Introduction

The dynamic nature of modern business environment, coupled with rapid advances and complexities in communication and technology have resulted in development of diverse business strategies aimed at promoting business competitiveness in the global markets (Bower 2003).

Companies are currently seeking positions of competitive advantage over their rivals by strategizing towards the creation of long term consumer and supplier loyalty.

In addition, business leaders are pursuing new and advanced business paradigms that provide opportunities for their companies to work closely with long term and new business partners in order to effectively adapt to the rapid changes occurring in the market place (Bower 2003).

New and beneficial business relationships are arrived at through development of project procurement strategies that aim at striking a balance between work, motivation, and risks for long term sustainable business efficiency.

Procurement refers to the process of acquiring new services and products at the most efficient prices and incorporates activities such as contract strategy, contract documentation and contractor selection (Bower 2003). In simpler terms, procurement concerns itself with the function of purchasing inputs that are used in the firm’s value chain such as raw materials, supplies, machinery etc.

The process employs specific technology which facilitates in dealing with vendors, qualification tools, and information systems (Barnes & Open University 2001). Procurement practice is one the processes that organizations and teams acknowledge as a most important element of project management (Dinsmore 2010)

Project Procurement Management

Project procurement management knowledge is essential for firms to operate efficiently (Tomczyk 2005). Knowledge and expertise in this field assists in decision making on purchasing of goods and services from external suppliers, contractors, and suppliers. Project procurement deals with the interactions between purchasers and contractors as well as contract administration (Tomczyk 2005).

Project procurement management is further concerned with inventory management which is especially important due to the tremendous amount of uncertainties associated with the same (Willoughby 2001).

Consequently, effective procurement management requires a comprehensive understanding of project management processes, ability to utilize specific procurement tools at each stage of the project and a clear understanding of the benefits associated with integration of procurement tools rather than executing the procurement process in isolation (Hairston 2005).

Project procurement activities are spread throughout the firm with the purchasing and contracting function being conducted by the purchasing department, plant managers, office managers, sales persons, or in some cases by the chief executive officers (Barnes & Open University 2001). A particular procurement activity is often associated with specific value activity which it supports.

Consequently, procurement choices are geared towards value maximization by making the most efficient choices regarding contracts, engaging stakeholders, as well as linking business strategy to project selection (Rowlinson & Walker 2007).

Procurement choices should be made in such a way that they ensure balancing demands and responsibilities, protecting the reputation of those involved in the projects, encouraging innovation and promoting knowledge transfer where it can reap value (Rowlinson & Walker 2007). In addition, such choices should seek to attract and develop a skilled pool of talent which has the ability to deliver expected value to the stakeholders.

The cost of project procurement in most firms represents an insignificant proportion of the total costs. However the cost has a large impact on the overall cost of the firm which demands procurement executives to improve procurement and purchasing practices in order to achieve maximum efficiency.

In response to this, companies have adopted E- Procurement strategies which have become an increasingly important cost reduction tool. E- Procurement is being implemented in most organizations in a bid to reduce overall operational costs (Buchanan 2008).

In order to further manage associated costs, project management processes require the executives to focus more on the risks associated with the project, definition of track and measurement of quality, as well as effective control and communication (Great Britain 2002).

The Concept of Value

The definition of value depends on the perspective taken as well as the perceiver’s needs at the specific moment (Moser 2007). Numerous scholars have sought to define the concept of value in terms of financial benefits, social benefits, goal attainment and competitive advantage.

These diverging explanations have served to prove that value is a multi-dimensional construct that can be evaluated through various approaches. The concept has been widely used while referring to consumer needs with much less emphasis being put on the integration of suppliers in the value concepts.

However, in business procurement, researchers conceptualize value in business relationships in terms of the value of the supplier bundle of products and services that is exchanged at a price to the purchaser and the long term costs and benefits associated with the relationship established between the purchasing firm and the supplier (Moser 2007).

The value of the relationship depicts the aggregate worth of all the transactions that will be undertaken by the two firms over the contractual period while the perceived financial value refers to the present value of cash benefits accruing from the current and future transactions (Moser 2007).

The client expects to obtain value from their investment, timely delivery of project, durability of the end product, reasonable running costs, and defect free completion of the project from the contractor (Masterman 2002). In order to achieve this, the client’s needs and objectives must be addressed in the project procurement process.

The financial based perception of value is limited to cash benefits and does not account for non cash benefits associated with effective business procurement management such as technological transfer and continuous quality improvement derived from the interactions between the purchasers and suppliers (Koppellman 1998).

In the past, supplier selection focused on issues such as costs, quality, and delivery of the goods and services in question. This focus has however shifted towards supplier’s long term capabilities and the long term benefits that the purchaser is likely to derive from such interaction.

Benefits of Effective Procurement to Business Organizations

Effective procurement is important in firms since it facilitates appropriate decision making with regard to purchase of the right product and service at the right price (NCC 2006).

The process maximizes the level of service provision and plays an important role ensuring a balanced budget for the organization, promoting savings, creating a diverse market, promoting innovation, and delivering an organization’s strategic objectives (NCC, 2006). Effective procurement practices significantly cuts costs and improve efficiency within an organization (CIPS n d).

In modern business environment, more focus is being awarded to efforts aimed at cutting costs through elimination of unnecessary costs. However, these strategies are often associated with increased time consumption, widespread unemployment and often create severe staff morale problems (CIPS n d).

Consequently, organizations’ managements are seeking to devise other means through which they can cut costs within their organizations. Procurement provides one such opportunity that organizations can manoeuvre to reduce overall operational since the value of input products and services forms a substantial part of the firm’s turn over (CIP n d).

The world’s major airlines have been experiencing cost related difficulties in the recent past. For instance, the British Airways has faced numerous challenges ranging from terrorist threats to deteriorating business climate which has put the organization’s procurement function under question (CIP n d).

This prompted the organization to enhance its procurement function by negotiating lower prices through electronic auctions and limiting the number of suppliers. This move led to reduction in cost amounting to 650 million pounds in 2004 and savings worth over twenty million (CIP n d).

Improving efficiency in procurement and supply chain management generates benefits beyond price reduction for products and services (CIP n d). An organization’s ability to effectively manage its supply chain provides the real benefits to the organizations. For example, a retailer seeking to refurbish his sites would have to look for contractors who will guarantee maximum return from the investment.

Consequently, the retailer should carefully evaluate the options available in the supply market and cooperate with the selected contractors in order to reduce operation costs and duration. Failure to effectively manage the procurement process often results in project delay which in turn increases overall costs. In addition, Effective procurement promotes security of supply (CIP n d).

The process promotes timely risk identification which creates room for risk mitigation and management (NRC 2005). Further, establishment of good relationships between purchasers and suppliers ensures continuous flow of goods and services to the firm which in turn promotes consistency in production and service provision.

Establishing good relationships with suppliers enables a firm to access new and advanced products on a timely basis. A firm may reap additional benefits by engaging suppliers in the product design process which promotes technology transfer where both the purchasers and suppliers exchange ideas in order to achieve product innovation (CIP n d).

Procurement and supply chain management process has the ability to deliver value if it is managed as a whole. The suppliers and purchaser must work together in order to reap the benefits associated with effective procurement management.

This is because in absence of cooperation between the stakeholders, each function pursues its own interests which often results in conflict of interest. Therefore, firms must ensure consistency between the purchase and supply management decision making which in turn translates to the organization’s objectives, culture and structure.

Example of Project Procurement in the Construction Industry

In the construction industry, effective procurement is manifested in sustainable and sensitive use of resources, affordable and well functioning designs incorporating high standards of inbuilt utility and safety (Harris 2006). This can only be achieved by engaging able project managers who in turn make appropriate choices in awarding of contracts to competent and skilled designers and contractors (Harris 2006).

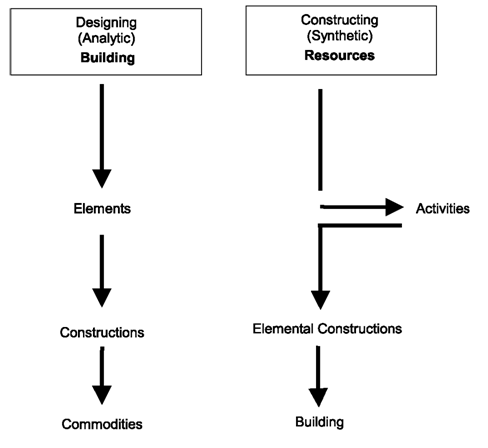

As shown in the figure below, construction projects are complex and require extensive planning. Indeed, according to Brown et al (2001), construction projects, regardless of their simplicity involve the participation of people from different teams who are integrated into a single team that is expected to efficiently execute a particular task.

According to Alhazmi & McCaffer (n.d), it has been estimated that the selection of an appropriate procurement method would result in approximately 5% reduction in construction production costs. Since each project has its unique set of requirements and characteristics, the chosen procurement method must address the technical issues of the project as well as the client and contractor needs (Alhazmi & McCaffer n d).

Various procurement considerations arise while undertaking construction projects (Edgerton 2008). The person wishing to pursue a construction project should put into considerations factors such as the objectives and constraints of the project, skills, and experience of the contractor firm (Edgerton 2008).

Brown et al. (2001) conducted an extensive analysis of the UK construction industry and revealed that the highly differentiated nature of the industry resulted in poor quality, cost escalations, and schedule overruns. The costs were attributed to lack of cooperation between the stakeholders in the project.

Consequently, firms in the industry sought to reduce construction costs by awarding tenders to contractors who focused on project duration cost and client expectations (Brown et al., 2001). In order to overcome the challenges prevalent in the industry, contractors developed new strategies which aimed at achieving cooperation between the contractors and the clients.

Further, a new project delivery process was established as a means of promoting improvement and innovation in the UK construction industry (Brown et al., 2001).

In conclusion, business organizations are moving towards online procurement which has proven to be especially effective in large corporations (Davila 2002). E-Procurement facilitates acquisition of goods and services via the internet and enhances work automation, organizational spending and information availability.

Advance in technology has aided firms to move towards the creation of collaborative supply chain management tools which serve to reduce administrative costs, reducing the project life cycle, lowering inventory and price levels and increasing inter organization collaboration.

Reference list

Alhazmi, T., & McCaffer R., 2000. Project Procurement System Selection Model. Web.

Barnes, D., & Open University, 2001. Understanding Business: Processes. London, Routledge.

Bower, D., 2003. Management of Procurement. London: Thomas Telford.

Brown, C. D., Ashleigh J. M., Riley J.M., Shaw D R., 2001. New Project Procurement Process. Web.

Buchanan, M., 2008. Profitability Buying Strategies: How To Cut Procurement Costs And Buys Your Way To Higher Profits. New York, Kogan Page Publishing.

CIPS. Not dated. Why Purchasing Key-The Message to Business Leaders. Web.

Davila, A., 2002. Moving Procurement Systems to the Internet to the Internet: the Adoption and Use of E-Procurement Technologies Models. Web.

Dinsmore, C. P., 2010. The AMA Handbook of Project Management. New York, AMACOM Division American Management Association.

Edgerton, W. W., 2008. Recommended Contract Practices For Underground Construction. London, SME Publishing.

Great Britain, 2002. Business Benefits through Project Management. London, The stationery Office.

Harris, F. 2006. Modern Construction Management. London, Wiley Blackwell

Hairston, J., R., 2005. Integrating Procurement and Project Management. Web.

Jagger, D., 1988. Logistics Information Management MCB UP Ltd. Journal of Enterprise Information Management. Web.

Koppelmann, U., 1998. Procurement Marketing: A Strategic Concept. Berlin, Springer.

Masterman, E. W. J., 2002. Introduction to Building Procurement Systems. New York, Taylor & Francis.

Moser, R., 2007. Strategic Purchasing and Supply Management: A Strategy Based Selection of Suppliers. Wiesbaden, DUV.

National Research Council, 2005. The Owner’s Role in Project Risk Management. Washington DC, National Academies Press.

New Castle City Council, 2006. Supporting People: Procurement Plan. Web.

Tomczyk, A. C., 2005. Project Manager’s Spotlight on Planning. California, John Wiley & Sons.

Rowlinson, M. S & Walker T.H.T., 2007. Procurement Systems: A Cross-Industry Project Management Perspective. London, Routledge.

Willoughby, A. K., 2001. Project procurement and disposal decisions: An inventory management model, NY: Elsevier. International journal of production economies. Web.