Discussion

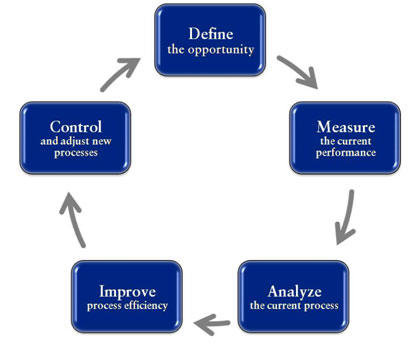

The DMAIC process is Six Sigma methodology which is used to improve accessible or established process of the projects in any organization. It contains five stages and every stage can be applied in repeated or iterative manner. Every step in these processes is connected to each other.

The first step is the definition of the process and depends on both sketching and Failure Modes Analysis. The objective for this step is a defined procedural map with all activities, outputs and inputs along with Failure Modes Effects Analysis (FMEA) chart (Gygi, DeCarlo, & Williams, 2005, p. 41).

Measure

Provided there is a defined process, this stage is intended to take metrics on every stage to establish if the process is taking place as designed. It also establishes if the process is taking place within the chosen quality conditions.

A proper measurement plan should be defined to make sure that the measurements are not statistically tilted. The measurement step depends mostly on Statistical Process Control (SPC) methodologies for collecting information (Shanka, 2009, p. 11).

Analyze

After carrying out the process metrics, several analysis devices can be applied to determine the failures and barriers within the process to attain the performance conditions or where unpredicted action is taking place.

Improve

Once the process has passed through analysis stage, improvements of the process may be performed. These enhancements are derived from the data and analysis, and are intended to take the process to meet its declared goals.

Control

Once the process has been improved, the next step of the methodology concentrates on constant measurement to confirm that the process goes on to attain its final or production goals. The control step is intended to make sure that the process does not turn out as corrupted.

If environmental conditions change, the process is required to be restructured. The diagram below shows the processes of Six Sigama (Shanka, 2009, p. 95):

TRMC’s Six Sigma

Six Sigma has been used by Thibodaux Regional Medical Center (TRMC) since 2002 and they changed their management styles to cope with operational and medical matters (Palagyi & Hamelynch, 2003). An example of an activity which is aligned with the strategic plan of the business was a proposal to decrease pressure ulcer or nosocomial. This is an example of the major performance metrics showing quality of care.

Even though the rate of pressure ulcer at the health care facility was highly superior to the industry standards, the constant quality improvement data identified an increase between the 2004 and 2005 (Henderson, 2011, p. 6).

In September 2005, a Six Sigma project to tackle this problem was implemented by the hospital’s management and the team started to simplify the problem statement. Their target was to be effective and efficient by solving matters resulting to the growth of nosocomial pressure ulcers.

To ensure that their plans are generating an optimistic change on the patient care setting, the hospital constantly measures worker and patient satisfaction through Press Ganey.

Worker satisfaction is constantly graded in the 97th percentile and inpatient satisfaction is measured in the 99th percentile (Henderson, 2011, p. 6). TRMC also have been acknowledged for its success including awards such as Press Ganey Excellence Award and Louisiana Performance Excellence Award.

Black Belt and the head of pressure ulcer project, Sheri Eschete, claimed that the project is an excellent instance of the need to validate fundamental causes through application of valid data, instead of relying on first instinct only. Six Sigma has helped the hospital with several approaches to solve some real issues so that they can create appropriate improvements (Henderson, 2011, p. 6).

Application of Six Sigma mechanism has extended into several areas beyond manufacturing. Regardless of various criticisms of DMAIC strategy, it remains to produce great impact on the way industries or organizations meet and maintain excellence.

References

Gygi, C., DeCarlo, N., & Williams, B. (2005). Six Sigma For Dummies. Hoboken NJ: John Wiley & Sons.

Henderson, R. (2011). Six Sigma Quality Improvement with Minitab. West Sussex: ohn Wiley & Sons.

Palagyi, S., & Hamelynch, A. (2003). Understanding the Value of Six Sigma. Supply Chain Forum , 4(1): 48-50.

Shanka, R. (2009). Process Improvement Using Six Sigma: A Dmaic Guide. New York: ASQ Quality Press.