Introduction

Chemistry is the branch of science that deals with chemicals are reactions. There are several aspects of chemistry, for instance, synchrotron radiation. Radiation is the energy that is emitted from a source as electromagnetic and travels via or through space or some materials. On the other hand, a synchrotron is a cyclotron where a magnetic field strength may increase with the energy of the respective particles keeping the radius of the orbit constant.

Therefore, synchrotron radiation may be said to be the radiation of electromagnetic that are emitted by particles that are charged and passes through a magnetic field. Synchrotron radiation is a chemical process that can also be used in the determination of the structure and composition of coating in a metal. There are several applications of synchrotron radiation. However, this is a research paper on how thin-film analysis using synchrotron radiation may be used to determine the structure and composition of coating in an aircraft metal. This report aims at investigating and utilizing synchrotron radiation to determine the structure and composition of the coat and develop an analytic plan for the sample used.

Literature review

Synchrotron radiation can be applied in several chemical processes. This process is important in scientific research and study, especially chemical-related research. The process can be applied in X-ray and determination f coating in metals among others. Furthermore, synchrotron radiation can also be applied in astronomy. Several factors can cause coating in a metal. Generally, coating in metals is rust. Rust is caused by a combination of oxygen and water on metal surfaces. This affects the quality of the respective metal and other effects among others (Mouse 2006).

Synchrotron radiation is concerned with electromagnetic emission that is transmitted through a surface or a particle. The coating on metal is caused due to electromagnetic emission. Several applications can be used in the determination of metal coats through synchrotron radiation, for instance, thin-film analysis. Therefore, the determination of structure and composition of coating on metal may be easy through the application of thin-film analysis using synchrotron radiation. Several properties can be used in the determination of synchrotron radiation, for instance, high stability. Synchrotron radiation is stable hence enabling it to easily be applied in several chemical processes.

This has also increased the reliability of the process in different chemical applications where it is used (Nelson 2006). Secondly, polarization, synchrotron radiation is polarized hence has both circular and linear properties. This enables synchrotron radiation to be used in different chemical application processes. Third, synchrotron has high flux. High flux in the synchrotron is characterized by photon beams of high intensity that are essential in rapid experiments. This enables the synchrotron to easily accommodate any chemical processes irrespective of its strength. This feature enables synchrotron to be applied in both strong and weak scattered crystals (Lyn 1995).

Synchrotron radiation also has a broad spectrum. This allows users to easily select the desired wavelength for the respective experiment they are conducting. This has increased the application of synchrotron radiation in different chemical applications or experiments. Synchrotron radiation also has a pulsed time structure. This is considered among the most important characteristics or features of synchrotron radiation. It enables synchrotron radiation to be used in different chemical processes, but with the result being obtained at the same time or within the same time frame. The feature has enabled synchrotron radiation to possess’ the ability to allow for resolution of processes within the same time frame (Liveris 2000).

Several factors may cause coats on metals. Metal coats have several effects, especially metals that are in use such as motor vehicles and aircraft among others. Furthermore, components of coating on metals also differ depending on the cause of the coat. There are several effects of metal coats on aircraft. Generally, most of the coating on aircraft metals leads to accidents and aircraft failure during taking offs. There are several incidences of aircraft failure during taking off and landing due to the coats on the respective aircraft. However, there are other components and structures of coats on metals that can be controlled hence avoiding the risks associated with coats on aircraft metals such as take-off and landing failure. The coating on aircraft adds weight to aircraft leading to take off and landing failure (Lenox 2005).

Methodology

Several research methodologies can be used in the determination of structure and components of metal coats, for instance, quantitative and qualitative research methods. This section focuses on the research methodology of the study and the theory of research design in detail. There are different types of research methodologies that can be used in research methods, for instance, qualitative or quantitative. Choice of the research method to use in research depends on the subject matter or topic nature of the study and intended data to be collected among other statistical characteristics or features. Furthermore, the research should be designed in such a way that the study topic is effectively and adequately addressed.

The data collection method should also be reliable depending on the nature of the study and required data. There are two types of data collection methods, for instance, primary and secondary data collection methods (Kessler 2007).

Considering the nature of the transport industry, especially aircraft, the research should apply both qualitative and quantitative research methods. The application of both research methods will enable effective and adequate research on the study topic considering the dynamic nature of the industry and the subject of study (St. James Press 2004).

Moreover, the data collection methods should be both primary and secondary data collection methods. Data required for this research should be obtained from primary sources and secondary sources to enable comparison of the obtained data with past research on the industry because there are similar researches that have been conducted in the past and different results obtained. This will also ensure that the results are realistic and reliable hence used for future reference by other researchers in the field of study. The results of the research may also be useful for professionals in the transport industry especially those dealing with the safety of aircrafts (John 2011).

Problem statement

What are the components and structure of aircraft metal coats?

Desk research

Secondary sources search will be conducted with an aim of refining objectives and provision of enquiry lines for the subsequent stage of the research. This stage of research will assist in the evaluation of components and structure of aircraft metal coating that has been obtained in the past and a comparison made with the present result that will be obtained from the research study. This stage will also be useful and important because it will require the identification of characteristics that have been used in the identification of aircraft metal components in the past years. There are several objectives of this stage of the research though its main objective is comparison and evaluation of past results on this study topic and the present result obtained. Several procedures must be followed to ensure that the study topic is adequately and effectively handled (Patrice 2004).

This stage will be conducted after obtaining data from primary sources or after conducting the research personally and coming up with results. Results obtained from the primary data must be compared with results of past research on components and structure of aircraft coating. Several articles, research journals and books on the study topic will be useful in this area. It will also enable validation of the research results obtained from the research study (Jeffries 2011).

Desk research is a secondary data obtaining method. This is because it involves obtaining data or information from stored or electronic sources. It involves the use of past information. There are different components and structures of metal coating. However, this study must involve past research on components of metal coating that were determined through the synchrotron radiation process. It will also involve a comparison of other chemical application processes that synchrotron radiation have been used or applied and the result obtained (Hill 2000).

Quantitative research

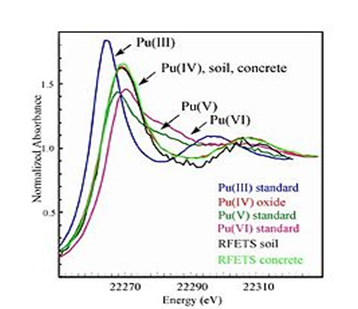

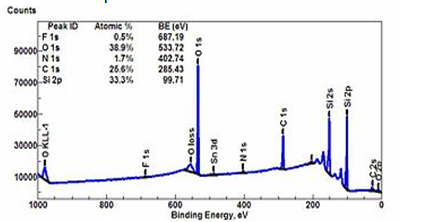

The study will be quantitative research. Different quantitative researches methods can be used; however, this research study will incorporate the use of experiments. This is because results can only be obtained from this research after an experiment is conducted to determine the components and structure of the metal coat of the aircraft. An experiment procedure must be designed to ensure appropriate data is obtained from the research study. EXAFS, SIMS, XANES and XPS will be incorporated hence desired analytic information obtained (Goldblatt 2010).

Experiment procedure

A sample of the metal must be obtained and present in a laboratory for the experiment. Necessary chemicals must also be presented to ensure that the required equipment and materials are availed before the experiment is conducted. The experiment should be conducted in a scientific laboratory. The experiment to be conducted aims at determining or identifying features or characteristics of different metals and coating agents. There are different types of metals and coating agents. However, they have different reactions to chemicals. Therefore, the chemical will be used in the aircraft and observation made.

Thereafter conclusion was made on the possibility of the metal and coating used in the aircraft considering observations made and results of past research on the coating of aircraft and materials used in designing and manufacture of an aircraft and their chemical characteristics. Furthermore, the comparison must be made with the past result because several pieces of research have been conducted to determine the composition and structure of aircraft metal coating (Ferguson 2010).

Results

The research carried on components and structure of aircraft metal coating revealed that metal used for aircraft is steel with an electroplated metal coating. Furthermore, the steel used in aircraft is coated with chromium. The coating lacks nickel and copper thickness under layers. Generally, the aircraft metal coat was discovered to compose of steel and chromium. This is because the steel used in aircraft was discovered to be electroplated steel with chromium coating.

Furthermore, the results revealed that there were traces of nickel and copper. The nickel and copper were present as under layers. They were about 2mil in thickness. This made it difficult to easily determine their presence in coated aircraft metal. However, chromium was the most dominant component in the structure and composition of the coated aircraft metal. Generally, the structure of the metal was designed as follows, chromium, traces of nickel and copper about 0.3 to 2mil thickness and steel, which was the main metal being coated.

Discussion

Results obtained from the experiment revealed that the metal used in aircraft is steel. Furthermore, the steel is coated with chromium. This is because the metal coating is used to reduce the corrosion of metals and increase their durability in the environments where they are used. These results conform to past results on the composition and structure of aircraft metal coating. However, the earliest research on the study topic revealed that zinc was also used in the coating of aircraft metal before the electroplate coat was developed (Conley 1998).

Many metallic materials have been developed. There are different areas where metals are being used hence the use of a metal determines the choice of the respective metal to use. However, steel has been proved to be the best metal for the construction of different materials and equipment in the entire globe. This is due to its durability and reliability status. Basically, steel is commonly used in the manufacture of automobiles, industrial machinery and other appliances among others. Steel is exposed to chemical attacks on the environment. Steel can also be attacked by other simple corrosion available on the environment.

There are several corrosion components available in the environment. This has made it impossible or difficult for a single metal component to effectively resist corrosion in the environment. Therefore, this has necessitated the coating of metals used in the environment to increase or boost their durability and resistance to corrosion in the environment (Chart.com 2011).

Coating recommended for metals is considered with the respective environment where the coated metal is intended for use. Before choosing the metal coat to use for metal, several factors must be considered or put into consideration. Generally, the factors that must be considered include mechanical conditions where the respective metal is going to be used. Metal coats should effectively be able to resist mechanical threats and increase the durability of the metal. This will reduce the number of changes that have to be made and services required for the respective metal while in use in the respective field or environment, for instance, aircraft.

An aircraft requires a metal that has a coating that can adequately prevent the metal from mechanical conditions involved considering the nature of aircraft and the mechanical challenges exposed to aircraft (Sweeney 2010). Secondly, the environment, metals used in aircraft should effectively protect the aircraft from environmental corrosions. Several environmental factors lead to the corrosion of metals. Therefore, metal coating of metals used in aircraft should effectively resist corrosion caused by environmental factors. Aircraft are highly exposed to environmental factors that can easily cause corrosion considering nature of the transport and conditions under which aircrafts operate (Uche 2003). Finally, thermal, this is also considered one of the most important factors to be considered in choice of the coating to use in aircraft metals.

Aircrafts are not only exposed to environmental factors and mechanical conditions but also thermal conditions. Aircrafts operate both in air and land. This is because an aircraft has to land and fly to its destination. Different environmental conditions are prevailing in air and on land. Differentials in environmental conditions in air and on land have led to differentials in thermal conditions. However, metals used in aircrafts have to adapt by both thermal conditions prevailing in the air and that on land. This makes it difficult to decide on a metal coat to use for aircrafts. The coat should be able to effectively resist and adapt to the differential thermal conditions prevailing in air and on land (Bowdin 2009).

In the past, aircraft metals were zinc coated. However, due to improved technology and the development of other important and most effective methods of coating. An electroplated method of coating metals was adopted. Aircraft uses steel because steel is the metal that is used in most metal manufactured materials in the globe. However, due to environmental, thermal and mechanical factors consideration, steel cannot effectively be used and desired durability and efficiency achieved.

Therefore, the electroplated metal coating is the most effective and efficient coating that is recommended for aircraft metals. Generally, electroplated metal coat embraces the use of nickel and chromium plating because several materials were used but restricted by Environmental Protection Agency. The methods that have been banned by the environmental protection body are lead-bearing, cadmium and cyanide solutions.

Though nickel and chromium plates are the recommended metal coats used mostly, aircraft basically uses the chromium coating. This is because the chromium coating has low friction and anti-galling characteristics. However, chromium coating is usually applied without the incorporation of nickel or copper thickness under layers. The metal coating is an important factor in chemistry. This is scientific research that has been developed due to the high-risk exposure of metals to broadband corrosion (Brown 2011).

Steel is the metal that is considered best in aircraft use. However, it is exposed to corrosion due to thermal, environmental and mechanical conditions that aircraft are exposed to. This is because steel like any other metal is vulnerable to attacks posed by thermal, environmental and mechanical conditions. These attacks compromise the quality of steel use. However, coating of steel reduces corrosion risk and enables the steel to adequately resist corrosion. The coating also enables the steel to last long. Steel is extensively used in the manufacture of different appliances, for instance, aircraft and cooking materials among others.

The most appropriate coating technique for steel is electroplated metal coating. Though there are different types of electroplated metal coating, the application of each depends on the mechanical, environmental and thermal conditions the material is exposed to, for instance, cooking equipment (USC Marshall 2011). The best-electroplated metal coating method suitable for food handling or cooking equipment is nickel coating.

This is due to thermal, mechanical conditions and environmental factors or risks the materials are exposed to. Nickel is best in heat regulation and other factors that may cause corrosion for steel while in use. On the other, chromium coating is the best-electroplated metal coating method that can be used in the protection of steel used in aircraft. This is because chrome can effectively resist thermal, mechanical conditions and environmental factors that aircraft are exposed to (Abram 2009).

Conclusion

Several coating methods can be used in metals. The metal coating is used to reduce the corrosion of metals and increase their durability. Though steel is extensively used in the manufacture of different materials and equipment, it cannot effectively resist corrosion. Metals are also used in different environments hence exposed to different corrosion threats. Environments, where metals are being used, determine the corrosion possibility of the respective metals.

In the past years, zinc coating was extensively used in the coating of steel. However, due to increased research, the electroplate coating method was developed. Due to environmental preservation and concern, some certain materials or components are prohibited for use in electroplating, for instance, lead-bearing, cadmium and cyanide. Other materials are recommended for use but nickel and chromium are the commonly used coating materials. Choice of the coating material to use entirely depends on the environment where the material will be used and the corrosion threat it is exposed to. An experiment was conducted to determine the composition and structure of aircraft metal and it was discovered that the metal used was steel. Furthermore, the steel was electroplated with chromium.

Traces of nickel and copper wire with a thickness of about 0.3 and 2mil was detected. These components also had importance in protecting the metal from thermal effects especially heat that aircraft are exposed to. They were also important in ensuring control of mechanical conditions that aircraft are exposed to. Basically, the steel used in aircraft is electroplated with chromium because chromium is the most suitable coating material that can effectively and efficiently resist corrosion that can be caused by thermal, mechanical conditions and environmental factors that an aircraft is exposed to.

Furthermore, chromium is effective in corrosion resistance if used with copper and nickel because they assist in thermal control and mechanical condition that aircraft are exposed to. Therefore, considering thermal, mechanical conditions and environmental factors and past research and design of an aircraft. An aircraft is indeed made of steel that is electroplated with chromium. Additionally, thin-film analysis using synchrotron radiation was the best method to determine the composition and structure of the aircraft metal coating.

List of References

Abram, D 2009, Modern techniques of physical science. Indiana: Pearson Education.

Bowdin, F 2009, mass spectrometry principles and applications. New York: Springer.

Brown, A 2011, Atkins physical chemistry. U.S.A: World Future Society.

Chart. 2011, Physical chemistry: Atkins. Indiana: Pearson Education.

Conley, T 1998, surface science: Modern techniques. Chicago: Yale University Press.

Ferguson, M 2010, Mass spectrometry: Applications and principles. New Jersey: Treason Publishers.

Goldblatt, B 2010, Synchrotron radiation: Chemical applications. Cambridge: Cambridge UP.

Hill, C 2000, Chemical applications of synchrotron radiation. New Jersey: Treason Publishers.

Jeffries, J 2001, Essentials of synchrotron radiation. Chicago: Yale University Press.

John, B 2011, Synchrotron radiation: characteristics. Cambridge: Cambridge UP.

Kessler, A 2007, Physical science: Introduction. Chicago: Yale University Press.

Lenox, M 2005, Physical science: modern techniques. New York: Springer.

Liveris, A 2000, Surface science: modern world techniques. New York: Springer.

Lyn B 1995, Aircraft metal coat structure and composition. Cambridge: Cambridge UP.

Mouse, M 2006, Surface Science. Chicago: Pearson Education.

Nelson, W 2006, Research techniques. New York: Springer.

Patrice, A 2004, Quantitative research methods. Oxford: Oxford University Press.

St. James Press 2004, Applications and Principles of mass spectrometry. New York: Springer.

Sweeney, B 2010, Physical chemistry: Atkins. New York: LexisNexis Butterworth.

Uche, A 2003, Chemical applications of Synchrotron radiation. Cambridge: Cambridge UP.

USC Marshall, 2011, Synchrotron radiation: Applications. Chicago: Pearson Education.