Introduction

Transportation is one of the most critical economic activities in a business supply chain. It is based on the fundamental principles of moving goods and resources from the location where they are produced to the location where they are demand, essentially linking suppliers to consumers without which the business and economy as whole would not be existent. The back-end concepts of a business such as supply chain management and logistics are ultimately dependent on transportation functioning effectively and efficiently since goods and products consistently have to be moved in between locations. Transportation is a vital part of the supply chain management and a key element to its function, serving as a necessity and enabler to virtually any business activity or strategy.

Background

A major driving force for supply chain in the 21st century are globalization and technology. Globalization has resulted in supply chains being stretched across the world, particularly with production shifting to cheaper labor markets while major consumers remain in affluent Western regions. To facilitate the depth and scope of these extensive supply chains, transportation became critical to supply chain management, figuratively described as the “glue” and “life blood” of global supply chains, vital to growth and development of businesses and economies as a whole. Transportation is the most critical industry in an industrialized society, as a tool without which no element of the economy would be able to function, ranging from a grocery store to a factory. The more complex the economy, business, or company – the more indispensable an efficient and effective transportation system becomes (Novack et al., 2016).

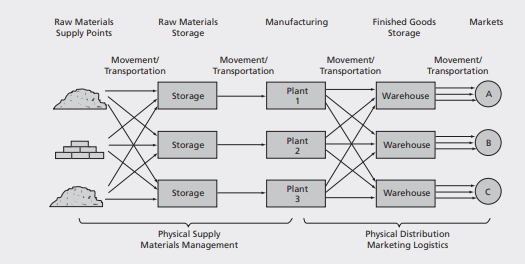

Logistics is an element of supply chain management that “plans, implements, and controls the efficient, effective forward and reverse flow and storage of goods, services and related information from the point of origin to the point of consumption in order to meet customers’ requirements” (Goldsby et al., 2014, par. 7). In this definition, the term flow is synonymous with transportation, which has the function of providing the flow of inventory from points of origin to points of use and production to final places of sale or consumption. Businesses commonly manage inbound logistics which involves receiving raw materials, and outbound logistics which focuses on distribution of goods to markets, the complexity of both can be seen in the figure below. Logistics involves activities such as forecasting demand, inventory planning, and the storage and delivery of goods. Optimized logistics systems ensure that the activities are done efficiently and in unison so that customers are satisfied with the logistics (time and speed) while incurred costs for the company are minimal. Transportation is the one activity critically responsible for “providing time and place utilities through inbound and outbound” (Goldsby et al., 2014 par. 9).

Impact on Business

Transportation as part of logistics and supply chain management is a key component in business activities of a company. Transportation directly influences inventory flow, with effective transportation able to keep the supply chain moving and keeping inventory lean. Inventory consistently has to be moved in and out of production and storage, and transportation is able to impact warehouse efficiently, reduce lead time, and reduce expenses in areas such as storage management. Any supply chain disruptions, particularly those caused by transportation are costly and impact the bottom line for operations. Transportation is also one point where a company has direct contact with the consumer via shipping of products. The point of delivery commonly reflects the competency of a business. Transportation plays a key role in the ‘last mile’ delivery, which is often the most complex and costly while being prone to disruptions. Therefore, the logistics of transportation during the point of delivery can impact customer satisfaction based on the speed and quality of the transported product (PLS Logistics, n.d.).

Transportation directly affects the economic side of things in various business activities. For example, transportation helps to manage price hikes and allow for profit maximization. Transportation allows to coordinate between less and more supplied regions, moving goods conveniently, thus being able to fulfill demand at any different locations where customers seek to purchase goods at stable prices. Profit maximization occurs when transportation is used to deliver cheap raw materials from various locations to areas of production where labor is cheapest, and then distributed to high profit markets. Transportation aids in large scale production by supplying each part of the supply chain without interruption and at scale, which helps businesses to manufacture and sell product at a cheaper cost, but also serving a large number of customers and increasing revenue (Novack et al., 2016).

Transportation Strategy

Given the key logistics function of transportation in supply chains, it is common for large companies to develop their own transportation strategies. A transportation strategy contributes to effective supply chain management by fitting the movement of goods into the general corporate supply chain. Instead of ensuing carrier competition or ineffective planning, the transportation strategy seeks to be a dynamic response to the needs of the business and its operations (LTD Management, n.d.). Transportation strategy needs to examine the supply chain holistically, not just the technicalities of transportation (such as using technology for most efficient routes) and enable strategic collaboration between the various entities and players in the supply chain to reach the objectives that the organization has set.

State of the art supply chains use competent management to reduce inventory and warehousing costs while speeding up delivery – therefore, the effectiveness is inherently linked to the appropriate implementation of transportation strategy. For example, Wal-Mart utilizes a responsive transportation system which calls for cross-docking at distribution centers. Thus, product is exchanged between trucks so that each truck heading to the retail location maintains a variety of products from differing suppliers. This has helped the retail giant to lower costs since total transportation costs include elements such as transportation decisions, responsiveness levels, and inventory expenses (SupplyChainDive, 2017). In the end, companies must match transportation strategy to its competitive strategy for the best performance.

Transportation Risks

Alongside being one of the most critical factors in a supply chain, transportation is also the most vulnerable and prone to risk. The majority of adverse events occurring in the supply chain are due to transportation-related causes which then cause ripple effects up the supply chain. Carriers inherently undertake a significant risk because of this since shipments allow for companies to continue operating. Any accidents, disruptions, or losses of cargo will disrupt the supply chain and result in decreased financial profit. Transportation companies can face risks such as integrity and safety of the transportation method, personnel safety and retention, compliance issues, and environmental impacts (Wensing, 2018).

Transportation and logistics services are virtually outsourced operations making them high value, but also high impact elements of the supply chain. The risk increases since each part of the supply chain deals in its own regulatory framework, contractual agreements, and business practices. Since transportation is usually outsourced, unless it is an extremely large company (even then, some stages are still reliant on third parties, after all Wal-Mart does not have its own ships and does not deliver the product to the front door itself), there are inherent risks dealing with carriers, transportation management providers, customs, export agents, and warehousing companies. Competent supply chains integrate transportation risk as a leading concept in its supply chain risk mitigation strategies, with resilience to leverage the outlined problems during procurement of transportation services and subsequent operations management (Todd, 2017).

Transportation Costs

The business of moving inventory through the supply chain to the end market is a major expense for companies. An analysis of logistics activities costs conducted by CSCMP suggests that transportation costs in the supply chains in the United States exceed $836 billion annually, or 62.8% of total logistics expenses (seen in the table below). Commercial transportation is so large, that it accounts for 5.4% of the U.S. GDP (Goldsby et al., 2014). Costs can vary significant in transportation due to a wide variety of factors ranging from distance to transportation type to specifics of storage conditions. The more difficult it is to move a product over distance, the greater the friction of distance, the higher the cost. A modern supply chain is highly spread out, so both suppliers and companies are competing, and the ease of transporting goods will affect competitiveness.

In the 1990s and early 2000s, low cost of transportation and high availability of freight services led to businesses to focus on fast delivery to end markets and consumers, moving inventory to reduce expenses. However, the status quo has changed with the development of e-commerce and exponentially rising costs in transportation due to rising oil prices and generally low supply in comparison to demand – all while consumer expectations have only shifted towards expectations of rapid availability and delivery. As a result, certain industry shifts have occurred in supply chain management in regard to transportation. In some companies and products, there has been a notable shift from offshoring to nearshoring in order to reduce distance of shipments travel. Product design as well as packaging has evolved also towards more efficient production but also incorporating shipping considerations such as size efficiency, protection of goods efficiency, and processes of offloading and repackaging. Finally, the inventory management in the supply chain has changed from lean inventory to hybrid lean and transportation strategies which has long-reaching impacts in the supply chain management designed to overcome transportation challenges and costs (Russell et al., 2014).

Case Study

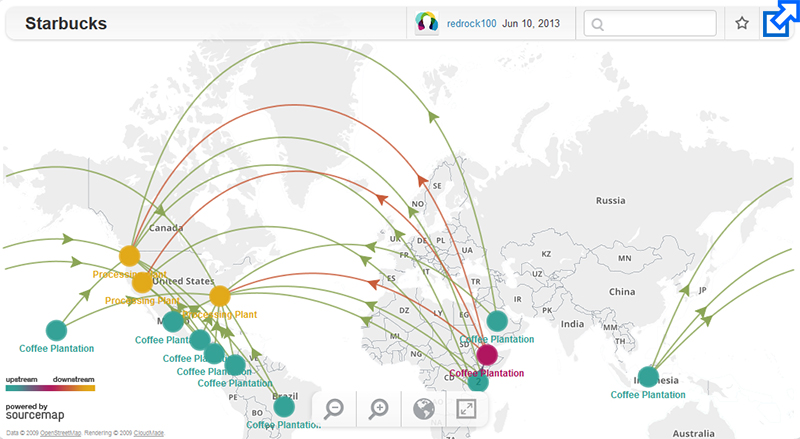

A company which critically relies on transportation in its expansive supply chain is Starbucks. Starbucks operates a highly centralized and vertically integrated supply chain network which is one of a kind, but also offers it complete control or involvement in every step of the process. The primary goods sold by Starbucks are coffee and coffee associated products. Therefore, Starbucks relies on coffee beans as its raw material. Working directly with plantation farmers, Starbucks imports various sorts of coffee beans from small to medium sized plantations in South and Central America, Africa and Middle East, and Asia/Oceania. Upon collection and packaging of coffee beans, they are delivered by truck to the nearest port. Coffee beans must be transported without moisture in ventilated containers, which presents some challenges considering most are shipped via sea transport. The beans are shipped to one of six storage sites in U.S. and Europe, the number being low to ensure close management of site operation and ensuring that all products are prepared and packaged the same way. The beans are roasted, specially packaged, and shipped to one of eight centralized or of the 50 regional distribution centers. From there, the beans are sent directly to Starbucks stores and restaurants or a few select retailers selling their products (Sargent, n.d.).

It is evident from the numerous contact points in the Starbucks supply chain, that transportation is critical to their functioning. Transportation is necessary from plantations to port (via ground), port to storage center (via sea and ground), then to distribution centers (via ground or air), and from distribution center to stores (via ground). Previously, Starbucks spent approximately 70% of its supply chain costs on outsourcing transportation and logistics. Upon a radical transformation of its system in 2008, virtually all transportation is under Starbucks’ supervision as part of the “deliver” function of its supply chain structure. Starbucks now attempts to utilize a regionalized approach to coffee manufacturing by refining coffee beans nearest to the region where they are to be sold. This allowed to reduce transportation costs and lead times, even switching coffee plant operations to 5 days rather than 7. Starbucks operates six plants of its own and relies on 24 co-manufacturers around the world (Cooke, 2010).

Inevitably, the Starbucks delivery and transportation process is demanding and complex. Unlike most other companies with suppliers and production in a specific region, Starbucks imports and then reships coffee beans all over the world. Starbucks processes about 70,000 deliveries to its stores in 69 countries per week. During its supply chain reorganization, Starbucks had to consider efficiency in its logistics. Each transport carrier was assessed for performance, and only the best were left as partners to this global company. Furthermore, Starbucks implemented a variety of technological solutions within the supply chain to continuously improve efficiencies. In the first two years that Starbucks reformed its supply chain system, they have curtailed costs by approximately $500 million without compromising service delivery (Cooke, 2010).

Conclusion

Transportation is a critical element of logistics responsible for the movement of product from one location to another along the supply chain, ranging from beginning to when the product reaches consumers. It is a costly and complex endeavor that has far-reaching impact on business operations and profit margins. Most high-profile companies recognize the key role of transportation and have developed appropriate transportation strategy to integrate into the supply chain management ranging from vendors being used and cost-savings to technology tracking and positioning of distribution centers. Globalization has contributed to the growing complexity of supply chains, creating more distance and chains in between the raw materials delivery to the final product shipment. Meanwhile, transportation is both limited in availability and both financially and ecologically unprofitable. Going forward businesses are seeking to optimize and make supply chains more efficient, with a primary focus on transportation modes and planning.

References

Cooke, J. A. (2010). From bean to cup: How Starbucks transformed its supply chain.Supply Chain Quarterly. Web.

Goldsby, T.J., Iyengar, D., Rao, S., & CSCMP. (2014). The critical role of transportation in business and the economy. Web.

Novack, R. A., Gibson, B. J., Suzuki, Y., & Coyle, J.J. (2019). Transportation a global supply chain perspective. Boston Cengage Learning.

LTD Management. (n.d.). Transportation strategy for supply chains. Web.

PLS Logistics. (n.d.). The 5 benefits of transportation management. Web.

Russell, D., Coyle, J.J., Ruamsook, K., & Thomchick, E.A. (2014). The real impact of high transportation costs.Supply Chain Quarterly. Web.

Sargent, M. (n.d.). Supply chain putting the star in Starbucks. Web.

SupplyChainDive. (2017). The transportation supply chain. Web.

Todd, J. (2017). Mitigating supply chain risk: effective transportation and logistics provider diligence and management practices. Web.

Wensing, M. (2018). Everything you wanted to know about transportation risk management. Web.