The significance of EPC can hardly be overrated. The specified tool allows for a quick arrangement of information and prioritization of goals, thus, helping the managers get the company’s priorities straight and develop the plan that will inform the staff concerning the further actions to be taken.

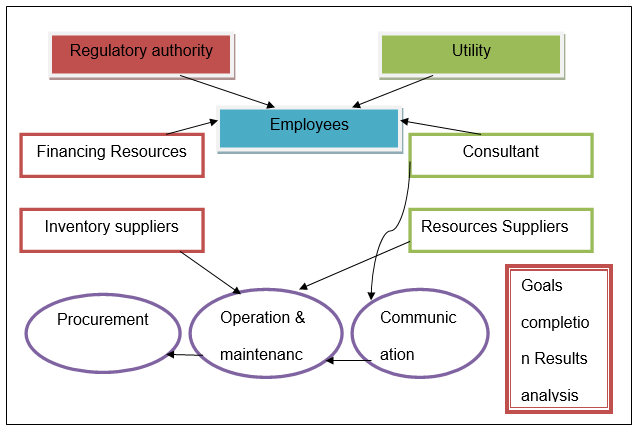

The adoption of the specified tool allows for viewing the current business problems from a new perspective, therefore, creating premises for the development of an entirely new approach and the design of a brand-new strategy. According to a recent study (Weske 169), the adoption of the model in question allows for the location of the basic objectives, as well as their further prioritization (Fig. 1).

However, it would be wrong to assume that the very phenomenon of EPC boils down to merely scheduling the actions to be taken and decisions to be made by the company. While the above-mentioned process also makes a very important part of EPC, the latter, in fact, embraces a much vaster concept of goals analysis (Kriemeyer and Linderman 130).

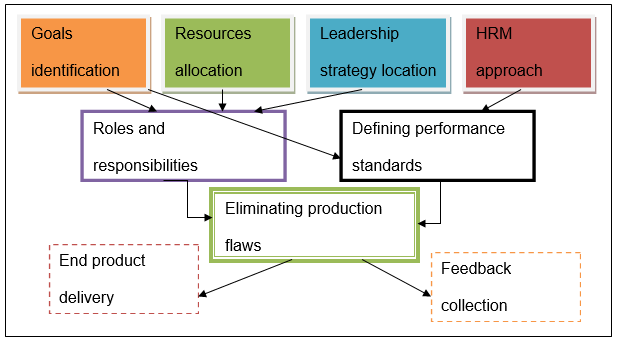

To be more specific, the specified strategy defines the very course of the further workflow and, therefore, creates the premises for easier management of the company’s key processes: “Subsequently, the processes and sub-processes identified and the reasons underlying this type of sub-division were examined in detail” (Bertolini et al. 47). As Fig. 2 shows, the specified approach towards identifying the major objectives and supervising their accomplishment can be viewed as a major foot forward in addressing the company’s organizational and production-related processes.

It is also remarkable that the approach suggested by Bertolini et al. provides tools for introducing a more efficient time management strategy. As the study claims, the waiting time for patients has been reduced significantly since the adoption of the strategy (Kurbel 105). The phenomenon under analysis can be explained by the fact that the rearrangement of objectives creates the environment, in which the stages required to complete the objectives are identified and characterized in a much more efficient manner. As a result, a more elaborate time management approach can be developed.

The incorporation of new time management tools, in its turn, helps improve the manager’s understanding of the dynamics of the workplace processes. To be more exact, the specified tool helps arrange the workplace processes according to their relevance and the time required for their completion. As a result, a grid with a clear plan of goals to be accomplished and the links between these goals as well as the amount of time required for the completion of these objectives is represented with the help of EPC (Jäger 27).

Therefore, the EPC process must be viewed as not merely helpful but essential to the success of the company’s operations. Creating the premises for the further progress of the organization, it structures the key processes. Consequently, the roles and responsibilities are distributed evenly among the staff, and the dynamic process involving cooperation among the staff, information transfer, production process supervision, quality control, etc., is galvanized with the help of the EPC tool (Claus-Peter 134).

Although relying on EPC entirely would be wrong, the tool in question will clearly help arrange the fundamental processes occurring in an organization. Defining the company’s hierarchy and the roles that every single member of the staff is provided with, EPC serves as a means of maintaining the workflow.

Works Cited

Bertolini, Massimo, Maurizio Bevilacqua, Filippo Emanuele Ciarapica, and Giovanni Giacchetta. “Business process re-engineering in healthcare management: a case study.” Business Process Management Journal 17.1 (2011): 42-66. Print.

Claus-Peter , Praeg. Quality Management for IT Services: Perspectives on Business and Process Performance: Perspectives on Business and Process Performance. New York City, NY: IGI Global, 2010. Print.

Jäger, Anna-Lena. Global Purchasing Processes in the Business Sector Automotive Aftermarket: Development of a Reference Model. Berlin: Springer Science & Business Media, 2013. Print.

Kriemeyer, Matthias and Udo Linderman. Complexity Metrics in Engineering Design: Managing the Structure of Design Processes. Berlin: Springer Science & Business Media, 2011. Print.

Kurbel, Karl E. Enterprise Resource Planning and Supply Chain Management: Functions, Business Processes and Software for Manufacturing Companies. Berlin: Springer Science & Business Media, 2013. Print.

Weske, Mathias. Business Process Management: Concepts, Languages, Architectures. Berlin: Springer Science & Business Media, 2012. Print.