participants whether they believe that digitalization has affected companies in the oil and gas industry. the responses revealed a 100% agreement with the statement. The participants were then asked to reveal, in their opinion, whether digital transformation has affected research and development in the oil and gas industry. Findings showed that there was mixed reaction to the question with the majority, 40%, being neutral (selected choice “F” which is a 5 out of 10). 30% of the participants gave an above average of 6 out of ten while 20% gave a 7 out of 10. The remaining 10% gave a 0 out of 10, to mean they did not know.

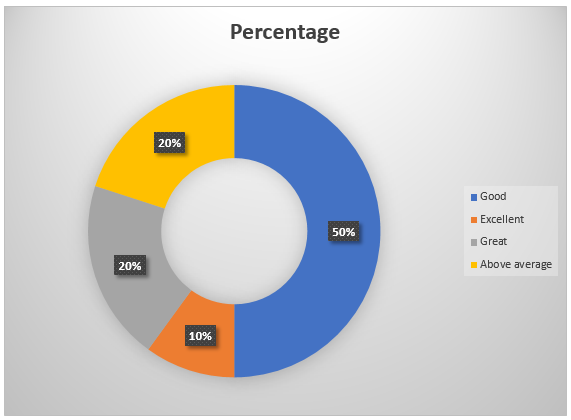

Important to note, 50% of the sample population stated that digital transformation has had a “good” impact on Baker’s Hughes. 10% agreed that it was “excellent”, 20% stated it was “great” and the remaining 20% agreed that it was above average.

In regards to whether digitization has been used in the corporation as an enabler for undertaking challenges and generating added value amid all the stakeholders’ benefits, a majority of the participants, 50% agreed to a 6 out of 10 score. 20% gave an average score of 2. Question 12 inquired how digitization had been used in the corporation as an enabler for undertaking challenges and generating added value amid all the stakeholders. 40% of the participants stated that none of the answers that were given to the question were correct, in their opinion. 30% of the sample population stated that the company had an active platform for sharing lessons learned with all stakeholders. 20% said that all the answers given were relevant.

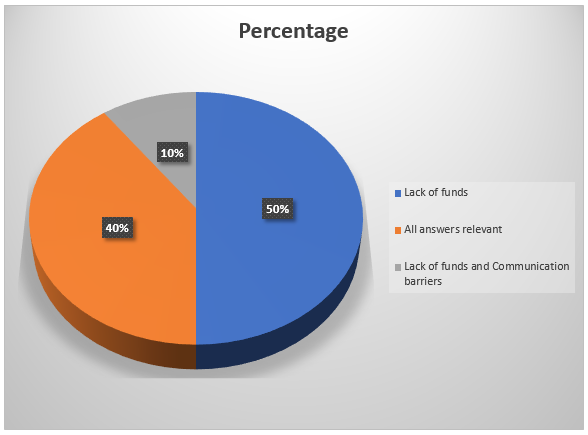

Findings also revealed that the lack of funds to set up technology needed for digitalization was the core limitation in Baker’s Hughes’ ability to implement digital transformation activities, being selected by 50% of the sample population. 40% of the sample population stated that all the answers given in the question were challenges that limited the application of digital transformation. The remaining 10% argued that both the lack of funds and communication barriers affected the applicability of the same. Question 14 elicited a 100% positive response to the question whether digitization had helped improve some of the processes at Baker Hughes.

Additionally, 80% of the sample population agreed that all the answers provided for question 15 were correct in regards to how the application of digital transformation by Baker Hughes and other companies in the oil and gas industry can be improved. The answers given were the inclusion of staff from the beginning to ensure buy-in and refresher training on the innovations incorporated. 10% of the participants stated that none of the answers was correct while the remaining 10% agreed that only the inclusion of staff from the beginning to ensure buy-in was relevant.

Also, 90% of the participants felt that the customers of Baker’s Hughes company had benefitted from the company’s transition in regards to digital transformation. 10% said they did not know whether they had benefitted or not. Question 17 inquired on the opinion of the participants whether suppliers of the company had benefitted from the digital transformation adopted by Bakers Hughes. The question elicited 100% positive response from the participants.

Indeed, there was mixed reactions on how digital transformation had benefitted customers and suppliers of Bakers Hughes. 30% of the participants stated that they had been benefited through better service delivery. An additional 30% agreed that they had benefitted through all the mentioned points namely, efficient production. better service delivery, better customer service, and faster pay offs. 30% of the participants felt that both customers and suppliers of Bakers Hughes had benefitted through better service delivery and better customer service. The remaining 10% agreed that both customers and suppliers had benefited through efficient production only.

Asked to give their opinion on a scale of 1 to 10 on how Baker Hughes’s supply chain benefited from the digital transformation, 50% of the participants gave the average answer of 5. 30% gave an average of 6 while 10% gave an average of 7. The remaining 10% stated that they did not know, thereby, giving an average of 0. Further, the participants had a near unanimous positive answer on whether the digital transformation of processes and operations at Baker Hughes had given it a competitive edge over rival companies, with 90% stating that it had. The remaining 10% agreed that they did not know.

The findings showed that there was mixed reactions on how digitization had helped improve communication and solving of problems between different departments in Baker Hughes. 50% of the sample population stated that they had an active platform for sharing lessons learned with all stakeholders while 40% agreed that none of the answers given was relevant. The answers that were given were we have an active platform for sharing lessons learned with all stakeholders, our reports are automatic and computer generated, and our system automatically detects challenges in our processes and operations and sends out a report to the involved. The remaining 10% agreed that all the answers were relevant.

Discussion

There are several things that have to be considered when discussing digitalization or digital transformation. In the oil and gas industry, digital transformation has mainly targeted processes (Derani & Naidu 2016). For instance, there have been automations of processes to ensure efficient production processes of the natural resources. However, there has been a push of incorporating technology in all operations of a company in the oil and gas industry. It is important to discuss the relevance of technology in other aspects of the oil and gas industry as stipulated in the gap in literature. One of the secondary findings realized is that more focus is given on how digital transformation has enhanced processes and systems but not elements that would be considered “soft” like research and development, communication and even human resources.

A comparison between the secondary research findings and the literature available also reveals that some critics use the terms automation and digitalization interchangeably. This is wrong due to the fact that whereas automation mainly focuses on processes and systems, digitalization encompasses all sections of the company. It can be argued that the fact that there is little literature on the impact of digitalization on the oil and gas industry can be partly attributed to the confusion of the two terms.

The findings realized from the primary research reveal several important things. The first is that digital transformation should include everyone in a company in order for its impact to be recorded positively. As stated, the findings showed that the participants came from different departments in the Bakers Hughes company and all agreed that they had previous interactions with some form of digital transformation in their different roles.

Additionally, in regards to communication, skills and knowledge transfer, ERP, Facebook Workplace and the intranet were common among the staff. With a majority of the staff having worked in the oil and gas industry for three years or less, it is relevant to state that the oil and gas industry has become more open to digital transformation in the last three years or so. It can be argued that the progress made so far highlights the importance of digitization not only of the core processes but also of supporting departments in the oil and gas industry.

In line with the aim of the study, that is how digital transformation has affected the oil and gas industry, the primary data shows that first, it has helped the industry through the creation of a seamless and efficient knowledge and skills transfer approach. The findings show that a majority of the participants believed that digital transformation has helped the oil and gas industry, in particular, Bakers Hughes company, share information easily.

This is relevant and important in ensuring the progression of the industry and the company. It is also critical to point out that the finding reveals that employees or rather people working in the oil and gas sector have already noted the different changes that digital transformation has encouraged. Secondly, a majority of the participants also agreed that digitization has affected the industry and company through improved research and development. However, the findings on the same component show that a significant number of the sample population had an average answer indicating that whatever has been done so far was neither impressive or discouraging.

This finding indicates that more has to be done in the company, and in the industry at large, to encourage the use of digital transformation in research and development. This is especially relevant due to the changing elements of the industry based on lower oil and gas natural reserves.

Another interesting finding that goes hand in hand with the aim of the study is that the impact of digital transformation in Bakers Hughes company was seen as good. The finding reveals two things, first, that more can still be done to ensure companies in the oil and gas sector benefit more from digital transformation. This can be achieved by making the staff in the different companies understand the processes and the objectives of digital transformation both in their departments and in the industry as well. It is important to note that the participants also agreed that digital transformation has had a good impact on both customers and suppliers. This goes to show that the impact of digitalization is not only internal but also external. Thus, it can lead to an increase in productivity and profitability.

Research Limitations

Sample Size

There are four main research limitations that were encountered. The first, as stated is the fact that the sample size. Crucially, the oil and gas industry is one of the largest industries in today world. It is also the most profitable. It is prudent to mention that the industry hires both professional and casual laborers, thus, has a significant number of staff. However, this research project only focused on one company, Baker Hughes Company, and its staff. Additionally, the sample size was significantly small compared to the target population. As stated earlier, the sample population was made up of 10 individuals. There are two main reasons why the research settled for a relatively small sample size.

The first is the availability of the staff of the company. The oil and gas industry, like many other industries, works in different location globally. This means that getting the whole staff at the same time is difficult. The research did not want to do the study in different days so as to avoid any discussions between the participants.

Secondly, the research was only limited to using one company due to the access to data from staff. Although the initial idea was to use samples from different companies, it proved difficult to convince the management of the other companies to allow their staff to be interviewed or patriciate in the survey. Since the study is voluntary, the research became content with using just one company to do the survey. On the same note, many oil and gas companies have not embraced any form of digital transformation in their operations and processes. This made the search for the appropriate companies to acquire the sample size challenging. However, the significantly small sample size was enough to warrant a reliable study.

Gender Imbalance

The second limitation of this research study is the fact that the sample population was made up of more men than women. Kamsu-Foguem (2016) argues that the oil and gas industry has so far been dominated by the male gender. There are several reasons why this is so. One is the fact that women have been informed over the decades that there are some careers that were for the male gender. Careers such engineering, medicine and even finance were described as male careers. Thus, very few women were first interested in such fields of work, and secondly, allowed to take up careers in the said fields. Kamsu-Foguem (2016) goes further to explain that women found in the oil and gas industry initially help junior positions. Arguably, there are still very few women holding decision-making positions in the oil and gas industry.

The oil and gas industry also started developing in countries with little, if any, female empowerment. Nations in both the Middle East and North Africa have been highlighted in terms of gender bias. Women in these regions were limited with options when it comes to career and employment in the past, thus, could not get careers in the oil and gas industry earlier. The additional fact that the industry has been highly politicized makes it more complex to fight for gender rights within the industry at a time.

However, it is important to state that a lot of effort has been put to ensure that more women interested in the oil and gas industry are absorbed into the industry. However, a combination of these two factors made it harder to get a balanced number of men and women in the study. Due to this, the variant of gender was not used in the data collection tools or in the analysis of the data.

Industry Limitations

There were several industry limitations that were observed during the study. The first, as mentioned previously, is the limitation of finding more than one company to draw the sample population from. One of the advantages of drawing the sample population from different companies is the fact that a comparison based on the level of digital transformation in the two or more companies can be drawn. Such a comparison would also enhance the debate on the importance of digital transformation in the oil and gas industries. Additionally, such comparisons enrich the study and provide other angles for future studies.

However, due to high levels of competition and both global and local politics, the other approached oil and gas companies declined to participate in the study. Also, companies and corporations in the field are scarce and apart. Thus, the research was unable to reach out to other companies that were in other different locations.

The second industry limitation is the little usage of digital innovations in the industry. The right sample population has to have at least some form of understanding of digital transformation. However, many of the companies approached did not have these systems in place, especially in regards to knowledge sharing and documentation. This automatically ruled out some of the possible companies that would have participated in the study. Also important to note is the high employee turnover in the oil and gas industries. Interestingly, employees move from one company to the other and so many know each other from the previous work places. Industry issues such as shift schedule, work load and even supervisor permissions also made the research project challenging.

Time and Cost

Time needed and cost of the project were identified as the fourth research limitations. Indeed, whereas the research would have been willing to do a large-scale project, there was no time. Additionally, the cost of doing such a large-scale research project might require fund to do so and need more people evolvement to help in the project. This is because some of the companies that were initially approached were located far from each other. Baker Hughes Company is ideally the nearest as it was easy to conducting of the research with staff from the same company which you have contact with.

An alternative to the distant companies was the use of digitalized surveys. There are several applications that allow participants from all over the world to be part of a research study. This was, however, disqualified due to various reasons. The first is that it would be difficult to follow-up on people in different areas due to the busy nature of the industry. Secondly, it would require much time to approach the industries and get approvals to conduct the research study. However, the research did not have much time due to the nature of the assignment.

Also important to point out is that the sensitivity of the information, and the industry required a personal visit to explain the objectives of the study. As mentioned previously, the oil and gas industry is highly political. Thus, there are several sensitive issues that had to be addressed before the researcher was able to conduct the survey. It can be argued that the research would have taken more time and been more costly if a large-scale approach was adopted. Despite the research limitations, the researcher was able to conduct a reliable and trustworthy study that sort to answer the stated research question.

Research Ethics

Every research project has to consider the ethical concerns that are associated with it. One concern was the identity of the participants of the study. Due to the sensitivity of the industry, the participants were worried that their identity and association with the results of the study might make them questioned related to the support and believes in AI digital transformation within in their work places, especially by management. Due to this, the research study did not collect any personal information that would have identified the survey participants. Additionally, the participants were informed of their rights.

For example, they had the right to stop the survey at any point they deemed necessary. The participants also had the right to ask any questions regarding the study and the use of their responses in the study. The researcher made it clear that the study was purely for academic purposes and that their individual responses would be disposed according to research project guidelines. They were also informed that the final report would include a culmination of the data and not individual responses.